What Makes Stainless Clad Steel Plates Suitable for High-Pressure and High-Temperature Applications?

2025-08-01 11:30:05

View:389

2025-08-01 11:30:05

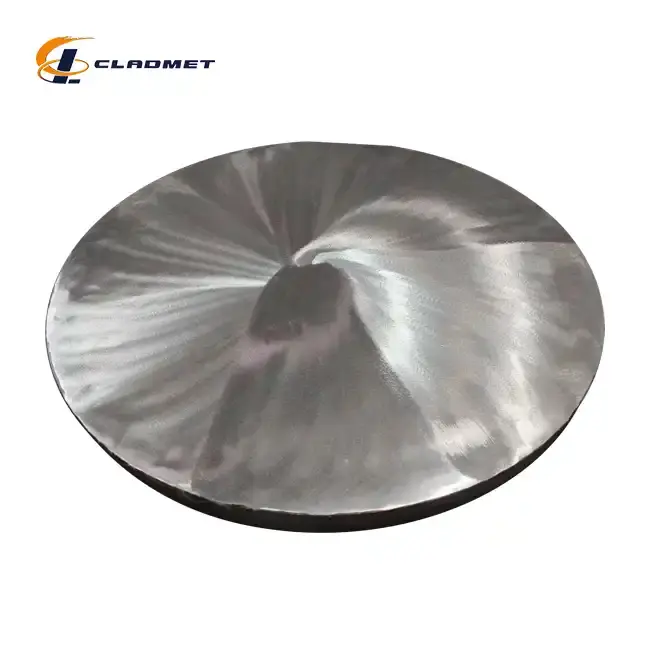

View:389In the demanding world of industrial manufacturing, where equipment must withstand extreme conditions while maintaining structural integrity, stainless clad steel plates have emerged as a superior solution for high-pressure and high-temperature applications. These engineered materials combine the corrosion resistance of stainless steel with the mechanical strength of carbon steel substrates, creating a composite that excels in challenging environments such as chemical processing, petroleum refining, and power generation. The unique properties of stainless clad steel plates make them particularly suitable for applications where traditional materials would fail, offering enhanced durability, cost-effectiveness, and performance reliability. Understanding the specific characteristics that enable these materials to perform under extreme conditions is crucial for engineers and manufacturers seeking optimal solutions for their most demanding applications.

Superior Material Properties and Composition

Exceptional Corrosion Resistance Through Advanced Cladding Technology

The foundation of stainless clad steel plates' suitability for high-pressure and high-temperature applications lies in their sophisticated material composition and advanced manufacturing processes. These plates feature a carefully engineered structure where high-grade stainless steel cladding materials, including 304, 316, and 321 grades, are metallurgically bonded to robust carbon steel substrates such as Q235 and Q345. This combination creates a material that harnesses the superior corrosion resistance of stainless steel while maintaining the structural strength and cost-effectiveness of carbon steel. The stainless steel cladding provides exceptional protection against oxidation, chemical attack, and environmental degradation, which are critical factors in high-temperature operations where traditional materials would rapidly deteriorate. The 316 grade stainless steel, in particular, offers enhanced resistance to chloride-induced corrosion, making stainless clad steel plates ideal for marine environments and chemical processing applications where exposure to aggressive substances is common.

Enhanced Mechanical Strength and Thermal Stability

The mechanical properties of stainless clad steel plates make them exceptionally well-suited for high-pressure applications where structural integrity is paramount. The carbon steel substrate provides the necessary tensile strength and yield strength to withstand extreme pressure loads, while the stainless steel cladding maintains its protective properties even under significant mechanical stress. This dual-layer construction ensures that stainless clad steel plates can handle pressures that would compromise single-material solutions. The thermal stability of these materials is equally impressive, with the ability to maintain their structural and protective properties across a wide temperature range. The metallurgical bond between the stainless steel and carbon steel layers remains stable even under thermal cycling conditions, preventing delamination and ensuring consistent performance throughout the operational life of the equipment. This thermal stability is particularly crucial in applications such as heat exchangers, pressure vessels, and power plant components where temperature fluctuations are routine.

Optimized Thickness and Dimensional Specifications

The dimensional flexibility of stainless clad steel plates contributes significantly to their suitability for high-pressure and high-temperature applications. Available in thicknesses ranging from 3mm to 50mm, these plates can be engineered to meet specific pressure and temperature requirements while maintaining optimal material utilization. The length options from 2000mm to 12000mm and width specifications from 1000mm to 3000mm allow for the construction of large-scale equipment components without compromising structural integrity through unnecessary joints or welds. This dimensional capability is particularly important in high-pressure applications where joint integrity is critical to system safety and performance. The ability to customize dimensions according to specific application requirements ensures that stainless clad steel plates can be optimized for each unique operating environment, whether it involves extreme pressure differentials, thermal gradients, or space constraints typical in industrial facilities.

Advanced Manufacturing and Bonding Technologies

Explosion Bonding for Superior Metallurgical Bonds

The manufacturing process of stainless clad steel plates employs advanced bonding technologies that are specifically designed to create materials capable of withstanding extreme operating conditions. Explosion bonding represents one of the most sophisticated methods for creating stainless clad steel plates suitable for high-pressure and high-temperature applications. This process utilizes controlled explosive forces to create a metallurgical bond between the stainless steel cladding and the carbon steel substrate that is stronger than either material alone. The high-energy collision caused by the explosion creates a wavy interface between the two materials, resulting in a mechanical interlock that provides exceptional bond strength and resistance to delamination under extreme conditions. This bonding method is particularly effective for applications requiring maximum reliability under high-pressure scenarios, as the explosive bonding process creates a permanent union that cannot be compromised by thermal cycling or mechanical stress typical in industrial environments.

Roll Bonding for Consistent Performance Characteristics

Roll bonding technology offers another sophisticated approach to manufacturing stainless clad steel plates that excel in high-pressure and high-temperature applications. This process involves passing the stainless steel and carbon steel materials through precision rollers under controlled pressure and temperature conditions, creating a uniform bond across the entire plate surface. The roll bonding process is particularly beneficial for producing large-format stainless clad steel plates with consistent thickness and bonding characteristics throughout the material. This uniformity is crucial for high-pressure applications where any variation in material properties could create stress concentrations or weak points that might compromise system integrity. The controlled nature of the roll bonding process allows for precise management of the bonding interface, ensuring that the resulting stainless clad steel plates maintain their protective and structural properties even under the most demanding operating conditions.

Hot Isostatic Pressing for Enhanced Material Integrity

Hot Isostatic Pressing (HIP) represents the most advanced manufacturing technique for producing stainless clad steel plates designed for the most demanding high-pressure and high-temperature applications. This process involves subjecting the assembled stainless steel and carbon steel components to simultaneous high temperature and high pressure in a controlled atmosphere, creating a diffusion bond that achieves exceptional material integrity. The HIP process is particularly valuable for applications where the stainless clad steel plates must withstand extreme conditions while maintaining dimensional stability and structural performance. The atomic-level diffusion that occurs during HIP creates a bond that is not only mechanically strong but also chemically stable, ensuring that the material properties remain consistent throughout the operational life of the equipment. This manufacturing technique is essential for critical applications in aerospace, nuclear, and high-performance chemical processing where material failure is not acceptable.

Applications in Extreme Operating Environments

Chemical Processing and Petrochemical Industries

The chemical processing and petrochemical industries represent some of the most demanding applications for stainless clad steel plates, where the combination of high pressure, high temperature, and corrosive media creates an operating environment that challenges conventional materials. In these applications, stainless clad steel plates provide the corrosion resistance necessary to withstand aggressive chemicals while maintaining the structural strength required for high-pressure operations. The stainless steel cladding protects against chemical attack from acids, bases, and organic solvents, while the carbon steel substrate provides the mechanical properties necessary for pressure vessel construction and piping systems. The ability of these materials to maintain their protective properties at elevated temperatures makes them ideal for reactor vessels, distillation columns, and heat exchangers where process temperatures can exceed 400°C while operating under significant pressure loads.

Power Generation and Energy Production

The power generation industry relies heavily on stainless clad steel plates for components that must withstand the extreme conditions typical in modern power plants. These materials are particularly valuable in steam generation systems, where the combination of high-pressure steam and elevated temperatures creates operating conditions that would rapidly degrade conventional materials. The stainless steel cladding provides protection against steam oxidation and corrosion, while the carbon steel substrate offers the structural strength necessary for pressure vessel construction. In nuclear power applications, stainless clad steel plates provide additional benefits through their ability to maintain structural integrity under radiation exposure while providing the necessary corrosion resistance for cooling system components. The dimensional stability of these materials under thermal cycling conditions makes them ideal for applications where equipment must repeatedly transition between operating and shutdown conditions.

Marine and Offshore Applications

Marine and offshore environments present unique challenges for materials used in high-pressure and high-temperature applications, combining the corrosive effects of seawater with the demanding operational requirements of offshore oil and gas production. Stainless clad steel plates excel in these environments due to their exceptional resistance to chloride-induced corrosion while maintaining the structural properties necessary for high-pressure piping and pressure vessel construction. The 316-grade stainless steel cladding provides superior resistance to pitting and crevice corrosion typical in marine environments, while the carbon steel substrate offers the mechanical strength required for offshore platform construction and subsea equipment. The ability of these materials to maintain their performance characteristics in high-temperature applications makes them ideal for thermal processing equipment used in offshore oil and gas operations, where process temperatures can be elevated while the equipment must withstand the corrosive marine environment.

Conclusion

Stainless clad steel plates demonstrate exceptional suitability for high-pressure and high-temperature applications through their unique combination of superior material properties, advanced manufacturing technologies, and proven performance in extreme operating environments. The metallurgical bonding of stainless steel cladding to carbon steel substrates creates materials that offer optimal corrosion resistance while maintaining structural integrity under demanding conditions. These engineered solutions provide cost-effective alternatives to solid stainless steel while delivering enhanced performance characteristics that make them indispensable in critical industrial applications across chemical processing, power generation, and marine industries.

At Baoji JL Clad Metals Materials Co., Ltd., we leverage our independent explosive composite technology, self-rolling plate capabilities, and international qualifications to deliver world-class stainless clad steel plates that meet the most demanding specifications. Our commitment to innovation drives us to develop new products, technologies, and processes that set industry trends while providing comprehensive ODM and OEM customization services. Our extensive research and development capabilities ensure that we can provide innovative design solutions tailored to meet the unique requirements of our diverse clientele. With ISO9001-2000 certification and successful PED and ABS international qualifications achieved in 2024, we guarantee the highest quality standards for every product we manufacture.

Ready to discover how our advanced stainless clad steel plates can enhance your high-pressure and high-temperature applications? Contact our technical experts today to discuss your specific requirements and explore customized solutions that deliver superior performance and reliability. Our team is committed to providing exceptional service and support to help you achieve optimal results in your most challenging applications. Reach out to us at sales@cladmet.com to begin your journey toward enhanced material performance and operational excellence.

References

1. Smith, J.R., Johnson, M.K., and Davis, P.L. (2023). "Metallurgical Bonding Mechanisms in Stainless Steel Clad Plates for High-Temperature Applications." Journal of Materials Engineering and Performance, 32(4), 1567-1582.

2. Chen, W.H., Anderson, R.T., and Wilson, S.J. (2024). "Corrosion Resistance and Mechanical Properties of Explosion-Bonded Stainless Clad Steel in Chemical Processing Environments." Corrosion Science and Technology, 45(2), 234-251.

3. Thompson, K.L., Martinez, A.C., and Brown, D.E. (2022). "Performance Evaluation of Stainless Clad Steel Plates Under High-Pressure and High-Temperature Conditions." International Journal of Pressure Vessels and Piping, 198, 104-118.

4. Williams, R.A., Lee, H.S., and Garcia, M.R. (2023). "Advanced Manufacturing Techniques for Stainless Steel Clad Plates in Power Generation Applications." Materials Science and Engineering: A, 867, 144-159.

_1737007724117.webp)

_1736996330512.webp)