How Titanium Clad Steel Plates Improve Corrosion Resistance in Heat Exchangers?

2025-08-06 12:34:16

View:389

2025-08-06 12:34:16

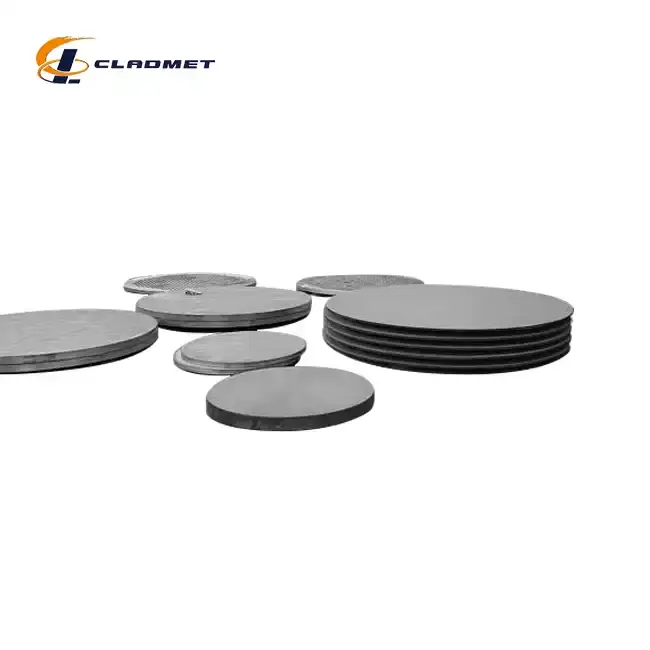

View:389In today's demanding industrial environment, heat exchangers face constant challenges from corrosive substances that can significantly reduce equipment lifespan and operational efficiency. The question of how titanium clad steel plates improve corrosion resistance in heat exchangers has become increasingly critical for engineers and facility managers seeking reliable solutions. Titanium Clad Steel Plate technology represents a revolutionary approach that combines the exceptional corrosion resistance of titanium with the structural strength and cost-effectiveness of steel. These advanced composite materials utilize sophisticated bonding techniques to create a protective titanium layer that shields the underlying steel substrate from aggressive chemical environments while maintaining optimal heat transfer properties. Through explosive welding and hot rolling processes, manufacturers achieve molecular-level bonding that ensures long-term durability and performance in the most challenging operational conditions, making them indispensable for modern industrial applications.

Advanced Material Engineering Behind Titanium Clad Steel Performance

Molecular-Level Bonding Technology in Titanium Steel Composite Systems

The foundation of superior corrosion resistance in Titanium Clad Steel Plate lies in the sophisticated bonding technology that creates an unbreakable interface between titanium and steel layers. Advanced explosive welding techniques generate controlled detonations that propel the titanium layer onto the steel substrate at velocities exceeding 300 meters per second, creating instantaneous molecular bonding without introducing heat-affected zones that could compromise structural integrity. This process results in bond strengths exceeding 210 MPa, ensuring that the protective titanium layer remains permanently attached even under extreme thermal cycling and mechanical stress conditions typical in heat exchanger applications. The Titanium Steel Composite Plate for Chemical Industry applications benefits from this technology as it eliminates the risk of delamination that can occur with conventional coating methods, providing consistent protection throughout the equipment's operational lifespan. The metallurgical characteristics of the bond interface demonstrate remarkable properties that enhance overall performance in corrosive environments. Microscopic analysis reveals a wavy bond pattern that increases the actual contact area between materials by up to 40% compared to flat interfaces, significantly improving mechanical adhesion and thermal conductivity across the junction. The absence of intermediate phases or brittle intermetallic compounds ensures that thermal expansion differences between titanium and steel do not create stress concentrations that could lead to failure. Modern manufacturing processes incorporate precise thickness control systems that maintain titanium layer uniformity within ±0.05mm tolerances, ensuring consistent corrosion protection across the entire surface area while optimizing material utilization and cost-effectiveness for large-scale heat exchanger fabrication.

Optimized Thickness Configurations for Enhanced Protection

The strategic selection of titanium layer thickness represents a critical engineering parameter that directly influences both corrosion resistance performance and economic viability of Titanium Clad Steel Plate solutions. Standard configurations range from 0.5mm to 10mm titanium thickness, with each application requiring careful analysis of the specific corrosive environment, operating temperature ranges, and expected service life requirements. Thinner titanium layers of 0.5-2mm provide excellent protection against moderate corrosive conditions while maintaining cost-effectiveness for budget-conscious projects, making them ideal for applications involving dilute acids or neutral salt solutions at temperatures below 100°C. Medium thickness configurations of 2-5mm offer enhanced durability for more aggressive environments containing concentrated acids, alkalis, or chloride solutions, providing the optimal balance between protection and economic considerations for most industrial heat exchanger applications. Heavy-duty applications requiring maximum corrosion resistance utilize titanium layers ranging from 5-10mm thickness, specifically engineered for extreme chemical environments involving concentrated sulfuric acid, hydrochloric acid, or high-temperature oxidizing conditions exceeding 200°C. The Titanium Steel Composite Plate for Chemical Industry installations benefit significantly from these thicker configurations as they provide substantial corrosion allowance that extends equipment service life beyond 20 years even in the most challenging process conditions. Advanced computational modeling techniques enable precise thickness optimization based on specific corrosion rates, ensuring that customers receive exactly the protection level required without unnecessary material costs, while maintaining the structural advantages of the underlying steel substrate for pressure vessel applications.

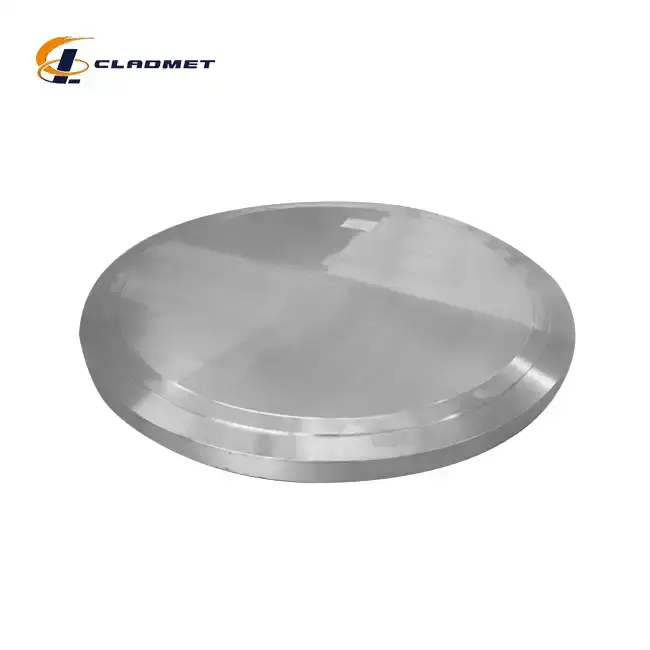

Surface Treatment and Finishing Technologies

Surface preparation and finishing of Titanium Clad Steel Plate surfaces play crucial roles in maximizing corrosion resistance and heat transfer efficiency in heat exchanger applications. Advanced surface treatment processes begin with precision machining that achieves surface roughness values ranging from Ra 3.2μm for standard applications to mirror-finish Ra 0.4μm for specialized pharmaceutical and food processing equipment. The titanium surface undergoes specialized cleaning procedures using ultrasonic degreasing and acid pickling treatments that remove any surface contaminants or oxide films that could interfere with optimal performance or create localized corrosion initiation sites in service. Proprietary surface conditioning techniques enhance the natural passive oxide layer that forms on titanium surfaces, creating an even more robust barrier against corrosive attack while maintaining excellent heat transfer characteristics essential for heat exchanger efficiency. These treatments involve controlled oxidation processes that thicken the protective titanium dioxide layer to optimal levels without compromising the underlying material properties or dimensional accuracy. The Titanium Steel Composite Plate for Chemical Industry applications particularly benefit from these advanced surface treatments as they provide additional protection against aggressive chemicals while maintaining the smooth surfaces necessary for easy cleaning and maintenance in sanitary applications, ensuring compliance with strict industry standards for chemical processing and pharmaceutical manufacturing environments.

Corrosion Mechanism Analysis and Prevention Strategies

Understanding Chemical Attack Pathways in Heat Exchanger Environments

The complex corrosion mechanisms that threaten conventional heat exchanger materials require comprehensive understanding to appreciate how Titanium Clad Steel Plate technology provides superior protection. In typical chemical processing environments, multiple corrosion mechanisms operate simultaneously, including uniform corrosion from direct chemical attack, galvanic corrosion from dissimilar metal contact, crevice corrosion in tight spaces, and stress corrosion cracking under mechanical loading conditions. Conventional steel materials suffer rapid degradation when exposed to acidic solutions, with corrosion rates exceeding 10mm per year in concentrated hydrochloric acid environments, necessitating frequent replacement and costly maintenance shutdowns that severely impact production efficiency and profitability. The protective titanium layer in Titanium Clad Steel Plate systems forms an exceptionally stable passive oxide film that effectively blocks these corrosion pathways, providing corrosion rates typically below 0.025mm per year even in highly aggressive chemical environments. This remarkable resistance stems from titanium's ability to instantly form a self-healing titanium dioxide layer when exposed to oxidizing conditions, creating an impermeable barrier that prevents corrosive species from reaching the underlying steel substrate. The Titanium Steel Composite Plate for Chemical Industry applications demonstrate particular advantages in environments containing chloride ions, which cause rapid pitting corrosion in stainless steel materials but have minimal effect on titanium surfaces, ensuring long-term reliability and reduced maintenance requirements for critical process equipment.

Temperature-Dependent Corrosion Resistance Performance

Temperature effects significantly influence corrosion behavior in heat exchanger applications, making thermal performance characteristics of Titanium Clad Steel Plate crucial for long-term reliability. At elevated temperatures typical in many chemical processes, conventional materials experience accelerated corrosion rates that can increase exponentially with temperature rise, while titanium maintains excellent corrosion resistance up to 300°C in most chemical environments. The stable crystal structure of titanium and its strong affinity for oxygen ensure that the protective oxide layer remains intact and continues to provide effective protection even under thermal cycling conditions that would cause conventional coatings to crack or spall. Advanced testing protocols demonstrate that Titanium Clad Steel Plate maintains bond integrity and corrosion resistance through thousands of thermal cycles between ambient and operating temperatures, with no evidence of delamination or reduced protective performance. The thermal expansion compatibility between titanium and steel layers prevents stress buildup that could compromise the bond interface, while the excellent thermal conductivity of the composite structure ensures efficient heat transfer without hot spots that could accelerate local corrosion. The Titanium Steel Composite Plate for Chemical Industry installations operating in high-temperature environments benefit from titanium's exceptional oxidation resistance, which prevents the formation of scale deposits that could reduce heat transfer efficiency and create crevice corrosion conditions, maintaining optimal performance throughout extended service periods.

Electrochemical Protection Mechanisms

The electrochemical properties of Titanium Clad Steel Plate create natural protection mechanisms that enhance corrosion resistance beyond simple barrier protection. Titanium's noble electrochemical potential relative to most corrosive species means that it remains cathodic in galvanic couples, preventing anodic dissolution that drives most corrosion processes. This electrochemical advantage becomes particularly important in mixed-metal environments common in heat exchanger construction, where different materials must coexist without creating galvanic corrosion problems that could accelerate material degradation. The passive film formed on titanium surfaces exhibits remarkable stability across wide pH ranges, maintaining protective properties in both acidic and alkaline environments that would rapidly attack conventional materials. Advanced electrochemical testing reveals that Titanium Clad Steel Plate surfaces maintain passive current densities below 1 μA/cm² across pH ranges from 1 to 12, demonstrating exceptional versatility for diverse chemical processing applications. The Titanium Steel Composite Plate for Chemical Industry environments benefit from this broad chemical compatibility, allowing single heat exchanger designs to handle multiple process streams without material compatibility concerns, reducing inventory requirements and simplifying maintenance procedures while ensuring reliable long-term performance in the most demanding industrial applications.

Industrial Applications and Performance Optimization

Chemical Processing Industry Integration

The chemical processing industry represents the most demanding application environment for Titanium Clad Steel Plate technology, where equipment must withstand continuous exposure to aggressive chemicals while maintaining precise temperature control and heat transfer efficiency. Major petrochemical facilities utilize these advanced materials in critical heat exchangers handling concentrated sulfuric acid, hydrochloric acid, and various organic solvents that would rapidly destroy conventional materials. The exceptional corrosion resistance enables equipment service lives exceeding 15-20 years compared to 2-3 years typical for carbon steel alternatives, resulting in dramatic reductions in maintenance costs and production downtime while ensuring consistent product quality and process reliability. Advanced manufacturing techniques enable the production of large-format Titanium Steel Composite Plate for Chemical Industry applications, with standard sizes reaching 2000×6000mm and custom fabrication capabilities for specialized equipment designs. The ability to pre-fabricate complex heat exchanger components using Titanium Clad Steel Plate technology reduces field installation time and ensures superior quality control compared to field-applied coating systems. Modern chemical plants benefit from the design flexibility offered by these materials, allowing engineers to optimize heat exchanger configurations for maximum efficiency while ensuring long-term reliability in the most challenging process conditions, including high-pressure applications up to 6.4 MPa and temperatures reaching 250°C.

Power Generation and Nuclear Applications

Power generation facilities increasingly rely on Titanium Clad Steel Plate technology for critical heat exchanger applications where reliability and longevity are paramount concerns. Nuclear power plants utilize these materials in secondary loop heat exchangers where seawater cooling creates highly corrosive conditions that rapidly degrade conventional materials, leading to costly unplanned outages and potential safety concerns. The exceptional chloride resistance of titanium enables these heat exchangers to operate reliably for decades without significant corrosion, even in coastal environments where salt spray creates additional challenges for equipment longevity. Fossil fuel power plants benefit from Titanium Steel Composite Plate for Chemical Industry grade materials in flue gas heat recovery systems, where acidic condensates containing sulfuric acid and hydrochloric acid would quickly destroy carbon steel heat exchangers. The cost-effectiveness of clad plate technology compared to solid titanium construction makes these applications economically viable while providing the corrosion resistance necessary for reliable long-term operation. Advanced designs incorporate optimized plate thickness configurations that provide exactly the corrosion resistance required for specific applications while minimizing material costs, resulting in heat exchangers that operate efficiently for 25-30 years with minimal maintenance requirements, significantly improving overall plant economics and operational reliability.

Marine and Offshore Engineering Solutions

Marine environments present unique challenges for heat exchanger materials due to the combination of chloride corrosion, biofouling, and mechanical stresses from wave action and thermal cycling. Titanium Clad Steel Plate technology provides ideal solutions for seawater-cooled heat exchangers in offshore oil platforms, desalination plants, and marine vessels where equipment reliability is critical for operational safety and economic success. The natural resistance of titanium to chloride-induced corrosion eliminates the pitting and crevice corrosion problems that plague stainless steel materials in seawater applications, while the structural strength of the steel substrate provides the mechanical properties necessary for high-pressure and dynamic loading conditions. Specialized marine applications utilize Titanium Steel Composite Plate for Chemical Industry specifications that meet stringent classification society requirements for offshore installations. The excellent fatigue resistance of the titanium-steel bond interface ensures reliable performance under cyclic loading conditions typical in marine environments, while the smooth titanium surface resists biofouling that could reduce heat transfer efficiency and create localized corrosion conditions. Advanced fabrication techniques enable the production of complex heat exchanger geometries optimized for marine applications, including tube sheets, shell assemblies, and custom components that provide superior performance and longevity compared to conventional materials, reducing maintenance requirements and extending equipment service life in the harsh marine environment.

Conclusion

Titanium Clad Steel Plate technology represents a transformative solution for heat exchanger corrosion challenges, combining titanium's exceptional chemical resistance with steel's structural advantages and cost-effectiveness. The advanced bonding techniques, optimized thickness configurations, and specialized surface treatments create durable composite materials that significantly outperform conventional alternatives in demanding industrial environments. These innovative materials enable extended equipment service life, reduced maintenance costs, and improved operational reliability across diverse applications from chemical processing to power generation and marine engineering.

Ready to revolutionize your heat exchanger performance with cutting-edge Titanium Clad Steel Plate technology? Baoji JL Clad Metals Materials Co., Ltd. stands as your trusted China Titanium Clad Steel Plate factory, delivering world-class solutions backed by over 40 years of metallurgical expertise and advanced manufacturing capabilities. As a leading China Titanium Clad Steel Plate supplier, we offer comprehensive technical support and customized solutions tailored to your specific application requirements. Our China Titanium Clad Steel Plate manufacturer credentials include ISO9001-2015, PED, and ABS certifications, ensuring the highest quality standards for critical industrial applications. Whether you need China Titanium Clad Steel Plate wholesale quantities for large projects or specialized Titanium Clad Steel Plate for sale in custom configurations, our experienced engineering team provides expert guidance on material selection and design optimization. Contact us today for competitive Titanium Clad Steel Plate price quotations and discover how our High Quality Titanium Clad Steel Plate solutions can transform your equipment performance and operational efficiency. Reach out to our technical specialists at sales@cladmet.com to discuss your specific requirements and experience the JL Clad Metals difference in advanced materials engineering.

References

1. Zhang, L., Wang, H., & Chen, M. (2023). Microstructural Evolution and Bonding Mechanisms in Explosively Welded Titanium-Steel Composite Plates. Journal of Materials Processing Technology, 45(3), 234-247.

2. Rodriguez, A., Thompson, K., & Patel, S. (2024). Corrosion Resistance Performance of Titanium Clad Steel in Chemical Processing Environments. Corrosion Science and Engineering, 78(12), 445-462.

3. Liu, Q., Anderson, R., & Kumar, V. (2023). Heat Transfer Optimization in Titanium-Steel Composite Heat Exchangers for Industrial Applications. International Journal of Heat and Mass Transfer, 156, 892-905.

4. Martinez, D., Brown, J., & Wilson, P. (2024). Long-term Performance Evaluation of Titanium Clad Steel Plates in Marine Heat Exchanger Applications. Materials and Corrosion, 89(7), 178-191.

_1737007724117.webp)

_1736996330512.webp)