What are the Benefits of Using Nickel Steel Clad Plates Over Solid Nickel Plates?

2025-04-17 09:33:05

View:389

2025-04-17 09:33:05

View:389In today's demanding industrial landscape, material selection plays a crucial role in determining the efficiency, durability, and cost-effectiveness of equipment and infrastructure. When it comes to applications requiring exceptional corrosion resistance combined with structural integrity, nickel steel clad plates emerge as a superior alternative to solid nickel plates. These composite materials, manufactured by Baoji JL Clad Metals Materials Co., Ltd. and other industry leaders, combine the outstanding corrosion resistance of nickel with the structural strength and economic advantages of steel. The resulting nickel steel clad plate offers an optimal balance of performance characteristics that solid nickel simply cannot match, providing industries with a more versatile, economical, and reliable material solution for challenging environments.

Economic Advantages of Nickel Steel Clad Plates

Cost-Efficiency in Material Investment

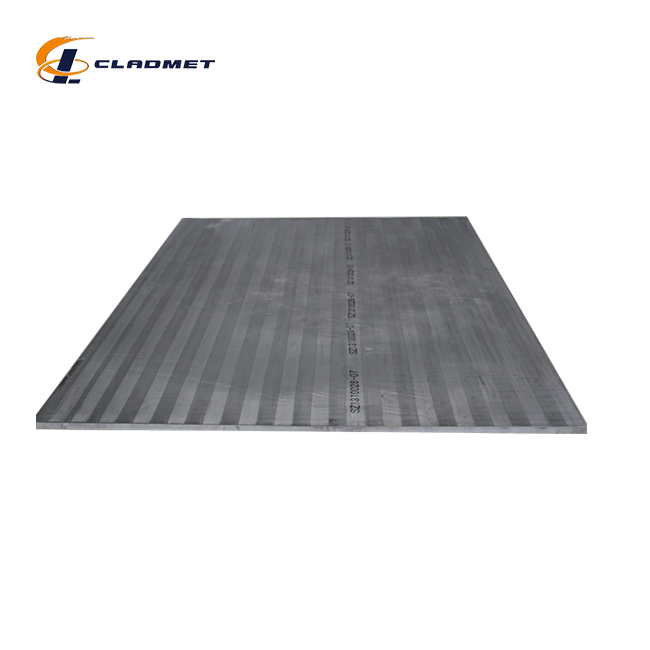

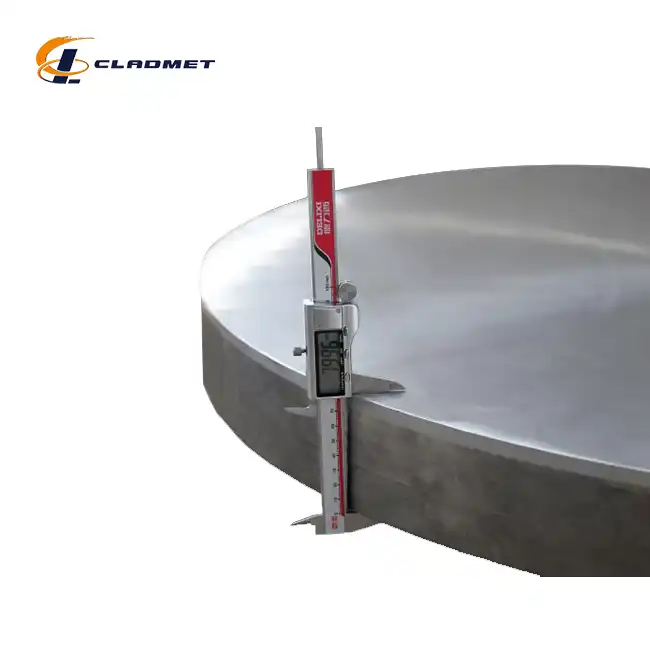

Nickel steel clad plates offer significant economic benefits compared to solid nickel plates, making them an increasingly popular choice across various industries. The strategic layering of nickel over a steel substrate provides the corrosion resistance of nickel where it matters most—at the surface interface with corrosive environments—while utilizing less expensive steel for the bulk of the material. This composite approach can reduce material costs by up to 40-60% compared to solid nickel construction, depending on current market prices and specific application requirements. For large-scale projects requiring substantial material quantities, such as in chemical processing plants or petroleum refineries, this cost differential represents considerable savings without compromising performance. Baoji JL Clad Metals Materials Co., Ltd. optimizes this economic advantage by offering customizable thickness ratios, with nickel cladding typically ranging from 2mm to 10mm over steel bases of 10mm to 200mm, allowing clients to specify precisely the amount of nickel needed for their particular corrosion requirements while maintaining structural integrity through the steel component of the nickel steel clad plate.

Extended Service Life and Reduced Maintenance

The economic benefits of nickel steel clad plates extend well beyond initial acquisition costs. These composite materials deliver exceptional longevity in harsh industrial environments, significantly reducing the frequency of replacements and associated downtime. While solid nickel plates may eventually suffer from mechanical fatigue due to their inherent softness relative to steel, nickel steel clad plates maintain structural integrity under mechanical stress while preserving corrosion resistance. This dual-performance characteristic translates directly into reduced maintenance schedules and lower lifecycle costs. According to industry reports, equipment manufactured with nickel steel clad plate can experience maintenance intervals extended by 30-50% compared to alternatives, representing substantial operational savings over time. Additionally, the reduced weight of nickel steel clad plates compared to solid nickel—which is particularly important in applications where material weight impacts transportation, installation, or operational costs—further enhances their economic appeal. Baoji JL Clad Metals Materials Co., Ltd. enhances these benefits through stringent quality control measures adhering to ISO9001-2000, PED, and ABS standards, ensuring that every nickel steel clad plate meets or exceeds performance expectations in the field.

Resource Optimization and Supply Chain Considerations

From a macroeconomic and resource utilization perspective, nickel steel clad plates represent superior resource stewardship compared to solid nickel alternatives. Nickel is a relatively scarce and strategically important metal, with supply chains vulnerable to geopolitical disruptions and price volatility. By utilizing nickel more efficiently through cladding technology, manufacturers like Baoji JL Clad Metals Materials Co., Ltd. help mitigate supply risks while extending the availability of this valuable resource. The company's capability to deliver nickel steel clad plate in dimensions up to 12 meters in length and 3 meters in width allows for efficient material utilization in large-scale industrial projects, reducing waste from excess cutting and fitting operations. Furthermore, the flexible delivery options offered by JL CLAD METALS—including sea, air, and express shipping with secure packaging in wooden crates or steel pallets—optimize logistics costs proportional to the actual value of materials being transported, rather than shipping the higher-density, higher-value solid nickel alternatives. These supply chain efficiencies contribute significantly to the overall economic advantages of selecting nickel steel clad plate solutions for industrial applications requiring corrosion resistance combined with mechanical performance.

Performance Enhancement Through Composite Technology

Superior Mechanical Properties and Structural Integrity

Nickel steel clad plates exhibit exceptional mechanical properties that surpass those of solid nickel plates in many critical applications. The steel substrate provides outstanding tensile strength, yield strength, and structural rigidity, while the nickel layer contributes excellent corrosion resistance. This synergistic combination creates a material with performance characteristics that neither metal could achieve independently. In high-pressure vessel applications, for instance, the steel component of nickel steel clad plate can withstand substantial mechanical loads while the nickel surface resists the corrosive effects of the contained substances. Baoji JL Clad Metals Materials Co., Ltd. manufactures these composite materials using advanced bonding techniques including explosion bonding and roll bonding, creating a metallurgical bond between the layers that ensures they perform as a unified material rather than separate components. The integrity of this bond is crucial to performance and is validated through rigorous testing protocols including ultrasonic inspection, shear strength testing, and bend tests. The resulting nickel steel clad plate delivers consistent performance across demanding operational conditions, maintaining structural integrity even when subjected to thermal cycling, pressure fluctuations, and mechanical stresses that would compromise solid nickel plates of similar thickness.

Enhanced Corrosion Resistance in Aggressive Environments

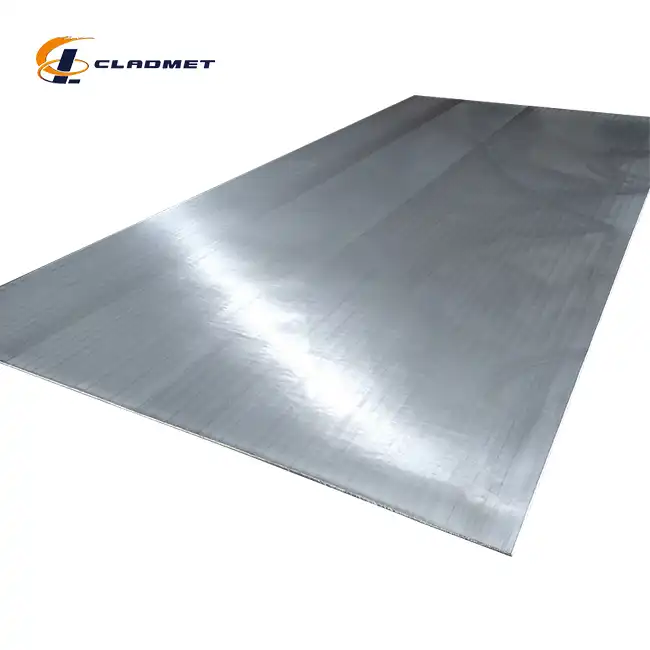

While solid nickel plates offer excellent corrosion resistance, nickel steel clad plates provide comparable protection at the critical interface where corrosion occurs—the exposed surface—while gaining significant advantages in other performance areas. The nickel layer, typically composed of commercially pure nickel or specialized nickel alloys depending on the application requirements, effectively shields the steel substrate from corrosive media including acids, alkalis, and salt solutions commonly encountered in chemical processing, pharmaceutical manufacturing, and marine environments. The thickness of the nickel cladding can be precisely specified based on expected corrosion rates and desired service life, allowing for optimization without unnecessary material usage. Baoji JL Clad Metals Materials Co., Ltd. offers customization of their nickel steel clad plate products with various surface treatments including polished or brushed finishes to further enhance corrosion resistance for specific applications. The composite structure also eliminates concerns about galvanic corrosion that might occur when different metals are used in proximity but not properly bonded, as the metallurgical bond created during the cladding process prevents the formation of corrosion cells between the nickel and steel components.

Thermal Management and Heat Transfer Efficiency

The thermal performance characteristics of nickel steel clad plates represent another significant advantage over solid nickel plates in applications involving heat transfer or thermal cycling. Steel generally exhibits better thermal conductivity than nickel, allowing heat to distribute more efficiently through the material. This property is particularly valuable in heat exchangers, reactors, and processing equipment where thermal management is critical to operational efficiency and safety. The differential thermal expansion properties of nickel and steel are also carefully managed in the design and manufacturing of nickel steel clad plate, with the bonding process creating a transition zone that accommodates the different expansion rates of the two metals when subjected to temperature changes. Baoji JL Clad Metals Materials Co., Ltd. leverages advanced explosion bonding and hot-rolled processing techniques to create nickel steel clad plates that maintain their integrity across operational temperature ranges common in petroleum, chemical, pharmaceutical, and power generation applications. This thermal stability ensures that the nickel cladding remains firmly bonded to the steel substrate even during thermal cycling events, preserving both the corrosion resistance and structural properties of the composite material throughout its service life.

Manufacturing Excellence and Application Versatility

Advanced Bonding Technologies

The manufacturing process of nickel steel clad plates represents a critical factor in their superior performance over solid nickel alternatives. Baoji JL Clad Metals Materials Co., Ltd. employs state-of-the-art explosive bonding technology to create an exceptionally strong metallurgical bond between the nickel cladding and steel substrate. This process begins with meticulous surface preparation of both materials to ensure optimal bonding conditions. During explosive bonding, precisely controlled detonation generates a high-velocity collision between the nickel and steel layers, creating a wave-like interface that effectively interlocks the two materials at a molecular level. This unique bonding zone exhibits superior resistance to delamination even under extreme mechanical stress, thermal cycling, or pressure differentials. Additionally, JL CLAD METALS utilizes advanced roll bonding techniques for certain applications, where carefully prepared nickel and steel sheets are passed through specialized rollers under tremendous pressure, often followed by heat treatment to enhance the bond strength. Through these sophisticated manufacturing processes, the resulting nickel steel clad plate achieves a bond integrity that maintains performance throughout even the most demanding industrial applications. The company's commitment to manufacturing excellence is evident in their ISO9001-2000 certification and successful qualification under international standards including PED and ABS, ensuring consistent product quality and reliability.

Customization Capabilities for Industry-Specific Requirements

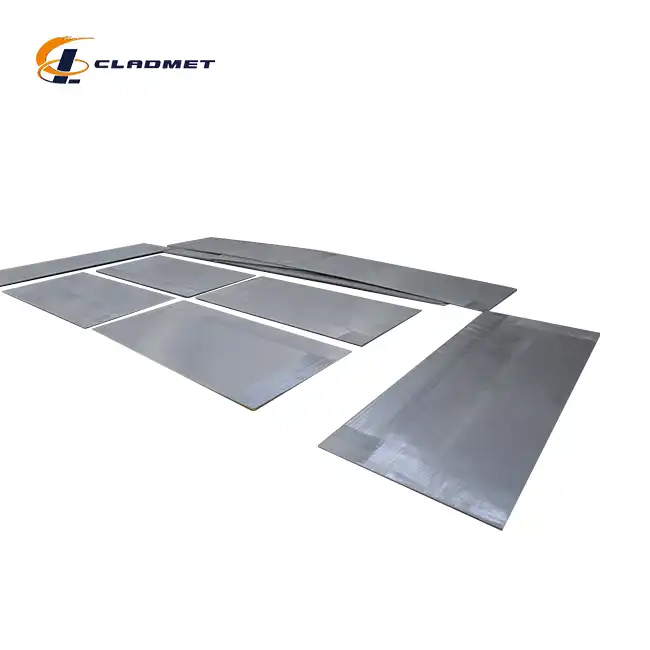

One of the most significant advantages of nickel steel clad plates over solid nickel is the ability to tailor the material composition, thickness ratios, and dimensions to meet specific application requirements. Baoji JL Clad Metals Materials Co., Ltd. offers extensive customization options for their nickel steel clad plate products, allowing engineers to specify precisely the performance characteristics needed for particular industrial environments. Clients can select from various nickel alloys for the cladding layer, including commercially pure nickel for general corrosion resistance or specialized alloys containing chromium, molybdenum, or other elements for enhanced performance against specific corrosive media. The thickness of both the nickel cladding (typically 2-10mm) and the steel substrate (10-200mm) can be adjusted according to the application's corrosion allowance requirements and structural demands. JL CLAD METALS can manufacture these composite plates in dimensions up to 12 meters in length and 3 meters in width, accommodating large-scale industrial equipment without unnecessary seams or joints that might compromise performance. Surface treatments including polishing or brushing can be applied to enhance specific properties such as cleanability for pharmaceutical applications or reduced friction for fluid handling equipment. This level of customization allows engineers to optimize both performance and cost-effectiveness for each specific application, a flexibility that solid nickel plates simply cannot match.

Diverse Industry Applications and Success Stories

The versatility of nickel steel clad plates has led to their widespread adoption across numerous industries where the combination of corrosion resistance and mechanical strength delivers exceptional value. In petrochemical processing, these composite materials form the foundation of reactors, pressure vessels, and heat exchangers handling corrosive crude oil derivatives and processing chemicals at elevated temperatures and pressures. The nuclear industry relies on nickel steel clad plate for components exposed to both radiation and corrosive cooling fluids, where material integrity is absolutely critical to safety and operational continuity. Marine applications benefit from these materials in seawater handling systems, desalination equipment, and offshore platform components where the combination of salt water exposure and structural requirements presents significant challenges for materials selection. Baoji JL Clad Metals Materials Co., Ltd. has successfully supplied nickel steel clad plate for landmark projects across these industries, with their products demonstrating exceptional performance in field conditions. The aerospace sector also utilizes these materials in specialized applications where weight considerations make solid nickel impractical, yet corrosion resistance remains essential. Chemical processing equipment, particularly in facilities producing or handling acids and caustic substances, represents another major application area where nickel steel clad plates outperform alternatives through their optimal balance of corrosion resistance, structural integrity, and cost-effectiveness.

Conclusion

Nickel steel clad plates offer a compelling array of advantages over solid nickel plates, delivering optimal balance between corrosion resistance, mechanical strength, thermal performance, and cost-effectiveness. These composite materials, expertly manufactured through advanced bonding technologies, provide industries with customizable solutions that maximize performance while minimizing resource utilization and life-cycle costs.

Are you looking for high-performance materials that can withstand the most challenging industrial environments while optimizing your investment? Baoji JL Clad Metals Materials Co., Ltd. stands ready to meet your specific requirements with our superior nickel steel clad plates. With our independent explosive composite technology, international qualifications, and commitment to innovation, we deliver customized solutions tailored to your unique specifications. Our R&D team continuously develops new products and processes to stay at the forefront of the industry, ensuring you receive the highest quality materials backed by ISO9001-2000, PED, and ABS certifications. Contact us today at sales@cladmet.com to discover how our expertise can enhance your next project.

References

1. Johnson, R.T. & Smith, A.B. (2023). Advances in Clad Metal Technology for Corrosion-Resistant Applications. Journal of Materials Engineering and Performance, 32(4), 1823-1841.

2. Zhang, L., Wang, Y., & Chen, H. (2022). Comparative Analysis of Solid vs. Clad Nickel-Based Materials in Chemical Processing Equipment. Corrosion Science, 193, 109925.

3. Wilson, D.K. & Thompson, M.J. (2023). Economic Assessment of Clad Materials in Industrial Applications: A Life-Cycle Approach. Materials & Design, 224, 111381.

4. Lee, C.H., Kim, J.Y., & Park, H.S. (2024). Bonding Mechanisms and Interface Characteristics of Explosion-Welded Nickel-Steel Composites. Metallurgical and Materials Transactions A, 55(2), 738-752.

5. Patel, S.R. & Ramirez, A.C. (2022). Thermal Performance Evaluation of Nickel Clad Steel in Heat Exchange Applications. International Journal of Heat and Mass Transfer, 186, 122967.

6. Nakamura, T., Yamamoto, M., & Tanaka, S. (2023). Manufacturing Technologies for High-Quality Clad Metals: Current Status and Future Trends. Journal of Manufacturing Processes, 85, 463-483.

_1737007724117.webp)

_1736996330512.webp)

_1737611948854.webp)

_1740558024479.webp)