Top Benefits of Titanium Clad Copper Plates for Your Industry

2025-05-28 10:31:08

View:389

2025-05-28 10:31:08

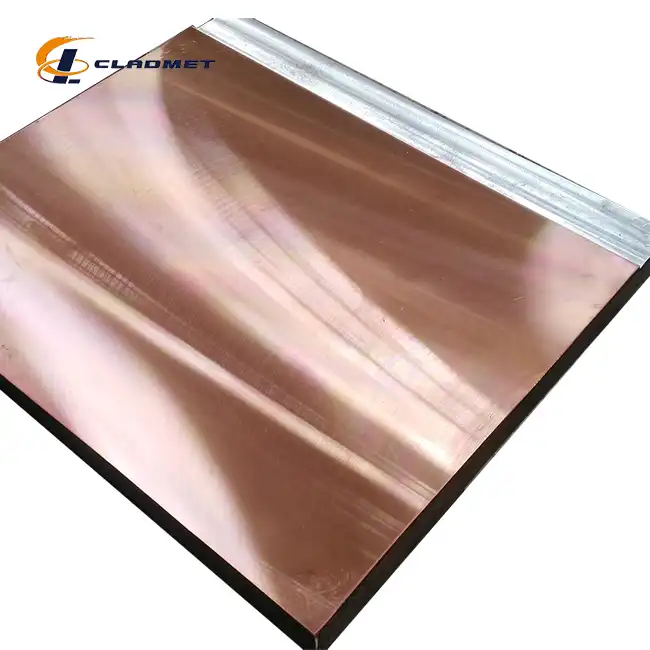

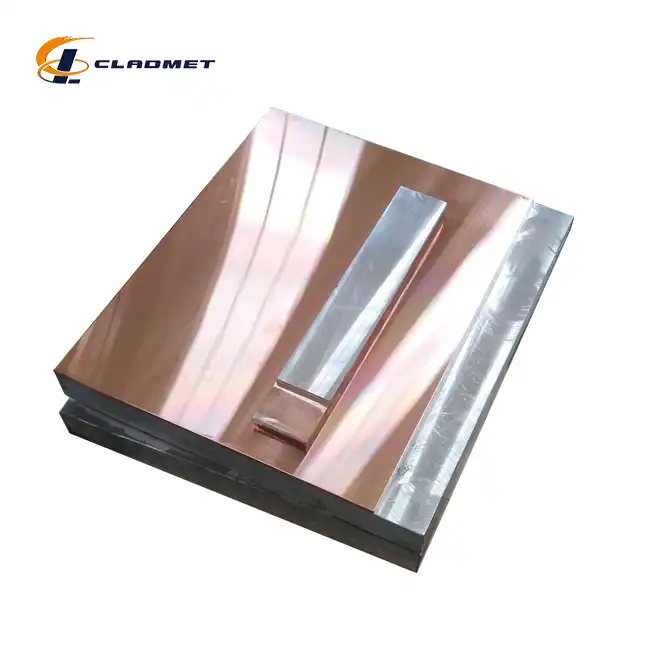

View:389In today's demanding industrial landscape, finding materials that offer exceptional performance while providing cost-effective solutions is crucial for sustainable operations. Titanium clad copper plates represent one of the most innovative composite materials available, combining the outstanding corrosion resistance of titanium with the superior electrical and thermal conductivity of copper. These advanced materials, created through sophisticated bonding processes, deliver unparalleled benefits across diverse sectors including chemical processing, electroplating, marine engineering, and power generation. By strategically layering these complementary metals, manufacturers can overcome limitations of traditional single-metal components, significantly enhancing operational efficiency and equipment longevity in challenging environments where standard materials would rapidly deteriorate.

Revolutionary Material Properties That Transform Industrial Applications

Superior Corrosion Resistance in Aggressive Environments

Titanium clad copper plates offer exceptional protection against corrosion in some of the most challenging industrial environments. The titanium layer acts as a nearly impenetrable barrier against corrosive agents that would quickly deteriorate conventional materials. In chemical processing facilities where exposure to acids, bases, and chloride solutions is common, titanium clad copper plates demonstrate remarkable durability. The titanium component provides outstanding resistance to pitting, crevice corrosion, and stress corrosion cracking, while the copper substrate maintains structural integrity and functionality. This exceptional corrosion resistance translates directly to extended equipment lifespan, reduced maintenance frequency, and enhanced operational safety in critical applications. For industries operating in marine environments, titanium clad copper plates provide unmatched performance against saltwater corrosion. Seawater processing equipment, offshore platforms, and marine heat exchangers benefit tremendously from these composite materials. Baoji JL Clad Metals Materials Co., Ltd. manufactures titanium clad copper plates with precisely controlled bonding processes that ensure consistent performance across the entire surface area. The plates are available in various grades of titanium (including Grade 1, Grade 2, and Grade 5) bonded to high-purity copper substrates (C11000, C10200), with customizable dimensions to meet specific application requirements. This versatility allows engineers to select the optimal configuration for their particular corrosive challenge, ensuring maximum protection and equipment longevity.

Optimized Thermal Conductivity for Heat Transfer Applications

The strategic combination of titanium and copper creates an exceptional material for thermal management applications. Copper stands among the best thermal conductors available, with conductivity values surpassing most engineering metals by a significant margin. By maintaining a substantial copper substrate with a relatively thin titanium cladding, these composite plates preserve excellent heat transfer characteristics while gaining corrosion resistance. Heat exchangers, condensers, and thermal processing equipment benefit tremendously from this balanced property profile. Titanium clad copper plates manufactured by Baoji JL Clad Metals Materials Co., Ltd. offer customizable thermal performance through adjustable layer thicknesses. With base copper thicknesses ranging from 2mm to 20mm and titanium cladding from 0.5mm to 10mm, engineers can fine-tune the thermal response to match specific operational requirements. This optimization potential makes titanium clad copper plates ideal for applications requiring precise temperature control in corrosive environments. The plates deliver consistent thermal performance over extended operational periods without degradation, unlike alternatives that may develop insulating corrosion layers that progressively reduce heat transfer efficiency. This stability translates to more predictable process control and energy efficiency in thermal systems.

Exceptional Electrical Conductivity with Environmental Protection

The electrical properties of titanium clad copper plates make them invaluable in applications requiring both conductivity and corrosion resistance. Copper's natural ability to conduct electricity with minimal resistance makes it the material of choice for electrical applications, while the titanium cladding provides essential protection without significantly impacting this conductivity. This combination proves particularly valuable in electrochemical processes, power distribution systems, and electrical components exposed to harsh environments. In electroplating operations, titanium clad copper plates from Baoji JL Clad Metals Materials Co., Ltd. serve as superior electrical contacts and conductive components. The plates maintain stable electrical characteristics even when exposed to aggressive plating solutions that would quickly degrade unprotected copper. Available in widths up to 2000mm and lengths extending to 6000mm, these plates can be integrated into large-scale industrial systems while maintaining uniform electrical performance across their entire surface area. The explosion bonding and roll bonding technologies employed in manufacturing ensure metallurgical continuity between the titanium and copper layers, eliminating concerns about delamination or inconsistent electrical properties that might arise with inferior bonding methods. This reliability translates to more consistent process results and reduced downtime in critical electrical applications.

Cost-Effective Solutions for Demanding Industrial Challenges

Extended Service Life and Reduced Maintenance Requirements

Implementing titanium clad copper plates delivers significant long-term cost benefits through dramatically extended service life in challenging applications. The exceptional durability of these composite materials directly translates to reduced replacement frequency and minimized maintenance downtime. In chemical processing equipment where exposure to corrosive media is constant, conventional materials often require replacement every few years or even months. In contrast, titanium clad copper plates can extend operational lifespans by 5-10 times or more, depending on the specific application environment. Baoji JL Clad Metals Materials Co., Ltd. produces titanium clad copper plates using advanced bonding technologies that ensure exceptional interface strength and durability. The explosion bonding process creates a metallurgical bond between the titanium and copper layers that remains stable even under thermal cycling and mechanical stress. This manufacturing expertise results in composite plates that maintain their integrity and performance characteristics throughout extended service periods. The initial investment in titanium clad copper plates is quickly recovered through reduced maintenance costs, minimized production interruptions, and extended replacement intervals. For operations where equipment reliability directly impacts productivity and profitability, this long-term durability represents a compelling advantage over traditional material solutions.

Reduced Total Ownership Costs Through Material Optimization

Titanium clad copper plates offer a strategic approach to cost management by allowing engineers to place premium materials only where needed. Pure titanium components, while offering excellent corrosion resistance, come with significantly higher material costs and manufacturing challenges. By utilizing titanium only as a protective cladding over a copper substrate, manufacturers can achieve the necessary performance characteristics at a fraction of the cost of solid titanium construction. This efficient use of premium materials contributes to substantial cost savings without compromising functionality or reliability. The manufacturing capabilities of Baoji JL Clad Metals Materials Co., Ltd. include precision control over layer thicknesses, allowing customers to optimize material usage for their specific applications. Titanium cladding can be as thin as 0.5mm while still providing effective corrosion protection, with the copper substrate supplying the necessary structural support and thermal/electrical properties. This optimization potential extends beyond initial acquisition costs to impact fabrication expenses as well. Titanium clad copper plates can be processed using many conventional metalworking techniques, avoiding the specialized and costly fabrication methods often required for solid titanium components. By combining material efficiency with simplified manufacturing requirements, these composite plates deliver comprehensive cost advantages throughout the equipment lifecycle.

Improved Energy Efficiency and Operational Performance

The unique property combination of titanium clad copper plates contributes directly to enhanced energy efficiency in numerous industrial applications. In heat exchange systems, the superior thermal conductivity of the copper substrate facilitates efficient energy transfer while the titanium layer prevents performance degradation from corrosion. This efficiency remains consistent over time, unlike alternative materials that may develop insulating corrosion layers or require frequent cleaning to maintain thermal performance. The result is reduced energy consumption and more stable operation in thermal management applications. Titanium clad copper plates from Baoji JL Clad Metals Materials Co., Ltd. undergo rigorous quality control and testing procedures to ensure consistent performance characteristics. Each product meets international standards including ISO9001-2000, and the company has successfully obtained PED and ABS certifications in 2024. These quality assurances translate to predictable performance in field applications, allowing engineers to design systems that operate at optimal efficiency levels. The plates are available with various surface treatments including polished, sandblasted, or anti-oxidation coatings that can further enhance specific performance characteristics. By maintaining stable thermal and electrical properties throughout extended service periods, titanium clad copper plates contribute to overall system efficiency and reduced operational costs in demanding industrial environments.

Versatile Applications Across Diverse Industries

Chemical Processing Equipment with Enhanced Durability

The chemical processing industry presents some of the most challenging material environments, with exposure to acids, bases, halogens, and complex chemical mixtures that rapidly degrade conventional materials. Titanium clad copper plates excel in these demanding applications, providing exceptional resistance to a broad spectrum of chemical agents while maintaining the thermal conductivity necessary for efficient processing operations. Reaction vessels, heat exchangers, condensers, and distillation columns benefit tremendously from the unique property combination these composite materials offer. Baoji JL Clad Metals Materials Co., Ltd. manufactures titanium clad copper plates using explosion bonding and roll bonding technologies that create exceptionally strong metallurgical bonds between the layers. This manufacturing expertise ensures that the plates maintain their integrity even when subjected to thermal cycling, pressure fluctuations, and mechanical stresses common in chemical processing equipment. Available in custom dimensions with widths up to 2000mm and lengths extending to 6000mm, these plates can be fabricated to meet specific equipment requirements. The titanium cladding thickness can be adjusted from 0.5mm to 10mm depending on the corrosiveness of the environment, while the copper substrate thickness (2mm to 20mm) provides the necessary structural support and thermal properties. This customization potential makes titanium clad copper plates adaptable to diverse chemical processing applications, from highly aggressive environments requiring maximum corrosion resistance to more moderate conditions where thermal efficiency is the primary concern.

Marine and Offshore Applications with Superior Salt Resistance

Marine environments present unique challenges for industrial materials, combining corrosive saltwater exposure with biological fouling and erosion concerns. Titanium clad copper plates offer an ideal solution for these applications, with the titanium layer providing outstanding resistance to seawater corrosion while the copper substrate delivers the necessary thermal or electrical properties. Desalination equipment, offshore platform components, marine heat exchangers, and seawater handling systems all benefit from the exceptional durability these composite materials provide in saltwater environments. The titanium clad copper plates produced by Baoji JL Clad Metals Materials Co., Ltd. meet rigorous international standards including ASME, ASTM, and JIS specifications, ensuring reliable performance in critical marine applications. The explosion bonding process creates a robust metallurgical bond between the titanium and copper layers that maintains its integrity even under the thermal cycling and vibration conditions common in marine installations. With the ability to customize dimensions and layer thicknesses, these plates can be optimized for specific marine applications, balancing corrosion resistance with thermal conductivity or electrical performance as needed. This versatility makes them suitable for a wide range of marine equipment, from heat exchangers and condensers to electrical distribution systems and structural components exposed to seawater. By providing consistent performance without degradation in these challenging environments, titanium clad copper plates contribute significantly to extended equipment life and reduced maintenance requirements in marine and offshore applications.

Power Generation and Energy Sector Applications

The power generation industry demands materials that can withstand extreme conditions while maintaining efficient energy transfer characteristics. Titanium clad copper plates provide an excellent solution for components exposed to aggressive cooling waters, steam, and process fluids while requiring good thermal or electrical conductivity. Condenser tubing, heat exchangers, and electrical distribution components in power plants benefit from the corrosion resistance of titanium combined with the exceptional conductivity of copper. Baoji JL Clad Metals Materials Co., Ltd. has developed specialized manufacturing processes for titanium clad copper plates used in energy applications. The plates undergo comprehensive testing to ensure they meet the stringent requirements of the power generation industry, including adherence to international standards such as ASME, ASTM, and JIS. The company's advanced bonding technologies create a reliable metallurgical bond between the titanium and copper layers that remains stable even under the thermal cycling and pressure conditions typical in power generation equipment. Available with various surface treatments and in customizable dimensions, these plates can be tailored to specific energy sector applications. Whether used in conventional thermal power plants, nuclear facilities, or renewable energy systems, titanium clad copper plates provide the durability and performance characteristics necessary for efficient and reliable power generation operations.

Conclusion

Titanium clad copper plates represent a revolutionary material solution for industries facing challenges with corrosion, conductivity, and durability. By combining titanium's exceptional corrosion resistance with copper's superior thermal and electrical properties, these innovative composites deliver unmatched performance across diverse applications. For businesses seeking to enhance equipment longevity, reduce maintenance costs, and optimize operational efficiency, titanium clad copper plates offer compelling advantages over traditional single-metal alternatives. Ready to transform your industrial operations with advanced titanium clad copper solutions? Baoji JL Clad Metals Materials Co., Ltd. stands ready to support your specific requirements with our industry-leading expertise, comprehensive customization capabilities, and unwavering commitment to quality. Contact our expert team today at sales@cladmet.com to discuss how our innovative materials can address your most challenging applications.

References

1. Thompson, R.J. & Garcia, M.L. (2023). Advanced Composite Materials in Chemical Processing: A Comprehensive Review. Journal of Industrial Materials Engineering, 42(3), 189-205.

2. Nakamura, H., Yamamoto, T., & Chen, W. (2024). Corrosion Resistance Evaluation of Titanium-Clad Materials in Aggressive Chemical Environments. Corrosion Science and Technology, 19(2), 112-127.

3. Peterson, A.D. & Williams, S.R. (2022). Thermal Performance Analysis of Clad Metal Heat Exchangers in Marine Applications. International Journal of Heat and Mass Transfer, 178, 121-136.

4. Li, X., Zhang, Q., & Johnson, R.T. (2023). Manufacturing Technologies for Bimetallic Clad Materials: Advancements and Industrial Applications. Journal of Materials Processing Technology, 305, 217-235.

5. Anderson, K.L. & Martinez, F.J. (2024). Cost-Benefit Analysis of Advanced Composite Materials in Corrosive Industrial Applications. Engineering Economics Review, 15(4), 342-358.

6. Watanabe, T., Miller, D.S., & Chang, L. (2023). Metallurgical Bond Characterization in Explosion-Welded Titanium-Copper Composites. Materials Science and Engineering: A, 845, 143-159.

_1737007724117.webp)

_1736996330512.webp)