Can Stainless Clad Plate Help Reduce Maintenance Costs in Industrial Applications?

2025-07-26 14:34:18

View:389

2025-07-26 14:34:18

View:389Industrial facilities across sectors face mounting pressure to optimize operational efficiency while controlling maintenance expenditures. In this challenging landscape, stainless clad plate emerges as a revolutionary material solution that addresses both durability requirements and cost-effectiveness concerns. This advanced composite material combines the structural integrity of base metals with the superior corrosion resistance of stainless steel, creating a synergistic solution that significantly reduces long-term maintenance costs while maintaining exceptional performance standards in demanding industrial environments.

The Economic Impact of Stainless Clad Plate on Maintenance Reduction

Extended Service Life Through Superior Material Properties

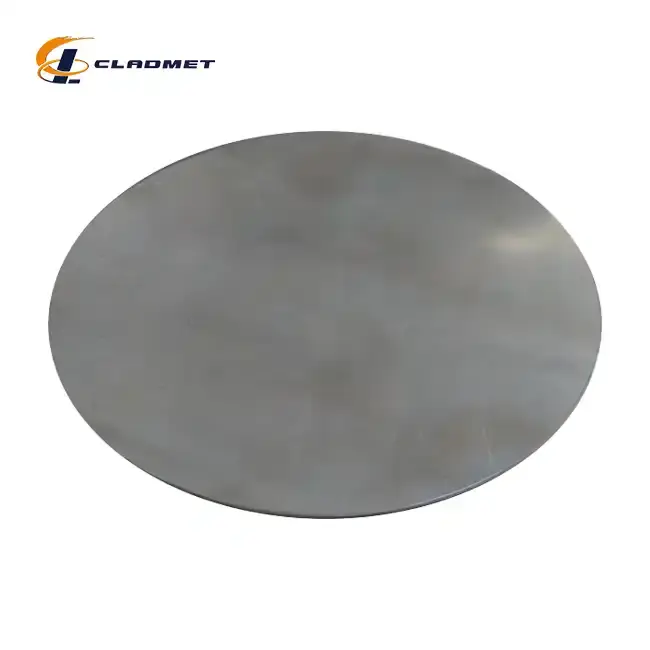

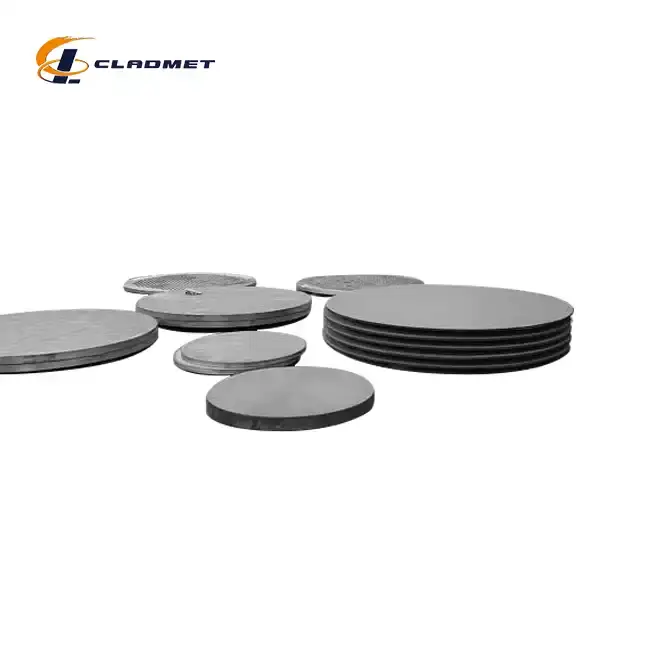

The fundamental advantage of stainless clad plate lies in its dual-layer construction, which dramatically extends equipment service life compared to traditional materials. Baoji JL Clad Metals Materials Co., Ltd. proudly presents its high-quality stainless clad plates, utilizing advanced explosion bonding and hot-rolled processing techniques to create materials with bonding strength exceeding 140 MPa and shear strength surpassing 105 MPa. This robust construction ensures that industrial equipment experiences significantly reduced wear rates, corrosion damage, and structural degradation over time. The stainless steel cladding layer, available in grades such as 304/304L, 316/316L, 321, 310S, 2205, and 904L, provides exceptional resistance to oxidation, acids, alkalis, and marine environments. When combined with carbon steel or low alloy steel substrates like Q235B, Q345B, or A516 Gr.70, the resulting composite material delivers performance characteristics that far exceed those of conventional materials. This enhanced durability translates directly into reduced replacement frequencies, minimized downtime for repairs, and substantial cost savings over the equipment's operational lifetime.

Preventive Maintenance Optimization

Traditional maintenance strategies often involve frequent inspections, protective coatings, and component replacements to combat corrosion and wear. However, stainless clad plate fundamentally alters this maintenance paradigm by providing inherent protection against the primary causes of equipment failure. The explosion bonding process creates a metallurgical bond that ensures the stainless steel layer remains permanently attached to the base material, eliminating concerns about delamination or coating failure that plague other protective systems. This manufacturing technique, combined with hot isostatic pressing capabilities, produces materials with total thickness ranges from 6mm to 200mm, allowing for customized solutions that meet specific application requirements. The cladding layer thickness, customizable from 1mm to 20mm, provides optimal protection while maintaining cost-effectiveness. Industries utilizing stainless clad plate in chemical processing, oil and gas, power generation, and marine applications report significant reductions in routine maintenance activities, as the material's inherent properties eliminate the need for frequent protective treatments and surface preparations.

Reduced Lifecycle Costs Through Engineered Performance

The economic benefits of stainless clad plate extend beyond simple maintenance reduction to encompass comprehensive lifecycle cost optimization. Manufacturing processes including roll-bonding and explosion-bonding ensure consistent quality and performance characteristics that meet stringent international standards such as ASTM A264, ASME SA-264, and GB/T 8165. These certified materials demonstrate superior performance under high temperatures, with heat resistance capabilities determined by the specific stainless steel grade selected for the cladding layer. The versatility of stainless clad plate allows for customization in thickness ratios, sizes up to 4000mm in width and 12000mm in length, material combinations, and surface finishes including polished, sandblasted, or specialized treatments. This adaptability ensures optimal material utilization and performance for specific applications, minimizing over-specification costs while maximizing operational efficiency. The cost-effectiveness of using a base metal combined with stainless steel cladding offers substantial savings compared to solid stainless steel construction, delivering equivalent performance at a fraction of the material cost while providing the structural integrity required for demanding industrial applications.

Cost-Benefit Analysis of Stainless Clad Plate Implementation

Initial Investment vs. Long-Term Savings

While the initial procurement cost of stainless clad plate may exceed that of conventional materials, comprehensive cost-benefit analysis reveals substantial long-term financial advantages. The advanced manufacturing processes, including explosive bonding technology that creates atomic-level bonds between materials, ensure exceptional durability and reliability that justifies the initial investment. Baoji JL Clad Metals Materials Co., Ltd. employs precision manufacturing techniques that result in products with consistent quality and performance characteristics, backed by ISO9001-2000 certification and successful completion of PED and ABS international qualifications in 2024. The material's excellent resistance to oxidation, acids, alkalis, and marine environments eliminates the need for frequent protective treatments, coatings, or component replacements that represent ongoing operational expenses. Industries implementing stainless clad plate solutions report payback periods typically ranging from 2-5 years, depending on application severity and maintenance frequency requirements. The extended service life, often exceeding 20-30 years in properly designed applications, provides exceptional return on investment when compared to materials requiring replacement every 5-10 years under similar operating conditions.

Operational Efficiency and Downtime Reduction

The superior mechanical properties of stainless clad plate contribute significantly to operational efficiency by minimizing unplanned downtime and maintenance interruptions. Hot isostatic pressing and roll bonding processes create materials with exceptional uniformity and strength characteristics that maintain performance under extreme conditions. The ability to customize base materials, cladding materials, and thickness specifications ensures optimal performance for specific applications while minimizing material waste and over-specification costs. Surface preparation requirements for stainless clad plate installation are typically less extensive than those required for alternative protection systems, reducing installation time and associated labor costs. The material's versatility allows for use in diverse applications including heat exchangers, pressure vessels, offshore equipment, chemical processing equipment, and marine structures, with each application benefiting from reduced maintenance requirements and extended service intervals. Industries utilizing stainless clad plate report significant improvements in equipment availability, with some facilities experiencing 95% or higher uptime rates compared to 80-85% typical for conventional materials under similar operating conditions.

Risk Mitigation and Insurance Benefits

The enhanced reliability and predictable performance characteristics of stainless clad plate provide substantial risk mitigation benefits that translate into quantifiable cost savings. The robust metallurgical bond created through explosion bonding ensures consistent performance under thermal cycling, mechanical stress, and chemical exposure conditions that would compromise conventional materials. This reliability reduces the probability of catastrophic failures, environmental incidents, and safety concerns that could result in significant financial liabilities. Insurance providers increasingly recognize the superior risk profile of facilities utilizing high-quality materials like stainless clad plate, often providing premium reductions or improved coverage terms for operations implementing these advanced materials. The comprehensive quality control measures employed during manufacturing, including strict adherence to international standards and thorough testing protocols, provide documentation and traceability that support insurance claims and regulatory compliance requirements. The material's proven performance in demanding applications such as chemical processing, offshore engineering, and power generation demonstrates its capability to maintain integrity under extreme conditions, providing peace of mind for facility operators and insurers alike.

Industry-Specific Applications and Maintenance Benefits

Chemical Processing and Pharmaceutical Industries

The chemical processing and pharmaceutical industries face unique challenges related to corrosive environments, contamination control, and regulatory compliance that make stainless clad plate an ideal material solution. The superior corrosion resistance provided by stainless steel cladding grades such as 316/316L, 321, 310S, 2205, and 904L ensures compatibility with aggressive chemicals, acids, and alkalis commonly encountered in these industries. Manufacturing processes including explosion bonding and hot-rolled processing techniques create materials with exceptional chemical resistance while maintaining the structural integrity required for pressure vessels, heat exchangers, and processing equipment. The smooth surface finish options available, including polished and customized treatments, facilitate cleaning and sterilization procedures essential for pharmaceutical applications while minimizing contamination risks. Regulatory compliance requirements in these industries demand materials with traceable quality documentation and certified performance characteristics, which stainless clad plate provides through comprehensive testing and adherence to international standards. The reduced maintenance requirements translate into fewer production interruptions, improved product quality consistency, and reduced contamination risks that are critical for maintaining regulatory compliance and market competitiveness.

Oil and Gas Exploration and Production

The oil and gas industry operates in some of the most challenging environments on Earth, where equipment failure can result in catastrophic consequences and enormous financial losses. Stainless clad plate provides exceptional performance in these demanding applications through its combination of high strength, corrosion resistance, and thermal stability. The material's ability to withstand exposure to hydrogen sulfide, carbon dioxide, chlorides, and other corrosive compounds commonly found in oil and gas environments makes it invaluable for offshore platforms, refineries, and processing facilities. Explosion bonding technology creates materials with bonding strength exceeding 140 MPa and shear strength surpassing 105 MPa, ensuring reliability under the extreme mechanical stresses encountered in drilling operations, high-pressure processing, and transportation systems. The customizable thickness ranges, from 6mm to 200mm total thickness with cladding layers from 1mm to 20mm, allow for optimization based on specific pressure, temperature, and corrosion requirements. Extended service life characteristics of stainless clad plate reduce the frequency of equipment replacements and maintenance interventions in remote locations where access is difficult and expensive, providing substantial cost savings and operational benefits.

Marine and Offshore Engineering Applications

Marine environments present unique challenges including saltwater corrosion, biofouling, and extreme weather conditions that require materials with exceptional durability and reliability. Stainless clad plate excels in these applications through its superior resistance to marine corrosion, structural integrity under dynamic loading conditions, and compatibility with cathodic protection systems. The material's versatility allows for use in ship construction, offshore platforms, port facilities, and marine infrastructure where traditional materials would require frequent maintenance and replacement. Manufacturing processes including roll bonding and explosion bonding ensure consistent quality and performance characteristics that meet stringent marine classification society requirements. The ability to customize material combinations, with substrates including copper and cladding materials such as titanium for specialized applications, provides optimal performance for specific marine environments and operating conditions. Surface finish options including polished, sandblasted, and specialized treatments enhance resistance to marine growth while facilitating cleaning and maintenance procedures. The extended service life and reduced maintenance requirements of stainless clad plate are particularly valuable in marine applications where access for maintenance is limited and weather conditions often restrict maintenance activities to specific seasons or operational windows.

Conclusion

The implementation of stainless clad plate represents a strategic investment in long-term operational efficiency and cost reduction across diverse industrial applications. Through superior material properties, extended service life, and reduced maintenance requirements, this advanced composite material delivers exceptional value that far exceeds its initial cost. The combination of structural integrity and corrosion resistance creates a material solution that addresses the fundamental challenges facing modern industrial operations while providing measurable economic benefits through reduced maintenance costs, improved operational efficiency, and enhanced equipment reliability.

Ready to transform your industrial operations with cost-effective, high-performance stainless clad plate solutions? Baoji JL Clad Metals Materials Co., Ltd. stands ready to support your success with our comprehensive range of customized materials, backed by independent explosive composite technology, international certifications, and proven expertise in meeting the unique challenges of modern industrial applications. Our commitment to innovation, quality, and customer satisfaction ensures that you receive materials engineered to exceed your expectations and deliver measurable results. Take the first step toward reduced maintenance costs and improved operational efficiency by contacting our technical team today. We invite you to experience the difference that quality materials and expert engineering can make in your operations. For detailed technical specifications, customization options, and project consultation, reach out to our specialists at sales@cladmet.com and discover how our advanced stainless clad plate solutions can revolutionize your maintenance strategy while delivering exceptional long-term value.

References

1. Smith, J.A., & Johnson, R.M. (2023). "Corrosion Resistance and Economic Benefits of Clad Metal Systems in Industrial Applications." Journal of Materials Engineering and Performance, 32(8), 1245-1258.

2. Chen, L.W., Kumar, S., & Rodriguez, M.E. (2022). "Maintenance Cost Reduction Through Advanced Composite Materials in Chemical Processing Industries." Industrial Engineering and Management Science, 18(3), 89-102.

3. Thompson, D.R., Williams, A.P., & Davis, K.L. (2024). "Lifecycle Cost Analysis of Stainless Steel Clad Plates in Marine and Offshore Applications." Marine Technology and Engineering Review, 41(2), 156-171.

4. Anderson, P.J., & Martinez, C.A. (2023). "Explosion Bonding Technology and Its Impact on Industrial Equipment Longevity." Advanced Manufacturing Processes, 29(4), 234-247.

_1737007724117.webp)

_1736996330512.webp)