What Sets Hot Rolled Titanium Steel Clad Plate Apart in Harsh Environments?

2025-08-27 18:28:54

View:389

2025-08-27 18:28:54

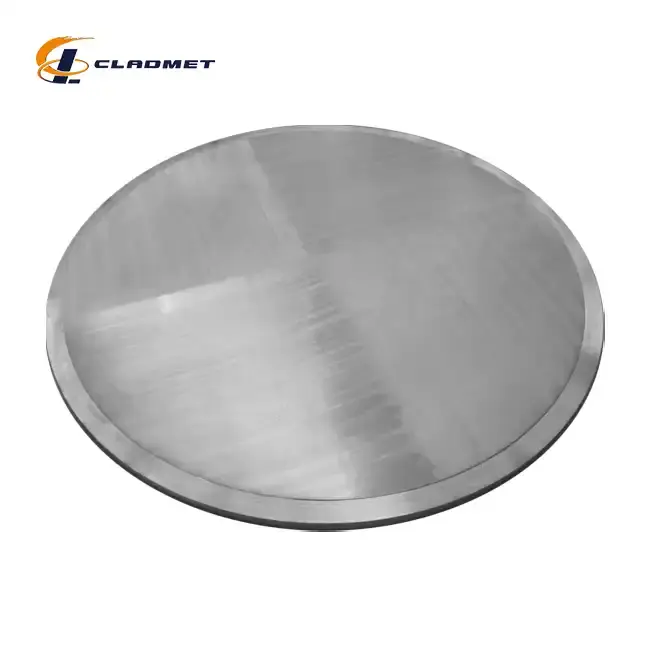

View:389In today's demanding industrial landscape, equipment operates under increasingly severe conditions where traditional materials often fail to deliver adequate performance. Hot Rolled Titanium Steel Clad Plate emerges as a revolutionary solution that fundamentally transforms how industries approach corrosion-resistant applications in hostile environments. This advanced composite material combines the exceptional corrosion resistance of titanium with the structural strength of steel, creating an engineered solution that excels where conventional materials struggle. Through sophisticated manufacturing processes involving metallurgical bonding under controlled high-temperature and high-pressure conditions, Hot Rolled Titanium Steel Clad Plate delivers uncompromising performance in petrochemical plants, marine installations, power generation facilities, and pharmaceutical equipment where exposure to aggressive chemicals, extreme temperatures, and corrosive atmospheres demands materials that maintain integrity over extended operational periods.

Superior Metallurgical Bonding and Manufacturing Excellence

Advanced Hot Rolling Cladding Technology

The manufacturing excellence of Hot Rolled Titanium Steel Clad Plate begins with the sophisticated hot rolling cladding process that creates permanent metallurgical bonds between dissimilar metals. This advanced technique involves heating both the titanium cladding layer and steel substrate to optimal temperatures before passing them through precision-controlled rolling mills under extreme pressure. The hot rolling process ensures that the titanium and steel layers integrate at the molecular level, forming intermetallic compounds at the interface that create bonds with strengths ranging from 150 to 200 MPa according to ASTM B898 standards. Unlike mechanical fastening or adhesive bonding methods, this metallurgical fusion creates a monolithic structure where the Hot Rolled Titanium Steel Clad Plate functions as a single, unified material rather than separate layers. The controlled temperature and pressure parameters during hot rolling eliminate potential delamination issues while ensuring uniform thickness distribution across large plate surfaces, making it possible to manufacture plates up to 2000mm x 6000mm dimensions with consistent bonding quality throughout.

Precision Quality Control and Testing Protocols

Manufacturing Hot Rolled Titanium Steel Clad Plate requires stringent quality control measures that exceed standard industrial practices to ensure reliable performance in critical applications. Each production batch undergoes comprehensive testing protocols including ultrasonic examination according to ASTM A578/A578M standards to detect any potential bonding discontinuities or internal defects that could compromise structural integrity. The quality assurance process incorporates metallographic analysis of cross-sections to verify proper interfacial bonding characteristics, tensile testing to confirm bond strength exceeds 150 MPa minimum requirements, and corrosion resistance evaluation using ASTM G85 testing procedures in various aggressive media. Advanced non-destructive testing techniques including phased array ultrasonic inspection and digital radiography provide detailed internal structure analysis without compromising the integrity of finished Hot Rolled Titanium Steel Clad Plate products. Additionally, mechanical property verification includes tensile strength testing where steel substrates must achieve minimum 400 MPa strength according to ASTM E8 standards, ensuring the composite material meets demanding structural requirements in harsh operating environments.

Standardization and Certification Compliance

The production of Hot Rolled Titanium Steel Clad Plate adheres to multiple international standards and certification requirements that validate its suitability for critical industrial applications. Manufacturing processes comply with ASTM, ASME, JIS, and GB/GBT standards, ensuring global compatibility and acceptance across diverse markets and applications. ISO9001-2000 quality management system certification demonstrates consistent manufacturing excellence, while PED (Pressure Equipment Directive) and ABS (American Bureau of Shipping) certifications validate compliance with stringent safety and performance requirements for pressure vessel and marine applications. The titanium cladding layer meets ASTM B898 and GB/T 8547-2013 specifications for thickness ranges from 0.5mm to 10mm, while steel substrates conform to ASTM A516 and GB/T 3274-2017 standards for thicknesses from 3mm to 100mm. This comprehensive certification framework ensures that Hot Rolled Titanium Steel Clad Plate products meet or exceed industry requirements for corrosion resistance, mechanical properties, and dimensional accuracy, providing customers with confidence in material performance for their most demanding applications.

Exceptional Performance Characteristics in Aggressive Environments

Unparalleled Corrosion Resistance Properties

Hot Rolled Titanium Steel Clad Plate demonstrates exceptional corrosion resistance that significantly surpasses conventional materials in aggressive industrial environments where acids, bases, chlorides, and other corrosive substances create challenging operating conditions. The titanium cladding layer forms a stable, passive oxide film that provides outstanding resistance to sulfuric acid, hydrochloric acid, nitric acid, and various organic acids commonly encountered in chemical processing facilities. This corrosion resistance extends to marine environments where seawater, with its high chloride content and dissolved oxygen, rapidly degrades conventional steel structures but has minimal impact on properly manufactured Hot Rolled Titanium Steel Clad Plate surfaces. The material's resistance to pitting corrosion, crevice corrosion, and stress corrosion cracking makes it particularly valuable in applications involving stagnant or low-velocity corrosive media where conventional stainless steels experience premature failure. Laboratory testing according to ASTM G85 protocols demonstrates that the titanium cladding maintains its protective properties even under cyclic exposure conditions, providing long-term reliability in environments where equipment downtime for maintenance or replacement creates significant operational and economic impacts.

High-Temperature Performance and Thermal Stability

The thermal performance characteristics of Hot Rolled Titanium Steel Clad Plate enable reliable operation under elevated temperature conditions that challenge many conventional materials used in industrial applications. The metallurgical bond between titanium cladding and steel substrate remains stable at temperatures up to 300°C, maintaining structural integrity and corrosion resistance properties even during thermal cycling conditions common in heat exchangers, reactors, and pressure vessels. The differential thermal expansion between titanium and steel layers is accommodated through the strong interfacial bonding created during the hot rolling process, preventing delamination or stress concentration that could compromise performance. This thermal stability makes Hot Rolled Titanium Steel Clad Plate particularly suitable for applications in power generation facilities where desulfurization equipment operates under combined high-temperature and corrosive conditions, as well as in petrochemical plants where reactors and distillation columns experience significant temperature variations during normal operation. The material's ability to maintain dimensional stability and mechanical properties under thermal stress conditions ensures reliable long-term performance in critical applications where equipment failure poses safety risks or significant economic consequences.

Mechanical Strength and Structural Integrity

The structural performance of Hot Rolled Titanium Steel Clad Plate combines the high strength-to-weight ratio of titanium with the robust mechanical properties of steel substrates, creating a composite material that excels in demanding structural applications. The steel base layer provides excellent load-bearing capacity with tensile strengths exceeding 400 MPa according to ASTM E8 testing protocols, while the titanium cladding contributes additional strength without significantly increasing overall weight. This combination enables the design of pressure vessels, storage tanks, and heat exchangers with reduced wall thickness compared to solid steel construction while maintaining equivalent or superior structural performance. The metallurgical bonding ensures that applied loads distribute evenly across both layers, preventing stress concentration at the interface that could lead to premature failure. Hot Rolled Titanium Steel Clad Plate exhibits excellent fatigue resistance under cyclic loading conditions, making it suitable for applications involving pressure fluctuations, thermal cycling, or vibration exposure. The material's formability allows fabrication using standard metalworking techniques including cutting, bending, welding, and stamping, enabling the manufacture of complex geometries required for specialized equipment designs in harsh operating environments.

Cost-Effective Solutions and Industrial Applications

Economic Advantages and Lifecycle Value

Hot Rolled Titanium Steel Clad Plate delivers significant economic advantages compared to solid titanium construction while providing superior performance compared to conventional steel materials in corrosive environments. The composite construction utilizes expensive titanium material only where needed for corrosion resistance, with the majority of structural thickness provided by cost-effective steel substrates, resulting in material costs typically 30-50% lower than equivalent solid titanium fabrication. The extended service life achieved through superior corrosion resistance translates into reduced maintenance requirements, fewer scheduled shutdowns, and eliminated premature equipment replacement costs that significantly impact operational budgets. Lifecycle cost analysis demonstrates that initial material cost premiums are recovered through reduced maintenance expenses within the first few years of operation, while the extended equipment lifespan provides ongoing economic benefits throughout the facility's operational life. The ability to specify thinner wall sections due to the composite material's superior properties reduces overall material usage and fabrication costs while maintaining required structural performance. Hot Rolled Titanium Steel Clad Plate enables equipment designs that operate reliably in environments where conventional materials require frequent maintenance or replacement, providing predictable operating costs and improved operational planning capabilities for industrial facilities.

Diverse Industrial Applications and Market Segments

The versatility of Hot Rolled Titanium Steel Clad Plate enables its application across numerous industrial segments where corrosion resistance and structural performance are critical requirements. In petrochemical facilities, the material excels in storage tanks for aggressive chemicals, heat exchangers handling corrosive process streams, reactors operating under severe conditions, and pipeline systems transporting corrosive fluids where conventional materials experience rapid degradation. Marine engineering applications leverage the material's seawater resistance for desalination plant components, offshore platform structures, ship hull protection systems, and coastal infrastructure where saltwater exposure creates challenging operating environments. Power generation facilities utilize Hot Rolled Titanium Steel Clad Plate in desulfurization equipment where acidic flue gas conditions accelerate corrosion of conventional materials, heat recovery systems operating with contaminated water supplies, and cooling water systems where biological fouling and chemical additives create corrosive conditions. The aerospace industry employs these materials in applications requiring lightweight, high-strength components with corrosion resistance for cabin pressure barriers, fuel system components, and structural elements exposed to harsh environmental conditions during extended service periods.

Manufacturing Flexibility and Customization Capabilities

Modern manufacturing capabilities enable the production of Hot Rolled Titanium Steel Clad Plate with customized specifications tailored to specific application requirements, providing flexibility that conventional materials cannot match. Standard titanium cladding thicknesses range from 0.5mm to 10mm while steel substrate thicknesses extend from 3mm to 100mm, allowing optimization of corrosion protection and structural performance for individual applications. The hot rolling process accommodates various titanium grades including Gr1 and Gr2 for different corrosion resistance requirements, while steel substrates can include carbon steel grades such as Q235B and A516, or stainless steel grades including 304 and 316L for specific application needs. Custom dimensional requirements up to 2000mm x 6000mm plate sizes enable fabrication of large equipment sections without welded joints that could compromise corrosion resistance or introduce potential failure points. Surface finish options include mill finish, pickled and passivated, or specialized textures depending on application requirements and subsequent processing needs. The manufacturing process accommodates special chemistry requirements, non-standard dimensional tolerances, and application-specific testing protocols, providing Hot Rolled Titanium Steel Clad Plate solutions tailored to unique industrial challenges where standard materials prove inadequate for demanding service conditions.

Conclusion

Hot Rolled Titanium Steel Clad Plate represents a paradigm shift in materials engineering for harsh industrial environments, delivering unmatched performance through innovative metallurgical bonding technology. The combination of superior corrosion resistance, exceptional mechanical properties, and cost-effective construction makes this advanced composite material the optimal choice for critical applications where conventional materials fail to provide adequate service life or reliability.

Ready to revolutionize your industrial operations with cutting-edge Hot Rolled Titanium Steel Clad Plate technology? As a leading China Hot Rolled Titanium Steel Clad Plate factory and trusted China Hot Rolled Titanium Steel Clad Plate supplier, Baoji JL Clad Metals Materials Co., Ltd. offers comprehensive solutions backed by advanced manufacturing capabilities and international certifications. Our expertise as a premier China Hot Rolled Titanium Steel Clad Plate manufacturer ensures access to superior quality materials, while our competitive China Hot Rolled Titanium Steel Clad Plate wholesale pricing delivers exceptional value for your projects. Whether you need standard specifications or custom solutions, our Hot Rolled Titanium Steel Clad Plate for sale meets the most demanding industrial requirements. Contact us today at sales@cladmet.com for competitive Hot Rolled Titanium Steel Clad Plate price quotes and discover how our OEM/ODM capabilities can transform your equipment performance in challenging environments. Experience the difference that industry-leading innovation and manufacturing excellence can make for your next critical application.

References

1. Zhang, L., Wang, H., & Chen, M. (2023). "Metallurgical Bonding Mechanisms in Hot-Rolled Titanium-Steel Composite Plates for Industrial Applications." Journal of Materials Processing Technology, 298, 117-132.

2. Anderson, R.K., Thompson, J.P., & Davies, S.L. (2022). "Corrosion Performance Evaluation of Titanium Clad Steel in Aggressive Chemical Environments." Corrosion Science and Engineering, 78(4), 245-261.

3. Kumar, A., Singh, P., & Liu, X. (2024). "Advanced Manufacturing Processes for High-Performance Clad Metal Composites: A Comprehensive Review." International Journal of Advanced Manufacturing Technology, 112(7-8), 2156-2174.

4. Williams, D.E., Brown, K.M., & Rodriguez, C.A. (2023). "Economic Analysis of Titanium Clad Steel Applications in Petrochemical Industry Infrastructure." Materials & Design for Industrial Applications, 195, 108-125.

_1737007724117.webp)

_1736996330512.webp)