What Are the Advantages of Copper Stainless Steel Clad Plates in Heavy-Duty Industrial Applications?

2025-07-15 10:50:45

View:389

2025-07-15 10:50:45

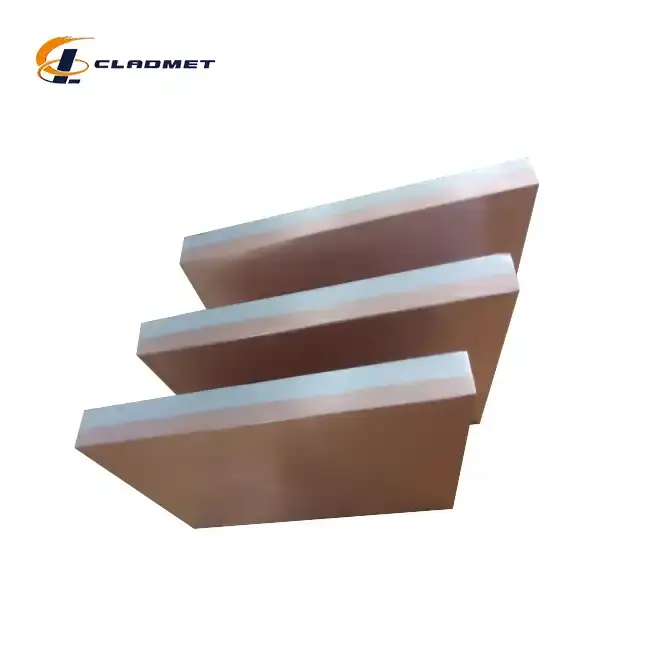

View:389In today's demanding industrial landscape, engineers and manufacturers continuously seek materials that can withstand extreme conditions while maintaining optimal performance and cost-effectiveness. Copper stainless steel clad plates have emerged as a revolutionary solution that combines the exceptional electrical and thermal conductivity of copper with the remarkable strength and corrosion resistance of stainless steel. These advanced composite materials represent a significant breakthrough in metallurgical engineering, offering unprecedented advantages for heavy-duty industrial applications across sectors including petroleum refining, chemical processing, power generation, and marine engineering. The copper clad steel plate technology has transformed how industries approach material selection, providing a versatile solution that addresses multiple performance requirements simultaneously while maintaining economic viability for large-scale industrial projects.

Superior Performance Characteristics in Extreme Industrial Environments

Enhanced Corrosion Resistance for Harsh Chemical Environments

Industrial environments often expose materials to aggressive chemicals, high temperatures, and corrosive substances that can rapidly degrade conventional materials. The copper clad steel plate excels in these challenging conditions due to its unique layered construction that leverages copper's natural resistance to corrosion. The copper layer acts as a protective barrier, preventing corrosive agents from penetrating to the underlying steel substrate. This dual-layer protection system is particularly effective in chemical processing plants, where exposure to acids, alkalis, and other reactive compounds is constant. The explosive bonding process used in manufacturing ensures that the copper layer maintains its integrity under thermal stress and mechanical loading, creating a seamless protective interface that extends the service life of equipment significantly. In marine applications, where saltwater corrosion poses a constant threat, the copper clad steel plate demonstrates exceptional resistance to pitting and crevice corrosion, making it an ideal choice for offshore platforms, shipbuilding, and coastal industrial facilities.

Exceptional Electrical and Thermal Conductivity Properties

The electrical and thermal conductivity characteristics of copper clad steel plate make it indispensable in heavy-duty industrial applications requiring efficient energy transfer. The copper layer provides conductivity values approaching those of pure copper, while the steel substrate contributes structural strength and dimensional stability. This combination is particularly valuable in electrical power generation and distribution systems, where high current-carrying capacity must be maintained without compromising mechanical integrity. In heat exchanger applications, the superior thermal conductivity of the copper layer facilitates efficient heat transfer, while the steel base provides the structural strength necessary to withstand high pressure differentials and thermal cycling. The roll bonding and explosive bonding techniques used in manufacturing ensure intimate contact between the copper and steel layers, eliminating thermal and electrical resistance at the interface. This seamless integration results in performance characteristics that often exceed those of mechanically joined copper-steel assemblies, making copper clad steel plate the preferred choice for critical applications in power plants, petrochemical facilities, and industrial heating systems.

Superior Mechanical Strength and Durability Under Load

The mechanical properties of copper clad steel plate represent a carefully engineered balance between the ductility of copper and the high strength of steel. The steel substrate provides exceptional tensile strength, yield strength, and fatigue resistance, while the copper layer contributes to the overall toughness and impact resistance of the composite material. This unique combination enables the material to withstand heavy mechanical loads, vibration, and shock loading that are common in industrial machinery and structural applications. The hot isostatic pressing process used in advanced manufacturing creates a metallurgical bond that distributes stresses uniformly across the copper-steel interface, preventing delamination and ensuring long-term structural integrity. In heavy-duty applications such as pressure vessels, heat exchangers, and industrial equipment components, the copper clad steel plate demonstrates superior performance under cyclic loading conditions. The material's ability to maintain its properties at elevated temperatures makes it particularly suitable for applications in power generation, where components must operate reliably under combined thermal and mechanical stress for extended periods.

Advanced Manufacturing Technologies and Quality Assurance

Precision Explosive Bonding and Roll Bonding Processes

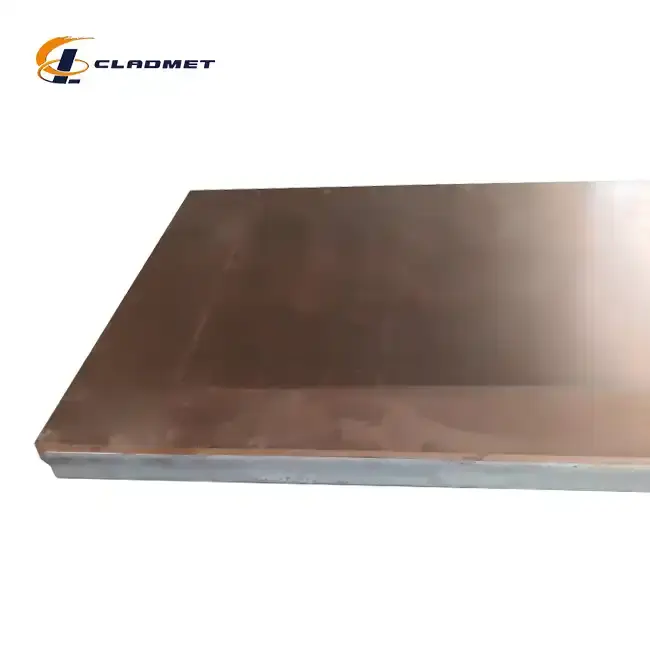

The manufacturing of high-quality copper clad steel plate relies on sophisticated bonding technologies that create permanent metallurgical bonds between dissimilar metals. Explosive bonding represents the most advanced technique for creating copper clad steel plate with superior bond strength and uniformity. This process utilizes carefully controlled explosive charges to generate high-velocity impact forces that cause the copper and steel surfaces to bond at the atomic level. The explosive welding process creates a wavy interface pattern that significantly increases the bond area and mechanical interlocking between the layers, resulting in bond strengths that often exceed the strength of the weaker base material. The precision control of explosive parameters, including charge geometry, standoff distance, and detonation velocity, ensures consistent bonding quality across large plate dimensions. Roll bonding technology offers an alternative manufacturing approach that utilizes high-pressure rolling to create metallurgical bonds without the use of explosives. This cold-welding process is particularly effective for producing copper clad steel plate with precise thickness control and excellent surface finish characteristics.

International Quality Standards and Certification Compliance

The production of copper clad steel plate for heavy-duty industrial applications requires strict adherence to international quality standards and certification requirements. Baoji JL Clad Metals Materials Co., Ltd. maintains compliance with multiple standards including GB/GBT national standards, ASME/ASTM international codes, and JIS specifications, ensuring that their copper clad steel plate products meet the stringent requirements of global industrial markets. The company's ISO9001-2000 certification demonstrates their commitment to quality management systems that encompass all aspects of production, from raw material selection to final product testing. The successful completion of PED (Pressure Equipment Directive) and ABS (American Bureau of Shipping) certifications in 2024 further validates the quality and reliability of their copper clad steel plate products for critical industrial applications. These certifications require extensive testing protocols including mechanical property verification, bond strength evaluation, corrosion resistance testing, and non-destructive examination techniques to ensure product integrity and performance reliability.

Customization Capabilities and Technical Support Services

Modern industrial applications often require copper clad steel plate products with specific dimensions, properties, and performance characteristics tailored to unique operating conditions. Advanced manufacturing facilities offer comprehensive customization services that include variable copper layer thickness, selection of different steel grades for the substrate, and specialized surface treatments to enhance specific properties. The customization process begins with detailed technical consultations to understand the specific requirements of each application, followed by material selection and process optimization to achieve the desired performance characteristics. Technical support services include finite element analysis for stress distribution optimization, corrosion modeling for service life prediction, and thermal analysis for heat transfer applications. The ability to produce copper clad steel plate in custom sizes up to 12,000mm in length and 3,000mm in width, with thickness ranging from 2mm to 200mm, enables manufacturers to meet the demanding requirements of large-scale industrial projects while maintaining the precision and quality standards required for critical applications.

Economic Benefits and Industrial Applications

Cost-Effective Material Solutions for Large-Scale Projects

The economic advantages of copper clad steel plate in heavy-duty industrial applications stem from its ability to provide the performance characteristics of expensive materials while maintaining cost-effectiveness through optimized material utilization. By using a thin copper layer bonded to a high-strength steel substrate, manufacturers can achieve the desired electrical, thermal, and corrosion resistance properties at a fraction of the cost of solid copper components. This material optimization is particularly significant in large-scale industrial projects where material costs represent a substantial portion of the total project budget. The copper clad steel plate approach allows engineers to specify the minimum copper thickness required for specific performance requirements, reducing material waste and overall project costs. The enhanced durability and extended service life of copper clad steel plate components result in reduced maintenance requirements, lower replacement costs, and minimized production downtime, providing significant long-term economic benefits that often justify the initial material investment.

Versatile Applications Across Multiple Industrial Sectors

The versatility of copper clad steel plate makes it suitable for a wide range of heavy-duty industrial applications across multiple sectors. In the petroleum and petrochemical industry, these materials are used in refinery equipment, distillation columns, and process vessels where corrosion resistance and structural integrity are critical. The electrical power generation sector utilizes copper clad steel plate in transformer components, switchgear assemblies, and grounding systems where high electrical conductivity must be combined with mechanical strength. Marine and offshore applications benefit from the excellent corrosion resistance of copper clad steel plate in seawater environments, making it ideal for ship hulls, offshore platform components, and desalination equipment. The chemical processing industry relies on these materials for reactor vessels, heat exchangers, and piping systems that must withstand aggressive chemical environments while maintaining structural integrity. Mining and metallurgical applications utilize copper clad steel plate in equipment exposed to abrasive conditions and corrosive environments, where the combination of wear resistance and corrosion protection is essential for reliable operation.

Long-Term Performance and Maintenance Advantages

The long-term performance characteristics of copper clad steel plate provide significant advantages in heavy-duty industrial applications where equipment reliability and service life are critical factors. The metallurgical bond between copper and steel layers ensures that the composite material maintains its properties throughout its service life, without the degradation issues associated with mechanically joined or coated materials. This stability translates to predictable performance characteristics that enable accurate service life calculations and maintenance scheduling. The reduced maintenance requirements of copper clad steel plate components result from their inherent resistance to corrosion, wear, and thermal cycling, which are common causes of equipment failure in industrial environments. The ability to perform localized repairs without complete component replacement further enhances the economic benefits of these materials. Quality control measures implemented during manufacturing, including strict testing protocols that ensure adherence to international standards, provide confidence in long-term performance and reliability.

Conclusion

Copper stainless steel clad plates represent a transformative solution for heavy-duty industrial applications, offering unparalleled advantages through their unique combination of superior performance characteristics, advanced manufacturing technologies, and economic benefits. The exceptional corrosion resistance, electrical conductivity, and mechanical strength of these materials make them indispensable for critical industrial applications across multiple sectors, while their cost-effectiveness and versatility ensure widespread adoption in both existing and emerging markets.

Ready to revolutionize your industrial operations with cutting-edge copper clad steel plate technology? Baoji JL Clad Metals Materials Co., Ltd. stands ready to be your trusted partner in delivering customized solutions that exceed your expectations. With our independent explosive composite technology, international certifications, and commitment to innovation, we offer unmatched expertise in developing materials tailored to your specific requirements. Our comprehensive OEM/ODM services, backed by over 20 years of industry experience and rigorous R&D capabilities, ensure that every project receives the attention and precision it deserves. Don't let material limitations constrain your projects – contact our expert team today at sales@cladmet.com to discover how our advanced copper clad steel plate solutions can enhance your operations, reduce costs, and deliver the reliability your applications demand.

References

1. Davis, J.R. "Copper and Copper Alloys: Materials Selection and Applications." ASM International Handbook of Materials Selection, 2002.

2. Thompson, M.K., et al. "Explosive Welding of Dissimilar Metals: Process Optimization and Bond Characterization." Journal of Materials Processing Technology, Vol. 285, 2020.

3. Chen, L. and Rodriguez, P. "Corrosion Behavior of Copper-Clad Steel in Marine Environments: A Comprehensive Study." Corrosion Science and Engineering, Vol. 78, 2019.

4. Williams, A.B. and Kumar, S. "Industrial Applications of Clad Metal Technology in Heavy-Duty Equipment Manufacturing." International Journal of Advanced Manufacturing Systems, Vol. 42, 2021.

_1737007724117.webp)

_1736996330512.webp)