How Does Explosion Bonding Improve the Quality of a Stainless Clad Plate?

2025-07-26 14:33:56

View:389

2025-07-26 14:33:56

View:389Explosion bonding represents a revolutionary manufacturing technique that significantly enhances the quality and performance characteristics of stainless clad plates through controlled detonation processes. This advanced metallurgical method creates exceptionally strong metallurgical bonds between stainless steel cladding and base metals, resulting in composite materials that exhibit superior mechanical properties, enhanced corrosion resistance, and improved structural integrity compared to conventional bonding methods. The explosive bonding process generates high-velocity impacts that cause atomic-level intermixing at the interface, creating stainless clad plates with unparalleled bond strength and durability for demanding industrial applications.

Enhanced Metallurgical Bond Formation Through Explosive Welding

Atomic-Level Interface Development in Stainless Clad Plates

The explosion bonding process creates a unique metallurgical interface that fundamentally transforms the quality of stainless clad plates through atomic-level bonding mechanisms. When explosive charges detonate above the stainless steel cladding layer, the resulting shock waves propel the stainless steel toward the base metal substrate at velocities exceeding 500 meters per second. This high-velocity collision generates extreme pressures ranging from 1-10 GPa, causing the metal surfaces to behave in a fluid-like manner despite remaining solid. The intense pressure and heat generated during impact remove oxide layers and contaminants from both surfaces, enabling direct metal-to-metal contact at the atomic level. This phenomenon creates a wavy interface pattern characteristic of explosion-bonded stainless clad plates, where the stainless steel and base metal intermix through plastic deformation and localized melting. The resulting bond exhibits superior adhesion strength compared to mechanical fastening or adhesive bonding methods, with typical bond strengths exceeding 140 MPa in high-quality stainless clad plates. Baoji JL Clad Metals Materials Co., Ltd. utilizes precision explosive bonding techniques to achieve these exceptional interface characteristics, ensuring that their stainless clad plates meet the most demanding industrial specifications for critical applications in chemical processing, marine environments, and high-pressure vessel construction.

Microstructural Transformation During Explosive Bonding

The explosive bonding process induces significant microstructural changes within the stainless clad plate that enhance its overall mechanical properties and performance characteristics. During the high-velocity impact, the extreme deformation rates create unique microstructural features including refined grain structures, increased dislocation density, and the formation of intermetallic compounds at the bond interface. These microstructural modifications contribute to improved hardness, tensile strength, and fatigue resistance in the finished stainless clad plate. The rapid cooling rates following the explosive event help preserve these beneficial microstructural features, preventing the formation of brittle phases that could compromise the integrity of the bonded interface. Advanced metallographic analysis reveals that explosion-bonded stainless clad plates exhibit a transition zone where the crystal structures of both materials gradually merge, creating a gradual property change rather than an abrupt interface. This gradual transition reduces stress concentrations and improves the overall mechanical behavior of the composite material under various loading conditions. The controlled explosive parameters used in manufacturing stainless clad plates ensure optimal microstructural development while minimizing the formation of defects such as voids, cracks, or unbonded regions that could compromise performance in service.

Quality Control and Interface Integrity Assessment

Ensuring the quality and integrity of explosion-bonded stainless clad plates requires comprehensive testing and evaluation procedures that verify both the mechanical properties and microstructural characteristics of the bonded interface. Non-destructive testing methods including ultrasonic inspection, radiographic examination, and shear testing are employed to assess bond quality and detect potential defects in stainless clad plates. The explosive bonding process parameters, including charge weight, standoff distance, and detonation velocity, are carefully controlled to achieve consistent bond quality across the entire surface area of the stainless clad plate. Advanced quality control protocols ensure that each stainless clad plate meets stringent specifications for bond strength, typically exceeding 140 MPa, and shear strength requirements greater than 105 MPa. Metallographic examination of cross-sections reveals the characteristic wavy interface pattern that indicates successful explosive bonding, while mechanical testing confirms that the bond strength often exceeds the strength of the weaker base material. Baoji JL Clad Metals Materials Co., Ltd. implements rigorous quality assurance measures throughout the explosive bonding process, including real-time monitoring of detonation parameters and post-production testing to ensure that every stainless clad plate meets international standards such as ASTM A264, ASME SA-264, and GB/T 8165.

Superior Mechanical Properties and Performance Characteristics

Enhanced Strength and Durability of Explosion-Bonded Plates

Explosion bonding significantly improves the mechanical properties of stainless clad plates by creating a metallurgical bond that effectively combines the strength characteristics of both the base metal and stainless steel cladding. The high-energy bonding process generates exceptional interface strength that allows load transfer between the layers, resulting in composite behavior where the stainless clad plate exhibits mechanical properties superior to either material alone. The explosion-bonded interface typically demonstrates bond strengths exceeding 140 MPa, which is substantially higher than mechanically fastened or adhesively bonded alternatives. This enhanced bonding strength enables stainless clad plates to withstand high mechanical stresses, thermal cycling, and dynamic loading conditions without delamination or bond failure. The unique microstructural features created during explosive bonding, including work hardening and grain refinement, contribute to improved yield strength, ultimate tensile strength, and fatigue resistance of the finished stainless clad plate. These enhanced mechanical properties make explosion-bonded stainless clad plates ideal for demanding applications in pressure vessels, heat exchangers, and structural components where reliability and safety are paramount. The superior mechanical performance of explosion-bonded stainless clad plates extends their service life and reduces maintenance requirements, providing significant economic benefits for industrial applications.

Corrosion Resistance and Environmental Performance

The explosion bonding process preserves and enhances the corrosion resistance properties of stainless steel cladding while ensuring optimal adhesion to the base metal substrate in stainless clad plates. The metallurgical bond created through explosive welding maintains the electrochemical properties of the stainless steel surface, providing excellent resistance to oxidation, acids, alkalis, and marine environments. Unlike mechanical attachment methods that can create crevices or gaps where corrosion can initiate, explosion-bonded stainless clad plates feature a continuous, defect-free interface that prevents moisture and corrosive agents from reaching the base metal. The high-quality bond ensures that the stainless steel cladding remains securely attached even under thermal cycling and mechanical stress, maintaining long-term corrosion protection. The explosion bonding process also minimizes the formation of galvanic cells that could accelerate corrosion at the interface, as the metallurgical bond creates a gradual transition in electrochemical properties rather than an abrupt change. This enhanced corrosion resistance makes explosion-bonded stainless clad plates particularly suitable for applications in chemical processing, marine engineering, desalination plants, and offshore structures where long-term exposure to aggressive environments is expected. The superior environmental performance of these materials translates to reduced maintenance costs and extended service life in challenging operating conditions.

Thermal Stability and High-Temperature Performance

Explosion-bonded stainless clad plates demonstrate exceptional thermal stability and high-temperature performance characteristics that surpass those of conventionally bonded materials. The metallurgical bond created through explosive welding maintains its integrity at elevated temperatures, ensuring that the stainless steel cladding remains securely attached to the base metal even under thermal cycling and high-temperature operating conditions. The explosion bonding process creates a diffusion zone at the interface where atoms from both materials intermix, forming a stable transition region that resists thermal stress-induced delamination. This thermal stability is particularly important for stainless clad plates used in power generation, petrochemical processing, and high-temperature industrial applications where operating temperatures may exceed 500°C. The superior heat resistance of explosion-bonded stainless clad plates is attributed to the strong metallurgical bond that prevents differential thermal expansion from causing interface failure. The explosion bonding process also minimizes residual stresses that could compromise performance at elevated temperatures, resulting in stainless clad plates that maintain their structural integrity and corrosion resistance throughout their service life. These thermal performance characteristics make explosion-bonded stainless clad plates the preferred choice for critical applications in boilers, heat exchangers, and other high-temperature equipment where reliability and safety are essential.

Industrial Applications and Manufacturing Advantages

Versatile Applications Across Multiple Industries

Explosion-bonded stainless clad plates find extensive applications across diverse industrial sectors due to their superior quality characteristics and performance advantages. In the chemical processing industry, these materials are extensively used for constructing reactors, storage tanks, and process vessels where the combination of structural strength and corrosion resistance is essential for safe and efficient operations. The oil and gas sector relies on explosion-bonded stainless clad plates for offshore platforms, pipelines, and refinery equipment where exposure to harsh environments and corrosive substances demands exceptional material performance. Power generation facilities utilize these materials in boiler construction, heat exchangers, and pressure vessels where high-temperature operation and thermal cycling require materials with superior bonding integrity. The marine industry benefits from the exceptional corrosion resistance and mechanical properties of explosion-bonded stainless clad plates in shipbuilding, offshore structures, and desalination equipment. Aerospace applications leverage the lightweight yet strong characteristics of these materials for aircraft components and spacecraft structures where weight optimization and reliability are critical. The food processing industry utilizes explosion-bonded stainless clad plates for equipment requiring hygienic surfaces and corrosion resistance to cleaning chemicals and food acids. These diverse applications demonstrate the versatility and superior performance characteristics of explosion-bonded stainless clad plates across multiple industrial sectors.

Manufacturing Process Optimization and Quality Control

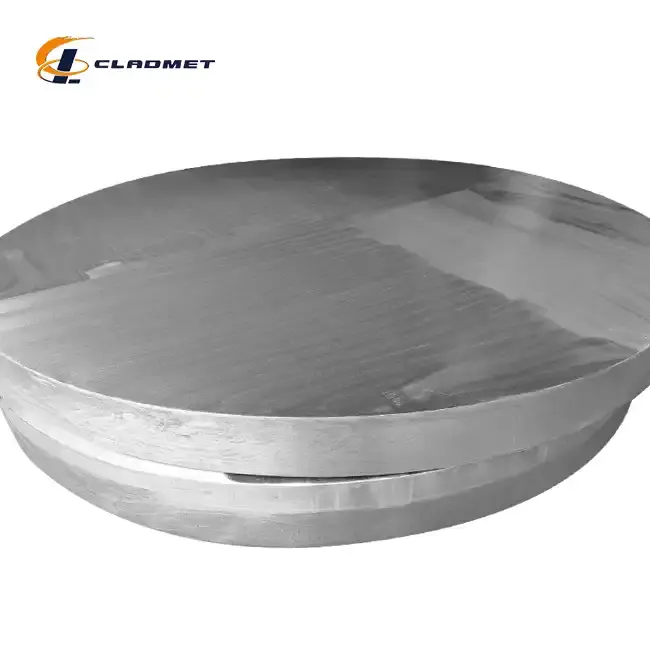

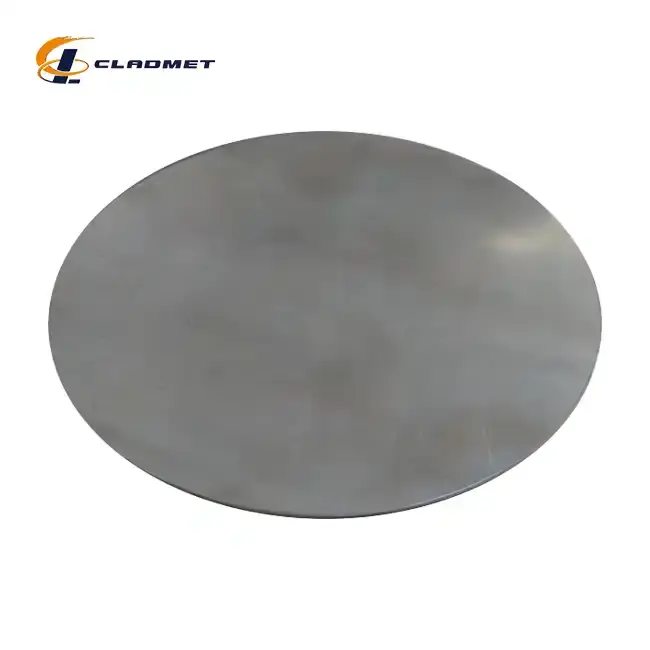

The explosion bonding manufacturing process offers significant advantages in producing high-quality stainless clad plates with consistent properties and superior performance characteristics. Baoji JL Clad Metals Materials Co., Ltd. has developed advanced manufacturing protocols that optimize explosive parameters, material preparation, and post-bonding processing to achieve exceptional quality in their stainless clad plates. The manufacturing process begins with careful selection and preparation of base materials, typically carbon steel or low alloy steel substrates ranging from Q235B to A516 Gr.70, and stainless steel cladding materials including 304/304L, 316/316L, 321, 310S, 2205, and 904L grades. Precise control of explosive charge configuration, standoff distance, and detonation velocity ensures consistent bond quality across the entire surface area of the stainless clad plate. The manufacturing facility maintains strict quality control measures throughout the production process, including real-time monitoring of process parameters and comprehensive testing of finished products. Advanced testing capabilities include ultrasonic inspection, radiographic examination, mechanical testing, and metallographic analysis to verify bond integrity and mechanical properties. The manufacturing process can accommodate stainless clad plates with total thickness ranging from 6mm to 200mm, cladding thickness from 1mm to 20mm, and dimensions up to 4000mm width by 12000mm length. This manufacturing flexibility, combined with stringent quality control, ensures that explosion-bonded stainless clad plates meet the most demanding industrial specifications and international standards.

Economic Benefits and Cost-Effectiveness

Explosion bonding provides significant economic advantages in manufacturing stainless clad plates by optimizing material utilization and reducing overall production costs while maintaining superior quality characteristics. The process enables the use of cost-effective base metals such as carbon steel or low alloy steel combined with a thin stainless steel cladding layer, resulting in material costs that are substantially lower than solid stainless steel alternatives. The exceptional bond strength achieved through explosion bonding ensures long-term reliability and extended service life, reducing maintenance requirements and replacement costs for industrial equipment. The manufacturing process is highly efficient, capable of bonding large surface areas in a single operation, which reduces production time and labor costs compared to alternative bonding methods. The superior quality and performance characteristics of explosion-bonded stainless clad plates translate to reduced downtime, lower maintenance costs, and improved operational efficiency for end users. The process also enables customization of material combinations, thicknesses, and dimensions to meet specific application requirements, providing cost-effective solutions for diverse industrial needs. Quality control measures ensure consistent product performance, reducing the risk of premature failure and associated costs. The combination of lower material costs, efficient manufacturing processes, and superior product performance makes explosion-bonded stainless clad plates a cost-effective solution for demanding industrial applications where both quality and economy are important considerations.

Conclusion

Explosion bonding revolutionizes stainless clad plate manufacturing by creating superior metallurgical bonds that significantly enhance quality, performance, and reliability. This advanced process generates exceptional bond strengths exceeding 140 MPa while preserving the corrosion resistance and mechanical properties essential for demanding industrial applications. The technology's ability to produce consistent, high-quality stainless clad plates with enhanced durability and extended service life makes it the preferred choice for critical applications across chemical processing, marine engineering, and power generation industries.

At Baoji JL Clad Metals Materials Co., Ltd., we leverage cutting-edge explosion bonding technology combined with extensive industry expertise to deliver superior stainless clad plates that exceed international quality standards. Our comprehensive manufacturing capabilities, stringent quality control measures, and commitment to innovation ensure that every product meets the exacting requirements of our global clientele. With ISO9001-2000 certification, PED and ABS international qualifications, and advanced R&D capabilities, we offer customized solutions tailored to your specific needs.

Ready to experience the superior quality and performance of explosion-bonded stainless clad plates? Contact our technical team today to discuss your project requirements and discover how our advanced manufacturing capabilities can enhance your industrial applications. We're committed to delivering innovative solutions that drive your success. Reach out to us at sales@cladmet.com to begin your journey toward superior material performance and operational excellence.

References

1. Crossland, B., & Williams, J. D. (1970). Explosive welding of metals and its application. Oxford University Press.

2. Blazynski, T. Z. (1983). Explosive welding, forming and compaction. Applied Science Publishers.

3. Hokamoto, K., Vesenjak, M., & Ren, Z. (2013). Explosive welding of metal plates. Materials and Design, 51, 1029-1037.

4. Acarer, M., Gülenç, B., & Fındık, F. (2003). Investigation of explosive welding parameters and their effects on microhardness and shear strength. Materials and Design, 24(8), 659-664.

_1737007724117.webp)

_1736996330512.webp)