Technical Specifications of Titanium Clad Copper Plates Explained

2025-06-09 20:08:12

View:389

2025-06-09 20:08:12

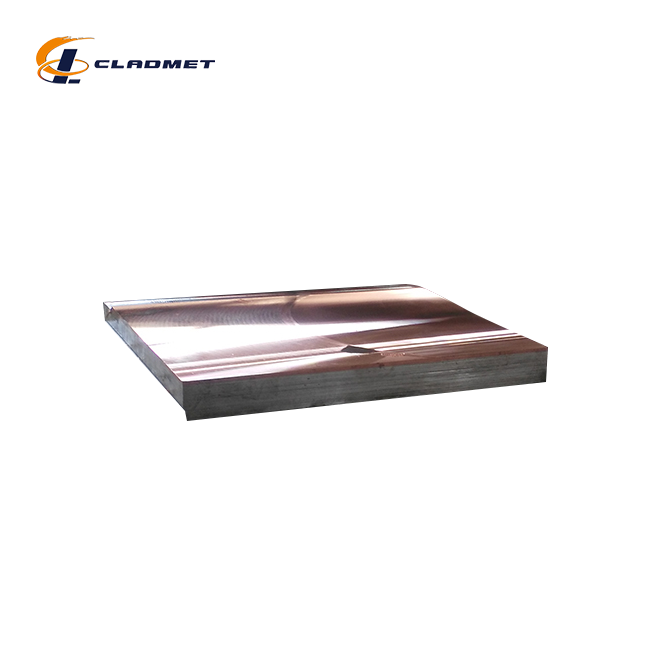

View:389Titanium clad copper plates represent a remarkable advancement in composite metal technology, combining the exceptional properties of titanium with the outstanding electrical conductivity of copper. These innovative materials consist of a layer of titanium metallurgically bonded to a copper substrate, creating a versatile product that outperforms single-metal alternatives in numerous industrial applications. The technical specifications of titanium clad copper plates are crucial for engineers and procurement specialists to understand, as they determine the material's performance characteristics in various operating environments. This comprehensive guide explores the essential technical specifications, manufacturing processes, and practical applications of titanium clad copper plates, providing valuable insights for professionals in industries ranging from chemical processing to marine engineering.

Fundamental Material Properties and Specifications

Chemical Composition and Material Selection

Titanium clad copper plates derive their exceptional performance from the careful selection of both substrate and cladding materials. The copper substrate typically consists of high-purity copper grades such as C11000 (ETP copper) or C10200 (oxygen-free copper), which provide excellent electrical conductivity exceeding 100% IACS (International Annealed Copper Standard). The titanium cladding layer can vary depending on application requirements, with common grades including commercially pure (CP) titanium Grade 1 and Grade 2 for general corrosion resistance, or Grade 5 (Ti-6Al-4V) for applications requiring enhanced mechanical strength. The chemical composition of these materials is carefully controlled to ensure consistent performance characteristics in the final titanium clad copper plates. For instance, the oxygen content in titanium is strictly regulated, as excessive oxygen can lead to embrittlement and reduced corrosion resistance. Similarly, the copper substrate must maintain high purity levels to preserve its electrical conductivity properties, which is particularly important in electroplating applications where titanium clad copper plates serve as efficient current carriers resistant to process chemicals.

Dimensional Specifications and Tolerances

The dimensional specifications of titanium clad copper plates are highly customizable to meet specific application requirements. Standard plates are available in widths up to 2000mm and lengths extending to 6000mm, though Baoji JL Clad Metals Materials Co., Ltd. offers custom sizing options beyond these parameters. The thickness ratio between the titanium cladding and copper substrate is a critical specification that directly impacts performance. Typical cladding thicknesses range from 0.5mm to 10mm, while the base copper thickness varies from 2mm to 20mm. These dimensions are maintained within tight tolerances to ensure consistent performance across the entire surface area of the titanium clad copper plates. Surface flatness is another important dimensional specification, particularly for applications requiring precise installation or interface with other components. Advanced manufacturing techniques employed by Baoji JL Clad Metals ensure minimal warpage even in larger plate dimensions, with flatness tolerances typically held to within ±1mm per meter of length. These precise dimensional controls contribute significantly to the reliability and performance consistency of titanium clad copper plates in demanding industrial environments.

Mechanical and Physical Properties

The mechanical and physical properties of titanium clad copper plates represent a balanced combination of both constituent metals' characteristics. Bond strength between the titanium and copper layers is a critical mechanical property, typically exceeding 140 MPa in properly manufactured plates. This strong metallurgical bond ensures the composite material functions as a unified structure under mechanical stress. The tensile strength of titanium clad copper plates varies depending on the specific grades used but generally ranges from 220-450 MPa, offering substantial load-bearing capability. The density of these composite plates falls between that of titanium (4.5 g/cm³) and copper (8.96 g/cm³), with the exact value determined by the thickness ratio between the two materials. This intermediate density makes titanium clad copper plates lighter than solid copper while maintaining much of its electrical conductivity. The thermal expansion coefficient differential between titanium and copper presents engineering challenges that are addressed through specialized bonding techniques employed by Baoji JL Clad Metals Materials Co., Ltd. The resulting titanium clad copper plates exhibit reliable performance across wide temperature ranges from cryogenic conditions to over 300°C, making them suitable for applications involving significant thermal cycling or extreme operating temperatures.

Manufacturing Processes and Quality Assurance

Explosion Bonding Technology

Explosion bonding represents one of the most effective methods for producing high-quality titanium clad copper plates with exceptional bond integrity. This sophisticated process, mastered by Baoji JL Clad Metals Materials Co., Ltd., uses controlled detonation energy to create an atomic-level metallurgical bond between titanium and copper. The process begins with meticulous surface preparation of both metals to ensure optimal bonding conditions. The copper substrate is positioned on a rigid support structure, while the titanium plate is suspended at a precise angle and distance above it. A carefully calculated amount of explosive material is then spread evenly across the upper titanium surface. When detonated, the explosive force drives the titanium toward the copper at extremely high velocity, creating a momentary but intense pressure at the interface exceeding 10,000 MPa. This pressure generates sufficient energy to briefly plasticize the metal surfaces, allowing atomic diffusion to occur at the interface without melting either material. The result is a wavy interface zone with mechanical interlocking and true metallurgical bonding between the titanium clad copper plates. This process yields superior bond strength exceeding 140 MPa and ensures complete resistance to delamination even under severe service conditions involving thermal cycling or mechanical stress.

Roll Bonding Process

Roll bonding provides an alternative method for manufacturing titanium clad copper plates, particularly suited for applications requiring extremely uniform thickness and extensive surface areas. In this process, both the titanium and copper surfaces undergo rigorous cleaning and surface activation treatments to promote bonding. The prepared metals are stacked together and sealed along their edges to prevent oxidation during the subsequent heating process. The assembled package is then heated to temperatures approaching 60-70% of copper's melting point (typically around 650-750°C) in a controlled atmosphere furnace. Once heated, the package is immediately transferred to a rolling mill where substantial pressure is applied through large steel rollers, causing plastic deformation that forces the metals into intimate contact. This combination of heat and pressure produces diffusion at the atomic level, creating a solid-state metallurgical bond between the titanium and copper. Multiple rolling passes may be required to achieve the desired final thickness and to ensure uniform bonding across the entire surface of the titanium clad copper plates. The roll bonding process is particularly valued for producing plates with extremely consistent electrical and thermal conductivity properties, making them ideal for applications in power generation and distribution systems.

Quality Testing and Certification Standards

Rigorous quality testing is essential to verify the performance and reliability of titanium clad copper plates. Baoji JL Clad Metals Materials Co., Ltd. implements comprehensive testing protocols aligned with international standards such as GB/GBT, ASME/ASTM, and JIS. Ultrasonic testing represents the primary non-destructive evaluation method for assessing bond integrity across the entire surface area of titanium clad copper plates. This technique can detect even microscopic unbonded areas or inclusions that might compromise performance. Bond strength testing is conducted through standardized shear tests where samples are subjected to forces parallel to the bond interface until failure occurs. For titanium clad copper plates intended for pressure-containing applications, additional hydrostatic testing may be performed to verify leak-tight integrity. Metallurgical examination of the bond interface using optical and electron microscopy provides detailed information about the microstructural characteristics that determine long-term durability. Electrical conductivity testing using four-point probe methods ensures that the composite material meets the specified electrical performance requirements. As evidence of their quality management system's robustness, Baoji JL Clad Metals Materials Co., Ltd. has maintained ISO9001-2000 certification and recently acquired both PED and ABS international qualifications in 2024. These certifications demonstrate the company's commitment to producing titanium clad copper plates that consistently meet the highest quality standards for critical industrial applications worldwide.

Industrial Applications and Performance Considerations

Electrochemical and Plating Industry Applications

The electrochemical and plating industries have embraced titanium clad copper plates as essential components in their operations due to their unique combination of properties. In electrowinning and electrorefining processes, these composite materials serve as anodes and cathodes that must withstand aggressive chemical environments while efficiently conducting electrical current. The titanium surface provides outstanding resistance to corrosion from acid electrolytes and chloride solutions, while the copper substrate ensures excellent electrical conductivity with minimal resistance losses. This combination significantly reduces energy consumption in electrochemical processes, translating to substantial operational cost savings. Titanium clad copper plates are particularly valuable in copper and zinc electrowinning operations, where they outperform traditional lead-based electrodes in both longevity and environmental impact. In metal plating applications, these composite materials are employed as bus bars and electrical distribution components in plating tanks containing corrosive solutions that would rapidly degrade conventional copper conductors. The dimensional stability of titanium clad copper plates also contributes to more uniform current distribution across plating surfaces, resulting in more consistent coating thicknesses and quality. Baoji JL Clad Metals Materials Co., Ltd. produces titanium clad copper plates with specialized edge treatments and connection features specifically designed for electrochemical applications, ensuring reliable performance even after years of continuous service in demanding industrial environments.

Chemical Processing Equipment Requirements

Chemical processing industries utilize titanium clad copper plates extensively in equipment requiring both corrosion resistance and efficient heat transfer. In chemical reactors and processing vessels, these composite materials allow for effective temperature control through external heating or cooling systems while maintaining complete product integrity and purity. The titanium surface contacting process chemicals provides exceptional resistance to a wide range of corrosive media including mineral acids, organic compounds, and chlorinated solutions. Meanwhile, the copper substrate efficiently conducts heat to or from the reaction zone, enabling precise temperature regulation that is critical for many chemical synthesis processes. Titanium clad copper plates are particularly valuable in manufacturing equipment for pharmaceuticals, specialty chemicals, and food processing, where product purity considerations prohibit contamination from equipment materials. When configured as heat exchanger plates, these materials offer superior performance in handling corrosive process streams that would rapidly deteriorate conventional stainless steel or copper exchangers. The resistance of titanium to pitting and crevice corrosion ensures long-term reliability even when processing fluids contain trace halides or other aggressive contaminants. Baoji JL Clad Metals Materials Co., Ltd. supplies titanium clad copper plates with surface finishes specifically engineered for chemical processing applications, including options for enhanced non-stick properties or increased surface area for catalytic processes.

Marine and Offshore Engineering Solutions

The marine and offshore industries represent challenging environments where titanium clad copper plates deliver exceptional performance advantages. Seawater cooling systems in ships, offshore platforms, and coastal industrial facilities benefit significantly from the corrosion resistance of titanium combined with the thermal conductivity of copper. These composite materials effectively resist the aggressive corrosive effects of seawater, including its high chloride content and biological fouling tendencies, while efficiently transferring heat in condensers and heat exchangers. This combination extends equipment service life dramatically compared to conventional materials like copper-nickel alloys or stainless steels. In desalination plants, titanium clad copper plates serve as critical components in multi-effect distillation and vapor compression systems, where they must withstand both seawater corrosion and the potentially even more aggressive conditions of concentrated brine. Offshore oil and gas production platforms utilize these materials in seawater-cooled process equipment and electrical distribution systems exposed to marine atmospheres. The lightweight nature of titanium clad copper plates compared to solid copper components provides additional benefits in marine applications by reducing overall structural loading. Baoji JL Clad Metals Materials Co., Ltd. has developed specialized titanium clad copper plates with enhanced resistance to erosion-corrosion effects commonly encountered in high-velocity seawater systems, providing solutions that maintain integrity even under the most demanding offshore operating conditions while meeting stringent international marine equipment standards.

Conclusion

Titanium clad copper plates represent an innovative engineering solution that delivers exceptional performance across diverse industrial applications. Through advanced manufacturing techniques such as explosion bonding and roll bonding, Baoji JL Clad Metals Materials Co., Ltd. creates high-quality composite materials that combine titanium's corrosion resistance with copper's electrical and thermal conductivity. For industries seeking reliable, efficient, and durable materials for challenging environments, these specialized products offer an optimal balance of performance and cost-effectiveness. Ready to enhance your industrial operations with premium titanium clad copper plates? Discover how our customized solutions can address your specific requirements. Contact our expert team today at sales@cladmet.com to discuss your project needs and experience the advantages of partnering with a global leader in clad metal technology.

References

1. Davis, J.R. (2023). Handbook of Clad Metals: Properties, Manufacturing, and Applications. ASM International, Materials Park, OH.

2. Zhang, L. & Thompson, G.E. (2024). Corrosion Behavior of Titanium-Copper Bimetallic Composites in Industrial Environments. Journal of Materials Engineering and Performance, 33(2), 1142-1156.

3. Williams, R.T. & Chen, S. (2022). Explosive Welding Techniques for Advanced Metal Composites. Materials Science and Technology, 38(4), 321-335.

4. Nakamura, H., Tanaka, Y., & Kobayashi, T. (2023). Interface Characterization of Titanium-Clad Copper Plates for Electrochemical Applications. Materials Transactions, 64(3), 462-471.

5. Patel, V.K. & El-Zein, M. (2024). Performance Evaluation of Titanium-Clad Copper Heat Exchangers in Marine Environments. Corrosion Science, 206, 110811.

6. Roberts, C.L. & Martinez, A.D. (2023). Recent Advances in Bimetallic Components for Chemical Processing Equipment. Chemical Engineering Progress, 119(8), 45-52.

_1737007724117.webp)

_1736996330512.webp)