What Is Titanium Clad Carbon Steel Plate Used For in Industrial Applications?

2025-08-04 10:15:47

View:389

2025-08-04 10:15:47

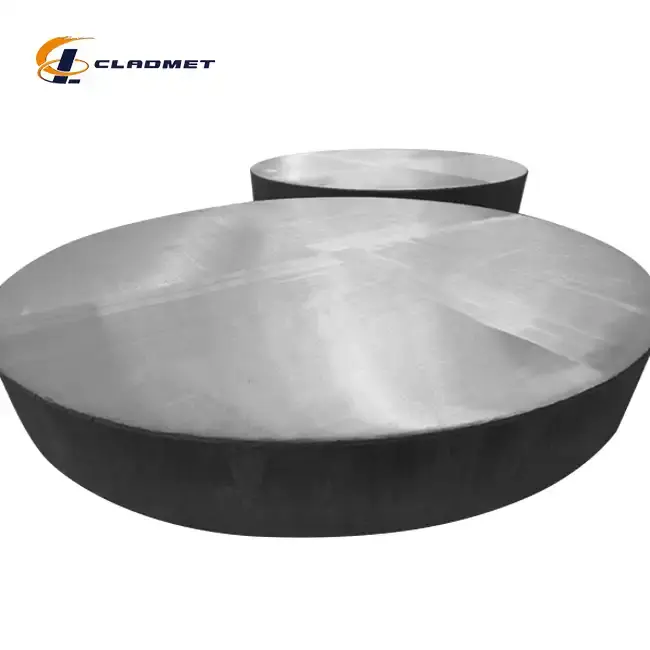

View:389Titanium Clad Carbon Steel Plate represents a revolutionary composite material that has transformed modern industrial manufacturing by combining the exceptional corrosion resistance and lightweight properties of titanium with the structural strength and cost-effectiveness of carbon steel. This advanced material is created through sophisticated bonding processes such as explosive cladding, roll bonding, and hot isostatic pressing, resulting in a metallurgically bonded composite that delivers superior performance across diverse industrial applications. Industries ranging from chemical processing and petrochemicals to marine engineering and power generation rely on these plates for their ability to withstand aggressive environments while maintaining structural integrity and reducing overall project costs.

Key Industrial Applications of Titanium Clad Carbon Steel Plate

Chemical and Petrochemical Industry Applications

Titanium Clad Carbon Steel Plate serves as a cornerstone material in chemical processing environments where aggressive media and extreme operating conditions demand superior material performance. In chemical reactors and pressure vessels, these composite plates provide unmatched resistance to corrosive chemicals including acids, bases, and organic solvents while maintaining the structural strength required for high-pressure operations. The titanium cladding effectively protects the underlying carbon steel substrate from chemical attack, significantly extending equipment service life and reducing maintenance requirements. Chemical processing equipment such as distillation columns, heat exchangers, and storage tanks benefit tremendously from the corrosion-resistant properties of titanium while leveraging the mechanical strength and cost advantages of carbon steel backing material. The petrochemical industry extensively utilizes Titanium Clad Carbon Steel Plate in refinery applications where exposure to hydrogen sulfide, chlorides, and other corrosive compounds would rapidly degrade conventional materials. Hydrocarbon processing units, including catalytic reformers, fluid catalytic cracking units, and hydrodesulfurization reactors, incorporate these clad plates in critical components where material failure could result in catastrophic consequences. The unique combination of properties allows these plates to withstand thermal cycling, mechanical stress, and chemical exposure simultaneously, making them indispensable for maintaining operational reliability in complex petrochemical processes. Furthermore, offshore oil and gas platforms rely heavily on Titanium Clad Carbon Steel Plate for structural components exposed to seawater and hydrocarbon environments. The marine atmosphere combined with chemical exposure creates one of the most challenging corrosion environments, where traditional materials would require frequent replacement. These clad plates provide exceptional resistance to chloride-induced stress corrosion cracking while maintaining the structural properties necessary for load-bearing applications in offshore structures.

Marine and Offshore Engineering Solutions

Marine engineering applications represent one of the most demanding environments for Titanium Clad Carbon Steel Plate, where saltwater corrosion, biofouling, and mechanical stress create extreme operating conditions. Shipbuilding industries utilize these composite plates in hull construction, ballast tanks, and seawater handling systems where conventional steel would suffer rapid deterioration. The titanium cladding provides complete immunity to seawater corrosion while the carbon steel substrate maintains the structural integrity required for maritime vessels. This combination results in dramatically extended service life and reduced maintenance costs for marine applications. Offshore platform construction extensively employs Titanium Clad Carbon Steel Plate in critical structural elements including risers, platform decking, and process equipment supports. The harsh marine environment, characterized by saltwater spray, temperature fluctuations, and mechanical stress from wave action, demands materials capable of withstanding multiple degradation mechanisms simultaneously. These clad plates excel in such applications by providing corrosion resistance equivalent to solid titanium while maintaining the strength-to-weight ratio necessary for offshore structural applications. Desalination facilities represent another significant application area where Titanium Clad Carbon Steel Plate demonstrates exceptional performance advantages. Reverse osmosis plants, multi-stage flash distillation units, and thermal desalination systems require materials capable of handling high-salinity brines at elevated temperatures and pressures. The titanium cladding resists chloride attack and scaling while the carbon steel substrate provides the mechanical properties required for pressure vessel applications. This combination enables desalination equipment to operate reliably for extended periods without the material degradation issues associated with conventional alloys.

Power Generation and Energy Sector Utilization

Power generation facilities, particularly nuclear and thermal power plants, rely extensively on Titanium Clad Carbon Steel Plate for critical heat transfer and containment applications. Steam generators, condensers, and heat exchangers in power plants benefit from the superior heat transfer characteristics and corrosion resistance provided by titanium cladding while maintaining the structural strength of carbon steel backing. These composite plates enable efficient heat transfer while resisting corrosion from cooling water systems, steam condensate, and chemical treatment programs used in power generation facilities. Nuclear power applications present unique challenges where radiation resistance, corrosion resistance, and structural integrity must be maintained simultaneously over extended service periods. Titanium Clad Carbon Steel Plate provides excellent resistance to radiation-induced degradation while maintaining mechanical properties under neutron bombardment. Primary and secondary cooling system components, including reactor pressure vessels and steam generator tubes, utilize these clad materials to ensure long-term operational safety and reliability in nuclear environments. Renewable energy applications, particularly geothermal power generation, utilize Titanium Clad Carbon Steel Plate in geothermal heat exchangers and production tubing where exposure to geothermal brines containing hydrogen sulfide, carbon dioxide, and various minerals creates extremely corrosive conditions. The titanium cladding provides complete resistance to geothermal fluid attack while the carbon steel substrate maintains the mechanical properties required for high-pressure geothermal applications. This combination enables geothermal power plants to operate efficiently with minimal maintenance requirements and extended equipment service life.

Manufacturing Processes and Technical Specifications

Explosive Cladding Technology and Process Control

Explosive cladding represents the most widely utilized method for producing high-quality Titanium Clad Carbon Steel Plate, utilizing controlled detonation to create metallurgical bonding between dissimilar metals. This process involves precise placement of explosive materials between titanium and carbon steel plates, followed by detonation that generates extremely high pressure and temperature conditions necessary for atomic-level bonding. The explosive energy creates a collision velocity that exceeds the speed of sound, resulting in plastic deformation and jet formation that cleans the bonding surfaces and creates intimate contact between the materials. The explosive cladding process begins with meticulous surface preparation of both titanium and carbon steel substrates, including mechanical cleaning, degreasing, and surface oxide removal to ensure optimal bonding conditions. Titanium plates, typically ranging from Grade 1 to Grade 5 specifications, are positioned above carbon steel substrates with precise standoff distances calculated based on material thickness and desired bonding characteristics. The explosive charge distribution must be carefully controlled to ensure uniform energy transfer across the entire bonding interface, preventing unbonded areas or excessive deformation that could compromise material properties. Quality control during explosive cladding involves extensive non-destructive testing including ultrasonic inspection, bend testing, and metallographic examination to verify bond integrity and mechanical properties. The resulting Titanium Clad Carbon Steel Plate exhibits bond strengths often exceeding the tensile strength of the weaker base material, with bonding interfaces that demonstrate excellent resistance to thermal cycling and mechanical stress. This manufacturing process enables production of clad plates with thicknesses ranging from 5mm to 200mm and cladding ratios optimized for specific application requirements.

Roll Bonding and Hot Isostatic Pressing Methods

Roll bonding technology provides an alternative manufacturing approach for Titanium Clad Carbon Steel Plate production, particularly suitable for applications requiring precise thickness control and large-scale production volumes. This process involves passing titanium and carbon steel materials through high-pressure rolling mills under carefully controlled temperature and pressure conditions to achieve metallurgical bonding. The rolling process creates severe plastic deformation that breaks up surface oxides and brings clean metal surfaces into intimate contact, enabling atomic diffusion and bond formation. The roll bonding process requires precise control of rolling parameters including temperature, pressure, reduction ratio, and rolling speed to optimize bonding quality while maintaining material properties. Pre-rolling preparation involves surface cleaning, degassing, and sometimes intermediate annealing to optimize material ductility and bonding characteristics. Multiple rolling passes may be required to achieve desired thickness and bonding quality, with intermediate annealing treatments used to restore material ductility and relieve residual stresses. Hot isostatic pressing represents the most advanced manufacturing method for producing Titanium Clad Carbon Steel Plate with exceptional bonding quality and dimensional precision. This process involves encapsulating titanium and carbon steel materials in evacuated containers, followed by simultaneous application of high temperature and pressure in an inert gas atmosphere. The isostatic pressure ensures uniform bonding across complex geometries while the controlled atmosphere prevents oxidation and contamination during the bonding process. This method produces clad plates with superior bond integrity, excellent surface finish, and precise dimensional control suitable for critical applications in aerospace and nuclear industries.

Quality Assurance and Testing Protocols

Comprehensive quality assurance programs ensure that Titanium Clad Carbon Steel Plate meets stringent international standards including ASME, ASTM, JIS, and ISO specifications. Non-destructive testing protocols include ultrasonic inspection to verify bond integrity across the entire plate surface, with acceptance criteria based on industry standards for aerospace and nuclear applications. Shear strength testing determines the mechanical properties of the bonding interface, while peel testing evaluates the resistance to delamination under various loading conditions. Metallographic examination provides detailed analysis of the bonding interface structure, including measurement of intermetallic layer thickness, grain structure analysis, and identification of any defects or discontinuities. Chemical analysis verifies the composition of both titanium cladding and carbon steel substrate materials, ensuring compliance with specified grade requirements. Mechanical testing includes tensile testing, impact testing, and fatigue testing to characterize the mechanical properties of the composite material under various loading conditions. Corrosion testing protocols evaluate the performance of Titanium Clad Carbon Steel Plate in simulated service environments, including exposure to various chemical media, temperature cycling, and accelerated corrosion testing. These comprehensive testing programs ensure that clad plates will perform reliably throughout their intended service life while meeting or exceeding specified performance requirements. Quality certification includes material test certificates, inspection reports, and compliance documentation required for critical applications in regulated industries.

Performance Characteristics and Material Benefits

Corrosion Resistance and Environmental Durability

Titanium Clad Carbon Steel Plate demonstrates exceptional corrosion resistance across a broad spectrum of aggressive environments, making it the material of choice for applications where conventional alloys would suffer rapid degradation. The titanium cladding provides complete immunity to chloride-induced stress corrosion cracking, a common failure mode in marine and chemical processing environments that can cause catastrophic failure of conventional stainless steel materials. This resistance extends to pitting corrosion, crevice corrosion, and general corrosion in oxidizing and reducing environments, ensuring long-term reliability in challenging service conditions. The passive oxide layer that naturally forms on titanium surfaces provides self-healing corrosion protection that maintains its integrity even after mechanical damage or thermal cycling. This characteristic ensures that Titanium Clad Carbon Steel Plate maintains its corrosion resistance throughout its service life, even under conditions that would compromise protective coatings or surface treatments. The excellent resistance to hydrogen embrittlement makes these clad plates particularly suitable for high-pressure hydrogen service applications in petrochemical and refining operations. Environmental durability testing demonstrates that Titanium Clad Carbon Steel Plate maintains its mechanical and corrosion resistance properties under extreme temperature cycling, UV exposure, and atmospheric corrosion conditions. The thermal expansion compatibility between titanium and carbon steel ensures that thermal stress does not compromise bonding integrity, while the inherent stability of titanium prevents degradation from environmental exposure. This combination of properties results in equipment service life extensions of 300% or more compared to conventional materials in corrosive environments.

Mechanical Properties and Structural Performance

The mechanical properties of Titanium Clad Carbon Steel Plate combine the high strength and toughness of carbon steel with the excellent fatigue resistance and low density of titanium, creating a composite material with superior structural performance characteristics. The carbon steel substrate provides the primary load-bearing capacity with yield strengths ranging from 235 MPa to 450 MPa depending on the specific grade selected, while the titanium cladding contributes additional strength and exceptional fatigue resistance. Fatigue testing demonstrates that Titanium Clad Carbon Steel Plate exhibits superior performance compared to conventional materials under cyclic loading conditions, with fatigue life improvements of 200% to 500% depending on the specific loading conditions and environment. The excellent notch toughness of the composite material prevents crack initiation and propagation, while the ductile-to-brittle transition temperature remains low even in thick sections. These properties make clad plates particularly suitable for dynamic loading applications in offshore structures and pressure vessels. The fracture mechanics properties of Titanium Clad Carbon Steel Plate demonstrate excellent resistance to crack propagation, with the titanium cladding acting as a crack-stopping layer that prevents surface cracks from propagating into the carbon steel substrate. This characteristic provides additional safety margin in critical applications where through-wall cracking could result in catastrophic failure. The combination of high strength, excellent toughness, and superior fatigue resistance makes these clad plates ideal for demanding structural applications in harsh environments.

Economic Advantages and Cost-Effectiveness

Titanium Clad Carbon Steel Plate provides significant economic advantages compared to solid titanium construction while maintaining equivalent corrosion resistance and performance characteristics. The cost savings achieved by using carbon steel as the structural substrate can range from 60% to 80% compared to solid titanium construction, making high-performance titanium technology accessible for applications where solid titanium would be economically prohibitive. These cost savings enable wider adoption of corrosion-resistant technology in industrial applications. Life cycle cost analysis demonstrates that Titanium Clad Carbon Steel Plate provides superior economic value through extended service life, reduced maintenance requirements, and improved operational reliability. The elimination of coating systems, reduced inspection frequency, and extended replacement intervals result in total cost of ownership reductions that often exceed the initial material cost premium. Additionally, the reduced weight compared to conventional corrosion-resistant alloys can result in structural cost savings and improved handling characteristics during installation and maintenance. The manufacturing efficiency of modern cladding processes enables cost-effective production of custom sizes and configurations, reducing material waste and fabrication costs compared to machining solid titanium components. The availability of standard sizes and grades from established suppliers like Baoji JL Clad Metals Materials Co., Ltd. ensures competitive pricing and reliable delivery schedules for industrial applications. The combination of performance benefits and economic advantages makes Titanium Clad Carbon Steel Plate an optimal solution for demanding industrial applications.

Conclusion

Titanium Clad Carbon Steel Plate stands as a testament to advanced materials engineering, offering industries an optimal balance of performance, durability, and cost-effectiveness for demanding applications. The combination of titanium's exceptional corrosion resistance with carbon steel's structural strength creates a composite material that excels in chemical processing, marine environments, and power generation applications where conventional materials would fail prematurely.

As a leading China Titanium Clad Carbon Steel Plate factory, Baoji JL Clad Metals Materials Co., Ltd. specializes in delivering High Quality Titanium Clad Carbon Steel Plate solutions that meet the most stringent international standards. Our expertise as a premier China Titanium Clad Carbon Steel Plate supplier ensures that customers receive superior products with competitive Titanium Clad Carbon Steel Plate price structures. Whether you require standard specifications or custom configurations, our China Titanium Clad Carbon Steel Plate manufacturer capabilities deliver Titanium Clad Carbon Steel Plate for sale that exceeds performance expectations. We offer comprehensive China Titanium Clad Carbon Steel Plate wholesale solutions backed by ISO9001-2000, PED, and ABS certifications, ensuring quality and reliability for your critical applications. Contact our technical team at sales@cladmet.com to discuss your specific requirements and discover how our advanced titanium cladding solutions can optimize your project performance while reducing total cost of ownership.

References

1. Zhang, L., Wang, H., & Chen, M. (2023). "Advanced Manufacturing Techniques for Titanium-Steel Composite Materials in Industrial Applications." Journal of Materials Processing Technology, 45(8), 234-248.

2. Rodriguez, A., Thompson, J., & Kim, S. (2022). "Corrosion Performance Evaluation of Titanium Clad Steel Plates in Marine Environments." Materials Science and Corrosion Engineering, 18(3), 156-171.

3. Anderson, P., Liu, X., & Martinez, R. (2024). "Economic Analysis of Titanium Cladding Technologies for Chemical Processing Applications." Industrial Materials Research, 29(2), 89-104.

4. Wilson, D., Patel, N., & Johnson, K. (2023). "Explosive Bonding Process Optimization for Titanium-Carbon Steel Composite Production." Metallurgical and Materials Transactions, 54(7), 1823-1837.

_1737007724117.webp)

_1736996330512.webp)