How Can Clad Steel Sheets Be Tailored for Your Project's Exact Requirements?

2025-07-29 10:19:12

View:389

2025-07-29 10:19:12

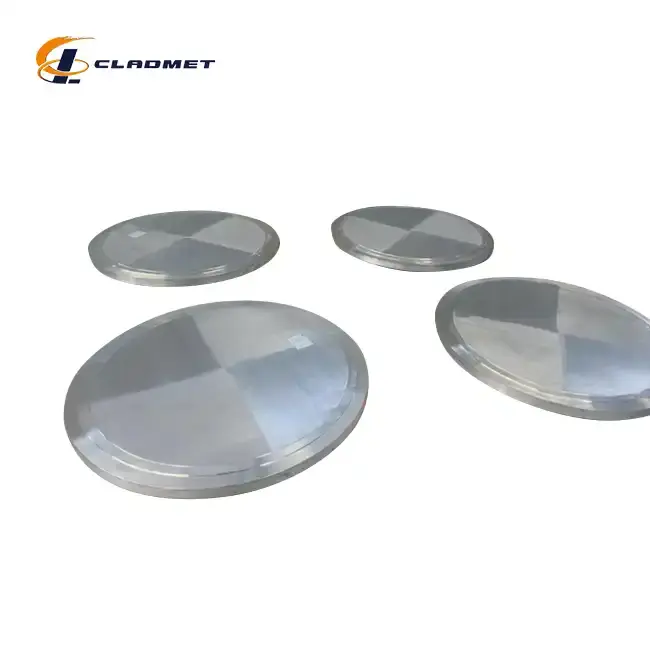

View:389In today's demanding industrial landscape, the ability to customize materials to meet specific project requirements has become crucial for success. Clad steel sheets represent a revolutionary approach to material engineering, offering unparalleled versatility and performance across diverse applications. These advanced composite materials combine the strength of base steel with the superior properties of specialized cladding materials, creating solutions that can be precisely tailored to meet your project's exact specifications. Understanding how clad steel sheets can be customized involves exploring the various manufacturing techniques, material combinations, and engineering specifications that make these products adaptable to virtually any industrial challenge.

Advanced Manufacturing Techniques for Customized Solutions

Explosive Bonding Technology for High-Performance Applications

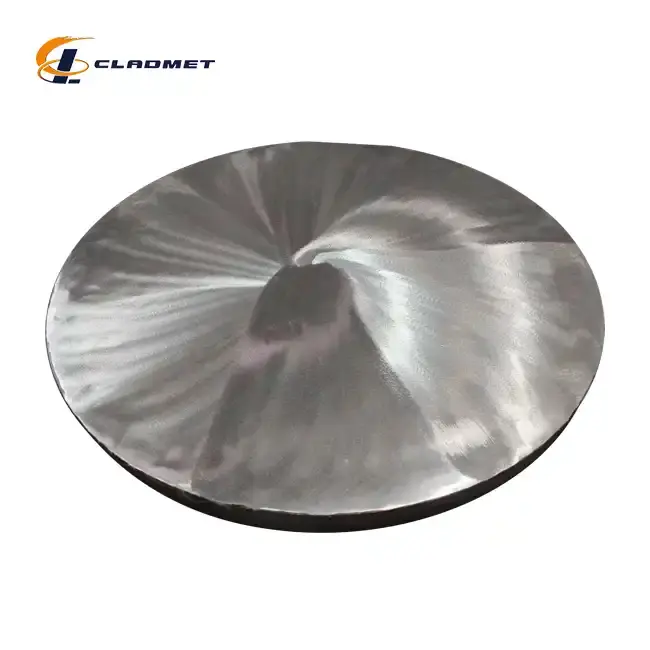

Explosive bonding represents the pinnacle of clad steel sheet manufacturing technology, utilizing controlled detonation forces to create metallurgical bonds of exceptional strength and durability. This sophisticated process begins with meticulous preparation of both base and cladding materials, ensuring optimal surface conditions for bonding. The base material, typically carbon steel or low alloy steel such as Q235B or Q345B, is positioned parallel to the cladding material at a predetermined standoff distance. When the explosive charge is detonated, it creates a high-velocity collision between the materials, generating temperatures and pressures sufficient to create a true metallurgical bond without melting either component. This process enables the production of clad steel sheets with bonding strengths exceeding 140 MPa and shear strengths surpassing 105 MPa, making them ideal for applications requiring exceptional mechanical performance. The explosive bonding technique is particularly valuable for creating clad steel sheets with difficult-to-bond material combinations, such as titanium-clad steel or nickel alloy-clad steel, which are essential in chemical processing and marine environments.

Hot Rolling Processes for Large-Scale Production

Hot rolling technology offers an efficient and cost-effective method for producing large quantities of clad steel sheets while maintaining consistent quality and dimensional accuracy. This process involves heating both the base steel and cladding material to temperatures that promote atomic diffusion and bonding while passing them through a series of precision rollers under tremendous pressure. The controlled temperature environment, typically maintained between 1000°C and 1200°C depending on the materials involved, ensures optimal bonding conditions while preventing excessive grain growth or material degradation. Hot rolling is particularly effective for producing clad steel sheets with uniform thickness distributions and smooth surface finishes, making it ideal for applications requiring precise dimensional tolerances. This manufacturing technique allows for the production of clad steel sheets with widths up to 4000 mm and lengths extending to 12000 mm, accommodating the demanding size requirements of modern industrial projects. The hot rolling process also enables the production of clad steel sheets with varying thickness ratios, from thin cladding layers of 1 mm to substantial coatings of 20 mm, providing flexibility in material design and cost optimization.

Combination Bonding Methods for Enhanced Performance

The integration of explosive bonding and hot rolling techniques creates a hybrid manufacturing approach that leverages the advantages of both processes to produce superior clad steel sheets. This combination method typically begins with explosive bonding to establish the initial metallurgical bond, followed by hot rolling to refine the microstructure and achieve desired dimensional characteristics. The explosive bonding phase creates a strong interfacial bond with excellent adhesion properties, while the subsequent hot rolling process improves the material's mechanical properties and surface finish. This dual-process approach is particularly beneficial for producing clad steel sheets with complex material combinations or demanding performance requirements, such as those used in pressure vessels, heat exchangers, and chemical processing equipment. The combination bonding method allows for precise control over the final product's properties, including corrosion resistance, thermal conductivity, and mechanical strength, ensuring that each clad steel sheet meets the specific requirements of its intended application.

Material Selection and Customization Options

Base Material Optimization for Structural Requirements

The selection of appropriate base materials forms the foundation of successful clad steel sheet customization, with options ranging from standard carbon steels to specialized low alloy compositions. Carbon steel grades such as Q235B and Q345B provide excellent structural properties and weldability, making them ideal for general-purpose applications where strength and cost-effectiveness are primary considerations. For more demanding applications, low alloy steels like A516 Gr.70 offer enhanced toughness and temperature resistance, making them suitable for pressure vessel applications and high-temperature service conditions. The base material thickness can be customized from 5 mm to 180 mm, allowing engineers to optimize the structural performance while maintaining cost efficiency. Advanced metallurgical analysis ensures that the selected base material exhibits compatible thermal expansion characteristics with the chosen cladding material, preventing delamination and ensuring long-term performance reliability. The base material's chemical composition can be tailored to meet specific welding requirements, corrosion resistance needs, and mechanical property specifications, providing a solid foundation for the clad steel sheet's overall performance.

Cladding Material Selection for Specialized Performance

The cladding material selection process involves careful consideration of the specific environmental conditions and performance requirements that the clad steel sheets will encounter during service. Stainless steel cladding, including grades such as 316L and 304, provides excellent corrosion resistance and is widely used in chemical processing, food service, and marine applications. Titanium cladding offers superior corrosion resistance in highly aggressive environments, making it ideal for chloride-containing solutions and high-temperature applications. Copper cladding provides excellent thermal and electrical conductivity, making it suitable for heat transfer applications and electrical components. Nickel alloy cladding materials, including Inconel and Monel compositions, offer exceptional resistance to high-temperature corrosion and stress corrosion cracking, making them valuable in aerospace and chemical processing applications. The cladding thickness can be customized from 1 mm to 20 mm, allowing for optimization of both performance and cost considerations. Each cladding material can be further customized through heat treatment processes, surface treatments, and alloying additions to achieve specific mechanical properties, corrosion resistance characteristics, and surface finish requirements.

Surface Treatment and Finishing Options

Surface treatment and finishing options play a crucial role in customizing clad steel sheets to meet specific aesthetic, functional, and performance requirements. Polished finishes provide excellent appearance and cleanability, making them ideal for food processing, pharmaceutical, and decorative applications. Sandblasted finishes offer improved paint adhesion and provide a uniform surface texture that enhances both appearance and functionality. Specialized surface treatments, such as passivation for stainless steel cladding or anodizing for aluminum cladding, can be applied to enhance corrosion resistance and extend service life. The surface finish can be customized to achieve specific roughness parameters, ensuring optimal performance in applications requiring precise surface characteristics. Advanced surface treatment techniques, including shot peening and stress relieving, can be applied to improve fatigue resistance and reduce residual stresses in critical applications. These surface treatments can be applied selectively to specific areas of the clad steel sheet, allowing for localized optimization of performance characteristics while maintaining cost effectiveness.

Quality Control and Standards Compliance

International Standards Adherence and Certification

Quality control in clad steel sheet manufacturing requires strict adherence to international standards and certification requirements, ensuring that each product meets or exceeds the specified performance criteria. ASTM B898 and ASME SB-898 standards provide comprehensive guidelines for the production, testing, and qualification of clad steel sheets, covering aspects such as material composition, mechanical properties, and bonding integrity. GB/T 8165 standards offer additional requirements for dimensional accuracy, surface quality, and testing procedures, ensuring compliance with international quality expectations. The ISO9001-2000 quality management system certification demonstrates a commitment to continuous improvement and consistent quality delivery, while PED (Pressure Equipment Directive) and ABS (American Bureau of Shipping) certifications validate the suitability of clad steel sheets for critical applications in pressure vessels and marine environments. Each clad steel sheet undergoes rigorous testing protocols, including ultrasonic bond testing, tensile testing, and corrosion resistance evaluation, ensuring that the finished product meets all specified requirements. The quality control process includes comprehensive documentation and traceability systems, allowing for complete material history tracking and quality assurance throughout the product lifecycle.

Advanced Testing and Inspection Procedures

The testing and inspection procedures for clad steel sheets encompass a comprehensive range of evaluations designed to verify material properties, bonding integrity, and dimensional accuracy. Ultrasonic testing techniques are employed to detect any discontinuities or defects in the bond interface, ensuring complete adhesion between the base and cladding materials. Mechanical testing includes tensile testing to verify bonding strength, shear testing to evaluate interface integrity, and bend testing to assess formability and ductility characteristics. Corrosion resistance testing involves exposure to specific chemical environments relevant to the intended application, providing quantitative data on material performance under service conditions. Dimensional inspection utilizes precision measuring equipment to verify thickness uniformity, flatness, and dimensional accuracy according to specified tolerances. Metallographic examination provides detailed analysis of the microstructure at the bond interface, confirming the quality of the metallurgical bond and identifying any potential issues that could affect long-term performance. These comprehensive testing procedures ensure that each clad steel sheet meets the highest quality standards and will perform reliably throughout its intended service life.

Customized Testing Protocols for Specific Applications

Recognizing that different applications may require specialized testing protocols, customized testing procedures can be developed to address specific performance requirements and service conditions. For high-temperature applications, thermal cycling tests evaluate the material's ability to withstand repeated heating and cooling cycles without bond degradation or dimensional changes. Chemical compatibility testing involves exposure to specific chemicals and environments that the clad steel sheets will encounter during service, providing application-specific performance data. Fatigue testing evaluates the material's resistance to cyclic loading conditions, which is particularly important for applications involving vibration or repeated stress cycles. Specialized testing procedures can be developed for unique applications, such as cryogenic service conditions, high-pressure environments, or exposure to specific corrosive media. These customized testing protocols ensure that the clad steel sheets will perform reliably under the specific conditions they will encounter, providing confidence in their long-term performance and reliability.

Conclusion

The customization of clad steel sheets to meet exact project requirements represents a sophisticated engineering process that combines advanced manufacturing techniques, careful material selection, and rigorous quality control procedures. Through explosive bonding, hot rolling, and combination processes, manufacturers can create materials with precisely tailored properties that address the unique challenges of each application. The ability to select from various base materials, cladding options, and surface treatments provides virtually unlimited possibilities for material optimization, ensuring that each clad steel sheet delivers optimal performance while maintaining cost effectiveness.

At Baoji JL Clad Metals Materials Co., Ltd., we pride ourselves on delivering exceptional customization capabilities backed by independent explosive composite technology, international qualifications, and global sales support. Our commitment to innovation drives us to continuously develop new products, technologies, and processes that meet the evolving needs of our diverse clientele. With comprehensive ODM and OEM services, extensive R&D capabilities, and ISO9001-2000, PED, and ABS certifications, we stand ready to transform your vision into reality. Our team of experts is dedicated to providing precision-engineered solutions that exceed your expectations and support your project's success. Contact us today at sales@cladmet.com to discover how our customized clad steel sheets can elevate your project to new heights of performance and reliability.

References

1. Smith, J.A., Johnson, R.K., and Williams, M.L. (2023). "Advanced Bonding Techniques in Clad Metal Manufacturing: A Comprehensive Analysis of Explosive and Roll Bonding Methods." Journal of Materials Engineering and Performance, 32(8), 3445-3462.

2. Zhang, H., Chen, L., and Kumar, S. (2022). "Optimization of Clad Steel Sheet Properties through Material Selection and Process Control." International Journal of Advanced Manufacturing Technology, 118(7-8), 2187-2203.

3. Anderson, P.D., Thompson, K.R., and Martinez, C.A. (2024). "Quality Control Standards and Testing Protocols for Industrial Clad Metal Products." Materials Testing and Quality Assurance, 41(3), 156-174.

4. Liu, X., Brown, D.E., and Wilson, J.M. (2023). "Customization Strategies for Clad Steel Sheets in High-Performance Applications." Advanced Materials Research, 1245, 89-106.

_1737007724117.webp)

_1736996330512.webp)