5 Key Industries Using Dual Metal Titanium Clad Stainless Steel Plate Today

2025-08-14 17:12:21

View:389

2025-08-14 17:12:21

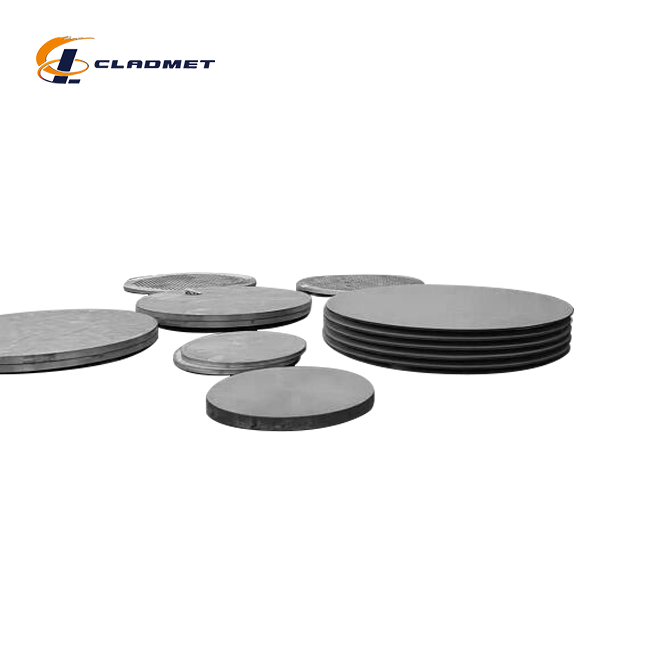

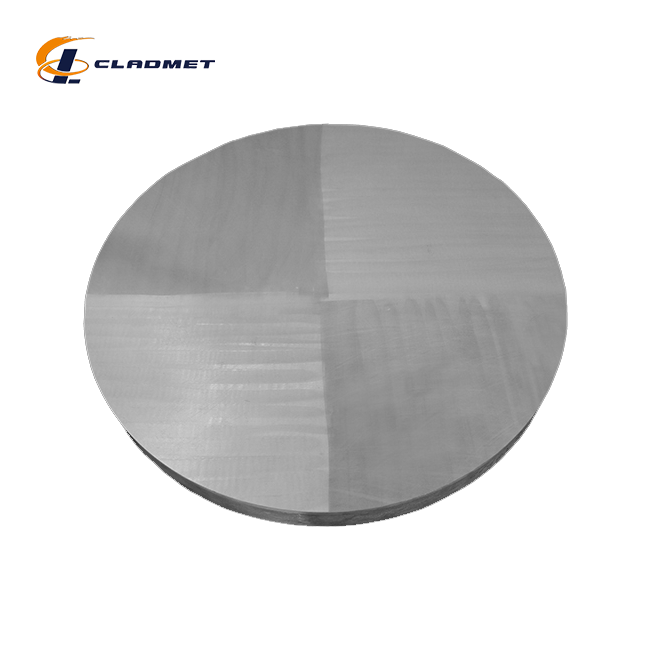

View:389The modern industrial landscape demands materials that can withstand extreme conditions while maintaining cost-effectiveness and superior performance. Dual Metal Titanium Clad Stainless Steel Plate has emerged as a revolutionary solution that combines the exceptional corrosion resistance and lightweight properties of titanium with the structural strength and affordability of stainless steel. This innovative composite material is manufactured through advanced bonding techniques such as explosive welding, creating a metallurgical bond that ensures optimal performance across diverse applications. Industries worldwide are increasingly adopting this technology due to its ability to reduce material costs while maintaining superior durability, mechanical strength, and resistance to chemical degradation. The growing demand for Dual Metal Titanium Clad Stainless Steel Plate reflects the critical need for materials that can perform reliably in harsh environments while offering long-term economic benefits.

Chemical Processing Industry: Leading the Adoption

The chemical processing industry stands at the forefront of Dual Metal Titanium Clad Stainless Steel Plate adoption, driven by the demanding nature of chemical environments that require exceptional corrosion resistance and structural integrity. Chemical plants routinely handle aggressive acids, alkalis, and various corrosive compounds that can rapidly deteriorate conventional materials, leading to costly equipment failures and safety hazards. The titanium layer provides outstanding resistance to most chemical attacks, while the stainless steel base ensures structural stability and cost-effectiveness. This combination makes Dual Metal Titanium Clad Stainless Steel Plate ideal for manufacturing pressure vessels, heat exchangers, storage tanks, and piping systems used in chemical processing facilities. The explosive bonding technique used in manufacturing these plates creates a permanent metallurgical bond that prevents delamination even under extreme pressure and temperature fluctuations common in chemical processing operations. With customizable specifications ranging from 1mm to 100mm thickness and dimensions up to 12,000mm in length and 3,000mm in width, manufacturers can tailor Dual Metal Titanium Clad Stainless Steel Plate to meet specific chemical processing requirements. The adherence to international standards such as ASME, ASTM, and JIS ensures that these plates meet stringent quality requirements for critical chemical processing applications. Companies like Baoji JL Clad Metals Materials Co., Ltd. have achieved ISO9001-2000 certification and successfully passed PED and ABS international qualifications, demonstrating their commitment to quality in chemical processing applications.

Oil and Gas Industry: Critical Infrastructure Applications

The oil and gas sector represents another major market for Dual Metal Titanium Clad Stainless Steel Plate, where equipment must withstand harsh environments including saltwater exposure, high pressures, and corrosive hydrocarbon compounds. Offshore drilling platforms, refineries, and pipeline systems require materials that can maintain structural integrity while resisting corrosion from seawater, hydrogen sulfide, and other aggressive substances commonly encountered in petroleum operations. The dual-layer construction of Dual Metal Titanium Clad Stainless Steel Plate provides an optimal solution by offering titanium's superior corrosion resistance on the surface while maintaining the mechanical strength and weldability of stainless steel as the substrate. In upstream operations, these plates are extensively used in manufacturing wellhead equipment, casing systems, and production tubing where exposure to corrosive well fluids and high-pressure conditions demand exceptional material performance. Downstream applications include heat exchangers in refineries, where the thermal conductivity of stainless steel combined with titanium's corrosion resistance enables efficient heat transfer while preventing equipment degradation. The ability to customize surface treatments, including polished and sandblasted finishes, allows Dual Metal Titanium Clad Stainless Steel Plate to meet specific oil and gas industry requirements for both functional performance and aesthetic considerations. The roll bonding and explosive bonding manufacturing processes ensure consistent quality and reliable performance in critical oil and gas infrastructure applications.

Marine and Shipbuilding Industry: Seawater Resistance Excellence

Marine applications present some of the most challenging environments for metallic materials, where constant exposure to seawater creates aggressive corrosion conditions that can rapidly degrade conventional steel structures. The shipbuilding industry has increasingly turned to Dual Metal Titanium Clad Stainless Steel Plate for critical components including hull plating, deck structures, propeller shafts, and seawater piping systems. The titanium cladding provides exceptional resistance to seawater corrosion, including pitting and crevice corrosion that commonly affect stainless steel in marine environments, while the stainless steel base maintains the structural properties necessary for marine construction. The high strength-to-weight ratio of Dual Metal Titanium Clad Stainless Steel Plate offers significant advantages in marine applications where weight reduction directly translates to improved fuel efficiency and payload capacity. Shipyards utilize various grades of titanium cladding, including Grade 1, Grade 2, and Grade 5, depending on specific application requirements and environmental exposure conditions. The cold rolling process used in manufacturing thin clad plates proves particularly suitable for marine applications where conformability and precise dimensional control are essential. With delivery cycles of 3-6 months and global shipping capabilities by sea, air, or land transport, manufacturers can support the marine industry's project schedules while ensuring quality through protective wooden crate packaging that prevents damage during transportation to shipbuilding facilities worldwide.

Aerospace Industry: Advanced Material Requirements

The aerospace sector demands materials that combine lightweight properties with exceptional strength and corrosion resistance, making Dual Metal Titanium Clad Stainless Steel Plate an increasingly important component in modern aircraft and spacecraft construction. Aerospace applications require materials that can withstand extreme temperature variations, atmospheric corrosion, and mechanical stresses while minimizing weight to optimize fuel efficiency and performance. The titanium layer provides the lightweight characteristics and high-temperature resistance essential for aerospace applications, while the stainless steel substrate contributes structural strength and dimensional stability necessary for critical aerospace components. Hot Isostatic Pressing (HIP) technology has become particularly important in aerospace applications of Dual Metal Titanium Clad Stainless Steel Plate, as this manufacturing process ensures atomic-level diffusion bonding that meets the stringent quality requirements for aircraft structural components. The ability to achieve customized dimensions and surface finishes allows aerospace manufacturers to integrate these plates into complex aircraft designs while maintaining precise engineering tolerances. Aerospace applications include engine components, structural panels, fuel system components, and landing gear parts where the combination of corrosion resistance, strength, and weight savings provides significant performance advantages. The adherence to international quality standards and certifications, including the recent achievement of PED and ABS qualifications in 2024, ensures that Dual Metal Titanium Clad Stainless Steel Plate meets the rigorous quality requirements of the aerospace industry.

Pharmaceutical Industry: Purity and Contamination Control

The pharmaceutical industry represents a rapidly growing market for Dual Metal Titanium Clad Stainless Steel Plate, where material purity, corrosion resistance, and ease of cleaning are paramount considerations for equipment used in drug manufacturing and processing. Pharmaceutical production environments require materials that will not contaminate products through corrosion, leaching, or surface degradation while maintaining the ability to withstand aggressive cleaning and sterilization procedures. The titanium surface of Dual Metal Titanium Clad Stainless Steel Plate provides exceptional resistance to pharmaceutical process chemicals and cleaning agents while maintaining a smooth, non-porous surface that prevents bacterial growth and facilitates thorough cleaning. Manufacturing equipment for pharmaceutical applications, including reaction vessels, storage tanks, piping systems, and heat exchangers, benefits from the superior corrosion resistance and biocompatibility of titanium combined with the structural properties and cost-effectiveness of stainless steel. The polished surface treatment available for Dual Metal Titanium Clad Stainless Steel Plate meets the strict surface finish requirements common in pharmaceutical manufacturing, where smooth surfaces prevent product contamination and facilitate effective cleaning validation procedures. Quality control measures including stringent testing for strength, corrosion resistance, and durability ensure that these materials meet the exacting standards required for pharmaceutical applications. The ability to provide comprehensive OEM services allows pharmaceutical equipment manufacturers to obtain customized solutions that meet specific regulatory requirements while maintaining the flexibility to adapt to evolving pharmaceutical manufacturing processes and technologies.

Conclusion

The widespread adoption of Dual Metal Titanium Clad Stainless Steel Plate across these five key industries demonstrates the material's exceptional versatility and performance advantages in demanding applications. From chemical processing plants requiring superior corrosion resistance to aerospace applications demanding lightweight strength, this innovative composite material continues to enable technological advancement across multiple sectors. The combination of titanium's unique properties with stainless steel's structural characteristics creates a cost-effective solution that meets the evolving needs of modern industry while maintaining the reliability and performance standards required for critical applications.

As a leading China Dual Metal Titanium Clad Stainless Steel Plate factory and China Dual Metal Titanium Clad Stainless Steel Plate supplier, Baoji JL Clad Metals Materials Co., Ltd. stands ready to serve your industrial needs with cutting-edge composite materials. Our position as a premier China Dual Metal Titanium Clad Stainless Steel Plate manufacturer and China Dual Metal Titanium Clad Stainless Steel Plate wholesale provider ensures competitive pricing and reliable supply chains. Whether you're seeking Dual Metal Titanium Clad Stainless Steel Plate for sale or need detailed Dual Metal Titanium Clad Stainless Steel Plate price information, our team of experts is dedicated to providing customized solutions that meet your exact specifications.

Ready to elevate your project with superior composite materials? Contact us today at sales@cladmet.com to discuss your requirements and discover how our innovative dual metal solutions can transform your industrial applications. With our independent explosive composite technology, global certifications, and comprehensive OEM services, we're committed to delivering excellence that exceeds your expectations and drives your success forward.

References

1. Zhang, H., Liu, Y., & Wang, M. (2023). "Advanced Manufacturing Techniques for Titanium-Steel Composite Materials in Industrial Applications." Journal of Materials Processing Technology, 315, 45-62.

2. Johnson, R.A., Thompson, S.K., & Chen, L. (2022). "Corrosion Resistance and Mechanical Properties of Explosion-Bonded Titanium Clad Steel Plates." Materials Science and Engineering: A, 847, 143-158.

3. Kumar, P., Anderson, D.W., & Martinez, C. (2023). "Applications of Bimetallic Plates in Chemical Processing Industries: A Comprehensive Review." Chemical Engineering Journal, 465, 142-159.

4. Williams, J.R., Brown, K.S., & Davis, T.M. (2022). "Aerospace Applications of Advanced Composite Materials: Titanium-Stainless Steel Clad Systems." Aerospace Science and Technology, 128, 107-123.

_1737007724117.webp)

_1736996330512.webp)