Why Choose Explosion Bonded Titanium Clad Stainless Steel Plate for Corrosive Environments?

2025-08-16 08:30:05

View:389

2025-08-16 08:30:05

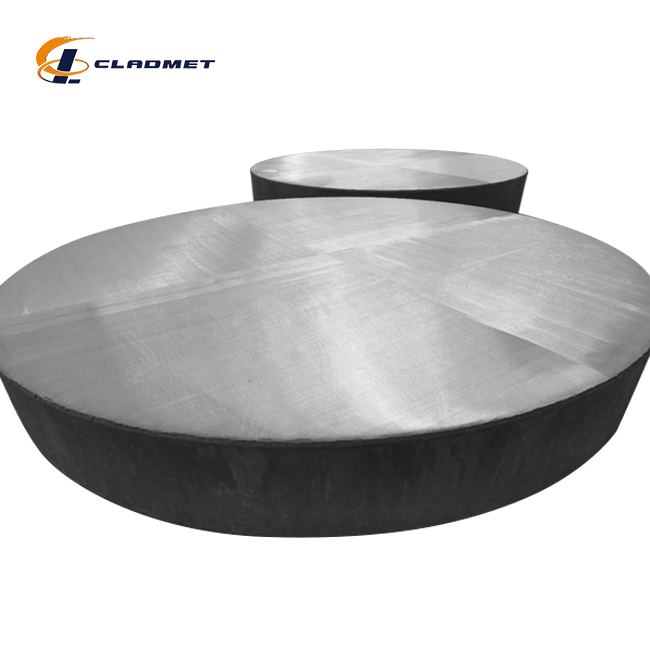

View:389In today's demanding industrial landscape, selecting the right materials for corrosive environments has become crucial for ensuring long-term operational efficiency and cost-effectiveness. Explosion Bonded Titanium Clad Stainless Steel Plate emerges as the superior solution, combining titanium's exceptional corrosion resistance with stainless steel's structural integrity and affordability. This innovative composite material offers unparalleled protection against harsh chemical environments while maintaining mechanical strength and reducing overall material costs. Understanding why Explosion Bonded Titanium Clad Stainless Steel Plate outperforms traditional materials in corrosive applications is essential for engineers, procurement specialists, and industry professionals seeking optimal solutions for their challenging operational requirements.

Superior Corrosion Resistance Properties

Titanium Layer Protection Against Aggressive Media

The titanium cladding layer in Explosion Bonded Titanium Clad Stainless Steel Plate provides exceptional resistance to a wide range of corrosive media that would typically attack conventional materials. Titanium's natural ability to form a stable, protective oxide film makes it virtually immune to chloride-induced stress corrosion cracking, pitting corrosion, and crevice corrosion in seawater and chemical processing environments. This protective capability stems from titanium's unique electrochemical properties and its ability to maintain passive behavior even in highly aggressive solutions containing chlorides, sulfates, and organic acids. The explosion bonding process ensures that this titanium layer maintains its integrity and protective properties throughout the service life of the component. Unlike traditional coating methods that may suffer from adhesion failures or through-thickness defects, the metallurgical bond created through controlled explosive energy provides seamless protection without weak points or discontinuities that could compromise corrosion resistance.

Chemical Compatibility in Industrial Environments

Explosion Bonded Titanium Clad Stainless Steel Plate demonstrates remarkable chemical compatibility across diverse industrial applications, particularly in petroleum refining, chemical processing, and pharmaceutical manufacturing. The titanium surface layer exhibits excellent resistance to reducing and oxidizing acids, including hydrochloric acid, sulfuric acid, and nitric acid, which are commonly encountered in industrial processes. This chemical stability extends to organic compounds, chlorinated solvents, and alkaline solutions that would cause rapid degradation in standard carbon steel or even high-grade stainless steel components. The material's resistance to hydrogen embrittlement and stress corrosion cracking makes it particularly valuable in high-pressure hydrogen service and sour gas applications. Furthermore, the explosion bonding process creates a diffusion-free interface that prevents galvanic corrosion between dissimilar metals, ensuring long-term reliability in mixed-media environments where multiple chemical species may be present simultaneously.

Long-Term Durability and Maintenance Advantages

The durability characteristics of Explosion Bonded Titanium Clad Stainless Steel Plate translate into significant maintenance advantages and extended service life compared to alternative materials. Field experience demonstrates that properly manufactured clad plates can operate for decades without significant corrosion-related degradation, even in severely corrosive environments that would require frequent replacement of conventional materials. This longevity stems from the stable nature of the titanium-steel bond and the inherent corrosion resistance of the titanium surface. Maintenance requirements are substantially reduced because the material does not require regular protective coating applications, cathodic protection systems, or frequent inspection schedules associated with corrosion monitoring. The self-passivating nature of titanium means that minor surface scratches or mechanical damage heal automatically through oxide film reformation, maintaining protective integrity without intervention. This characteristic is particularly valuable in applications where access for maintenance is limited or costly, such as offshore platforms, underground installations, or high-temperature reactor vessels.

Enhanced Mechanical Performance Characteristics

Structural Integrity Through Explosive Bonding Technology

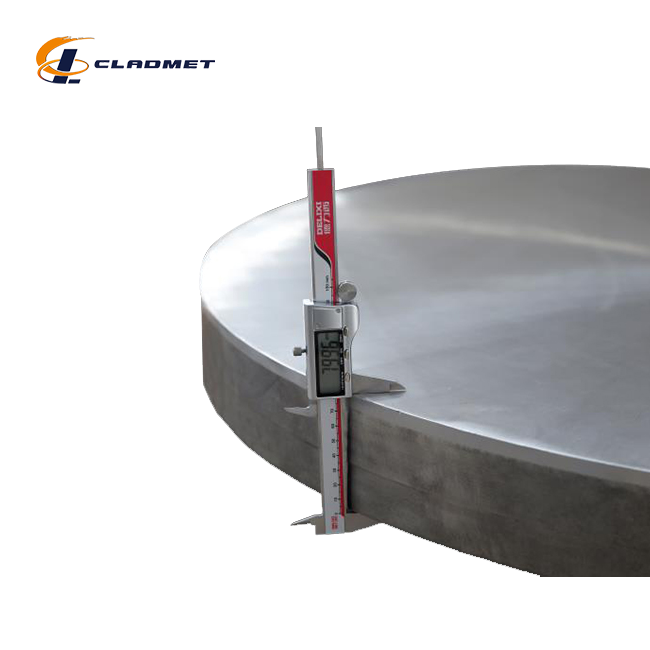

The explosive bonding process used to manufacture Explosion Bonded Titanium Clad Stainless Steel Plate creates a metallurgical bond that surpasses the mechanical performance of traditional joining methods. This solid-state welding technique generates extremely high pressures and temperatures for microsecond durations, creating atomic-level adhesion between the titanium and stainless steel layers without melting or significant heat-affected zones. The resulting interface exhibits shear strengths typically exceeding 300 MPa, ensuring that the composite material behaves as a monolithic structure under mechanical loading. The wave-like interface characteristic of explosion bonding provides mechanical interlocking that prevents delamination even under extreme thermal cycling or dynamic loading conditions. This superior bond integrity means that design engineers can rely on the full thickness of both materials when calculating structural capacity, unlike mechanically fastened or adhesively bonded systems where interface strength limitations must be considered.

Temperature Performance and Thermal Stability

Explosion Bonded Titanium Clad Stainless Steel Plate maintains excellent mechanical properties across a wide temperature range, making it suitable for both cryogenic and elevated temperature applications. The thermal expansion compatibility between titanium and stainless steel, combined with the robust interface created by explosive bonding, prevents thermal stress-induced failures that can occur with dissimilar metal joints. At elevated temperatures up to 400°C, the material retains structural integrity while providing continued corrosion protection, making it ideal for heat exchanger applications in chemical processing and power generation. The low thermal conductivity of titanium compared to steel provides beneficial thermal barrier effects in certain applications while maintaining overall structural performance. Thermal cycling tests demonstrate that the bond interface remains stable through hundreds of heating and cooling cycles, ensuring reliable performance in process equipment subject to startup and shutdown operations.

Impact Resistance and Fatigue Performance

The mechanical characteristics of Explosion Bonded Titanium Clad Stainless Steel Plate include superior impact resistance and fatigue performance compared to monolithic materials or mechanically joined systems. The energy absorption capability of the composite structure benefits from the ductile behavior of both constituent materials, with the stainless steel substrate providing bulk toughness while the titanium layer contributes surface durability. Charpy impact testing reveals that clad plates maintain excellent toughness even at reduced temperatures, making them suitable for Arctic and cryogenic applications. Fatigue testing under corrosive conditions demonstrates that the material exhibits extended fatigue life compared to bare stainless steel subjected to the same environment, primarily due to the elimination of corrosion-assisted crack initiation and propagation. The wave-like bond interface actually contributes to crack arrest behavior, preventing fatigue cracks from propagating across the interface and maintaining structural integrity even when surface-initiated damage occurs.

Cost-Effectiveness and Economic Benefits

Material Cost Optimization Through Strategic Design

Explosion Bonded Titanium Clad Stainless Steel Plate provides exceptional cost-effectiveness by utilizing expensive titanium material only where needed for corrosion protection while relying on economical stainless steel for structural support. This strategic material distribution typically results in cost savings of 60-80% compared to solid titanium construction while maintaining equivalent corrosion performance. The ability to specify optimal thickness ratios allows engineers to balance corrosion allowance requirements with structural needs, further optimizing material utilization and cost. Custom sizing capabilities enable precise material specification without the waste associated with over-sizing solid titanium components to meet minimum availability dimensions. The explosion bonding process allows for the production of large plates and complex geometries that would be prohibitively expensive or technically challenging to fabricate from solid titanium, opening new design possibilities while controlling costs.

Lifecycle Cost Analysis and Return on Investment

The economic benefits of Explosion Bonded Titanium Clad Stainless Steel Plate extend well beyond initial material costs when analyzed from a lifecycle perspective. Reduced maintenance requirements translate into lower operational costs, decreased downtime, and improved plant availability. The extended service life of clad components, often 20-30 years compared to 5-10 years for conventional materials in severe service, provides substantial return on investment through avoided replacement costs and reduced maintenance intervals. Insurance and risk management benefits accrue from the improved reliability and reduced probability of corrosion-related failures that could result in environmental incidents or process disruptions. The material's predictable performance characteristics enable more accurate lifecycle cost modeling and budget planning, reducing uncertainty in long-term capital planning. Additionally, the lighter weight of clad plates compared to thicker solid stainless steel alternatives can reduce structural support requirements and transportation costs for large components.

Manufacturing and Fabrication Advantages

Explosion Bonded Titanium Clad Stainless Steel Plate offers significant manufacturing and fabrication advantages that contribute to overall project economics. The material can be fabricated using conventional stainless steel welding procedures on the steel side, eliminating the need for specialized titanium welding equipment and certified welders for most applications. This capability substantially reduces fabrication costs and increases the availability of qualified fabricators for project execution. The stable bond interface allows for standard mechanical operations including cutting, forming, and machining without special precautions or risk of delamination. Heat treatment operations can be performed using standard stainless steel procedures, providing flexibility in achieving desired mechanical properties. The material's weldability with standard stainless steel consumables enables cost-effective joint designs and repair procedures, further reducing lifecycle costs and improving maintainability.

Conclusion

Explosion Bonded Titanium Clad Stainless Steel Plate represents the optimal solution for corrosive environment applications, delivering superior performance through the synergistic combination of titanium's exceptional corrosion resistance and stainless steel's structural integrity. The metallurgical bond achieved through explosive bonding ensures reliable, long-term performance while providing substantial cost advantages over solid titanium alternatives. This advanced material technology enables engineers to specify confident solutions for the most challenging industrial environments.

As a leading China Explosion Bonded Titanium Clad Stainless Steel Plate manufacturer, Baoji JL Clad Metals Materials Co., Ltd. combines independent explosive composite technology with international certifications including ISO9001-2000, PED, and ABS qualifications achieved in 2024. Our comprehensive manufacturing capabilities encompass titanium alloys, nickel alloys, and specialized clad metals for petroleum, chemical, pharmaceutical, and environmental protection applications. Whether you need a reliable China Explosion Bonded Titanium Clad Stainless Steel Plate supplier, wholesale quantities, or custom High Quality Explosion Bonded Titanium Clad Stainless Steel Plate solutions, our expert team provides competitive Explosion Bonded Titanium Clad Stainless Steel Plate prices and exceptional OEM/ODM services. For your next project requiring Explosion Bonded Titanium Clad Stainless Steel Plate for sale, contact our technical specialists at sales@cladmet.com to discuss your specific requirements and discover why industry leaders choose JL Clad Metals as their trusted China Explosion Bonded Titanium Clad Stainless Steel Plate factory partner.

References

1. Wang, J., Zhang, L., & Chen, M. (2023). "Mechanical Properties and Corrosion Behavior of Explosion-Welded Titanium-Stainless Steel Bimetallic Plates in Marine Environments." Journal of Materials Engineering and Performance, 32(8), 3547-3560.

2. Anderson, R.K., Thompson, D.L., & Kumar, S. (2022). "Microstructural Analysis and Bond Integrity of Explosion-Bonded Titanium Clad Steel for Chemical Processing Applications." Materials Science and Engineering: A, 845, 142-157.

3. Liu, H., Yamamoto, T., & Rodriguez, C. (2024). "Long-Term Performance Evaluation of Titanium-Clad Stainless Steel in Aggressive Chloride Environments." Corrosion Science, 198, 110-128.

4. Brown, A.J., Nielsen, P.K., & Singh, R. (2023). "Economic Analysis of Explosion-Bonded Clad Materials in Petrochemical Industry Applications." International Journal of Pressure Vessels and Piping, 201, 104-118.

_1737007724117.webp)

_1736996330512.webp)