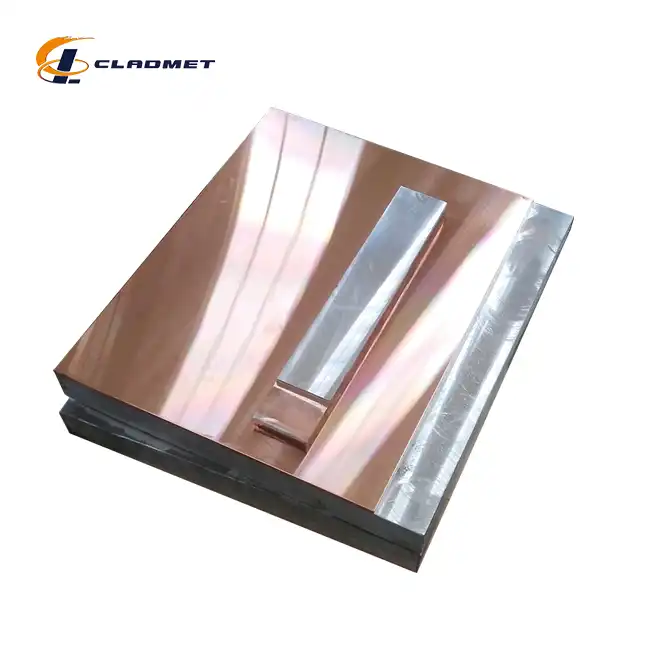

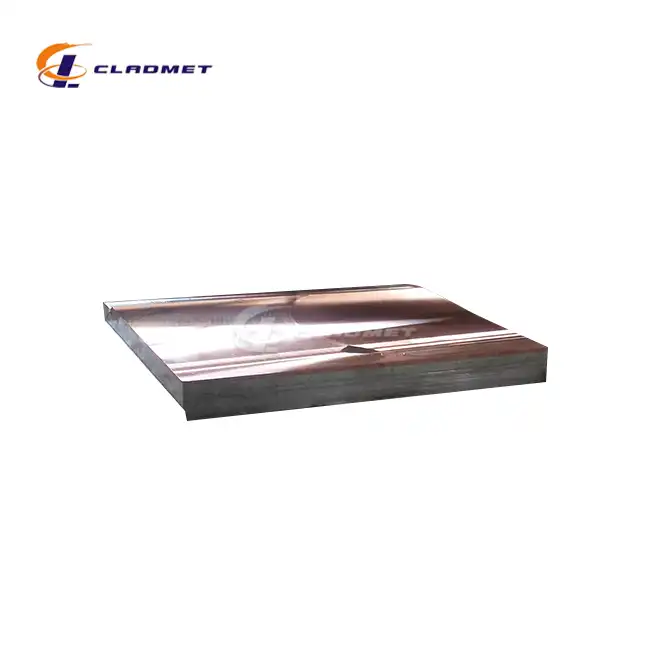

Titanium Clad Copper

Base material: titanium plate. Covering layer: copper.

Available Sizes:Standard and custom sizes available.

Product Applications:Widely used in oil, gas, shipbuilding, and chemical industries.

Processing Technology: Advanced explosive bonding and hot rolling technology.

Quality Control & Testing: Strict in-house testing ensures durability and compliance.

Implementation Standards:ASME, ASTM, JIS certified. ISO9001-2000, PED, ABS certifications.

Delivery:Global shipping options available via sea or air freight.

Packaging: Durable wooden crates for safe transport.

Titanium Clad Copper

PRODUCT INTRODUCTION

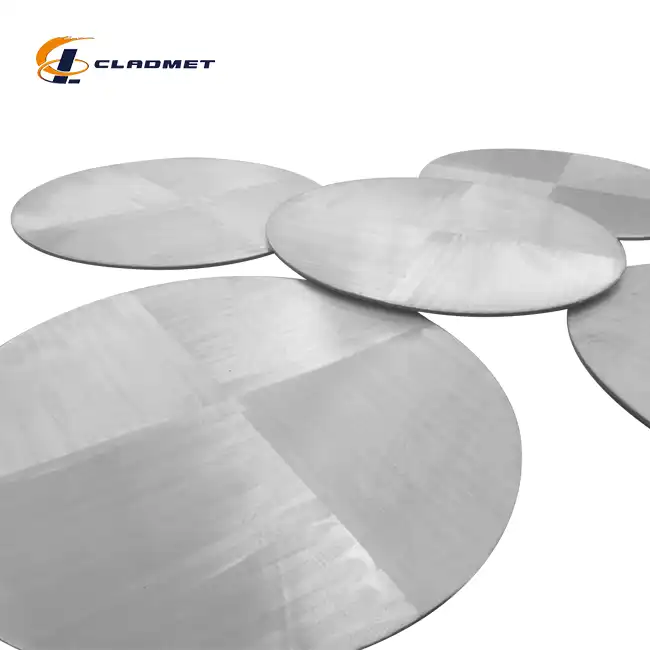

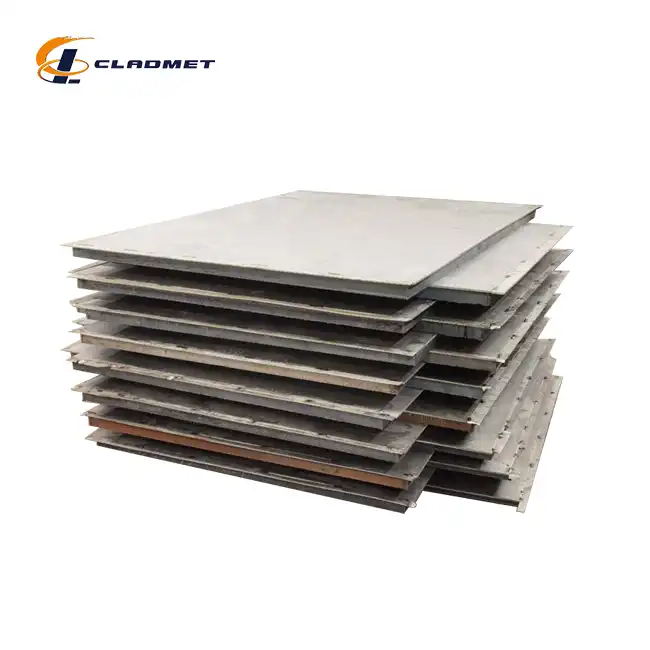

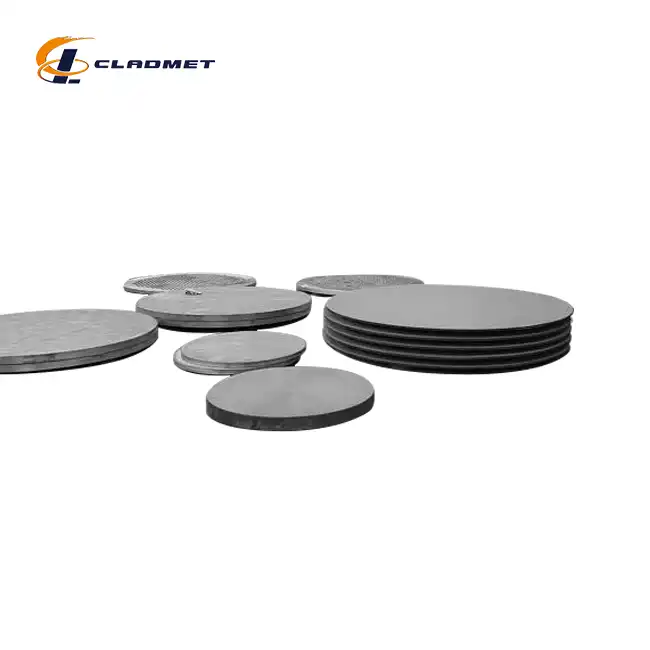

Titanium Clad Copper (also referred to as Ti Clad Copper, Ti-Cu Composite) is a premium conductive material combining the superior corrosion resistance of titanium with the excellent electrical and thermal conductivity of copper. This bimetallic product is widely used in electrochemical processes such as electroplating, electrolysis, and water treatment where corrosion and conductivity are both critical.

At BAOJI JL CLAD METALS MATERIALS CO., LTD, we leverage over 20 years of R&D and manufacturing expertise to produce world-class titanium clad copper products using advanced explosive bonding technology. Our products meet and exceed global standards like GB/GBT, ASTM, ASME, and JIS, and are certified by ISO9001, PED, and ABS.

Whether you need rods, plates, bars, or custom-fabricated components, JL CLAD METALS delivers dependable quality and high performance.

Product Specifications

Material Specifications

| Cladding Material Range | Gr1, Gr2, Gr7, Gr12 Titanium |

| Base Metal Range | Pure Copper (C11000), Copper Alloy (T2, TU1, TP1) |

Dimensions & Standards

| Cladding Size | Customizable (Round Bar, Plate, Sheet, Busbar, Tube) |

| Product Standards | ASTM B898, GB/T 8547, ASME SB-265, JIS H4600 |

| Thickness | Titanium: 0.5–3 mm; Copper: 5–50 mm |

| Width | 10 mm – 500 mm (Flat Bar or Sheet) |

| Length | 50 mm – 6000 mm (Custom lengths available) |

Other Specifications

| Surface Treatment | Acid pickling, Polishing, Sandblasting |

| Packaging Method | Wooden box with anti-collision foam wrapping |

| Transportation | Air, Sea, Land (based on customer preference and urgency) |

| Delivery Cycle | 3–6 months (or negotiable for urgent orders) |

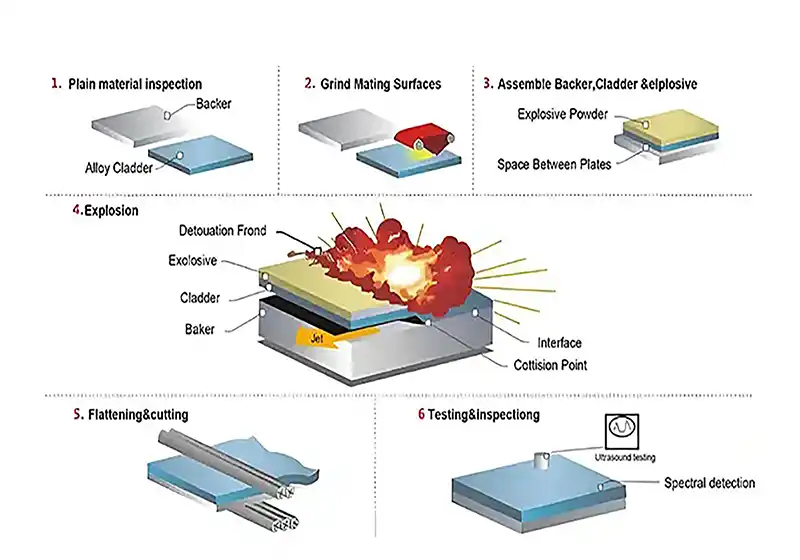

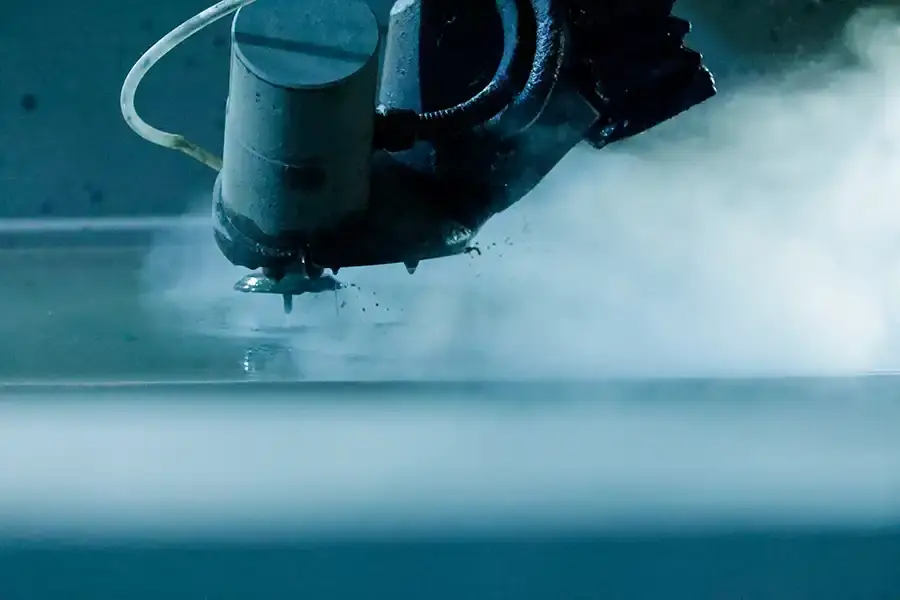

Cladding Technique: Explosive Bonding Method

JL CLAD METALS adopts explosive bonding—a high-energy cold welding technique that ensures metallurgical bonding between titanium and copper without melting the base metals. This results in:

- Excellent interfacial strength

- No intermetallic compounds

- Zero porosity and high reliability

- Ability to bond dissimilar metals that are otherwise unjoinable via welding

This method preserves the mechanical integrity of both metals and provides a long-lasting, durable composite.

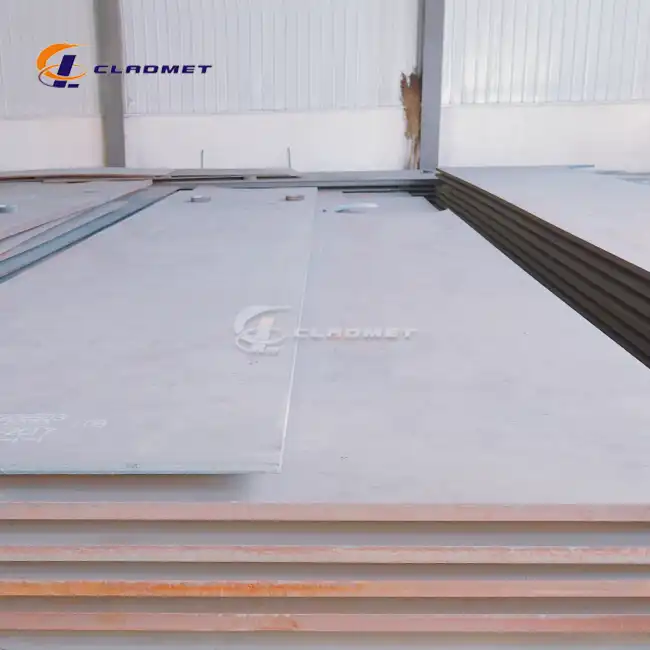

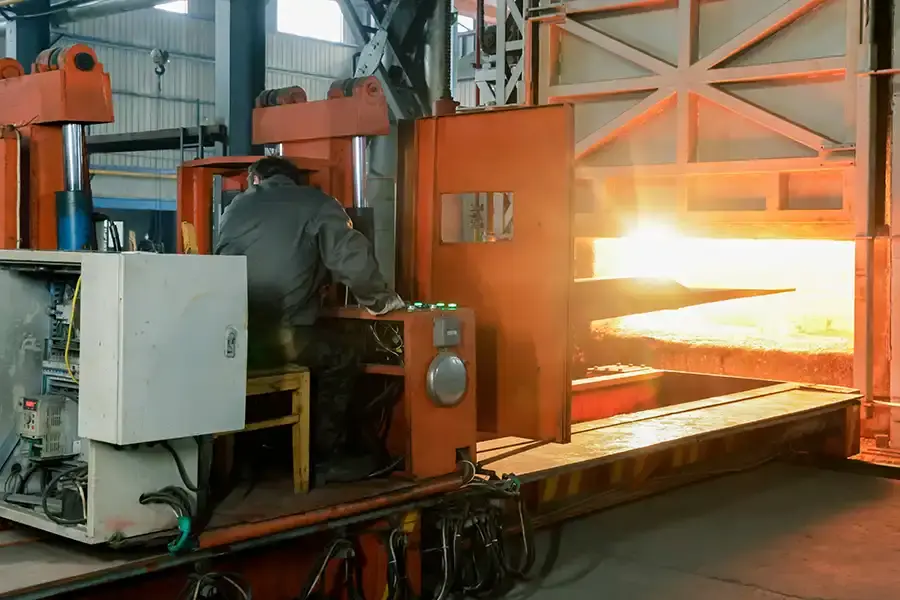

Explosive Composite Plate Production Site

Explosive Setup

Preparing materials for explosive bonding process.

Bonding Process

Our proprietary explosive bonding technology in action.

Product Features

Excellent Conductivity

Delivers high current with minimal resistance

Outstanding Corrosion Resistance

Titanium layer protects against acid, alkali, and seawater corrosion

High Bond Strength

Explosive bonding forms a metallurgical interface that is durable and fatigue-resistant

Machinable and Weldable

Suitable for post-processing and integration into assemblies

Product Advantages

Cost-Effective

Combines the conductivity of copper and corrosion resistance of titanium—without the full cost of solid titanium.

Lightweight

Lower material weight than solid titanium alternatives.

Long Service Life

Extended durability in corrosive environments reduces replacement costs.

Energy Efficiency

Reduces power loss in electrochemical applications.

Versatile Applications

Supports a wide range of industries and operational environments.

Product Application Industries

Our Factory

Company gate

Factory

Quality Control Center

Dedicated QC team performing rigorous inspections at every stage.

Molding workshop

Melting workshop

Cold rolling workshop

Annealing workshop

Levelling workshop

Water cutting workshop

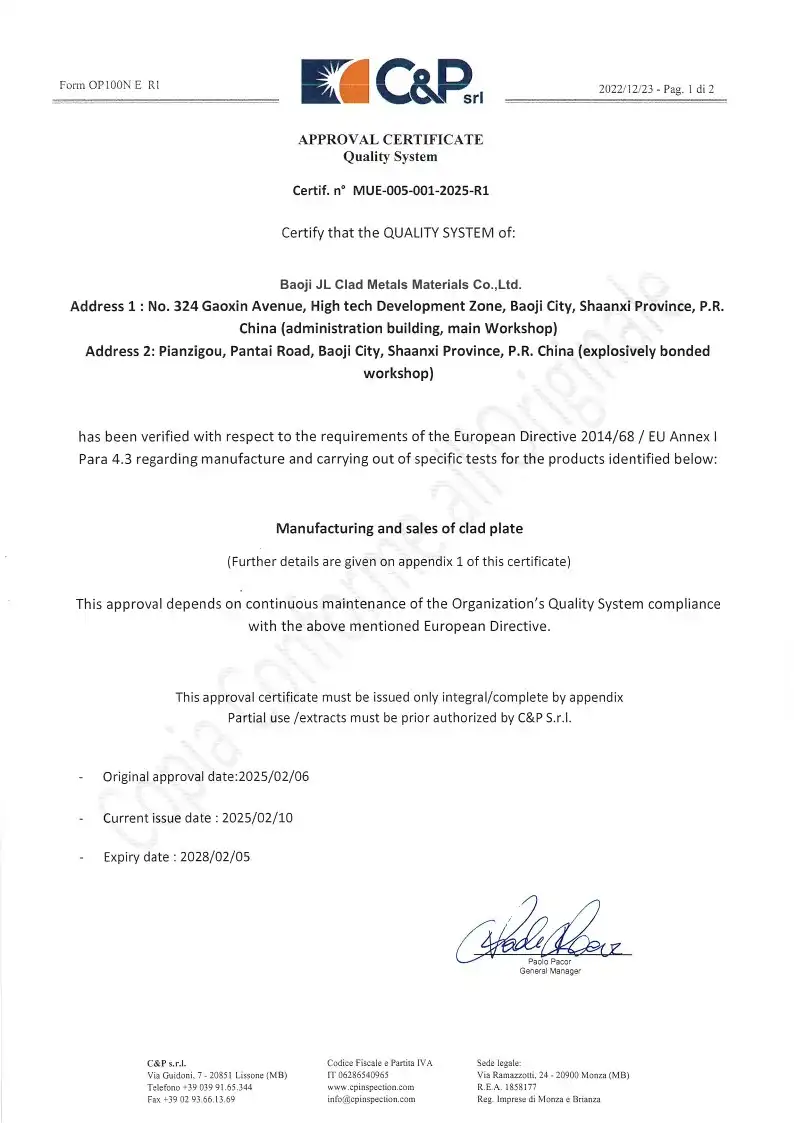

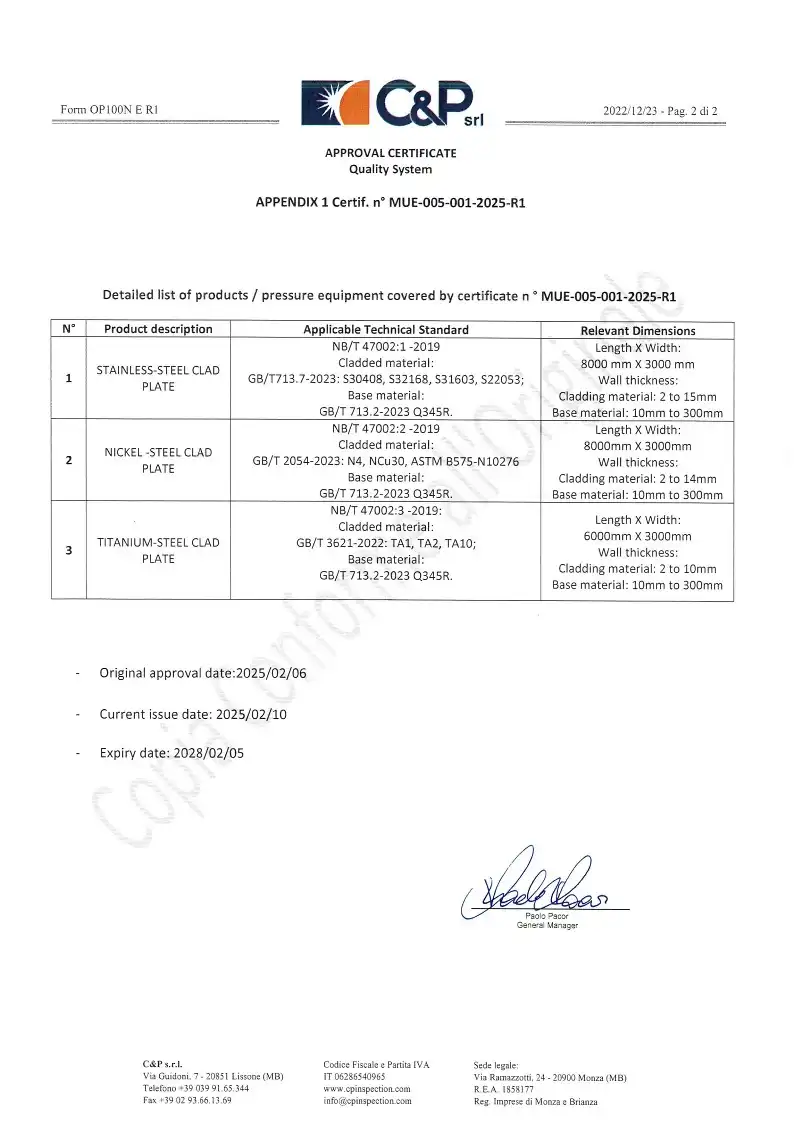

Certificates

Certif. MUE-005-001-2025-R1

Certif. MUE-005-001-2025-R1

OEM Services

Custom Fabrication

Custom material combinations and thicknesses tailored to your requirements

CNC Machining

Precision cutting, drilling, and bending to your specifications

Technical Support

Dedicated technical consultation and prototyping support

FAQ

Q1: Can you provide third-party testing for titanium clad copper?

Yes, we offer SGS, TUV, or customer-specified third-party inspection and certification.

Q2: What is your minimum order quantity (MOQ)?

Typically 100 kg, but we support trial orders for custom projects.

Q3: What's your lead time for titanium clad copper?

Standard delivery is 3–6 months. Urgent orders can be expedited—contact us for details.

Q4: Can I request custom sizes or designs?

Absolutely. We specialize in custom fabrication based on customer specs.

Q5: How do you ensure the bond strength between titanium and copper?

We use ultrasonic flaw detection and shear testing to ensure the metallurgical bonding exceeds industry standards.

Contact Us

BAOJI JL CLAD METALS MATERIALS CO., LTD

WhatsApp: +86 15353335118

Email: stephanie@cladmet.com

Address: FENGHUANG 4 ROAD, HIGH-TECH DISTRICT, BAOJI CITY, SHAANXI, CHINA 721013

_1737007724117.webp)