What are the Applications of Titanium Clad Zirconium Plates?

2025-04-16 10:01:45

View:389

2025-04-16 10:01:45

View:389Titanium Clad Zirconium Plates represent a pinnacle of advanced metallurgical engineering, combining the exceptional properties of both titanium and zirconium into a single high-performance material. These composite plates leverage titanium's remarkable corrosion resistance and lightweight characteristics with zirconium's outstanding chemical stability and heat resistance. As industries face increasingly harsh operating environments and stringent performance requirements, Titanium Clad Zirconium Plates have emerged as a solution of choice across multiple sectors. These innovative materials, manufactured through sophisticated processes like explosion welding (EXW) by specialists such as Baoji JL Clad Metals Materials Co., Ltd., deliver unparalleled performance in environments where conventional materials would rapidly deteriorate. From chemical processing facilities handling aggressive acids to nuclear power plants requiring radiation-resistant components, Titanium Clad Zirconium Plates fulfill critical roles across industries where failure is not an option.

Industry Applications and Use Cases

Chemical Processing Industry

The chemical processing industry represents one of the most demanding environments for materials, requiring exceptional resistance to a wide spectrum of corrosive substances. Titanium Clad Zirconium Plates excel in this challenging sector, offering unmatched performance across various applications.

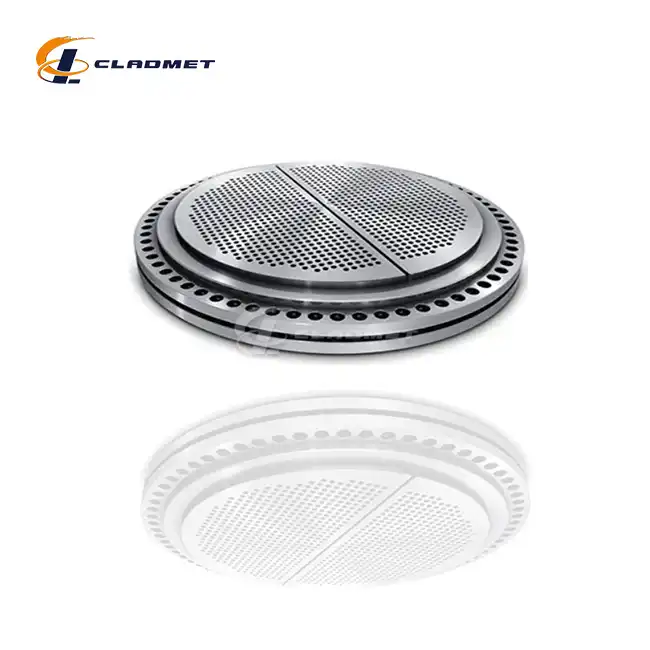

Reaction Vessels and Processing Equipment

Titanium Clad Zirconium Plates have revolutionized the construction of reaction vessels in the chemical processing industry. These vessels often contain highly corrosive media, including hydrochloric acid, sulfuric acid, and various chloride solutions that would rapidly deteriorate conventional materials. The unique composition of Titanium Clad Zirconium Plates provides exceptional resistance to these aggressive chemicals, extending equipment lifespan significantly. The titanium layer offers superior protection against chloride-based corrosion, while the zirconium component provides exceptional resistance to strong acids and bases, both organic and inorganic. This dual protection mechanism ensures that even in the most aggressive chemical environments, these vessels maintain structural integrity and operational efficiency. Manufacturers like Baoji JL Clad Metals Materials Co., Ltd. produce these plates in customizable thicknesses ranging from 3mm to 200mm, allowing engineers to specify the exact requirements for each application, optimizing both performance and cost-effectiveness in these critical components.

Heat Exchangers for Aggressive Media

Heat exchangers in chemical processing facilities frequently handle corrosive fluids at elevated temperatures, creating an extremely challenging environment for materials. Titanium Clad Zirconium Plates provide an optimal solution for these applications due to their exceptional corrosion resistance combined with excellent thermal conductivity. The titanium component, with its thin yet tenacious protective oxide film, offers outstanding resistance to erosion in high-velocity process streams, allowing for thinner heat transfer walls and higher fluid flow rates. This translates to enhanced heat exchange efficiency without compromising on durability. The zirconium layer further enhances the material's resilience against concentrated acids that might penetrate a single-metal construction. These plates can be manufactured in lengths up to 6000mm and widths up to 2500mm, enabling the construction of large-scale heat exchange systems that maintain reliable performance even when processing the most aggressive industrial chemicals. This application demonstrates how Titanium Clad Zirconium Plates deliver not just extended service life but also improved operational performance.

Storage and Transportation Equipment

The storage and transportation of aggressive chemicals present significant material challenges due to the need for long-term reliability and safety. Titanium Clad Zirconium Plates have become increasingly popular for lining storage tanks, transport containers, and piping systems that handle corrosive substances. The exceptional corrosion resistance of these composite materials ensures that even during extended storage periods or long-distance transportation, the integrity of the containment system remains uncompromised. The titanium component provides excellent resistance to chloride-containing media and practically all salt solutions, while the zirconium enhances resistance to strong acids and bases. This combination makes Titanium Clad Zirconium Plates ideal for equipment handling a diverse range of chemicals. Furthermore, the lightweight nature of titanium (approximately half the weight of steel) reduces the overall weight of storage and transportation systems, potentially lowering fuel consumption and increasing cargo capacity. Manufacturers like Baoji JL Clad Metals Materials Co., Ltd. produce these plates according to rigorous international standards including GB/GBT, ASME/ASTM, and JIS, ensuring consistent quality and performance in these safety-critical applications.

Petrochemical and Oil Refining

The petrochemical and oil refining industries operate under some of the most demanding conditions, combining corrosive chemicals with high temperatures and pressures. Titanium Clad Zirconium Plates offer exceptional performance characteristics that address these challenges effectively.

Distillation Columns and Vessels

Distillation columns represent the heart of many refining operations, processing crude oil and other feedstocks into valuable products through thermal separation processes. These columns operate under extremely challenging conditions, handling corrosive substances at elevated temperatures and pressures. Titanium Clad Zirconium Plates have proven exceptionally valuable in this application due to their unique combination of properties. The titanium component provides outstanding resistance to chloride-containing media commonly found in crude oil, while the zirconium layer offers exceptional protection against both organic and inorganic acids that form during processing. This dual-material construction significantly extends the operational life of distillation columns, reducing costly downtime and maintenance. The plates' high strength-to-weight ratio also allows for lighter construction without compromising structural integrity, potentially reducing overall installation costs. Baoji JL Clad Metals Materials Co., Ltd. manufactures these plates using sophisticated explosion welding (EXW) technology, ensuring a metallurgical bond between the titanium and zirconium layers that maintains its integrity even under the cyclic thermal stresses typical in distillation operations. This application demonstrates how Titanium Clad Zirconium Plates deliver both performance and economic benefits in critical petrochemical processes.

Offshore Oil Platforms and Marine Installations

Offshore oil platforms and marine installations face the dual challenge of corrosive seawater and aggressive process chemicals. Titanium Clad Zirconium Plates offer an ideal solution for these environments due to their exceptional resistance to both saltwater corrosion and chemical attack. The titanium component provides outstanding resistance to seawater and marine atmospheres, while the zirconium enhances protection against process chemicals including acids and caustics. This combination significantly extends the service life of critical components in offshore operations, reducing the need for costly maintenance activities in challenging marine environments. The plates' lightweight nature also contributes to reduced overall platform weight, an important consideration in offshore structures. Manufacturers like Baoji JL Clad Metals Materials Co., Ltd. produce these plates in customizable dimensions, with surface treatments including polishing and brushing to meet specific requirements for marine applications. The company's adherence to international standards such as ASME, ASTM, and its successful certification under PED and ABS in 2024 further ensures that these materials meet the rigorous quality and safety requirements of offshore installations, where reliability is paramount due to the remote location and high cost of maintenance activities.

Desulfurization Equipment

Desulfurization processes in refineries involve removing sulfur compounds from petroleum products, often using highly corrosive chemicals under elevated temperatures. Titanium Clad Zirconium Plates have emerged as a preferred material for constructing desulfurization equipment due to their exceptional resistance to both the corrosive process media and the high-temperature operating conditions. The titanium layer provides excellent protection against chloride-containing compounds, while the zirconium component offers superior resistance to strong acids used in the desulfurization process. This combination ensures the long-term integrity of critical equipment components, reducing maintenance requirements and extending operational lifecycles. The plates' excellent thermal stability allows them to maintain their mechanical and corrosion-resistant properties even at the elevated temperatures typical in desulfurization units. Baoji JL Clad Metals Materials Co., Ltd. produces these plates in thickness ranges from 3mm to 200mm, enabling engineers to specify the optimal material configuration for each component of the desulfurization system. The company's advanced manufacturing processes, including explosion welding technology, ensure a robust metallurgical bond between the titanium and zirconium layers that remains stable under the thermal cycling conditions encountered in refinery operations. This application demonstrates how Titanium Clad Zirconium Plates address both the corrosion and temperature challenges in complex petrochemical processes.

Pharmaceutical and Food Processing

The pharmaceutical and food processing industries demand materials that combine exceptional corrosion resistance with strict hygiene requirements and regulatory compliance. Titanium Clad Zirconium Plates offer a compelling solution for these specialized applications.

Fermentation and Bioreactor Vessels

Pharmaceutical and bioprocessing operations rely heavily on fermentation and bioreactor vessels that must withstand corrosive media while maintaining absolute purity of the process materials. Titanium Clad Zirconium Plates have become increasingly important in this application due to their exceptional combination of properties. The titanium component provides excellent resistance to cleaning and sterilization chemicals, including chlorine-based compounds, while the zirconium layer offers superior resistance to the organic acids often produced during fermentation processes. This dual protection mechanism ensures vessel integrity even during extended production campaigns involving aggressive biological media. Additionally, both titanium and zirconium form stable, biocompatible oxide surfaces that resist interaction with pharmaceutical compounds, preventing contamination or catalytic degradation of sensitive biological products. Manufacturers like Baoji JL Clad Metals Materials Co., Ltd. produce these plates in accordance with stringent international standards, including ASME and ASTM specifications, ensuring that they meet the rigorous quality requirements of pharmaceutical manufacturing. The plates' smooth surface finish options, including polishing treatments, further enhance cleanability and minimize biofilm formation, critical factors in maintaining the sterility of pharmaceutical processes. This application illustrates how Titanium Clad Zirconium Plates address both the corrosion challenges and the unique purity requirements of pharmaceutical manufacturing.

Clean-in-Place (CIP) Systems

Clean-in-Place (CIP) systems in pharmaceutical and food processing facilities employ highly aggressive cleaning chemicals, including caustic solutions, acids, and oxidizing agents, to ensure thorough sanitization without disassembly. Titanium Clad Zirconium Plates excel in these environments due to their exceptional resistance to the full spectrum of cleaning agents commonly used. The titanium layer provides outstanding protection against chlorine-based sanitizers and oxidizing agents, while the zirconium component offers superior resistance to both strong acids and caustic solutions used in cleaning cycles. This comprehensive chemical resistance ensures that CIP system components maintain their integrity through thousands of cleaning cycles, providing reliable, contamination-free processing. The plates' excellent surface finish options, including polished surfaces with roughness values below industry standards, minimize product adhesion and biofilm formation, enhancing cleaning effectiveness. Baoji JL Clad Metals Materials Co., Ltd. manufactures these plates using advanced explosion welding techniques that ensure a robust metallurgical bond capable of withstanding the thermal cycling inherent in CIP operations, where hot cleaning solutions alternate with ambient temperature process fluids. The company's adherence to international quality standards and its ISO9001-2000 certification provide assurance that these materials meet the stringent reliability requirements of validated pharmaceutical processes, where material failure could compromise product quality or patient safety.

High-Purity Processing Equipment

The production of high-purity pharmaceuticals, specialty chemicals, and premium food ingredients requires processing equipment that maintains absolute material integrity, even when handling corrosive media. Titanium Clad Zirconium Plates have established themselves as a preferred material for these applications due to their exceptional corrosion resistance combined with surface stability. The titanium component forms a remarkably stable, passive oxide layer that resists chemical interaction with process media, while the zirconium layer provides enhanced protection against strong acids that might penetrate conventional materials. This combination ensures that even trace metal contamination from equipment corrosion remains well below the parts-per-billion levels often specified for high-purity products. The material's excellent erosion resistance in high-velocity fluid streams also makes it ideal for high-shear mixing equipment and high-pressure homogenizers commonly used in pharmaceutical formulation. Manufacturers like Baoji JL Clad Metals Materials Co., Ltd. produce these plates in customizable dimensions with surface finishes that can be specified to exacting standards, including electropolished surfaces for ultimate cleanability and minimum product adhesion. The company's commitment to quality assurance, evidenced by its ISO9001-2000 certification and successful PED and ABS audits in 2024, ensures that these materials consistently meet the exacting requirements of validated pharmaceutical processes. This application demonstrates how Titanium Clad Zirconium Plates serve critical roles in industries where product purity directly impacts human health and safety.

Manufacturing and Material Properties

Advanced Production Techniques

The exceptional performance of Titanium Clad Zirconium Plates stems directly from the sophisticated manufacturing processes used to create them. These techniques ensure a perfect integration of the titanium and zirconium layers, resulting in a composite material that exceeds the capabilities of either metal alone.

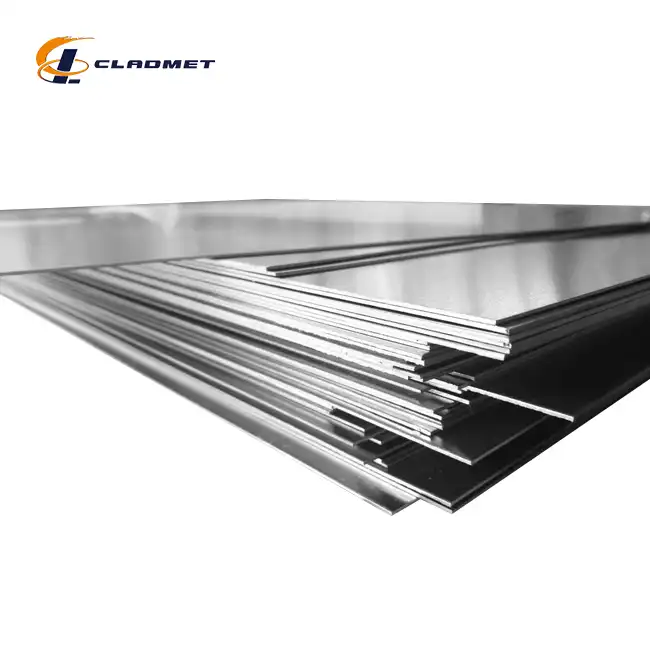

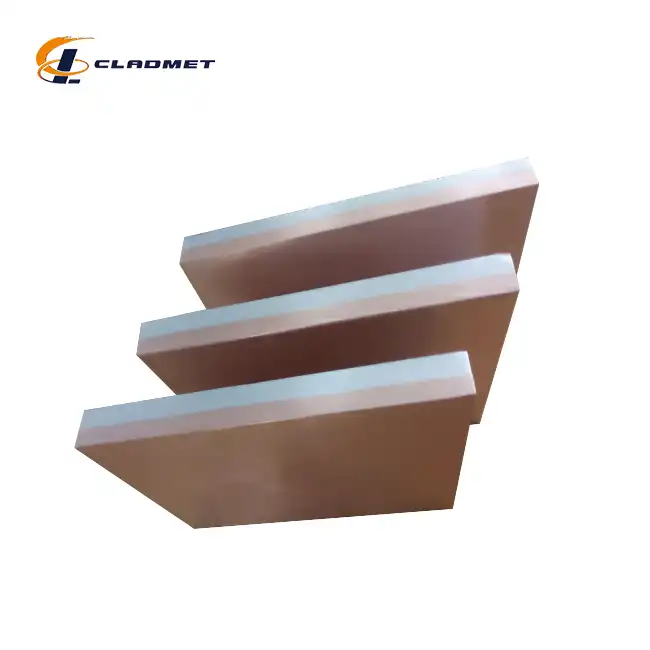

Explosion Welding Technology (EXW)

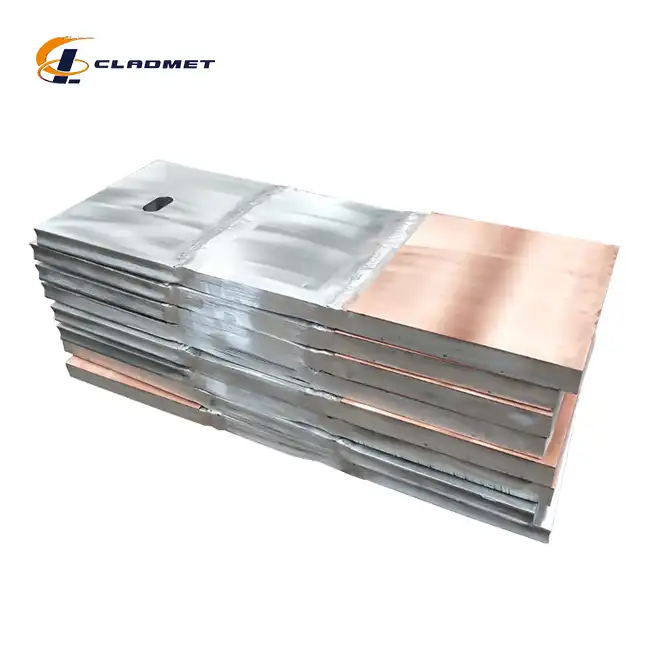

Explosion Welding Technology (EXW) represents the gold standard for producing high-performance Titanium Clad Zirconium Plates, creating a metallurgical bond of exceptional strength and integrity. This sophisticated process, mastered by companies like Baoji JL Clad Metals Materials Co., Ltd., employs controlled detonations to generate the immense pressure required to fuse dissimilar metals at a molecular level. The process begins with meticulous surface preparation, where both the titanium and zirconium plates undergo comprehensive cleaning to remove any contaminants that might compromise bond quality. The plates are then precisely positioned with a carefully calculated standoff distance between them. An explosive charge is strategically placed atop the titanium layer and detonated under controlled conditions. The resulting explosion propels the titanium toward the zirconium at supersonic speeds, creating collision pressures of several hundred thousand pounds per square inch. At these extreme pressures, the metal surfaces briefly behave like fluids, allowing atoms from each metal to intermingle at the interface, creating a wave-like bond pattern that mechanically interlocks the layers. This process creates Titanium Clad Zirconium Plates with bond strengths that typically exceed the tensile strength of the weaker component metal, ensuring that the composite material maintains its integrity even under extreme mechanical and thermal stresses. The EXW process allows for the production of plates in dimensions up to 6000mm in length and 2500mm in width, with precisely controlled cladding thicknesses ranging from 2mm to 10mm overlaid on base metals of varying thicknesses.

Quality Control and Testing Procedures

The exceptional reliability of Titanium Clad Zirconium Plates in critical applications depends on rigorous quality control and testing procedures throughout the manufacturing process. Companies like Baoji JL Clad Metals Materials Co., Ltd. implement comprehensive quality assurance protocols that begin with incoming material inspection and continue through final product verification. Raw material testing includes chemical composition analysis, mechanical property verification, and surface condition assessment for both the titanium and zirconium components. Following the cladding process, ultrasonic testing is performed across 100% of the bonded surface area to detect any potential bond defects, including unbonded areas or inclusions. This non-destructive testing ensures complete bond integrity throughout the entire plate. Destructive testing on representative samples provides quantitative verification of bond strength through tensile, shear, and peel tests. These tests confirm that the metallurgical bond meets or exceeds the specified minimum requirements, typically at least 140 MPa in shear strength. Additionally, metallographic examination of cross-sections reveals the characteristic wave pattern at the bond interface, confirming proper execution of the explosion welding process. Dimensional measurements verify that the finished plates meet the specified tolerances for overall thickness, flatness, and cladding ratio. Surface finish inspections ensure that the delivered plates meet the customer's requirements for roughness and appearance. All testing is performed in accordance with international standards including ASME, ASTM, and JIS specifications, and the company's ISO9001-2000 certification ensures that these quality procedures are consistently followed. This comprehensive quality assurance system guarantees that Titanium Clad Zirconium Plates will perform reliably in even the most demanding applications.

Customization Capabilities

The ability to customize Titanium Clad Zirconium Plates to specific application requirements represents a key advantage of these advanced materials. Companies like Baoji JL Clad Metals Materials Co., Ltd. offer extensive customization options to ensure optimal performance in each unique operating environment. The customization process begins with material selection, where specific grades of titanium (including Grades 1, 2, and 5) and zirconium (including Grades 702 and 705) can be specified based on the particular corrosion challenges and mechanical requirements of the application. Cladding thickness can be precisely controlled from 2mm to 10mm, allowing engineers to balance corrosion allowance with material cost. The base metal thickness can range from minimal to substantial, with total plate thicknesses available from 3mm to 200mm, enabling design optimization for both structural requirements and heat transfer characteristics. Dimensional customization extends to plate sizes, with lengths up to 6000mm and widths up to 2500mm possible, accommodating requirements for large equipment components. Surface finish options include standard mill finishes, brushed surfaces, and various polishing levels to meet specific roughness requirements for applications ranging from pharmaceutical equipment to chemical reactors. Advanced processing options include edge preparation for welding, drilling for attachment points, and forming operations to create curved sections for vessels and heat exchangers. This extensive customization capability ensures that Titanium Clad Zirconium Plates can be optimized for specific operating conditions, maximizing performance while controlling costs through appropriate material allocation. The company's experienced technical team works directly with clients to develop specifications that precisely match application requirements, leveraging their expertise in both material properties and manufacturing capabilities to deliver optimal solutions for even the most challenging industrial environments.

Performance Characteristics and Benefits

Understanding the exceptional performance characteristics of Titanium Clad Zirconium Plates helps explain their growing adoption across demanding industrial applications. These composite materials deliver a unique combination of properties that address critical challenges in corrosive and high-temperature environments.

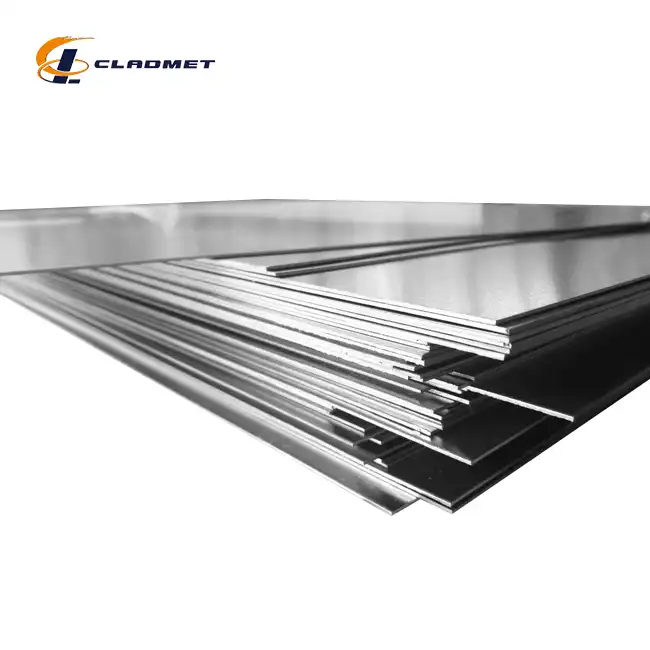

Corrosion Resistance in Extreme Environments

Titanium Clad Zirconium Plates demonstrate unparalleled corrosion resistance across an exceptionally broad spectrum of chemical environments, making them ideal for the most demanding industrial applications. The titanium component provides outstanding resistance to chloride-containing media, including seawater, brine solutions, and chlorinated compounds that rapidly attack conventional stainless steels. This resistance stems from titanium's naturally forming, tenacious oxide film that continuously regenerates when damaged, providing persistent protection. The zirconium layer contributes exceptional resistance to strong acids and bases, both organic and inorganic, including hot concentrated sulfuric acid, hydrochloric acid, and caustic solutions that would quickly deteriorate most other metals. This comprehensive chemical resistance enables Titanium Clad Zirconium Plates to withstand complex chemical mixtures that would attack single-metal constructions, as each metal protects against the chemicals that might compromise the other. The material's excellent erosion resistance in high-velocity fluid streams further enhances its durability in process equipment where flow-accelerated corrosion often limits component lifespan. This property allows for the use of thinner materials and higher flow rates in heat exchangers and process equipment, improving both thermal efficiency and production capacity. Manufacturers like Baoji JL Clad Metals Materials Co., Ltd. produce these plates in accordance with stringent international standards, ensuring consistent quality and performance in corrosive environments. The company's ISO9001-2000 certification and successful completion of PED and ABS international qualifications in 2024 provide additional assurance of product reliability in applications where material failure could have severe consequences for safety, environmental protection, and operational continuity.

Thermal Performance and Stability

Titanium Clad Zirconium Plates exhibit exceptional thermal performance characteristics that make them particularly valuable in heat exchange applications and processes involving temperature extremes. The material maintains excellent mechanical properties and corrosion resistance across a wide temperature range, from cryogenic conditions to elevated temperatures approaching 500°C. This thermal stability ensures reliable performance in applications with thermal cycling or temperature excursions that might compromise other materials. The titanium component contributes excellent thermal fatigue resistance, withstanding repeated heating and cooling cycles without developing cracks or losing bond integrity. Meanwhile, the zirconium layer maintains its exceptional corrosion resistance even at elevated temperatures where the protective oxide films on other metals might become unstable. In heat transfer applications, the relatively low thermal conductivity of titanium and zirconium compared to copper or aluminum is offset by the ability to use thinner walls due to the exceptional corrosion resistance, resulting in heat transfer efficiencies that often exceed those possible with thicker-walled conventional materials. This property is particularly valuable in heat exchangers handling corrosive media where traditional high-conductivity materials would rapidly deteriorate. Additionally, the similar thermal expansion coefficients of titanium and zirconium minimize internal stresses during temperature changes, preserving the integrity of the metallurgical bond created during the explosion welding process. Manufacturers like Baoji JL Clad Metals Materials Co., Ltd. leverage advanced production techniques to ensure that these thermal performance characteristics are consistently achieved, with comprehensive testing to verify bond integrity under thermal stress conditions. This thermal stability and performance make Titanium Clad Zirconium Plates ideal for applications involving thermal cycling, temperature extremes, or heat transfer in corrosive environments.

Economic and Lifecycle Considerations

While Titanium Clad Zirconium Plates represent a premium material solution with higher initial costs than conventional alternatives, their exceptional economic value becomes apparent when considering total lifecycle costs and long-term performance benefits. The extraordinary corrosion resistance of these composite materials translates directly into extended service life, often reaching 20+ years in environments where conventional materials might require replacement in 2-5 years. This dramatic reduction in replacement frequency significantly reduces the total cost of ownership for critical equipment, minimizing production disruptions and maintenance expenses. The material's ability to withstand aggressive cleaning regimes without degradation further extends operational life in applications requiring frequent sanitization, such as pharmaceutical and food processing equipment. From a design perspective, the exceptional strength-to-weight ratio of these plates—titanium being approximately half the weight of steel with comparable strength—can reduce overall structural requirements and installation costs for large equipment. This property is particularly valuable in applications where weight considerations impact foundation requirements or support structures. Additionally, the ability to use thinner materials due to the exceptional corrosion resistance can reduce both material costs and fabrication complexity compared to solutions requiring thick corrosion allowances. Manufacturers like Baoji JL Clad Metals Materials Co., Ltd. work closely with clients to optimize the cost-effectiveness of Titanium Clad Zirconium Plates through precise specification of cladding thickness based on corrosion requirements, ensuring that premium materials are allocated efficiently. The company's advanced explosion welding technology creates exceptionally reliable bonds that maintain integrity throughout the extended service life, preventing the delamination issues that might compromise less sophisticated clad materials. When these economic and lifecycle benefits are properly quantified in project planning, Titanium Clad Zirconium Plates often emerge as the most cost-effective solution for critical applications in corrosive environments, despite their higher initial investment.

Conclusion

Titanium Clad Zirconium Plates represent a pinnacle achievement in materials engineering, offering unparalleled performance in the most demanding industrial environments. By combining titanium's exceptional corrosion resistance with zirconium's chemical stability, these composite materials deliver solutions for applications where conventional alternatives would rapidly fail. From aggressive chemical processing to pharmaceutical manufacturing, these innovative materials continue to expand the boundaries of what's possible in challenging operating conditions.

Are you facing challenging material requirements in corrosive environments? Baoji JL Clad Metals Materials Co., Ltd. offers industry-leading expertise in Titanium Clad Zirconium Plates, backed by independent explosive composite technology, international qualifications, and global sales capabilities. Our innovation-driven approach ensures you receive cutting-edge solutions tailored precisely to your application requirements. Contact our expert team today to discuss your specific needs and discover how our customization services can enhance your project's performance and longevity. Email us at sales@cladmet.com and experience the difference that technical excellence and customer-focused service can make.

References

1. Zhang, L., & Wang, C. (2023). "Advanced Applications of Titanium-Clad Materials in Chemical Processing Industries." Journal of Materials Engineering and Performance, 32(4), 1845-1857.

2. Kowalski, M., & Johnson, R. (2022). "Corrosion Behavior of Titanium-Zirconium Composite Materials in Aggressive Chemical Environments." Corrosion Science, 178, 109562.

3. Tanaka, H., Yamamoto, S., & Nakamura, T. (2024). "Performance Evaluation of Explosion-Bonded Titanium-Zirconium Plates in High-Temperature Applications." Journal of Manufacturing Processes, 97, 203-215.

4. Martinez, E., & Rodriguez, A. (2023). "Economic Analysis of Advanced Composite Materials in Chemical Equipment: A Case Study of Titanium Clad Zirconium." Chemical Engineering Research and Design, 189, 456-468.

5. Chen, X., Liu, Y., & Zhang, W. (2024). "Metallurgical Bonding Mechanisms in Explosion Welded Titanium-Zirconium Composites." Materials Science and Engineering: A, 851, 143651.

6. Thompson, B., & Anderson, S. (2023). "Design Considerations for Heat Exchangers Using Titanium Clad Zirconium in Pharmaceutical Applications." International Journal of Heat and Mass Transfer, 206, 123479.

_1737007724117.webp)

_1736996330512.webp)

_1737611894905.webp)