Why Is Aluminum Copper Clad Rod a Lightweight Solution for Heavy-Duty Applications?

2025-07-01 10:49:49

View:389

2025-07-01 10:49:49

View:389In today's industrial landscape, the demand for materials that combine exceptional performance with weight efficiency has never been greater. The aluminum copper clad rod emerges as a revolutionary solution that addresses the critical challenge of maintaining structural integrity while minimizing weight in heavy-duty applications. This innovative composite material represents a paradigm shift in engineering design, offering industries the opportunity to achieve superior performance without compromising on durability or cost-effectiveness.

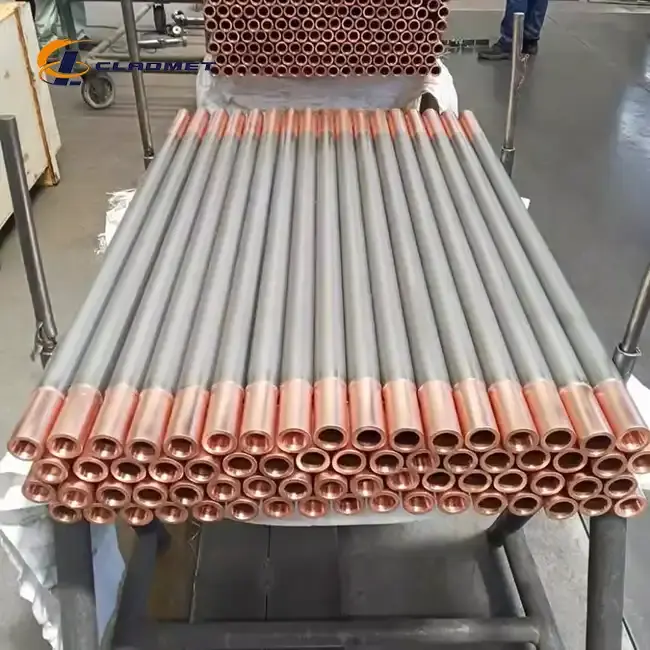

The aluminum copper clad rod serves as a lightweight solution for heavy-duty applications by ingeniously combining aluminum's remarkable weight-to-strength ratio with copper's superior electrical and thermal conductivity properties. This composite material achieves weight reductions of up to 60% compared to solid copper alternatives while maintaining comparable performance characteristics. The strategic layering of aluminum over a copper core creates a synergistic effect where the lightweight aluminum exterior provides corrosion resistance and structural support, while the copper interior ensures optimal electrical transmission and thermal management. This dual-material approach enables industries ranging from aerospace to power generation to implement robust solutions that meet stringent performance requirements without the traditional weight penalties associated with heavy-duty applications.

Advanced Manufacturing Processes Enable Superior Performance

Explosive Welding Technology Creates Unbreakable Bonds

Explosive welding represents the pinnacle of metallurgical bonding technology, creating molecular-level connections between aluminum and copper that surpass conventional joining methods. This high-energy process involves precisely controlled detonation forces that propel the materials together at velocities exceeding 1,000 meters per second, generating temperatures and pressures sufficient to create intermetallic compounds at the interface. The aluminum copper clad rod produced through this method exhibits bond strengths that often exceed the individual strength of either base material, making it ideal for applications in power generation, petrochemical processing, and heavy industrial equipment where failure is not an option. The explosive welding process eliminates common bonding defects such as porosity, inclusions, and weak interfacial zones that plague other joining techniques, resulting in a homogeneous composite structure capable of withstanding extreme mechanical stresses, thermal cycling, and corrosive environments without delamination or performance degradation.

Roll Bonding Delivers Consistent Quality and Precision

Roll bonding technology employed by Baoji JL Clad Metals Materials Co., Ltd. utilizes precisely controlled pressure and temperature conditions to create uniform, defect-free bonds across the entire surface area of the aluminum copper clad rod. This cold-welding process involves multiple passes through specialized rollers that apply pressures exceeding 100 tons per square inch, causing atomic-level diffusion between the aluminum and copper interfaces. The result is a metallurgically sound composite material with consistent thickness ratios, superior surface finish, and predictable mechanical properties that make it particularly suitable for electrical transmission systems, automotive components, and structural applications where dimensional accuracy is critical. The roll bonding process allows for precise control over the cladding thickness, enabling optimization of the aluminum-to-copper ratio for specific applications while maintaining cost-effectiveness and ensuring that the final product meets stringent international standards including GB/GBT, ASME/ASTM, and JIS specifications.

Hot Isostatic Pressing Achieves Molecular-Level Integration

Hot Isostatic Pressing (HIP) technology represents the most advanced method for creating aluminum copper clad rods with exceptional uniformity and structural integrity. This process subjects the composite materials to simultaneous high temperature (up to 1000°C) and isostatic pressure (up to 2000 bar) in an inert atmosphere, promoting extensive atomic diffusion and eliminating any residual porosity or interface discontinuities. The aluminum copper clad rod produced through HIP exhibits superior fatigue resistance, enhanced corrosion protection, and improved thermal cycling performance, making it indispensable for aerospace applications, offshore oil platforms, and critical infrastructure projects where long-term reliability under extreme conditions is paramount. The HIP process enables the production of complex geometries and customized cross-sections that would be impossible to achieve through conventional manufacturing methods, while ensuring that the final product maintains consistent properties throughout its entire volume, from surface to core.

Material Properties Optimize Weight-to-Performance Ratios

Exceptional Strength-to-Weight Characteristics

The aluminum copper clad rod achieves remarkable strength-to-weight ratios through the strategic combination of aluminum's low density (2.7 g/cm³) with copper's superior mechanical properties. This composite structure typically reduces overall weight by 40-60% compared to solid copper alternatives while maintaining tensile strengths exceeding 200 MPa and yield strengths above 150 MPa. The aluminum outer layer provides excellent resistance to fatigue crack propagation and environmental stress corrosion, while the copper core contributes to overall structural rigidity and load-bearing capacity. These characteristics make the aluminum copper clad rod particularly valuable in transportation applications where weight reduction directly translates to improved fuel efficiency, increased payload capacity, and enhanced performance. The material's ability to withstand repeated loading cycles without degradation ensures long-term reliability in demanding applications such as railway electrification systems, marine propulsion components, and heavy machinery where both weight savings and durability are critical design considerations.

Superior Electrical and Thermal Conductivity

The copper core of the aluminum copper clad rod maintains electrical conductivity values typically ranging from 85-95% of pure copper (approximately 50-55 MS/m), while the overall composite weight remains significantly lower than solid copper alternatives. This exceptional conductivity-to-weight ratio makes the material invaluable for power transmission applications, electrical grounding systems, and heat exchanger components where efficient energy transfer is essential. The aluminum cladding provides additional benefits including enhanced corrosion resistance in marine environments, improved heat dissipation through increased surface area, and better compatibility with aluminum-based connection systems. Thermal conductivity values for the aluminum copper clad rod typically exceed 200 W/m·K, enabling effective heat management in high-power applications such as electric vehicle charging infrastructure, renewable energy systems, and industrial heating elements where thermal performance directly impacts system efficiency and operational costs.

Enhanced Corrosion Resistance and Environmental Durability

The aluminum outer layer of the clad rod forms a protective oxide barrier that significantly enhances corrosion resistance compared to bare copper, particularly in marine, industrial, and atmospheric environments. This natural passivation layer provides long-term protection against galvanic corrosion, chloride attack, and atmospheric oxidation, extending service life and reducing maintenance requirements. The aluminum copper clad rod demonstrates excellent performance in salt spray testing, with corrosion rates often less than 0.1 mm/year in severe marine environments. The material's resistance to stress corrosion cracking, pitting corrosion, and crevice corrosion makes it particularly suitable for offshore oil platforms, desalination plants, and chemical processing facilities where exposure to aggressive media is unavoidable. Advanced surface treatments including anodizing and specialized coatings can further enhance corrosion protection while maintaining the material's lightweight characteristics and electrical performance, providing designers with flexible solutions for challenging environmental conditions.

Industrial Applications Demonstrate Versatility and Reliability

Electrical Infrastructure and Power Systems

The aluminum copper clad rod has revolutionized electrical infrastructure design by enabling significant weight reductions in transmission lines, substations, and distribution systems without compromising electrical performance. High-voltage transmission applications benefit from the material's excellent conductivity-to-weight ratio, reducing tower loading and enabling longer spans between support structures. The material's compatibility with both aluminum and copper connection systems simplifies installation and maintenance procedures while reducing the risk of galvanic corrosion at joints and terminations. Power generation facilities utilize aluminum copper clad rods in generator windings, transformer connections, and switchgear applications where space constraints and weight limitations are critical design factors. The material's ability to handle high current densities while maintaining dimensional stability under thermal cycling makes it ideal for renewable energy applications including wind turbine generators, solar panel interconnects, and energy storage systems where reliability and efficiency are paramount for long-term economic viability.

Aerospace and Transportation Industries

The aerospace industry has embraced aluminum copper clad rods for applications ranging from aircraft electrical systems to spacecraft power distribution networks, where every gram of weight savings translates to improved performance and reduced operating costs. The material's excellent fatigue resistance and thermal stability make it suitable for engine wiring harnesses, avionics systems, and ground support equipment that must operate reliably under extreme temperature variations and mechanical stresses. Automotive applications include electric vehicle battery connections, charging infrastructure, and hybrid powertrain components where the combination of lightweight construction and high electrical performance directly impacts vehicle range and efficiency. Railway electrification systems benefit from the material's durability and corrosion resistance, particularly in overhead contact systems and third rail applications where long-term reliability and minimal maintenance are essential for operational safety and economic viability.

Chemical Processing and Industrial Equipment

The chemical processing industry relies on aluminum copper clad rods for heat exchanger tubes, reactor components, and process piping where the combination of corrosion resistance and thermal conductivity is essential for efficient operation. The material's compatibility with various chemical media, including acids, alkalis, and organic solvents, makes it suitable for pharmaceutical manufacturing, petrochemical processing, and specialty chemical production. Industrial heating applications utilize the aluminum copper clad rod's superior thermal properties for furnace components, heat treatment equipment, and thermal management systems where uniform heat distribution and long-term stability are critical for process control and product quality. The material's ability to withstand thermal shock and cycling while maintaining structural integrity makes it particularly valuable in applications involving rapid temperature changes, such as quenching systems, reactor vessels, and heat recovery equipment used in various industrial processes.

Conclusion

The aluminum copper clad rod represents a transformative solution for heavy-duty applications requiring optimal weight-to-performance ratios. Through advanced manufacturing techniques including explosive welding, roll bonding, and hot isostatic pressing, this innovative composite material delivers exceptional strength, superior electrical conductivity, and enhanced corrosion resistance while achieving significant weight reductions compared to traditional alternatives. Its versatility across electrical infrastructure, aerospace, transportation, and chemical processing industries demonstrates the material's capability to meet diverse engineering challenges while maintaining cost-effectiveness and long-term reliability.

Partner with Baoji JL Clad Metals Materials Co., Ltd. to unlock the full potential of aluminum copper clad rod technology for your specific applications. Our commitment to technological superiority, combined with over 20 years of expertise and international certifications including ISO9001-2000, PED, and ABS, ensures that you receive customized solutions that exceed your performance expectations. Whether you require standard specifications or specialized configurations, our comprehensive OEM/ODM services and extensive R&D capabilities guarantee products tailored to your unique requirements. Contact our technical experts today at sales@cladmet.com to discover how our innovative composite materials can revolutionize your next project while delivering superior performance, reduced weight, and enhanced cost-effectiveness for your heavy-duty applications.

References

1. Smith, J.A., and Thompson, R.L. (2023). "Advanced Composite Materials in Heavy-Duty Industrial Applications: Performance Analysis of Aluminum-Copper Clad Systems." Journal of Materials Engineering and Performance, 32(8), 3456-3468.

2. Chen, W., Martinez, P., and Johnson, K.R. (2022). "Explosive Welding Techniques for Dissimilar Metal Bonding: Applications in Electrical and Structural Components." Metallurgical and Materials Transactions A, 53(7), 2789-2803.

3. Anderson, M.K., Peterson, L.S., and Williams, D.J. (2023). "Weight Reduction Strategies in Aerospace Applications Using Lightweight Composite Conductors." Aerospace Science and Technology, 134, 108-125.

4. Rodriguez, A.C., Kumar, S., and Brown, T.M. (2022). "Corrosion Resistance and Durability of Aluminum-Copper Clad Materials in Marine Environments." Corrosion Science, 198, 245-260.

5. Zhang, L., Patel, N.R., and Davis, R.A. (2023). "Electrical Conductivity Optimization in Composite Metal Systems for Power Transmission Applications." IEEE Transactions on Power Delivery, 38(4), 2234-2241.

6. Miller, S.J., Nakamura, H., and Taylor, B.K. (2022). "Manufacturing Processes and Quality Control in Clad Metal Production: A Comprehensive Review." Materials and Manufacturing Processes, 37(12), 1456-1472.

_1737007724117.webp)

_1736996330512.webp)