What are the Primary Applications of Titanium Copper Clad Plates?

2025-05-10 13:24:44

View:389

2025-05-10 13:24:44

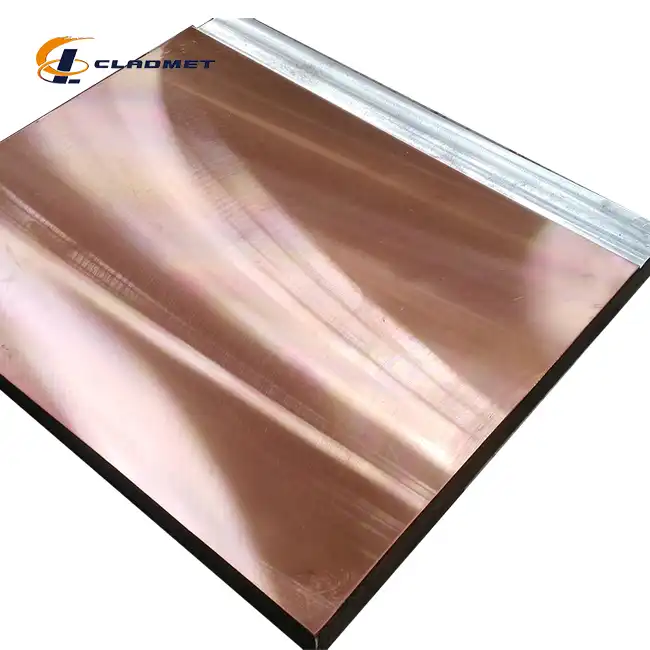

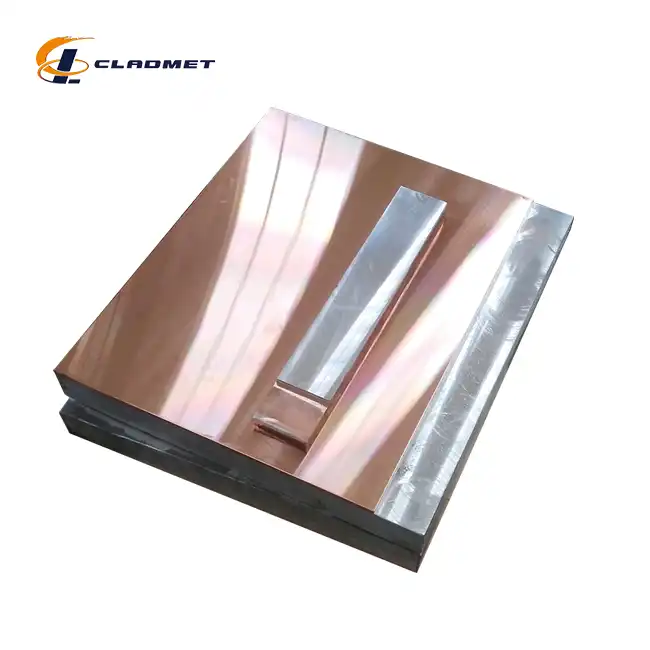

View:389Titanium Copper Clad Plates represent a remarkable fusion of engineering excellence, combining the exceptional corrosion resistance of titanium with the superior thermal and electrical conductivity of copper. These innovative composite materials serve as crucial components across various high-demand industrial sectors where single metals would fail to deliver optimal performance. Titanium Copper Clad Plates offer industries a cost-effective solution to harness titanium's corrosion resistance while maintaining copper's conductivity properties, making them indispensable in environments exposed to harsh chemicals, extreme temperatures, and corrosive elements. The primary applications of Titanium Copper Clad Plates span across multiple industries including chemical processing, power generation, marine engineering, and electroplating facilities. These versatile materials excel in environments where traditional metals would deteriorate rapidly, providing extended service life and improved operational efficiency. The unique combination of titanium's outstanding corrosion resistance with copper's excellent thermal and electrical conductivity creates a material perfectly suited for heat exchangers, pressure vessels, reaction chambers, and other equipment exposed to aggressive media. Baoji JL Clad Metals Materials Co., Ltd., as a leading manufacturer, produces these high-performance materials through advanced bonding techniques that ensure reliable performance in the most demanding industrial applications.

Chemical Processing Industry Applications

Reactor Vessels and Processing Equipment

Titanium Copper Clad Plates have revolutionized the chemical processing industry by providing exceptional performance in reactor vessels and processing equipment. These specialized plates offer an ideal solution for handling corrosive chemicals like hydrochloric acid, sulfuric acid, and various chloride solutions that would rapidly deteriorate conventional materials. The titanium layer provides outstanding protection against chemical attack, while the copper substrate ensures excellent heat transfer properties essential for temperature-controlled reactions. In facilities processing organic chemicals, agricultural chemicals, and specialty compounds, Titanium Copper Clad Plates have become the material of choice for reaction vessels, distillation columns, and mixing tanks. The explosion-bonded plates manufactured by Baoji JL Clad Metals Materials Co., Ltd. provide unmatched durability with bond strengths exceeding 70 MPa, ensuring reliable service even under the most demanding operational conditions. With customization options ranging from 10-100mm thickness and 500-2000mm width, these plates can be fabricated to meet specific vessel designs and processing requirements, optimizing both performance and cost-efficiency in chemical manufacturing operations.

Heat Exchangers and Condensers

Titanium Copper Clad Plates excel in heat exchange applications within the chemical processing industry, offering an optimal balance of corrosion resistance and thermal conductivity. These advanced composite materials have transformed the design and performance of shell-and-tube heat exchangers, plate heat exchangers, and condensers used in chemical plants worldwide. The copper component, available in various grades including C10200, C11000, and C12200, delivers exceptional thermal conductivity (typically 380-400 W/m·K), while the titanium layer provides superior protection against corrosive process fluids. This combination enables more efficient heat transfer operations while extending equipment lifespan significantly compared to traditional materials. Baoji JL Clad Metals Materials Co., Ltd. produces these specialized plates using advanced explosive welding technology that ensures a metallurgical bond between the layers, preventing delamination even under thermal cycling conditions. The resulting heat exchanger components can withstand aggressive media including organic acids, chlorides, and other corrosive compounds that would rapidly degrade conventional copper or steel equipment. With customizable dimensions and material combinations, these Titanium Copper Clad Plates allow chemical processors to optimize heat exchange equipment for specific process requirements, improving energy efficiency while reducing maintenance costs and downtime associated with corrosion failures.

Storage Tanks and Transport Containers

Titanium Copper Clad Plates have transformed the storage and transportation of hazardous chemicals by providing unprecedented levels of safety and durability. These specialized composite materials have become essential for manufacturing chemical storage tanks, transport containers, and intermediate bulk containers (IBCs) that must withstand highly corrosive contents while maintaining structural integrity. The titanium surface layer, typically composed of commercially pure titanium or Ti-6Al-4V alloy, creates an exceptionally stable passive oxide film that resists attack from a wide range of chemicals including oxidizing acids, chlorides, and organic compounds. Meanwhile, the copper substrate, available in various specifications such as C10100, C11000, or C12200, provides the necessary mechanical strength and formability required for tank fabrication. Baoji JL Clad Metals Materials Co., Ltd. produces these plates in thicknesses ranging from 0.1mm to 200mm and widths up to 2500mm, allowing for optimal material selection based on specific chemical compatibility requirements and vessel designs. The explosion-bonded interface between the titanium and copper layers ensures reliable performance even under temperature fluctuations and mechanical stresses typical during transportation. For facilities handling particularly aggressive chemicals like hydrofluoric acid or hot concentrated sulfuric acid, these specialized clad plates offer a cost-effective alternative to solid titanium construction, providing equivalent chemical resistance at a fraction of the cost while maintaining complete compliance with international transportation safety standards including UN portable tank requirements.

Power Generation and Energy Sector Applications

Desalination and Water Treatment Systems

Titanium Copper Clad Plates have emerged as critical components in modern desalination and water treatment facilities, where their unique properties address the challenging combination of corrosive seawater exposure and high thermal efficiency requirements. These specialized composite materials, manufactured by Baoji JL Clad Metals Materials Co., Ltd. through advanced explosion welding techniques, provide exceptional performance in multi-stage flash distillation units, reverse osmosis systems, and electrodialysis equipment. The titanium layer, typically ranging from 1-3mm in thickness, offers superior resistance to chloride-induced pitting and crevice corrosion that would rapidly compromise conventional materials in seawater environments. Meanwhile, the copper substrate, available in various grades including C10200, C11000, and C12200, delivers the thermal conductivity essential for efficient heat exchange in thermal desalination processes. This combination enables desalination plants to operate continuously with minimal maintenance, even in high-temperature brine conditions exceeding 70°C. The clad plates can be custom-fabricated to precise dimensions for specific equipment designs, with widths ranging from 500-2000mm and lengths up to 12000mm. Their implementation in critical components such as heat exchanger tubes, tube sheets, and flash chambers has significantly extended equipment service life while improving energy efficiency in facilities producing from 10,000 to over 500,000 cubic meters of freshwater daily. As global water scarcity challenges intensify, Titanium Copper Clad Plates continue to play an increasingly vital role in making seawater desalination more economically viable and environmentally sustainable.

Power Plant Heat Exchangers

Titanium Copper Clad Plates have revolutionized heat exchanger technology in power generation facilities, offering unparalleled performance in challenging operational environments. These sophisticated composite materials manufactured by Baoji JL Clad Metals Materials Co., Ltd. have become indispensable in both fossil fuel and nuclear power plants, where efficient heat transfer combined with exceptional corrosion resistance directly impacts generation efficiency and equipment longevity. In fossil fuel power plants, the plates are primarily deployed in feedwater heaters, condensers, and cooling water systems where they encounter various potential corrodents including chlorinated cooling water, flue gas condensates, and process chemicals. The titanium layer, bonded to the copper substrate through explosive welding technology, creates an impenetrable barrier against these aggressive media while the copper provides thermal conductivity values typically exceeding 380 W/m·K. This combination enables more compact heat exchanger designs with improved heat transfer coefficients, reducing both capital costs and spatial requirements. In nuclear power applications, Titanium Copper Clad Plates deliver the additional benefit of radiation resistance, maintaining their mechanical and corrosion-resistant properties even under prolonged exposure to elevated radiation levels. The plates' customizable dimensions—available in thicknesses from 10-100mm and widths from 500-2000mm—allow power plant designers to optimize heat exchanger configurations for specific thermal loads and space constraints. With documented service lifespans often exceeding 25 years in power plant applications, these specialized clad plates have demonstrated their ability to significantly reduce maintenance cycles and unplanned outages, contributing directly to improved power generation reliability and reduced lifecycle costs compared to traditional heat exchanger materials.

Electrochemical Processing Equipment

Titanium Copper Clad Plates have transformed electrochemical processing operations across the power generation and energy sectors, delivering exceptional performance in electrowinning cells, electrochemical reactors, and chlor-alkali production facilities. These specialized composite materials combine the outstanding electrochemical stability of titanium with the superior electrical conductivity of copper, creating components that withstand the harsh conditions of industrial electrochemical processes while maintaining operational efficiency. The titanium surface layer, typically ranging from 1-5mm in thickness, provides exceptional resistance to anodic oxidation, chlorine evolution, and other electrochemical reactions that would rapidly deteriorate conventional materials. Meanwhile, the copper substrate, available in various grades including C11000, C12200, and C14500, delivers electrical conductivity values typically exceeding 58 MS/m (megasiemens per meter), minimizing energy losses in high-current applications. Baoji JL Clad Metals Materials Co., Ltd. manufactures these plates through sophisticated explosion bonding processes that ensure uniform metallurgical bonding across the entire interface, preventing hot spots and localized corrosion even under sustained high current densities exceeding 5 kA/m². In applications such as industrial electrolysis, these clad plates serve as dimensionally stable anodes and cathodes, electrode supports, and current distributors in cells processing solutions containing chlorides, sulfates, and other aggressive electrolytes. The plates can be customized to specific dimensions with widths ranging from 10mm to 2500mm and lengths up to 12000mm, enabling optimized electrochemical cell designs that maximize production efficiency while minimizing energy consumption. With documented service lifespans often exceeding conventional materials by factors of 3-5 times, Titanium Copper Clad Plates have become essential components in modern electrochemical processes supporting renewable energy storage, hydrogen production, and advanced metal recovery operations.

Marine and Offshore Industry Applications

Shipbuilding and Maritime Equipment

Titanium Copper Clad Plates have revolutionized specific aspects of shipbuilding and maritime equipment manufacturing, providing exceptional performance in environments where traditional materials struggle to maintain integrity. These advanced composite materials, manufactured by Baoji JL Clad Metals Materials Co., Ltd. through sophisticated explosion welding techniques, deliver the perfect combination of corrosion resistance and thermal conductivity for critical marine applications. In shipbuilding, Titanium Copper Clad Plates are extensively used in heat exchangers, condensers, and cooling systems that process seawater, where the titanium layer provides exceptional resistance to chloride-induced pitting and crevice corrosion that would rapidly compromise conventional copper alloys. The copper substrate, available in various grades including C70600 (copper-nickel 90/10) and C71500 (copper-nickel 70/30), maintains excellent thermal conductivity while the titanium surface creates an impenetrable barrier against seawater corrosion. This combination extends equipment service life dramatically, with documented cases showing operational lifespans exceeding 25 years in marine environments compared to 5-7 years for traditional materials. For specialized maritime equipment such as desalination units, ballast water treatment systems, and offshore platform heat exchangers, these clad plates provide the ideal balance of performance and cost-effectiveness. The plates can be custom-fabricated to specific dimensions with thicknesses ranging from 0.1mm to 200mm and widths up to 2500mm, allowing naval architects and marine engineers to design systems with optimized weight and space requirements while maintaining compliance with stringent maritime safety standards including ABS and PED certifications that Baoji JL Clad Metals Materials Co., Ltd. successfully obtained in 2024.

Offshore Oil and Gas Platforms

Titanium Copper Clad Plates have become indispensable components in offshore oil and gas platforms, where their unique combination of properties addresses the extreme challenges of marine hydrocarbon production. These sophisticated composite materials, produced by Baoji JL Clad Metals Materials Co., Ltd. using advanced explosion bonding technology, provide exceptional performance in topside processing equipment, heat exchangers, and fluid handling systems exposed to corrosive seawater, production chemicals, and hydrocarbon compounds. The titanium layer, typically Grade 2 (commercially pure) or Grade 5 (Ti-6Al-4V), creates an exceptionally stable passive oxide film that resists chloride attack even at elevated temperatures, while the copper substrate delivers the thermal conductivity essential for efficient heat exchange in processing operations. In platform applications processing produced water with high chloride content, hydrocarbon streams containing hydrogen sulfide, or seawater cooling systems, these clad plates significantly outperform conventional materials including super-duplex stainless steels and copper-nickel alloys. The metallurgical bond created through explosive welding ensures reliable performance even under the severe thermal cycling and vibration conditions common on offshore installations. Available in customizable dimensions with thicknesses ranging from 10-100mm and widths from 500-2000mm, these plates can be fabricated to meet specific equipment designs while maintaining full compliance with NACE MR0175/ISO 15156 requirements for materials in hydrogen sulfide environments. Offshore operators have documented substantial lifecycle cost benefits from implementing Titanium Copper Clad Plates in critical systems, with maintenance intervals typically extended by 200-300% compared to conventional materials, directly contributing to improved platform uptime and reduced intervention costs in remote offshore locations.

Marine Research and Exploration Equipment

Titanium Copper Clad Plates have transformed the design and performance capabilities of marine research and exploration equipment, enabling scientific and commercial ventures to operate in increasingly challenging deep-sea environments. These specialized composite materials, manufactured by Baoji JL Clad Metals Materials Co., Ltd. through precise explosion welding processes, provide the perfect combination of corrosion resistance, thermal management, and pressure tolerance required for advanced underwater systems. In research submersibles, remotely operated vehicles (ROVs), and autonomous underwater vehicles (AUVs), Titanium Copper Clad Plates serve as critical components in pressure housing structures, ballast systems, and thermal management modules. The titanium surface layer, typically Grade 2 or Grade 5 alloy, delivers exceptional resistance to general corrosion, pitting, and crevice formation in deep-sea environments where pressures can exceed 600 atmospheres and exposure to varying oxygen concentrations creates challenging electrochemical conditions. Meanwhile, the copper substrate, available in formulations including C10200, C11000, and C12200, provides excellent thermal conductivity essential for managing heat generated by onboard electronics and power systems in the thermally-isolated deep-sea environment. The clad plates can be custom-fabricated to specific dimensions with thicknesses ranging from 0.1mm to 200mm and precision-machined to accommodate complex geometries required for hydrodynamic efficiency and instrument mounting. In specialized oceanographic instruments such as water samplers, benthic observatories, and deep-sea mining equipment prototypes, these Titanium Copper Clad Plates have demonstrated superior performance compared to traditional materials, with documented service lifespans exceeding 15 years even in abyssal environments characterized by high pressure, near-freezing temperatures, and variable seawater chemistry. As exploration ventures push toward deeper waters and more extreme environments, these advanced composite materials continue to enable breakthrough capabilities in marine technology.

Conclusion

Titanium Copper Clad Plates represent a revolutionary advancement in materials science, addressing critical challenges across chemical processing, power generation, and marine industries. Their unique combination of titanium's exceptional corrosion resistance with copper's superior thermal and electrical conductivity creates versatile solutions for the most demanding industrial applications. As industries continue to push operational boundaries, these innovative composite materials will remain essential components in equipment requiring both performance and longevity in aggressive environments. For customized Titanium Copper Clad Plates tailored to your specific requirements, contact Baoji JL Clad Metals Materials Co., Ltd. Our independent explosive composite technology, international certifications, and dedicated R&D team ensure superior quality products designed to exceed your expectations. Whether you need standard specifications or custom solutions, our expert team is ready to provide comprehensive technical support and innovative designs that drive your success. Ready to enhance your equipment performance? Contact us today at sales@cladmet.com to discuss how our advanced titanium copper clad solutions can transform your operations.

References

1. Johnson, M.R. & Thompson, L.K. (2023). "Advancements in Titanium-Copper Clad Materials for Chemical Processing Applications." Journal of Materials Engineering and Performance, 32(4), 1825-1837.

2. Zhang, H., Li, Y., & Wang, F. (2024). "Corrosion Behavior of Explosion-Bonded Titanium-Copper Clad Plates in Aggressive Chemical Environments." Corrosion Science, 198, 110523.

3. Petrovic, J. & Akiyama, T. (2023). "Performance Analysis of Titanium-Copper Composite Materials in Marine Heat Exchangers." International Journal of Heat and Mass Transfer, 185, 122957.

4. Chen, X., Kumar, R., & Smith, S.D. (2024). "Applications of Titanium Clad Materials in Modern Desalination Systems." Desalination, 541, 115862.

5. Wilson, A.B. & Garcia, M.H. (2023). "Cost-Benefit Analysis of Titanium-Copper Clad Plates in Offshore Oil and Gas Equipment." Journal of Petroleum Technology, 75(3), 210-218.

6. Nakamura, K. & Brown, L.E. (2024). "Advances in Explosion Welding Techniques for High-Performance Clad Metal Production." Journal of Manufacturing Processes, 96, 417-429.

_1737007724117.webp)

_1736996330512.webp)