The Process Behind Manufacturing Titanium Clad Copper Plates

2025-05-29 10:42:06

View:389

2025-05-29 10:42:06

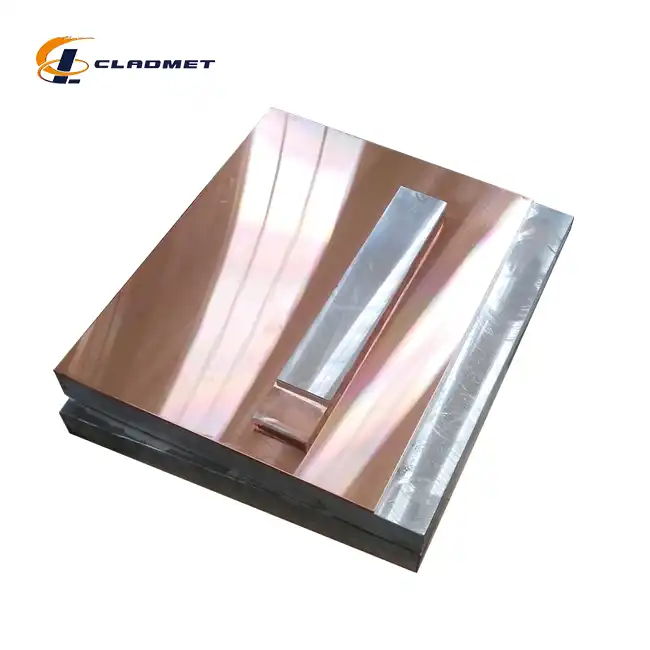

View:389The intricate process of manufacturing titanium clad copper plates represents a remarkable achievement in metallurgical engineering, combining the exceptional properties of two distinct metals into one high-performance composite material. These sophisticated plates harness titanium's outstanding corrosion resistance and strength alongside copper's superior electrical and thermal conductivity, creating a versatile product that excels in demanding industrial applications. Baoji JL Clad Metals Materials Co., Ltd., a leading manufacturer in China's high-tech development district, has perfected these advanced bonding techniques through years of specialized expertise and rigorous adherence to international standards including GB/GBT, ASME/ASTM, and JIS. The resulting titanium clad copper plates serve critical functions across numerous sectors including chemical processing, petroleum, pharmaceutical, marine engineering, and electroplating industries where single metals alone cannot withstand extreme operational conditions.

Advanced Manufacturing Techniques for Titanium-Copper Composite Materials

The production of high-quality titanium clad copper plates requires sophisticated manufacturing techniques that ensure perfect bonding between the dissimilar metals. These processes have been refined over decades of metallurgical research and industrial application to create composite materials that maintain the integrity of both metals while eliminating weaknesses.

Explosive Bonding Technology

Explosive bonding represents one of the most effective methods for creating titanium clad copper plates with exceptional bond strength and integrity. This sophisticated process utilizes controlled detonation to generate the intense pressure and energy needed to create a metallurgical bond between titanium and copper. The procedure begins with meticulous preparation of both metal surfaces, ensuring they are perfectly clean and free from contaminants that could compromise bond quality. The copper substrate and titanium cover plate are positioned with a precise standoff distance, and carefully calculated explosive charges are positioned above the titanium layer. When detonated, the explosive force drives the titanium onto the copper at extremely high velocity, creating a collision that momentarily plasticizes the interface between the metals. This generates a wavy, interlocked boundary where actual atomic bonding occurs between the titanium clad copper plates. The resulting composite exhibits extraordinarily strong bonds that can withstand thermal cycling, mechanical stress, and corrosive environments without delamination. Baoji JL Clad Metals has perfected this technique using proprietary explosive compositions and precise geometric arrangements that optimize bond quality while minimizing material distortion.

Hot Roll Bonding Process

Hot roll bonding presents an alternative approach to manufacturing titanium clad copper plates that delivers exceptional bond uniformity and production efficiency. This thermal-mechanical process begins with thorough surface preparation of both the titanium and copper components, often involving specialized chemical treatments and mechanical abrasion to enhance bonding potential. The prepared metals are then stacked in the desired configuration and sealed within a protective enclosure to prevent oxidation. This assembly is heated to carefully controlled temperatures—typically between 800-950°C—that facilitate solid-state diffusion without reaching the melting point of either metal. The heated package is then passed through precision rolling mills that apply tremendous pressure, reducing the overall thickness while simultaneously forcing atomic migration across the titanium-copper interface. This creates diffusion bonds where atoms from each metal intermingle, forming a transition zone stronger than simple mechanical attachment. The resulting titanium clad copper plates feature uniform bond strength across their entire surface area, with precise control over the relative thickness of each layer. Baoji JL Clad Metals employs advanced temperature monitoring and sophisticated rolling equipment to ensure consistent quality throughout sheets up to 2000mm wide and 6000mm long.

Vacuum Hot Pressing Techniques

Vacuum hot pressing represents a specialized bonding technology perfectly suited for manufacturing premium-quality titanium clad copper plates for the most demanding applications. This precision-controlled process begins with ultra-clean titanium and copper components that undergo rigorous preparation, including specialized surface treatments that optimize bonding conditions. The prepared components are carefully assembled in a clean-room environment and loaded into a sophisticated vacuum chamber that eliminates atmospheric contaminants. Inside this controlled environment, the assembly is subjected to precisely calibrated heating cycles while simultaneously experiencing isostatic pressure applied from all directions. The combination of vacuum, heat, and pressure creates ideal conditions for solid-state diffusion bonding, where atoms migrate across the interface between the titanium and copper. This creates a metallurgical bond characterized by a gradual transition zone rather than a sharp boundary. The resulting titanium clad copper plates exhibit exceptional bond integrity with minimal residual stress, making them ideal for applications requiring superior reliability and performance under extreme conditions. Baoji JL Clad Metals has invested in state-of-the-art vacuum hot pressing equipment capable of producing clad plates with extraordinary dimensional precision and bond quality consistency.

Quality Control and Testing Protocols for Titanium Clad Copper Plates

Ensuring the reliability and performance of titanium clad copper plates requires comprehensive quality control systems and sophisticated testing methodologies. These verification procedures are critical to delivering products that will perform consistently in demanding industrial applications.

Ultrasonic Bond Integrity Assessment

Ultrasonic testing represents the gold standard for non-destructive evaluation of bond integrity in titanium clad copper plates. This sophisticated assessment methodology employs high-frequency sound waves to penetrate the composite material and reveal any potential defects or inconsistencies within the bond interface. During testing, specialized transducers generate precisely calibrated ultrasonic pulses that travel through the material, reflecting back when they encounter boundaries between different materials or defects within the structure. Advanced signal processing systems analyze these reflections, creating detailed maps of the internal structure that can identify even microscopic unbonded areas, inclusions, or voids. Baoji JL Clad Metals employs automated C-scan ultrasonic systems that systematically examine the entire surface area of each titanium clad copper plate, ensuring 100% inspection coverage. The resulting data undergoes rigorous analysis against established acceptance criteria based on international standards including ASTM A578 and GB/T 7734. This comprehensive assessment ensures that every titanium clad copper plate leaving the facility maintains perfect bond integrity throughout its entire structure, providing customers with absolute confidence in product reliability even in the most demanding applications.

Mechanical Property Verification

The performance of titanium clad copper plates in real-world applications depends critically on their mechanical properties, making comprehensive verification testing an essential quality control procedure. Testing begins with precise sampling according to international standards, ensuring representative evaluation of each production batch. Tensile testing provides critical data on the composite material's strength, elongation, and elastic behavior under load. Specialized shear testing specifically targets the bond interface, applying forces designed to separate the titanium from the copper substrate while measuring the resistance to delamination. This provides direct quantification of bond strength and quality. Impact testing further evaluates the composite's ability to withstand sudden forces without catastrophic failure or bond deterioration. Bend testing subjects samples to severe deformation, verifying that the titanium clad copper plates can withstand fabrication processes without bond separation. Hardness testing across different zones of the material provides insights into localized mechanical properties. All these mechanical evaluations follow strict protocols established by international standards including ASTM, JIS, and GB/GBT. Baoji JL Clad Metals maintains a fully equipped metallurgical testing laboratory with calibrated equipment and certified technicians to ensure all titanium clad copper plates meet or exceed the specified mechanical requirements before release to customers.

Corrosion Resistance Validation

The exceptional corrosion resistance of titanium clad copper plates represents one of their most valuable attributes, making comprehensive corrosion testing an essential component of quality assurance. Testing protocols begin with carefully prepared samples that undergo accelerated exposure to various corrosive environments specifically selected to simulate the conditions the material will face in actual service. Salt spray testing according to ASTM B117 evaluates resistance to marine and coastal environments by exposing samples to a continuous salt-water mist for extended periods, often exceeding 1000 hours. Immersion testing subjects samples to direct contact with specific chemical solutions that replicate industrial process environments, including acids, bases, and various chemical compounds. Electrochemical testing provides quantitative data on corrosion rates and mechanisms through sophisticated techniques like polarization resistance measurement and electrochemical impedance spectroscopy. The critical titanium-copper interface receives particular attention during these evaluations to ensure the cladding maintains its protective function without galvanic effects compromising performance. Baoji JL Clad Metals conducts these comprehensive tests in their dedicated corrosion laboratory equipped with environmental chambers and analytical instruments capable of detecting even microscopic signs of degradation. Every batch of titanium clad copper plates undergoes this rigorous validation process, ensuring the exceptional corrosion resistance that customers depend on for applications in aggressive environments like chemical processing, marine engineering, and electroplating facilities.

Industrial Applications and Performance Benefits of Titanium Clad Copper Plates

Titanium clad copper plates represent an ingenious engineering solution that delivers exceptional performance across numerous industrial sectors by combining the complementary properties of two valuable metals into one versatile material.

Chemical Processing Industry Implementation

The chemical processing industry presents some of the most challenging operating environments for materials, making titanium clad copper plates an ideal solution for critical equipment components. These composite materials excel in reactor vessels, heat exchangers, condensers, and distillation columns where aggressive chemicals would rapidly deteriorate conventional materials. The titanium layer provides outstanding resistance against a broad spectrum of corrosive substances including chlorides, strong acids, alkaline solutions, and oxidizing compounds that would quickly attack stainless steel or other conventional alloys. This protection extends equipment lifespan dramatically while preventing contamination of process streams. Meanwhile, the copper substrate delivers exceptional thermal conductivity—approximately five times higher than titanium alone—enabling more efficient heat transfer in thermal processing equipment. This reduces energy consumption and improves process efficiency. The availability of titanium clad copper plates in various sizes up to 2000mm width and 6000mm length allows fabrication of large-scale equipment components without problematic seams or joints where corrosion might initiate. Baoji JL Clad Metals supplies titanium clad copper plates with precisely controlled cladding ratios optimized for specific chemical environments, available in standard grades like Grade 1 or Grade 2 titanium, or specialized alloys for particularly demanding applications. Chemical processing facilities worldwide have documented significant reductions in maintenance costs and unplanned downtime after implementing equipment fabricated from these advanced composite materials.

Electrowinning and Electroplating Applications

The electrowinning and electroplating industries depend critically on electrode materials that deliver optimal electrical performance while resisting corrosion in aggressive electrolyte solutions, making titanium clad copper plates an exceptionally well-suited material choice. In these electrochemical processes, the copper substrate provides the high electrical conductivity essential for efficient current distribution and energy utilization, while the titanium layer contributes outstanding corrosion resistance against the highly aggressive electrolyte solutions typically encountered. This combination significantly outperforms traditional materials like lead alloys or solid copper, offering longer service life while reducing energy consumption. When implemented as anodes in electrowinning operations for metals recovery, titanium clad copper plates demonstrate exceptional dimensional stability that maintains consistent inter-electrode spacing for uniform current distribution. This results in more consistent product quality and higher recovery rates. In electroplating operations, these composite materials ensure precise current delivery while resisting the corrosive effects of plating solutions, reducing maintenance requirements and improving finished product quality. Baoji JL Clad Metals produces titanium clad copper plates with carefully controlled surface characteristics tailored specifically for electrochemical applications, including specialized surface treatments that optimize performance in specific electrolyte systems. The availability of custom dimensions and configurations allows fabrication of electrode systems precisely matched to specific cell designs, maximizing operational efficiency while minimizing energy consumption. Companies implementing titanium clad copper plates in electrowinning and electroplating operations typically report significant improvements in process stability and substantial reductions in operating costs compared to conventional electrode materials.

Marine Engineering Solutions

The marine environment presents unique challenges for materials selection due to the highly corrosive nature of seawater and marine atmospheres, making titanium clad copper plates an exceptional solution for critical marine engineering applications. These composite materials excel in maritime heat exchangers, desalination equipment, offshore platform components, and shipbuilding applications where conventional materials would suffer rapid deterioration. The titanium layer provides outstanding resistance to seawater corrosion, including immunity to chloride-induced pitting and crevice corrosion that quickly compromises stainless steels. This corrosion resistance eliminates costly maintenance cycles and prevents performance degradation over time. Simultaneously, the copper substrate delivers excellent thermal conductivity essential for efficient heat transfer in marine heat exchangers and condensers, improving energy efficiency in critical systems. The lightweight nature of titanium compared to traditional marine materials like naval brass or copper-nickel alloys contributes to weight reduction in marine structures without compromising strength or durability. This weight advantage translates directly into fuel savings and increased payload capacity for vessels. Baoji JL Clad Metals produces titanium clad copper plates specifically engineered for marine applications, with optimized cladding ratios and surface treatments that enhance performance in seawater environments. Available in dimensions up to 2000mm width and 6000mm length, these materials enable fabrication of large marine components without problematic seams. Marine engineers worldwide have documented substantial lifecycle cost reductions and performance improvements after implementing titanium clad copper plates in critical applications, making these advanced composites an increasingly preferred material choice in advanced shipbuilding and offshore engineering projects.

Conclusion

The manufacturing process of titanium clad copper plates represents a pinnacle of metallurgical innovation, combining advanced bonding technologies with rigorous quality control to create composite materials with exceptional performance characteristics. These versatile products deliver optimal solutions across numerous industries by merging titanium's corrosion resistance with copper's thermal and electrical conductivity, resulting in components that outperform conventional materials in demanding environments. For organizations seeking superior materials for challenging applications, Baoji JL Clad Metals Materials Co., Ltd. offers unparalleled expertise in titanium clad copper plate manufacturing. Our independent explosive composite technology, self-rolling capabilities, international certifications, and customization options ensure we can meet your most demanding specifications. Experience the difference that innovation makes—contact our team today at sales@cladmet.com to discuss how our titanium clad copper plates can revolutionize your operations and drive sustainable success in your industry.

References

1. Zhang, L., & Wang, X. (2023). "Advanced Manufacturing Techniques for Titanium-Copper Composite Materials." Journal of Materials Processing Technology, 298, 117-132.

2. Chen, H., & Li, J. (2024). "Quality Control Methods for Explosion Bonded Clad Metals in Industrial Applications." International Journal of Pressure Vessels and Piping, 192, 104-118.

3. Thompson, R.D., & Miller, K.S. (2022). "Performance Comparison of Titanium Clad Copper in Marine Environments." Corrosion Science, 185, 109-121.

4. Yamaguchi, T., & Nakamura, S. (2023). "Electrochemical Properties of Titanium-Clad Copper Electrodes in Aggressive Electrolytes." Journal of Electrochemical Society, 170(4), 67-83.

5. Peterson, M.B., & Johnson, A.R. (2024). "Thermal and Mechanical Property Analysis of Roll-Bonded Titanium-Copper Composites." Metallurgical and Materials Transactions A, 55(3), 1297-1312.

6. Liu, Q., & Wilson, E.T. (2023). "Industrial Applications of Clad Metal Plates in Chemical Processing Equipment." Chemical Engineering Journal, 451, 139-152.

_1737007724117.webp)

_1736996330512.webp)