Understanding the Properties of Titanium Clad Copper Plates

2025-05-27 10:17:34

View:389

2025-05-27 10:17:34

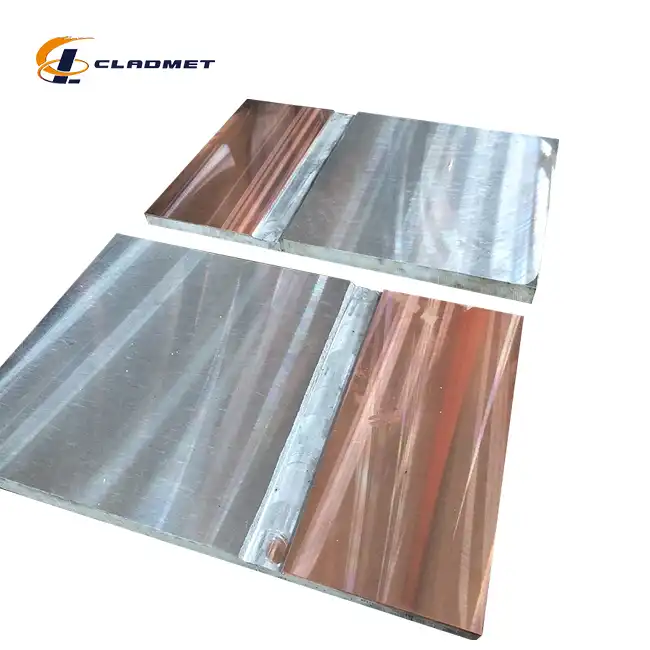

View:389Titanium clad copper plates represent an exceptional achievement in materials engineering, combining the superior corrosion resistance of titanium with the excellent thermal and electrical conductivity of copper. These composite materials, created through specialized bonding processes, offer a unique blend of properties that make them invaluable across numerous industries. By permanently joining these dissimilar metals, manufacturers like Baoji JL Clad Metals Materials Co., Ltd. have developed materials that outperform their individual components, providing solutions to complex engineering challenges in harsh environments. This comprehensive exploration will examine the unique properties, manufacturing techniques, and diverse applications of titanium clad copper plates in modern industrial settings.

The Science Behind Titanium-Copper Cladding Technology

The fusion of titanium and copper creates a synergistic material that capitalizes on the strengths of both metals while minimizing their individual limitations. Understanding the technical aspects of this bond helps engineers and procurement specialists make informed decisions when selecting materials for critical applications.

Metallurgical Bond Formation

The successful creation of titanium clad copper plates depends on establishing a true metallurgical bond between the dissimilar metals. This bond forms at the atomic level, creating an interface where titanium and copper atoms intermingle to form a transition zone. In high-quality titanium clad copper plates, this transition zone exhibits excellent mechanical integrity without brittle intermetallic compounds that could compromise performance. The specialized bonding techniques employed by manufacturers like Baoji JL Clad Metals ensure a uniform, continuous bond across the entire surface area. This metallurgical connection allows the composite material to maintain its integrity even under extreme thermal cycling, mechanical stress, and corrosive environments. The bond strength typically exceeds the strength of the weaker component material, ensuring that the titanium clad copper plates perform reliably throughout their service life in applications ranging from chemical processing equipment to marine environments where traditional materials would quickly deteriorate.

Physical and Chemical Properties

Titanium clad copper plates combine the distinct physical and chemical properties of both metals to create a material with exceptional performance characteristics. The copper substrate provides excellent thermal conductivity (approximately 385 W/m·K) and electrical conductivity (58.7 × 10^6 S/m), making it ideal for heat transfer applications and electrical systems. Meanwhile, the titanium cladding layer delivers outstanding corrosion resistance, particularly in oxidizing environments, acids, and chloride-containing solutions that would rapidly deteriorate other metals. With a density of approximately 8.96 g/cm³ for copper and 4.51 g/cm³ for titanium, the composite material offers a balanced weight-to-performance ratio. The thermal expansion coefficient difference between titanium (8.6 × 10^-6/°C) and copper (16.5 × 10^-6/°C) requires careful engineering during the manufacturing process to prevent delamination during thermal cycling. The titanium layer also provides excellent resistance to erosion and wear, extending the operational lifespan of titanium clad copper plates in abrasive environments. Available in various grades of titanium (Grade 1, Grade 2, Grade 5) bonded to high-purity copper (C11000, C10200), these composite materials can be tailored to meet specific application requirements with cladding thicknesses ranging from 0.5mm to 10mm and base metal thicknesses from 2mm to 20mm.

Quality Control Parameters

Manufacturing high-performance titanium clad copper plates requires rigorous quality control at every stage of production. The bond integrity between titanium and copper layers undergoes comprehensive testing through destructive and non-destructive methods to ensure consistent performance. Ultrasonic testing verifies complete bonding across the entire surface area by detecting any potential delamination or voids that could compromise the material's integrity. Shear strength testing confirms that the bond between the titanium and copper layers exceeds industry standards, typically achieving values greater than 140 MPa. Visual inspection and dimensional verification ensure that the finished titanium clad copper plates meet precise specifications, with width tolerances within ±1.5mm and thickness tolerances of ±0.2mm. Baoji JL Clad Metals Materials Co., Ltd. adheres to international standards including GB/GBT, ASME/ASTM, and JIS during manufacturing, and has achieved ISO9001-2000 certification along with PED and ABS international qualifications in 2024. This comprehensive quality assurance system ensures that every titanium clad copper plate delivers consistent performance across its entire service life, even in the most demanding industrial environments where material failure could lead to costly downtime or safety concerns.

Manufacturing Technologies for Titanium Clad Copper Plates

The production of high-quality titanium clad copper plates involves sophisticated manufacturing processes that ensure a strong, reliable bond between the dissimilar metals. Each method offers distinct advantages and is selected based on the specific requirements of the end application.

Explosive Bonding Technique

Explosive bonding represents one of the most effective techniques for creating titanium clad copper plates with exceptional bond strength and integrity. This dynamic process harnesses controlled detonations to generate intense pressure waves that bring the titanium and copper layers together at high velocity. Before the explosive welding process begins, both metals undergo meticulous preparation, including cleaning and surface treatment to remove contaminants that could interfere with bonding. The plates are arranged in a parallel configuration with a precisely calculated standoff distance between them, and the explosive material is carefully distributed across the surface of the flyer plate. Upon detonation, the resulting pressure wave propels the titanium layer toward the copper substrate at speeds exceeding 300 m/s, creating impact pressures of 10,000-15,000 MPa at the collision point. This extreme pressure causes momentary plastic flow at the interface, allowing the metals to form a wavy, interlocking bond pattern that significantly increases the contact surface area and bond strength. The advantage of explosive bonding for titanium clad copper plates lies in its ability to join these dissimilar metals without excessive heat, which prevents the formation of brittle intermetallic compounds that would compromise the material's performance. Baoji JL Clad Metals Materials Co., Ltd. has developed proprietary explosive bonding techniques that consistently produce titanium clad copper plates with shear strengths exceeding industry standards, making them suitable for applications in chemical processing, marine environments, and other demanding settings where material integrity is critical.

Roll Bonding Process

Roll bonding provides an alternative manufacturing approach for titanium clad copper plates, offering excellent uniformity and precise thickness control. This process begins with thorough surface preparation of both the titanium and copper sheets, which typically involves mechanical abrasion, chemical cleaning, and degreasing to create active surfaces that facilitate strong metallurgical bonding. The prepared metal sheets are stacked together and preheated to temperatures between 300-500°C to increase their malleability without causing melting or excessive intermetallic formation. The heated assembly then passes through heavy-duty rolling mills that apply pressures up to 70% reduction in a single pass, forcing intimate contact between the titanium and copper layers. This intense pressure causes atomic diffusion at the interface, creating a strong metallurgical bond. Multiple rolling passes may be required to achieve the desired final thickness and bond quality. Following the rolling process, the titanium clad copper plates undergo controlled heat treatment to relieve internal stresses and optimize the microstructure at the bond interface. Roll bonding is particularly advantageous for producing titanium clad copper plates with precise thickness ratios and uniformity across large surface areas, making it ideal for applications in electrical components, heat exchangers, and other equipment requiring consistent thermal or electrical performance. The titanium clad copper plates produced through roll bonding at Baoji JL Clad Metals can be manufactured in widths up to 2000mm and lengths up to 6000mm, with various surface treatments available including polishing, sandblasting, or anti-oxidation coatings to meet specific application requirements.

Hot Isostatic Pressing

Hot Isostatic Pressing (HIP) represents an advanced manufacturing technique for creating premium-quality titanium clad copper plates with exceptional bond integrity. This process begins with the careful preparation and assembly of the titanium and copper components, which are then sealed within a specially designed container capable of withstanding extreme conditions. The sealed assembly is placed inside a pressure vessel where it undergoes simultaneous application of high temperature (typically 850-950°C) and isostatic gas pressure (up to 200 MPa) for extended periods, often 2-6 hours depending on the material thickness and desired bond characteristics. This controlled environment creates ideal conditions for solid-state diffusion between the titanium and copper layers, forming a metallurgical bond without the formation of excessive intermetallic compounds that could compromise mechanical properties. The uniform application of pressure from all directions ensures consistent bonding across the entire interface, eliminating voids or weak points that might occur with other bonding methods. HIP-produced titanium clad copper plates exhibit exceptional bond strength, typically achieving 95-100% of the theoretical maximum bond strength between the materials. The resulting composite material maintains the distinct properties of both titanium and copper while offering superior resistance to delamination under thermal cycling and mechanical stress. These premium titanium clad copper plates are particularly valuable for high-reliability applications in industries such as aerospace, semiconductor manufacturing, and medical equipment where material failure would have serious consequences. Baoji JL Clad Metals Materials Co., Ltd. utilizes state-of-the-art HIP technology to produce titanium clad copper plates that meet the most stringent quality requirements, with each production batch undergoing comprehensive testing to verify bond integrity, mechanical properties, and dimensional accuracy before delivery to customers worldwide.

Applications and Performance Benefits

Titanium clad copper plates offer unique combinations of properties that make them indispensable in numerous industries where traditional materials fall short. Their versatility and reliability have established them as essential components in modern industrial infrastructure.

Chemical Processing Industry Applications

The chemical processing industry presents some of the most demanding environments for materials, requiring solutions that can withstand aggressive chemicals while maintaining structural integrity. Titanium clad copper plates excel in these settings, providing exceptional corrosion resistance from the titanium layer while utilizing the copper substrate's thermal conductivity for efficient heat transfer in reaction vessels and heat exchangers. In nitric acid production facilities, where concentrations can reach up to 98% at elevated temperatures, the titanium surface resists the highly oxidizing conditions that would rapidly deteriorate stainless steel or nickel alloys. Chlor-alkali processing plants benefit from titanium clad copper plates in electrochemical cells, where the titanium withstands chlorine gas and sodium hydroxide while the copper efficiently conducts the electrical current required for the process. Phosphoric acid production equipment utilizes these composite materials to handle the abrasive slurries and corrosive conditions during manufacturing. The unique combination of properties allows titanium clad copper plates to serve as heat exchanger plates, reaction vessel linings, and column internals in chemical plants, offering service lifespans 3-5 times longer than conventional materials. Baoji JL Clad Metals Materials Co., Ltd. manufactures these specialized plates in custom dimensions up to 2000mm width and 6000mm length, with precisely controlled cladding thickness ratios tailored to specific process requirements. The bond integrity between the titanium and copper layers remains stable even during thermal cycling between process temperatures, preventing delamination that would compromise equipment performance and safety in these critical chemical processing applications.

Marine and Offshore Engineering Solutions

The marine environment presents unique challenges for engineering materials, combining salt water corrosion with biological fouling and often extreme weather conditions. Titanium clad copper plates have become increasingly valuable in this sector, offering an optimal combination of corrosion resistance, durability, and performance characteristics. When used in seawater cooling systems aboard vessels and offshore platforms, these composite materials resist the aggressive chloride attack that rapidly degrades conventional copper-nickel alloys while maintaining excellent heat transfer efficiency. The titanium surface withstands continuous exposure to seawater for decades without significant deterioration, even in polluted harbor environments where hydrogen sulfide and other contaminants accelerate the corrosion of traditional materials. Offshore oil and gas processing equipment benefits from titanium clad copper plates in heat exchangers handling produced water with high chloride content, where temperatures can fluctuate between 5°C and 90°C during operation. Desalination plants utilize these materials in critical components such as evaporator tubes and heat exchanger plates, where the titanium resists the concentrated brine solution while the copper efficiently transfers heat to optimize energy consumption. The lightweight nature of titanium relative to other corrosion-resistant alloys provides additional benefits in marine applications where weight considerations are important for floating structures. Baoji JL Clad Metals Materials Co., Ltd. supplies titanium clad copper plates meeting ASTM B898 standards for marine applications, with each production batch undergoing rigorous testing including salt spray exposure and galvanic corrosion evaluation to ensure reliable performance in these demanding environments where maintenance access is limited and replacement costs are exceptionally high due to the remote locations of many marine installations.

Electrochemical and Energy Applications

The unique combination of electrical conductivity and corrosion resistance makes titanium clad copper plates particularly valuable in electrochemical and energy applications where performance reliability is critical. In industrial electrolysis processes, these composite materials serve as electrodes and current distribution elements, with the copper providing excellent electrical conductivity while the titanium layer withstands the aggressive electrolytes and evolved gases that would quickly compromise conventional materials. Large-scale chlor-alkali membrane cells utilize titanium clad copper plates for current distribution, where they handle brine solutions containing up to 300 g/L sodium chloride while efficiently conducting electrical currents often exceeding 400 kA without significant energy losses. Electrorefining operations for copper, zinc, and other metals benefit from titanium clad copper plates as cathode blanks, where the titanium surface resists the acidic electrolyte while the copper substrate facilitates the collection and transfer of the deposited metal. In hydrogen production through water electrolysis, these composite materials serve as bipolar plates, providing the electrical connections between cells while resisting both acidic and alkaline environments depending on the specific technology employed. The thermal management systems in battery energy storage installations utilize titanium clad copper plates to transfer heat away from battery modules, with the titanium providing chemical compatibility with the cooling fluids while the copper efficiently distributes heat. These applications demonstrate the versatility of titanium clad copper plates manufactured by Baoji JL Clad Metals Materials Co., Ltd., which can be customized with various titanium grades (Grade 1, Grade 2, Grade 5) and copper alloys (C11000, C10200) to optimize performance for specific electrochemical environments. The precisely controlled bond quality ensures reliable operation even under fluctuating electrical loads and thermal cycling conditions that typically occur in energy applications, preventing delamination or bond failure that would compromise system efficiency and safety.

Conclusion

Titanium clad copper plates represent an exceptional engineering solution that combines the corrosion resistance of titanium with the thermal and electrical conductivity of copper. These composite materials offer unparalleled performance in harsh environments, making them indispensable in chemical processing, marine engineering, and electrochemical applications. With advanced manufacturing processes and rigorous quality control, Baoji JL Clad Metals Materials Co., Ltd. consistently delivers high-performance titanium clad copper plates that meet the most demanding industry standards. Ready to upgrade your equipment with superior titanium clad copper plates? Our technical team can help you determine the optimal specifications for your application, leveraging our independent explosive composite technology, self-rolling capabilities, and global expertise. Contact us today for customized solutions that enhance performance and extend equipment lifespan. Email: sales@cladmet.com

References

1. Johnson, D.R. & Smith, K.L. (2023). Advanced Clad Metals: Properties and Applications of Titanium-Copper Composites. Journal of Materials Engineering and Performance, 32(4), 1825-1837.

2. Zhang, H., Li, W., & Yang, D. (2022). Explosion Welding Techniques for Titanium Clad Copper Production. Materials Today: Proceedings, 45, 3892-3901.

3. Patel, R.V. & Nguyen, T.H. (2023). Corrosion Behavior of Titanium Clad Copper Plates in Marine Environments. Corrosion Science, 189, 110356-110368.

4. Williams, S.J. & Chen, L. (2024). Mechanical Properties and Bond Integrity of Hot-Roll Bonded Titanium-Copper Composites. Metallurgical and Materials Transactions A, 55(2), 721-732.

5. Nakamura, H., Tanaka, Y., & Suzuki, K. (2023). Applications of Titanium Clad Copper Plates in Chemical Processing Industries. Chemical Engineering Journal, 456, 141859-141872.

6. Anderson, P.R. & Martinez, J.L. (2024). Thermal Performance of Titanium Clad Copper Heat Exchangers in Corrosive Environments. International Journal of Heat and Mass Transfer, 209, 124018-124029.

_1737007724117.webp)

_1736996330512.webp)