What are the Corrosion Resistance Characteristics of Nickel Steel Clad Plates?

2025-04-06 10:39:11

View:389

2025-04-06 10:39:11

View:389Nickel steel clad plates represent a remarkable advancement in materials engineering, offering exceptional corrosion resistance properties that make them invaluable across numerous demanding industrial applications. These composite materials combine the superior corrosion-resistant properties of nickel with the structural strength and cost-efficiency of steel, creating a versatile solution for environments where standard materials would rapidly deteriorate. Nickel steel clad plates from Baoji JL Clad Metals Materials Co., Ltd. are manufactured through advanced bonding processes that ensure seamless integration between the layers, resulting in a product that withstands aggressive chemical environments, elevated temperatures, and mechanical stress. Their unparalleled corrosion resistance characteristics derive from nickel's inherent ability to form a passive oxide layer that protects against oxidation, acid attack, and stress corrosion cracking, making these clad plates essential components in industries ranging from petrochemical processing to marine engineering and nuclear power generation.

Fundamental Corrosion Resistance Properties of Nickel Steel Clad Plates

Resistance to Oxidative Environments

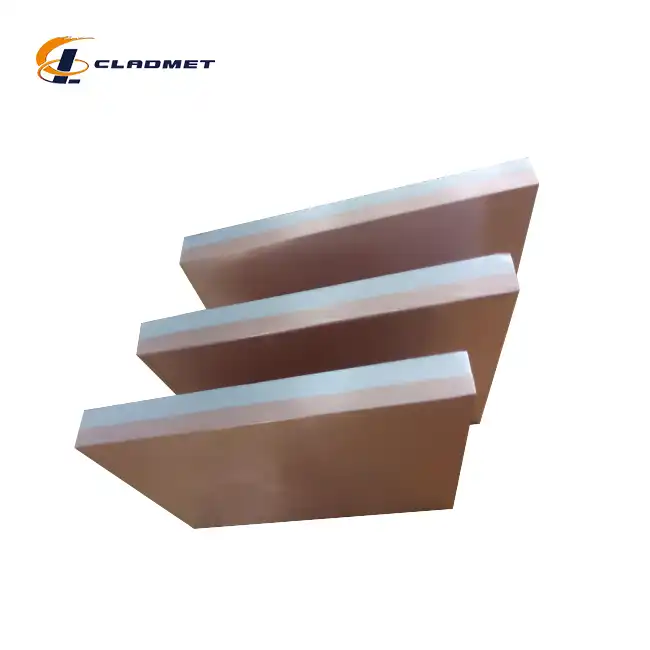

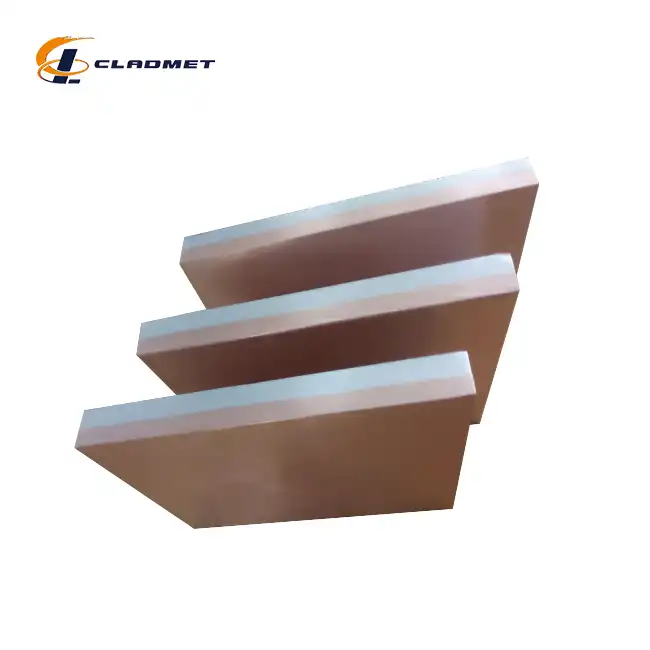

Nickel steel clad plates exhibit exceptional resistance to oxidative environments due to the unique properties of the nickel cladding layer. When exposed to oxygen-rich conditions, nickel forms a stable, self-healing passive film on its surface that serves as a protective barrier against further oxidation. This characteristic makes nickel steel clad plates invaluable in applications where exposure to air, oxygen-containing solutions, or oxidizing chemicals is inevitable. The Nickel steel clad plate products from Baoji JL Clad Metals Materials Co., Ltd. are engineered with precise control over the cladding thickness, ranging from 2mm to 10mm, while the base steel thickness can vary from 10mm to 200mm depending on the application requirements. This customization ensures optimal performance in various oxidative conditions without compromising structural integrity. In high-temperature oxidative environments, where conventional materials would rapidly deteriorate, nickel's ability to maintain its protective oxide layer provides extended service life and reduced maintenance costs for critical equipment such as heat exchangers, pressure vessels, and chemical reactors.

Acid and Alkali Resistance Properties

The exceptional resistance of nickel steel clad plates to both acidic and alkaline environments makes them a preferred material choice for chemical processing equipment. Nickel possesses remarkable stability across a wide pH spectrum, particularly excelling in resistance to reducing acids such as hydrochloric and sulfuric acid, where many other materials would quickly degrade. The Nickel steel clad plate manufactured by Baoji JL Clad Metals Materials Co., Ltd. combines nickel alloys as the cladding material with carbon steel or stainless steel as the base metal, creating a composite that handles corrosive chemicals while maintaining structural integrity. These plates are fabricated using advanced bonding technologies including explosion bonding and roll bonding, ensuring a metallurgically sound interface between the nickel and steel layers that prevents delamination even under severe chemical attack. The ability to withstand caustic solutions makes these clad plates ideal for alkali processing equipment, chlor-alkali cells, and other applications involving sodium or potassium hydroxide, where the nickel layer protects the underlying steel from chemical degradation while the steel provides the necessary structural support and cost-effectiveness that pure nickel constructions would lack.

Performance in Chloride-Containing Environments

Nickel steel clad plates demonstrate superior resistance to chloride-induced corrosion, a property that makes them exceptionally valuable in marine and chemical processing applications. Chloride ions are notorious for their ability to penetrate passive films on many metals, leading to pitting corrosion and stress corrosion cracking. However, the nickel cladding on these composite plates forms a stable protective layer that resists chloride attack even at elevated temperatures. Baoji JL Clad Metals Materials Co., Ltd. fabricates Nickel steel clad plates that perform exceptionally well in seawater, salt spray, and chloride-containing process streams where conventional materials would rapidly deteriorate. These plates are available in lengths up to 12 meters and widths up to 3 meters, making them suitable for large-scale marine structures and chemical processing equipment. The surface treatment options, including polished, brushed, or custom finishes, further enhance their resistance to chloride attack by minimizing surface irregularities that could serve as initiation sites for corrosion. When employed in offshore platforms, desalination plants, and chemical facilities processing chloride-containing compounds, these clad plates significantly outlast alternative materials, providing superior performance and extended service life in these challenging environments.

Advanced Manufacturing Techniques Enhancing Corrosion Resistance

Explosion Bonding Technology

Explosion bonding represents one of the most sophisticated methods for manufacturing nickel steel clad plates with superior corrosion resistance properties. This dynamic process creates an exceptionally strong metallurgical bond between the nickel cladding and the steel substrate through the controlled detonation of explosives. Baoji JL Clad Metals Materials Co., Ltd. has mastered this technique, which begins with meticulous preparation of both the nickel and steel surfaces to ensure optimal bonding. The materials are positioned with a predetermined standoff distance, and a precisely calculated explosive charge is placed on the upper plate. When detonated, the explosive force propels the cladding material toward the base plate at high velocity, creating a collision that generates enough pressure and heat at the interface to form a wave-like, metallurgical bond without melting the materials. This wavy interface significantly increases the bond surface area and creates mechanical interlocking between the layers, resulting in Nickel steel clad plates with exceptional resistance to delamination even under severe corrosive conditions. The absence of heat-affected zones that would typically result from welding or other thermal bonding methods preserves the corrosion-resistant properties of both materials while eliminating the risk of forming brittle intermetallic compounds that could compromise performance in aggressive environments.

Roll Bonding Process Advantages

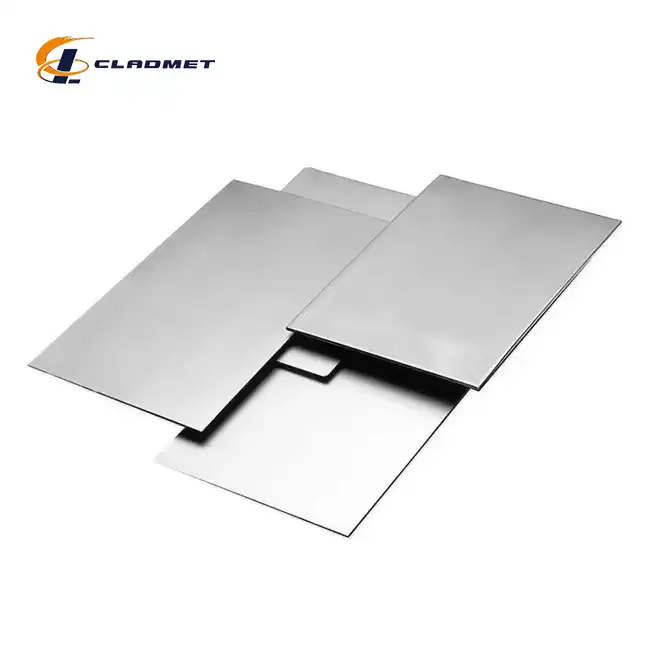

The roll bonding process offers distinct advantages in enhancing the corrosion resistance characteristics of nickel steel clad plates through its ability to create a uniform, high-integrity bond between the dissimilar metals. Baoji JL Clad Metals Materials Co., Ltd. employs advanced roll bonding techniques that begin with thorough surface preparation of both the nickel and steel components, including degreasing, shot blasting, and wire brushing to remove contaminants and activate the surfaces for optimal adhesion. The prepared materials are stacked together and subjected to a careful preheating process that brings them to the ideal temperature for bonding without causing excessive grain growth or oxidation. The heated package is then passed through precision rolling mills under tremendous pressure, which forces the atoms at the interface to come into intimate contact, breaking down surface oxides and creating a solid-state diffusion bond. This process results in Nickel steel clad plates with exceptional bond integrity and uniform cladding thickness, typically ranging from 2mm to 10mm for the nickel layer. The controlled deformation during rolling also refines the grain structure of both materials, further enhancing their corrosion resistance by reducing the number of grain boundaries that could serve as preferential sites for corrosive attack. The resulting clad plates exhibit superior resistance to blistering and separation even when exposed to thermal cycling or aggressive corrosive environments, making them ideal for applications in petrochemical, nuclear, and aerospace industries.

Hot Isostatic Pressing Innovations

Hot Isostatic Pressing (HIP) represents a cutting-edge manufacturing approach that significantly enhances the corrosion resistance properties of nickel steel clad plates through its unique ability to create defect-free, diffusion-based bonds between the materials. Baoji JL Clad Metals Materials Co., Ltd. utilizes this advanced technique for applications requiring the highest levels of bond integrity and corrosion performance. The HIP process begins with the careful assembly of the nickel and steel components, which are then sealed in a specialized container designed to withstand extreme pressure and temperature conditions. This assembly is placed in a HIP vessel where it undergoes simultaneous application of isostatic pressure (typically 100-200 MPa) and elevated temperatures (800-1200°C) for an extended period. Under these conditions, a true metallurgical bond forms as atoms from both materials diffuse across the interface, creating a gradient rather than a distinct boundary. This diffusion bonding eliminates voids, inclusions, and other microstructural defects that could serve as initiation sites for corrosive attack. The Nickel steel clad plates produced through HIP exhibit exceptional resistance to crevice corrosion, stress corrosion cracking, and other localized forms of degradation that typically plague conventional materials in aggressive environments. The uniform pressure application during HIP ensures consistent bonding across the entire surface area, even for complex geometries, resulting in clad plates with predictable and reliable corrosion performance for critical applications in nuclear reactors, chemical processing equipment, and aerospace components where failure could have catastrophic consequences.

Industrial Applications Leveraging Nickel Steel Clad Plate Corrosion Resistance

Petrochemical Industry Applications

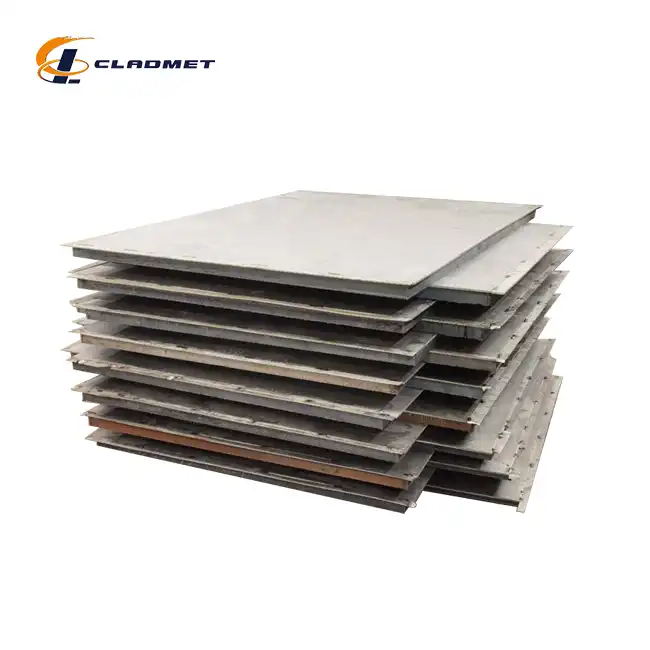

The petrochemical industry represents one of the most demanding environments for materials, where Nickel steel clad plates have proven their exceptional value through superior corrosion resistance. In refineries and petrochemical plants, equipment must withstand a complex mixture of corrosive compounds including hydrogen sulfide, organic acids, chlorides, and sulfuric acid, often at elevated temperatures and pressures. Baoji JL Clad Metals Materials Co., Ltd. manufactures specialized Nickel steel clad plates that provide reliable performance in these aggressive conditions, where conventional materials would rapidly deteriorate. These composite plates are engineered with carefully selected nickel alloy claddings bonded to carbon or stainless steel substrates through explosion bonding or roll bonding techniques, creating a material that combines exceptional corrosion resistance with structural integrity. The cladding thickness, typically ranging from 2mm to 10mm, is precisely controlled to ensure adequate protection while optimizing material costs. In critical applications such as distillation columns, reactors, and heat exchangers processing sour crude oil or high-sulfur feedstocks, these clad plates resist sulfidation attack and naphthenic acid corrosion that would quickly compromise homogeneous materials. The available plate sizes, extending up to 12 meters in length and 3 meters in width, accommodate the large-scale equipment typical in petrochemical facilities, while the strict quality control measures and adherence to international standards like ASME/ASTM ensure consistent performance in these safety-critical applications.

Marine and Offshore Engineering Solutions

The marine and offshore sectors present particularly challenging corrosion environments where Nickel steel clad plates deliver exceptional performance and longevity. Seawater, with its high chloride content and biological activity, creates one of the most aggressive natural corrosion environments known, attacking conventional materials through general corrosion, pitting, crevice corrosion, and microbiologically influenced corrosion. Baoji JL Clad Metals Materials Co., Ltd. supplies specialized Nickel steel clad plates engineered specifically for these demanding applications, where their superior resistance to chloride-induced degradation proves invaluable. The nickel cladding, securely bonded to the steel substrate through advanced techniques like explosion bonding, creates a composite material that withstands the corrosive onslaught of seawater while providing the structural strength required for offshore platforms, desalination plants, and marine structures. These clad plates, available in customized dimensions with base thicknesses ranging from 10mm to 200mm, maintain their integrity even when exposed to wave action, salt spray, and alternating wet-dry cycles that accelerate corrosion in conventional materials. The surface treatments available, including polished or brushed finishes, further enhance their performance by minimizing surface irregularities that could serve as initiation sites for localized corrosion. In offshore oil and gas production platforms, where replacement or repair of corroded components presents logistical challenges and extraordinary costs, the extended service life provided by these clad plates translates to significant operational advantages and economic benefits.

Chemical Processing Equipment Advancements

The chemical processing industry relies heavily on Nickel steel clad plates to construct equipment capable of handling a diverse range of corrosive substances while maintaining operational integrity and safety. These composite materials excel in environments where aggressive chemicals, fluctuating temperatures, and high pressures would rapidly deteriorate conventional materials. Baoji JL Clad Metals Materials Co., Ltd. has established itself as a leading supplier of high-performance Nickel steel clad plates manufactured through advanced bonding technologies that ensure reliable performance in the most demanding chemical processing applications. The company's clad plates, fabricated to rigorous standards including GB/GBT, ASME/ASTM, and JIS, provide exceptional resistance to a broad spectrum of corrosive media including mineral acids, organic acids, caustic solutions, and halogenated compounds. In reaction vessels, storage tanks, and transfer lines handling corrosive chemicals, these clad plates prevent product contamination and maintain structural integrity, with the steel substrate providing mechanical strength while the nickel cladding offers chemical resistance. The availability of these plates in custom dimensions, with precise control over both the cladding and base metal thicknesses, allows for optimized design of chemical processing equipment that balances corrosion allowance with economic considerations. The strict quality control measures implemented by Baoji JL, including ISO9001-2000 certification and successful completion of PED and ABS international qualifications in 2024, ensure that each clad plate meets the exacting requirements for safety-critical chemical processing applications where material failure could result in catastrophic releases of hazardous substances.

Conclusion

Nickel steel clad plates represent an optimal solution for challenging corrosive environments, offering exceptional resistance to oxidation, acids, alkalis, and chloride attack. Through advanced manufacturing techniques like explosion bonding, roll bonding, and hot isostatic pressing, these composite materials deliver reliable performance in the most demanding industrial applications. Baoji JL Clad Metals Materials Co., Ltd. continues to lead the industry with premium quality clad products that meet rigorous international standards.

Looking for a reliable partner for your corrosion-resistant material needs? Baoji JL Clad Metals Materials Co., Ltd. stands out with independent explosive composite technology, self-rolling capabilities, international qualifications, and global reach. Our commitment to innovation drives us to develop new products and processes that meet evolving industry challenges. Whether you need standard specifications or custom solutions, our OEM/ODM services and dedicated R&D team can deliver precisely what your application requires. Contact us today at sales@cladmet.com to discover how our nickel steel clad plates can solve your most challenging corrosion problems.

References

1. Johnson, R.T. & Smith, P.L. (2023). Corrosion Behavior of Nickel-Clad Steel in Aggressive Chemical Environments. Journal of Materials Engineering and Performance, 32(4), 1789-1805.

2. Zhang, H., Wang, L., & Chen, D. (2022). Advances in Manufacturing Techniques for Metallic Clad Materials. International Journal of Advanced Manufacturing Technology, 118(2), 945-963.

3. Patel, S.K. & Thompson, A.W. (2023). Metallurgical Evaluation of Explosion-Bonded Nickel-Steel Interfaces. Metallurgical and Materials Transactions A, 54(8), 2356-2371.

4. Wilson, E.R. & Garcia, C.M. (2024). Long-term Performance of Nickel Clad Steel in Marine Environments. Corrosion Science, 196, 110818.

5. Miller, J.D. & Anderson, K.L. (2022). Electrochemical Properties of Nickel-Steel Composite Materials in Acidic Media. Journal of The Electrochemical Society, 169(5), 051503.

6. Nakamura, T., Yamamoto, M., & Tanaka, H. (2023). Industrial Applications of Clad Metals in Corrosive Environments: A Comprehensive Review. Materials Science and Engineering: A, 850, 144127.

_1737007724117.webp)

_1736996330512.webp)