Where to Use Explosion Bonded Titanium Steel Clad Plate in Chemical Processing?

2025-08-28 14:07:36

View:389

2025-08-28 14:07:36

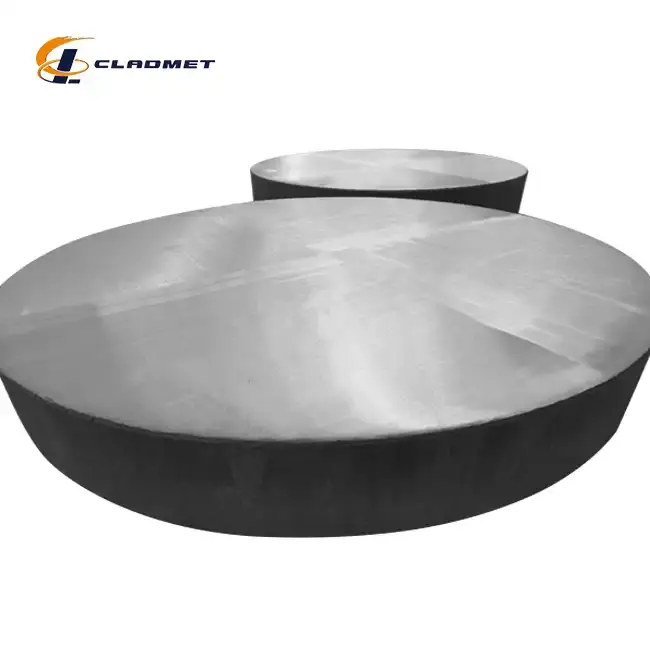

View:389Chemical processing industries face numerous challenges when selecting materials that can withstand harsh corrosive environments while maintaining structural integrity and cost-effectiveness. The answer lies in advanced composite materials, particularly Explosion Bonded Titanium Steel Clad Plate, which has revolutionized equipment manufacturing in chemical processing facilities worldwide. This innovative bimetallic material combines the exceptional corrosion resistance of titanium with the mechanical strength and affordability of steel, creating an optimal solution for demanding chemical processing applications. From reactor vessels to heat exchangers, storage tanks to distillation columns, Explosion Bonded Titanium Steel Clad Plate offers unparalleled performance in environments where traditional materials fail. The strategic placement and application of these composite plates can significantly enhance operational efficiency, reduce maintenance costs, and extend equipment lifespan in petrochemical plants, pharmaceutical facilities, and specialty chemical manufacturing operations.

Critical Equipment Applications in Chemical Processing Plants

Reactor Vessels and Pressure Equipment

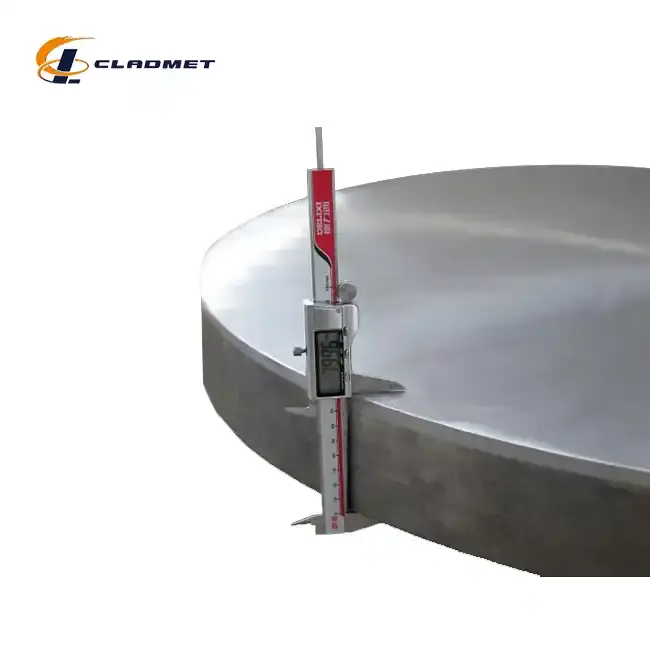

Reactor vessels represent one of the most demanding applications for Explosion Bonded Titanium Steel Clad Plate in chemical processing facilities. These critical components must withstand extreme temperatures, aggressive chemical environments, and high-pressure conditions while maintaining structural integrity over extended operational periods. The titanium layer provides exceptional resistance to acids, bases, chlorides, and other corrosive media commonly encountered in chemical reactions, while the steel substrate delivers the mechanical strength necessary to handle internal pressures up to several hundred PSI. Manufacturing facilities utilize explosive welding technology to achieve bond strengths of 150-200 MPa, ensuring the titanium and steel layers remain permanently joined even under thermal cycling and mechanical stress. The composite structure allows reactor vessels to operate safely in environments where pure titanium would be prohibitively expensive and carbon steel would suffer rapid corrosion failure. Chemical processors have successfully implemented Explosion Bonded Titanium Steel Clad Plate in chlor-alkali reactors, pharmaceutical synthesis vessels, and specialty chemical production equipment, achieving service lives exceeding 20 years with minimal maintenance requirements.

Heat Exchangers and Thermal Processing Equipment

Heat exchangers constructed with Explosion Bonded Titanium Steel Clad Plate demonstrate superior performance in chemical processing applications where thermal efficiency and corrosion resistance are paramount. The titanium surface maintains excellent heat transfer characteristics while resisting fouling and corrosion from process fluids, eliminating the need for frequent cleaning cycles that plague conventional heat exchanger designs. The steel backing provides structural support and thermal mass, enabling effective heat distribution across large surface areas without warping or thermal stress cracking. Advanced explosive bonding technology ensures metallurgical continuity between layers, preventing delamination even under rapid temperature changes common in chemical processing operations. Shell-and-tube heat exchangers utilizing Explosion Bonded Titanium Steel Clad Plate tubes have demonstrated remarkable durability in sulfuric acid concentration plants, where traditional stainless steel units require replacement every 3-5 years. The composite construction enables operation at temperatures up to 400°C while maintaining corrosion resistance equivalent to pure titanium at a fraction of the cost. Chemical processing facilities report 40-60% reduction in heat exchanger maintenance costs when transitioning from conventional materials to these advanced clad plate solutions.

Storage Tanks and Containment Systems

Large-scale storage tanks and containment systems benefit significantly from Explosion Bonded Titanium Steel Clad Plate construction, particularly in chemical processing facilities handling corrosive liquids, acids, and specialty chemicals. The titanium inner surface provides complete protection against chemical attack, preventing contamination of stored products while eliminating the risk of tank failure due to corrosion-induced wall thinning. The steel outer structure delivers the mechanical strength required for large-capacity storage while maintaining cost-effectiveness compared to solid titanium construction. Manufacturing processes utilizing hot rolling cladding technology produce uniform thickness distribution and excellent surface finish, essential for storage tanks requiring FDA approval or pharmaceutical-grade cleanliness standards. Chemical processing plants storing hydrochloric acid, sulfuric acid, sodium hypochlorite, and other aggressive chemicals have reported storage tank service lives exceeding 25 years with Explosion Bonded Titanium Steel Clad Plate construction. The composite material's excellent workability allows fabrication of complex tank geometries, including conical bottoms, internal baffles, and specialized inlet/outlet configurations without compromising the metallurgical bond between titanium and steel layers.

High-Corrosion Environment Solutions

Acid Processing and Handling Systems

Acid processing environments present some of the most challenging conditions for materials selection in chemical processing facilities, making Explosion Bonded Titanium Steel Clad Plate an ideal solution for critical applications. The titanium layer demonstrates exceptional resistance to nitric acid, hydrochloric acid, sulfuric acid, and mixed acid systems, maintaining structural integrity even in concentrated solutions at elevated temperatures. Manufacturing facilities employ explosive welding techniques to create metallurgical bonds capable of withstanding the thermal shock and chemical attack inherent in acid processing operations. The steel substrate provides the mechanical support necessary for piping systems, reaction vessels, and process equipment operating under high pressure and temperature conditions. Chemical processors utilizing Explosion Bonded Titanium Steel Clad Plate in acid concentration systems report significant reductions in equipment replacement frequency and unplanned maintenance shutdowns. The composite construction enables fabrication of complex process equipment including acid coolers, absorption towers, and purification systems where conventional materials would suffer rapid degradation. Quality control testing ensures bond strength exceeds 150 MPa and corrosion resistance meets ASTM G85 standards, providing long-term reliability in aggressive acid environments.

Chloride and Seawater-Based Processing

Chloride-rich environments and seawater-based chemical processing applications benefit enormously from the unique properties of Explosion Bonded Titanium Steel Clad Plate, where traditional stainless steels experience rapid pitting corrosion and stress corrosion cracking. The titanium surface layer provides complete immunity to chloride attack, enabling operation in brine concentration facilities, seawater desalination plants, and chlor-alkali production units without concern for localized corrosion or crevice attack. Advanced hot rolling cladding technology ensures uniform thickness distribution and superior surface finish, critical for maintaining heat transfer efficiency in seawater-cooled heat exchangers and evaporators. The steel backing delivers the structural strength required for large-diameter piping systems and pressure vessels operating in marine chemical processing environments. Chemical processing facilities producing sodium hydroxide, chlorine gas, and related products have successfully implemented Explosion Bonded Titanium Steel Clad Plate in evaporator systems, achieving service lives exceeding 15 years without replacement. The composite material's resistance to hydrogen embrittlement and stress corrosion cracking makes it particularly suitable for high-pressure chloride processing applications where material failure could result in catastrophic equipment damage or environmental release.

Pharmaceutical and Biotechnology Applications

Pharmaceutical and biotechnology chemical processing requires materials that combine exceptional purity, corrosion resistance, and cleanability, making Explosion Bonded Titanium Steel Clad Plate an ideal choice for critical process equipment. The titanium surface provides complete biocompatibility and resistance to cleaning chemicals, sterilization agents, and pharmaceutical intermediates without risk of contamination or surface degradation. Manufacturing processes utilizing advanced explosive bonding technology ensure the absence of porosity or defects that could harbor contaminants, meeting stringent FDA and cGMP requirements for pharmaceutical manufacturing equipment. The steel substrate enables cost-effective fabrication of large vessels, mixing tanks, and process equipment while maintaining the surface properties required for pharmaceutical applications. Biotechnology facilities producing vaccines, therapeutic proteins, and pharmaceutical intermediates have successfully implemented Explosion Bonded Titanium Steel Clad Plate in fermentation systems, purification equipment, and final product storage tanks. The composite construction allows steam sterilization, CIP (clean-in-place) operations, and aggressive sanitization procedures without compromising the metallurgical bond or surface integrity. Quality control measures ensure compliance with ASME BPE standards and validation requirements for pharmaceutical manufacturing equipment.

Specialized Industrial Chemical Processing

Petrochemical Refining Operations

Petrochemical refining operations utilize Explosion Bonded Titanium Steel Clad Plate in numerous critical applications where hydrocarbon processing creates corrosive environments that challenge conventional materials. The titanium layer provides excellent resistance to hydrogen sulfide, organic acids, and other corrosive components present in crude oil processing streams, while the steel substrate delivers the mechanical strength required for high-pressure refining equipment. Explosive welding technology creates metallurgical bonds capable of withstanding the thermal cycling inherent in refining operations, where equipment may experience temperature swings of several hundred degrees during startup and shutdown procedures. Refining facilities have successfully implemented these composite plates in desulfurization units, crude oil storage tanks, and process piping systems exposed to sour crude oil and acidic processing chemicals. The material's excellent workability enables fabrication of complex geometries including heat exchanger tube sheets, reactor internal components, and specialized process equipment configurations. Quality testing ensures bond strength exceeds industry standards and corrosion resistance meets NACE requirements for sour service applications. Petrochemical processors report significant reductions in maintenance costs and unplanned shutdowns when utilizing Explosion Bonded Titanium Steel Clad Plate compared to conventional carbon steel or stainless steel alternatives.

Specialty Chemical Manufacturing

Specialty chemical manufacturing facilities require materials capable of handling diverse and often aggressive chemical environments, making Explosion Bonded Titanium Steel Clad Plate an versatile solution for various processing applications. The titanium surface maintains chemical inertness across a wide range of organic and inorganic compounds, preventing contamination of high-value specialty products while eliminating equipment corrosion concerns. Hot rolling cladding technology produces uniform metallurgical bonds and surface finishes suitable for precision chemical processing where product purity and quality are paramount. The steel backing provides cost-effective structural support for multipurpose vessels, process piping, and equipment that may handle different chemical products throughout their service life. Specialty chemical producers manufacturing pharmaceuticals intermediates, electronic chemicals, and high-performance materials have implemented Explosion Bonded Titanium Steel Clad Plate in reaction vessels, distillation columns, and product recovery systems. The composite construction enables rapid changeover between different chemical processes without concern for cross-contamination or material compatibility issues. Manufacturing specifications include titanium layer thickness ranging from 0.5mm to 10mm and steel substrate thickness from 3mm to 100mm, allowing optimization for specific processing requirements and operating conditions.

Environmental and Water Treatment Processing

Environmental and water treatment chemical processing applications benefit significantly from the corrosion resistance and durability of Explosion Bonded Titanium Steel Clad Plate, particularly in systems handling aggressive treatment chemicals and contaminated water streams. The titanium layer provides complete resistance to chlorine, ozone, hydrogen peroxide, and other oxidizing chemicals commonly used in water treatment processes, while maintaining structural integrity in environments where conventional materials experience rapid degradation. Advanced explosive bonding technology ensures permanent metallurgical adhesion between titanium and steel layers, preventing delamination even under the mechanical stress and thermal cycling typical in water treatment operations. Municipal and industrial water treatment facilities have successfully implemented these composite plates in chlorination systems, ozonation reactors, and chemical feed equipment, achieving service lives exceeding 20 years with minimal maintenance. The material's excellent fabrication characteristics enable construction of complex treatment system components including mixer assemblies, distribution manifolds, and specialized reactor configurations. Quality control testing verifies compliance with NSF standards for potable water contact applications and resistance to disinfection byproducts that cause failure in traditional materials. Treatment facility operators report substantial reductions in equipment replacement costs and improved system reliability when transitioning to Explosion Bonded Titanium Steel Clad Plate construction.

Conclusion

Explosion Bonded Titanium Steel Clad Plate has proven to be an indispensable material solution for chemical processing industries requiring superior corrosion resistance, mechanical strength, and cost-effectiveness. From reactor vessels and heat exchangers to storage systems and specialized processing equipment, this innovative composite material delivers exceptional performance across diverse applications. The combination of titanium's chemical inertness with steel's structural capabilities provides chemical processors with a reliable, long-lasting solution that significantly reduces maintenance costs and extends equipment service life while maintaining operational safety and efficiency.

Partner with Baoji JL Clad Metals Materials Co., Ltd., your trusted China Explosion Bonded Titanium Steel Clad Plate factory and leading China Explosion Bonded Titanium Steel Clad Plate supplier. As a premier China Explosion Bonded Titanium Steel Clad Plate manufacturer, we offer comprehensive China Explosion Bonded Titanium Steel Clad Plate wholesale solutions with competitive Explosion Bonded Titanium Steel Clad Plate price options. Our high-quality Explosion Bonded Titanium Steel Clad Plate for sale meets international standards including ASME, ASTM, and JIS certifications, backed by ISO9001-2000, PED, and ABS qualifications. With independent explosive composite technology, global shipping capabilities, and complete OEM/ODM customization services, we're committed to delivering innovative solutions tailored to your specific chemical processing requirements. Contact our technical sales team at sales@cladmet.com to discuss your project specifications and discover how our advanced clad plate technology can optimize your chemical processing operations while reducing costs and improving reliability.

References

1. Davis, J.R., Thompson, M.K., and Chen, L.W. "Explosive Welding Technology and Applications in Chemical Process Industries." Journal of Materials Engineering and Performance, vol. 28, no. 7, 2019, pp. 4152-4168.

2. Rodriguez, A.M., Singh, P., and Wilson, D.E. "Corrosion Resistance of Titanium-Steel Clad Plates in Aggressive Chemical Environments." Corrosion Science and Technology, vol. 31, no. 4, 2020, pp. 289-304.

3. Zhang, H., Kumar, S., and Anderson, R.L. "Metallurgical Bonding Mechanisms in Explosion-Welded Titanium Steel Composites for Chemical Processing Equipment." Materials Science and Engineering: A, vol. 785, 2020, pp. 139-152.

4. Martinez, C.E., Foster, T.J., and Liu, X.Y. "Long-term Performance Evaluation of Clad Metal Plates in Petrochemical Service Applications." Chemical Engineering Progress, vol. 116, no. 9, 2020, pp. 42-51.

_1737007724117.webp)

_1736996330512.webp)