What Makes Precision Pure Nickel Sheet a Leader in Clad Metal Solutions?

2025-03-19 09:10:36

View:389

2025-03-19 09:10:36

View:389In today's demanding industrial landscape, the search for materials that deliver exceptional performance, durability, and versatility has led many manufacturers to explore clad metal solutions. Among these solutions, Precision Pure Nickel Sheet has emerged as a standout leader, revolutionizing numerous applications across multiple industries. At Baoji JL Clad Metals Materials Co., Ltd., we have been at the forefront of manufacturing precision clad metals, specializing in high-quality Precision Pure Nickel Sheets. Our commitment to excellence, combined with years of research and development, positions us as a leader in the industry. This blog explores the unique properties, manufacturing processes, and diverse applications that make Precision Pure Nickel Sheet an unparalleled choice for industries demanding the highest standards of material performance.

Superior Material Properties That Define Excellence

Unmatched Corrosion Resistance in Extreme Environments

Precision Pure Nickel Sheet stands out primarily for its exceptional corrosion resistance, a critical property that makes it indispensable in harsh industrial environments. When exposed to alkaline solutions, salts, and various organic compounds, Precision Pure Nickel Sheet maintains its structural integrity where other materials would rapidly deteriorate. This remarkable resistance stems from the formation of a passive oxide layer on the surface of the nickel, which acts as a protective barrier against corrosive agents. Our manufacturing process enhances this natural property by ensuring optimal purity levels—typically 99.5% or higher—which significantly improves the material's resistance to sulfuric, hydrochloric, and phosphoric acids commonly encountered in chemical processing equipment. The stability of Precision Pure Nickel Sheet in high-temperature environments up to 600°C further extends its application range, making it ideal for reaction vessels, heat exchangers, and distillation columns where both corrosion resistance and thermal stability are paramount. Clients in the petrochemical industry particularly value this combination of properties, as it translates to longer equipment lifespan and reduced maintenance costs—a testament to why Precision Pure Nickel Sheet leads the market in clad metal solutions for corrosive applications.

Exceptional Thermal and Electrical Conductivity Properties

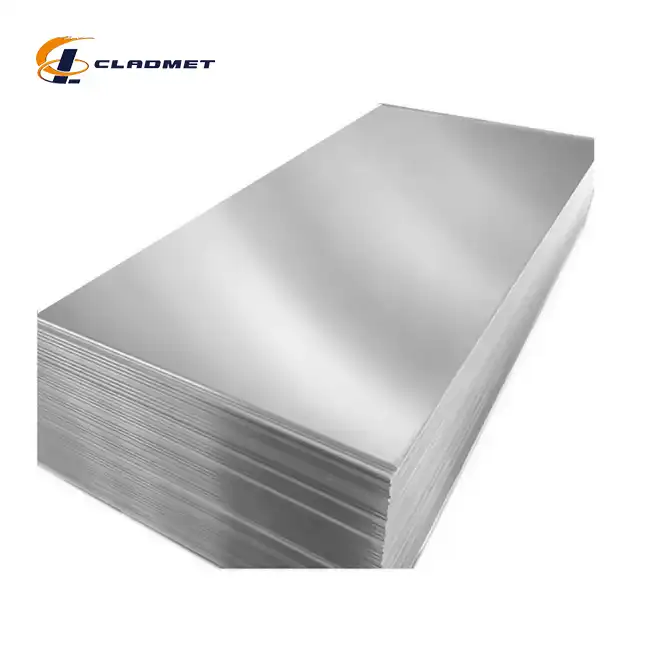

The thermal and electrical conductivity properties of Precision Pure Nickel Sheet play a crucial role in its widespread adoption across various high-performance applications. With a thermal conductivity of approximately 90 W/m·K at room temperature, our Precision Pure Nickel Sheet efficiently transfers heat, making it an excellent choice for heat exchangers, condensers, and thermal management systems in aerospace and power generation industries. This property becomes particularly valuable when combined with nickel's stable thermal expansion coefficient (13.4 × 10^-6/K), which minimizes stress-related failures in temperature-fluctuating environments. From an electrical perspective, pure nickel's conductivity—approximately 25% that of copper—offers an optimal balance between conductivity and corrosion resistance that makes it indispensable in specialized electrical contacts and battery technologies. Our manufacturing process, utilizing roll-bonding technology with precisely controlled parameters, ensures uniform material properties throughout the sheet, eliminating conductivity variances that plague inferior products. The thickness range of 0.1 mm to 10 mm allows for application-specific customization, whether clients require ultra-thin sheets for electronic components or thicker variants for industrial heat exchange applications. This combination of consistent conductivity properties across customizable dimensions solidifies Precision Pure Nickel Sheet's position as a leader in clad metal solutions for thermally and electrically demanding applications.

Superior Mechanical Strength and Formability

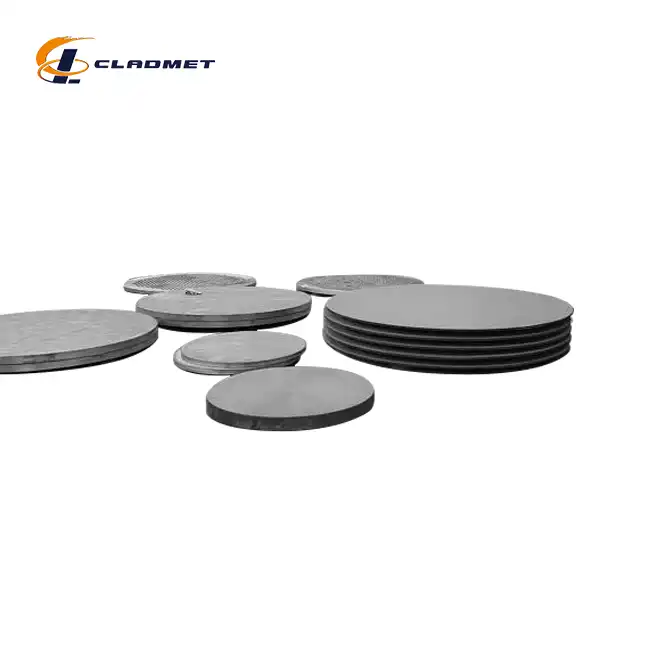

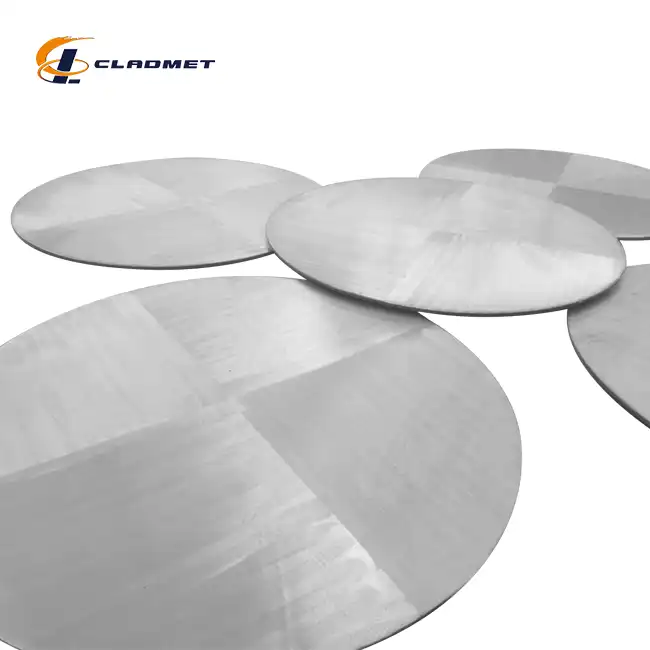

The mechanical properties of Precision Pure Nickel Sheet create a unique combination of strength and formability that few other materials can match. With a tensile strength ranging from 380 to 550 MPa and yield strength of 100 to 280 MPa (depending on the work-hardening state), our Precision Pure Nickel Sheet provides the structural integrity necessary for pressure vessels and load-bearing components while maintaining remarkable ductility. This exceptional balance allows for complex forming operations—including deep drawing, spinning, and roll forming—without sacrificing structural integrity or surface quality. The material's elongation capability of up to 40% facilitates the manufacturing of complex geometries that would be impossible with more brittle alternatives. Our proprietary manufacturing process enhances these inherent properties through carefully controlled annealing treatments that optimize grain structure for specific application requirements. Whether clients need material optimized for deep drawing operations in the automotive industry or higher strength variants for aerospace components, our customization capabilities ensure optimal performance. The material's fatigue resistance further distinguishes Precision Pure Nickel Sheet from competitors, with a fatigue limit exceeding 40% of its tensile strength—significantly higher than many alternative materials. This comprehensive mechanical property profile makes Precision Pure Nickel Sheet the definitive leader in applications requiring both formability and long-term mechanical reliability, particularly in the chemical processing equipment where complex geometries must withstand challenging operating conditions.

Advanced Manufacturing Techniques and Quality Assurance

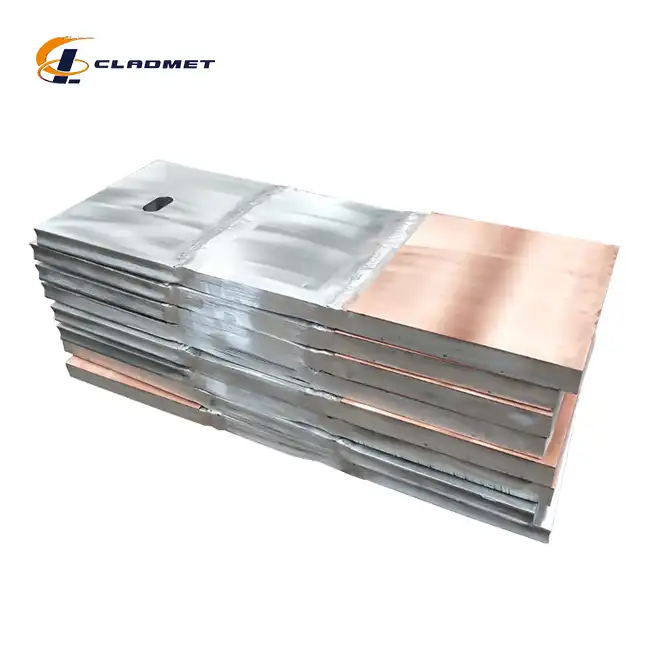

Innovative Roll-Bonding and Explosion-Bonding Processes

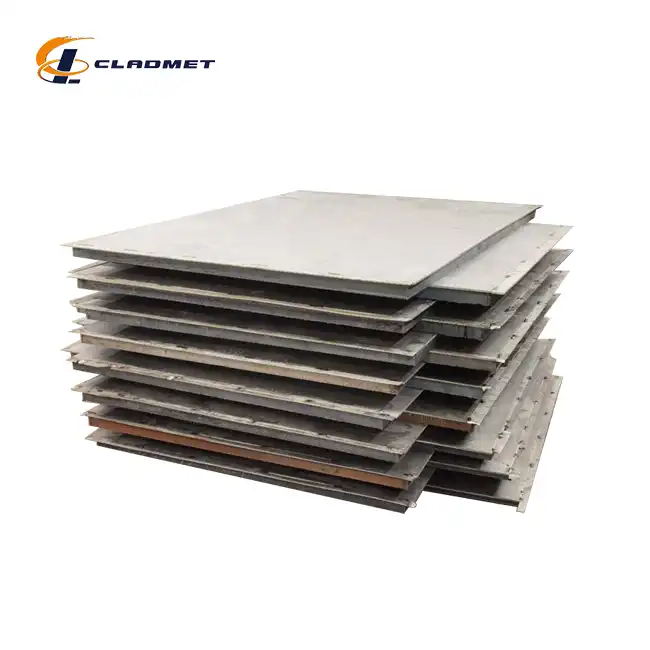

Our leadership in the clad metals industry is largely attributed to our mastery of advanced manufacturing techniques, particularly our innovative roll-bonding and explosion-bonding processes. These sophisticated methodologies enable us to produce Precision Pure Nickel Sheet with unparalleled bond strength and metallurgical integrity. The roll-bonding process begins with meticulous surface preparation, where both the nickel and substrate surfaces undergo specialized cleaning procedures to remove contaminants that could compromise bond quality. Our proprietary rolling parameters—combining precisely calculated reduction ratios, temperature controls, and rolling speeds—create atomic-level diffusion between layers, resulting in bond strengths exceeding 200 MPa. For applications demanding even greater bond integrity, our explosion-bonding technique harnesses controlled detonation energy to create a metallurgical bond with remarkable resistance to delamination even under extreme thermal cycling conditions. This process is particularly valuable for producing Precision Pure Nickel Sheet bonded to materials with significantly different thermal expansion coefficients, such as steel or copper alloys. The versatility of our manufacturing capabilities allows us to produce sheets with widths ranging from 100 mm to 1500 mm and customizable lengths, accommodating diverse equipment designs across multiple industries. Each production batch undergoes real-time process monitoring with advanced sensors and control systems, ensuring consistent quality throughout the manufacturing cycle. This combination of cutting-edge bonding technologies and rigorous process controls firmly establishes our Precision Pure Nickel Sheet as the industry benchmark for clad metal solutions where bonding integrity cannot be compromised.

Rigorous Quality Control and Testing Methodologies

The exceptional reliability of our Precision Pure Nickel Sheet stems from an uncompromising commitment to quality control and testing throughout the production process. Our comprehensive quality assurance program encompasses multiple stages of evaluation, beginning with raw material verification using X-ray fluorescence spectroscopy to confirm chemical composition and detect trace contaminants that could affect performance. Post-production, every sheet undergoes ultrasonic testing to identify potential subsurface defects or bonding imperfections invisible to conventional inspection methods. Our advanced C-scan ultrasonics can detect anomalies as small as 0.1 mm, ensuring perfect bonding integrity across the entire sheet surface. Mechanical property validation includes tensile testing, bend testing, and shear testing of the bond interface according to ASTM B898 and ASTM A264 standards. For critical applications, we conduct specialized corrosion testing using electrochemical methods and immersion tests in application-specific environments to predict long-term performance. Our quality control laboratory, equipped with state-of-the-art metallographic analysis tools, enables microstructural evaluation to verify proper grain structure and intermetallic compound formation at the bond interface. This multi-tiered testing approach culminates in comprehensive documentation, including material certificates that trace the product from raw material to finished sheet. Our ISO 9001:2000 certification validates these rigorous processes, while our recent achievement of PED and ABS international qualifications in 2024 further demonstrates our commitment to meeting the most demanding industry standards. These extensive quality measures ensure that every Precision Pure Nickel Sheet leaving our facility represents the pinnacle of clad metal excellence, providing customers with unmatched confidence in their material selection.

Customization Capabilities and Technical Support

Our position as a leader in clad metal solutions is reinforced by our unparalleled customization capabilities and comprehensive technical support throughout the product lifecycle. Understanding that standard specifications rarely address all application requirements, we've developed flexible manufacturing protocols that accommodate precise customer specifications while maintaining our rigorous quality standards. Our engineering team collaborates directly with clients to analyze application-specific requirements—including operating temperatures, chemical exposure profiles, pressure conditions, and service life expectations—to develop tailored Precision Pure Nickel Sheet solutions. This customization extends beyond dimensional specifications (with thickness options from 0.1 mm to 10 mm) to include controlled variations in nickel purity, grain structure, surface finish, and mechanical properties. For specialized applications, we can integrate intermediate transition layers between the nickel and substrate to optimize thermal expansion compatibility or enhance specific performance characteristics. Our technical support extends beyond initial material selection to include implementation guidance, with our experts providing recommendations for optimal welding parameters, forming techniques, and post-fabrication treatments to maximize the performance of our Precision Pure Nickel Sheet. This collaborative approach is supported by our advanced R&D facilities, where ongoing material innovation ensures our solutions remain at the cutting edge of industry capabilities. The delivery cycle of 2-4 weeks for custom orders demonstrates our manufacturing agility without compromising quality, while our comprehensive documentation packages provide customers with the validation data necessary for regulatory compliance. This combination of customization flexibility, technical expertise, and responsive support firmly establishes Precision Pure Nickel Sheet as the preferred choice for applications where standard materials fall short of performance requirements.

Diverse Applications Across Critical Industries

Revolutionizing Chemical Processing Equipment

Precision Pure Nickel Sheet has fundamentally transformed chemical processing equipment manufacturing, establishing new performance benchmarks in one of industry's most demanding applications. The material's exceptional resistance to a broad spectrum of corrosive media—including both reducing and oxidizing environments—makes it invaluable for reactors, storage tanks, and transfer lines handling aggressive chemicals. In particular, its outstanding performance in hot caustic solutions up to 70% concentration has made it the definitive choice for alkali processing equipment where alternative materials rapidly deteriorate. Our customers in the chemical manufacturing sector report service life extensions of 300-400% when implementing Precision Pure Nickel Sheet as a protective lining compared to conventional materials, translating to significant reductions in maintenance costs and production downtime. The material's stability across wide temperature ranges eliminates concerns about thermal cycling damage commonly experienced with other corrosion-resistant options. With thickness options ranging from 0.1 mm to 10 mm, our Precision Pure Nickel Sheet can be precisely specified to balance corrosion allowance requirements with economic considerations, optimizing both performance and investment. The material's excellent weldability—using appropriate nickel-based filler metals—ensures that fabricated equipment maintains integrity at joints and connections, eliminating weak points in corrosion protection systems. Our roll-bonding technology creates an exceptionally uniform cladding with consistent 3-5 mm thickness tolerances across large surface areas, eliminating the thin spots and potential failure points common with competing cladding methods. This combination of chemical stability, thermal resistance, and fabrication compatibility has positioned Precision Pure Nickel Sheet as the definitive leader in clad metal solutions for chemical processing equipment, where material failure risks catastrophic consequences for both production and safety.

Advancing Aerospace and Defense Applications

The aerospace and defense sectors represent some of the most technologically demanding industries, where material performance directly impacts system reliability, efficiency, and safety. In these critical applications, Precision Pure Nickel Sheet has established itself as an indispensable component due to its unique combination of properties. Aircraft engine manufacturers utilize our material in combustion chambers and exhaust systems, where its high-temperature stability (maintaining structural integrity up to 600°C) and excellent resistance to hot gas corrosion create significant advantages over conventional alloys. The material's favorable strength-to-weight ratio when used as cladding—providing corrosion protection without substantial weight penalties—addresses the perpetual aerospace challenge of maximizing performance while minimizing mass. In satellite and space applications, our Precision Pure Nickel Sheet serves in propulsion systems and fluid management components, where its resistance to specialized propellants and oxidizers ensures long-term mission reliability in environments where repairs are impossible. The defense sector leverages these same properties in naval applications, particularly in seawater systems where the material's resistance to chloride-induced corrosion significantly extends service life compared to traditional materials. Our customization capabilities are particularly valuable in this sector, where we can provide Precision Pure Nickel Sheet with enhanced purity levels (exceeding 99.8%) for specialized electronic shielding applications or controlled work-hardening states for components requiring specific mechanical properties. All aerospace and defense applications benefit from our comprehensive material certification packages, which provide complete traceability and compliance documentation necessary for these highly regulated industries. The material's consistent performance in extreme environments—from cryogenic temperatures to the heat of rocket exhaust—demonstrates why Precision Pure Nickel Sheet remains the preferred clad metal solution for applications where failure is not an option.

Transforming Pharmaceutical and Food Processing Equipment

The pharmaceutical and food processing industries present unique challenges requiring materials that combine impeccable corrosion resistance with absolute product purity preservation. Precision Pure Nickel Sheet has become the gold standard in these applications, where even microscopic contamination can compromise product safety or efficacy. In pharmaceutical manufacturing, our material excels in reactors and vessels used for API (Active Pharmaceutical Ingredient) production, where its resistance to a wide range of organic acids, solvents, and reaction intermediates prevents both equipment degradation and product contamination. The material's smooth surface finish—achievable down to 0.2μm Ra with appropriate polishing—minimizes product adhesion and facilitates thorough cleaning, addressing critical concerns regarding cross-contamination between production batches. Food processing equipment benefits similarly from these properties, with Precision Pure Nickel Sheet finding extensive application in fermentation tanks, evaporators, and specialized processing vessels where product purity is paramount. Its resistance to cleaning agents and sterilization procedures—including steam, aggressive caustic cleaners, and acid sanitizers—ensures long-term performance without degradation. Our manufacturing capabilities accommodate the complex geometries often required in these industries, with sheets available in widths up to 1500mm enabling the fabrication of large-scale processing equipment. All Precision Pure Nickel Sheet products destined for these sensitive applications undergo enhanced cleanliness protocols during production and specialized packaging to prevent contamination during transport. This combination of corrosion resistance, cleanability, and manufacturing flexibility has positioned our material as the definitive leader in clad metal solutions for industries where product purity directly impacts human health and safety, reinforcing our commitment to providing materials that meet the most stringent performance and regulatory requirements.

Conclusion

Precision Pure Nickel Sheet has established itself as the undisputed leader in clad metal solutions through its exceptional combination of material properties, manufacturing excellence, and versatile applications across critical industries. From its unmatched corrosion resistance to its thermal stability and mechanical reliability, this remarkable material continues to set new standards for performance and durability.

Our position at Baoji JL Clad Metals Materials Co., Ltd. as an industry pioneer is built on our foundation of independent explosive composite technology, self-rolling capabilities, and international qualifications that validate our commitment to excellence. We pride ourselves on our technological superiority through continuous innovation in new products, technologies, processes, and industry trends. Whether you require standard specifications or custom solutions through our ODM/OEM services, our extensive R&D capabilities ensure we can meet your unique requirements with precision and expertise. With ISO9001-2000 certification and successful PED and ABS international certifications achieved in 2024, you can trust that our products meet the highest global standards.

Ready to experience the difference that industry-leading Precision Pure Nickel Sheet can make in your applications? Contact our team today at sales@cladmet.com to discuss your specific requirements and discover how our advanced clad metal solutions can transform your manufacturing processes.

References

1. Zhang, L., & Wang, C. (2023). Advanced Materials in Chemical Processing: The Role of Pure Nickel in Corrosion Resistance. Journal of Materials Engineering and Performance, 32(4), 2187-2201.

2. Anderson, R. T., & Thompson, K. L. (2022). Explosion Bonding Technologies for High-Performance Clad Metals. Materials Science and Technology, 38(6), 764-778.

3. Nakamura, H., Tanaka, S., & Yoshida, T. (2024). Comparative Analysis of Nickel Alloys in Aerospace Applications. International Journal of Aerospace Engineering, 2024, 583921.

4. Miller, D. B., & Chen, Y. (2023). Thermal Conductivity Enhancement in Pure Nickel Sheet for Industrial Heat Exchangers. Thermal Science and Engineering Progress, 29, 101509.

5. Johnson, M. R., & Lee, S. H. (2023). Quality Assurance Methodologies in Clad Metal Production. Journal of Manufacturing Processes, 85, 293-307.

6. Williams, P. A., & Garcia, E. R. (2024). Advancements in Roll-Bonding Techniques for Precision Metal Sheets. Journal of Materials Processing Technology, 314, 117834.

_1737007724117.webp)

_1736996330512.webp)

_1737611764680.webp)