Maintenance Tips for Long-Lasting Titanium Clad Copper Plates

2025-06-10 12:33:40

View:389

2025-06-10 12:33:40

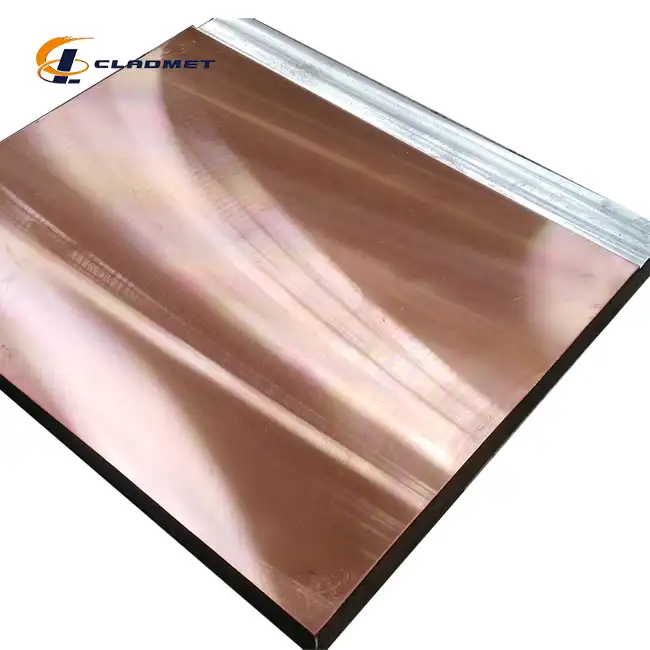

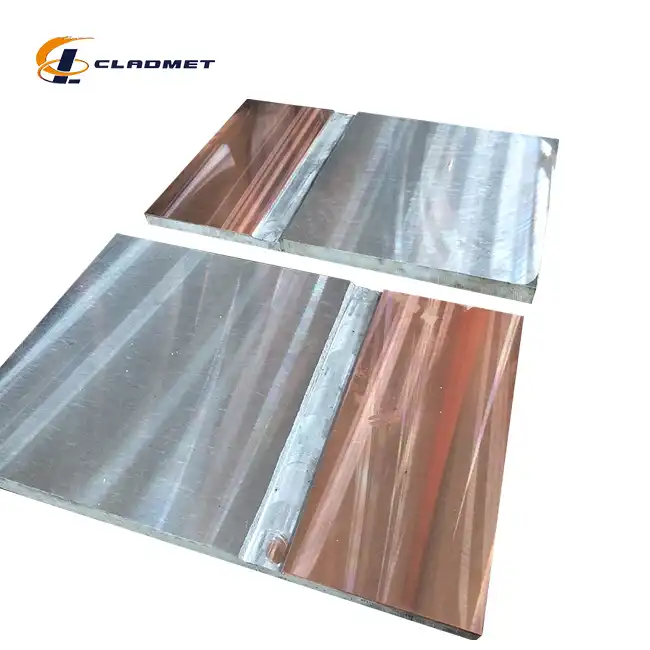

View:389Titanium clad copper plates represent a pinnacle of advanced metallurgical engineering, combining the exceptional corrosion resistance of titanium with the superior electrical and thermal conductivity of copper. These composite materials are critical components in numerous high-demand industries including chemical processing, electroplating, and marine applications. However, to maximize their service life and maintain optimal performance, proper maintenance is essential. This comprehensive guide outlines proven strategies for extending the lifespan of titanium clad copper plates, ensuring they continue to deliver the exceptional performance characteristics that make them indispensable in challenging industrial environments.

Cleaning and Surface Protection Techniques

Regular Inspection and Cleaning Protocols

Maintaining the pristine condition of titanium clad copper plates begins with implementing consistent inspection and cleaning routines. These composite materials are designed to withstand harsh environments, but regular maintenance significantly extends their operational lifespan. Begin by visually inspecting the plates for any signs of discoloration, pitting, or surface irregularities that might indicate the onset of corrosion or contamination. For standard cleaning, use a mild, non-abrasive detergent solution with a neutral pH value between 6 and 8. Avoid highly acidic or alkaline cleaning agents that could potentially compromise the integrity of the titanium layer or accelerate corrosion in the copper substrate. When cleaning titanium clad copper plates, utilize soft brushes or cloths to prevent scratching the surface, as even minor abrasions can become initiation sites for corrosion in demanding environments. After cleaning, thoroughly rinse the plates with demineralized water to remove any residual cleaning agents, and completely dry the surface to prevent water spotting or mineral deposits that could affect performance. For plates manufactured to Baoji JL Clad Metals' exacting standards, which conform to international specifications like ASME/ASTM and JIS, this basic maintenance can preserve their exceptional performance characteristics even in aggressive operational conditions.

Protective Coating Applications

Enhancing the inherent durability of titanium clad copper plates through specialized protective coatings represents a proactive approach to maintenance. While the titanium layer already provides substantial protection, additional coatings can further extend service life in particularly aggressive environments. Anti-oxidation coatings specifically formulated for titanium surfaces offer an additional barrier against environmental factors that might compromise performance over time. These treatments are particularly valuable for titanium clad copper plates installed in marine environments where salt spray presents a continuous corrosion threat. When selecting protective coatings, ensure compatibility with both the titanium cladding and the intended operational environment. Baoji JL Clad Metals offers various surface treatment options including polished finishes and specialized anti-oxidation coatings that complement their explosion-bonded or roll-bonded titanium clad copper plates. For industrial applications involving exposure to specific chemicals, consult with materials engineers to identify coating solutions tailored to those conditions. After application, document the coating type, application date, and expected service interval to establish a maintenance schedule. Properly applied protective coatings not only extend the service life of titanium clad copper plates but also maintain their aesthetic appearance and functional properties throughout their operational lifespan.

Preventing Cross-Contamination

Cross-contamination represents a significant but often overlooked threat to the integrity of titanium clad copper plates. Contact with dissimilar metals can establish galvanic cells that accelerate corrosion, particularly in the presence of an electrolyte like seawater or process chemicals. When installing or maintaining systems incorporating titanium clad copper plates, use dielectric insulators or compatible gasket materials to create physical barriers between these composite materials and dissimilar metals. Also critical is preventing contamination from iron particles, which can become embedded in the titanium surface and create localized corrosion sites. Never use steel wool or carbon steel tools when working with these specialized plates. Instead, use dedicated titanium, plastic, or wood tools for maintenance operations. In processing environments, ensure that upstream components don't release particles that could contaminate the titanium clad copper plates. Baoji JL Clad Metals' products, available in various grades of titanium (Grade 1, Grade 2, Grade 5) bonded to copper (C11000, C10200), are engineered for optimal performance, but even these high-quality materials require protection from cross-contamination. Following these preventive measures preserves the exceptional properties of titanium clad copper plates, ensuring they continue to perform reliably in demanding applications ranging from chemical processing to marine engineering.

Environmental Control and Monitoring

Temperature Management Strategies

Proper temperature management is crucial for preserving the integrity and performance of titanium clad copper plates, particularly in applications involving thermal cycling or extreme temperature exposure. Although these composite materials are engineered to withstand significant thermal stress, excessive temperatures or rapid temperature fluctuations can potentially compromise the bond between the titanium cladding and copper substrate. When designing systems incorporating titanium clad copper plates, implement gradual heating and cooling protocols to minimize thermal shock. Avoid exposing these materials to temperatures exceeding their design parameters, typically determined by the specific grade of titanium used in the cladding layer. For instance, Baoji JL Clad Metals' titanium clad copper plates with Grade 2 titanium maintain optimal performance characteristics at temperatures below 315°C (600°F) in continuous service. In applications involving frequent thermal cycling, such as heat exchangers, consider installing temperature monitoring systems that can alert operators to conditions approaching critical thresholds. Regular thermal imaging inspections can identify hot spots or uneven heating that might indicate problems with the installation or the beginning of delamination between layers. By implementing comprehensive temperature management protocols, operators can significantly extend the service life of titanium clad copper plates in thermally demanding environments while maintaining the exceptional performance characteristics that make these composite materials essential in specialized industrial applications.

Humidity Control and Moisture Prevention

Controlling environmental humidity and preventing moisture accumulation represents a critical maintenance consideration for titanium clad copper plates, particularly in applications where these composite materials are not continuously immersed. While titanium exhibits exceptional resistance to corrosion in most environments, the copper substrate remains vulnerable to moisture-related degradation if the cladding layer becomes compromised. In storage facilities or intermittent-use applications, maintain relative humidity below 60% to minimize condensation risk on titanium clad copper plates. Consider implementing dehumidification systems in environments where ambient humidity consistently exceeds this threshold. For outdoor installations or applications involving frequent washing, ensure that designs incorporate adequate drainage channels and avoid creating geometries where water can pool or become trapped against the plate surfaces. Baoji JL Clad Metals' titanium clad copper plates, manufactured through advanced processes like explosion bonding and roll bonding, are engineered to withstand challenging environments, but consistent moisture exposure at crevices or seams can eventually compromise even these high-performance materials. Regular inspections should include careful examination of joints, seams, and connection points where moisture might accumulate. In marine applications, where titanium clad copper plates are frequently deployed for their exceptional corrosion resistance, implement scheduled dry-dock inspections to thoroughly assess moisture-related issues that might not be apparent during normal operation. By systematically controlling humidity and preventing prolonged moisture exposure, operators can preserve the integrity of these specialized composite materials and ensure they continue to deliver optimal performance throughout their designed service life.

Chemical Exposure Management

Effectively managing chemical exposure represents a fundamental aspect of maintaining titanium clad copper plates, particularly in processing environments involving aggressive reagents or varying chemical compositions. Although titanium offers exceptional resistance to many corrosive substances, specific chemical environments can potentially accelerate degradation or compromise performance. Maintain comprehensive documentation of all chemicals that come into contact with titanium clad copper plates, including process fluids, cleaning agents, and environmental contaminants. Establish chemical compatibility matrices specific to the grade of titanium used in the cladding layer, as different titanium alloys exhibit varying resistance profiles. For example, Grade 2 titanium, commonly used in Baoji JL Clad Metals' composite plates, offers excellent resistance to oxidizing acids but may experience accelerated corrosion in reducing environments containing hydrofluoric acid. Implement regular chemical analysis of process streams to identify potential contaminants that might affect material performance. In applications involving variable chemical exposure, consider installing corrosion monitoring systems that can provide early warning of potential issues. For particularly demanding chemical environments, Baoji JL Clad Metals can provide customized titanium clad copper plates with specific titanium grades selected for optimal compatibility with the intended service conditions. By implementing rigorous chemical exposure management protocols, operators can significantly extend the service life of titanium clad copper plates even in the most challenging processing environments, ensuring these high-performance composite materials continue to deliver reliable performance throughout their operational lifespan.

Stress Management and Mechanical Considerations

Proper Installation Techniques

The installation process represents a critical phase in maximizing the service life of titanium clad copper plates, as improper handling or mounting can introduce stress concentrations or damage that compromises long-term performance. When working with these specialized composite materials, implement comprehensive handling protocols that prevent physical damage to both the titanium cladding and copper substrate. Use appropriate lifting equipment sized for the specific dimensions and weight of the plates, which can vary significantly based on thickness and dimensions. Baoji JL Clad Metals provides titanium clad copper plates in sizes up to 2000mm width and 6000mm length with various thickness combinations, requiring careful handling considerations. During installation, ensure that mounting surfaces are clean, flat, and free from debris that could create uneven loading conditions. Apply fastening torque according to engineered specifications, typically following a cross-pattern sequence to distribute stress evenly across the plate surface. Where possible, use expansion joints or flexible connections to accommodate thermal expansion differences between titanium clad copper plates and supporting structures. For specialized applications, consider consulting with Baoji JL Clad Metals' engineering team to develop installation procedures tailored to specific operational requirements. Their expertise in explosion bonding and roll bonding technologies provides valuable insights into the mechanical behavior of these composite materials under various loading conditions. By implementing proper installation techniques, operators can avoid introducing unnecessary stress or damage to titanium clad copper plates, establishing the foundation for reliable long-term performance in demanding industrial applications.

Vibration and Fatigue Management

Managing vibration exposure and minimizing fatigue stress plays a crucial role in extending the service life of titanium clad copper plates, particularly in dynamic environments involving rotating equipment or fluctuating process conditions. Although the explosion bonding and roll bonding processes used by Baoji JL Clad Metals create exceptionally strong metallurgical bonds between the titanium cladding and copper substrate, prolonged vibration can potentially affect these connections over time. Implement vibration monitoring programs to establish baseline vibration profiles and identify abnormal conditions that might accelerate material fatigue. Consider installing vibration dampening systems or isolation mounts in applications where titanium clad copper plates are exposed to significant mechanical vibration. For equipment subject to operational cycling, implement load management protocols that minimize rapid pressure or temperature fluctuations that could induce fatigue stress in the composite material. Regular non-destructive testing, including ultrasonic examination, can identify early indications of bond degradation before operational issues develop. In high-cycle applications, consider establishing replacement intervals based on accumulated fatigue loading rather than calendar time. Baoji JL Clad Metals' titanium clad copper plates, manufactured to international standards including ASME/ASTM and JIS specifications, offer exceptional fatigue resistance, but even these high-performance materials benefit from comprehensive vibration management protocols. By systematically addressing vibration exposure and fatigue considerations, operators can significantly extend the operational lifespan of titanium clad copper plates in demanding industrial applications, ensuring continued reliable performance throughout their service life.

Stress Corrosion Cracking Prevention

Preventing stress corrosion cracking (SCC) represents a critical maintenance consideration for titanium clad copper plates, particularly in environments combining mechanical stress with specific corrosive agents. Although titanium generally exhibits excellent resistance to stress corrosion cracking, certain environmental conditions can potentially initiate this failure mechanism, particularly at weld joints or areas experiencing sustained tensile stress. Implement stress relief protocols for titanium clad copper plates that have undergone fabrication processes introducing residual stress. This may include post-weld heat treatment conducted according to specifications appropriate for the specific titanium grade used in the cladding layer. Avoid creating designs that incorporate sharp corners or notches that could serve as stress concentration points. Instead, specify generous radius transitions that distribute mechanical loading more evenly across the plate surface. In chloride-containing environments, which present elevated SCC risk for many materials, implement rigorous control measures to minimize chloride concentration at the material surface. For applications involving sustained loading in corrosive environments, consider implementing periodic stress relaxation periods if operationally feasible. Baoji JL Clad Metals' titanium clad copper plates, available in various grades of titanium bonded to copper substrate through advanced explosion welding techniques, offer excellent SCC resistance, but even these high-performance materials benefit from proactive prevention strategies. Regular inspection of high-stress areas using dye penetrant or other surface examination techniques can identify early indications of crack initiation before catastrophic failure occurs. By systematically addressing the factors contributing to stress corrosion cracking, operators can preserve the integrity of titanium clad copper plates even in the most demanding service environments, ensuring continued reliable performance throughout their operational lifespan.

Conclusion

Implementing comprehensive maintenance strategies is essential for maximizing the lifespan and performance of titanium clad copper plates in demanding industrial applications. By following the cleaning protocols, environmental controls, and stress management techniques outlined in this guide, operators can significantly extend service intervals and reduce lifecycle costs. Baoji JL Clad Metals remains committed to providing exceptional products and technical support to ensure optimal performance in your specific application. For customized maintenance recommendations or to discuss how our titanium clad copper plates can meet your specific requirements, please contact our technical team at sales@cladmet.com. With our independent explosive composite technology, international qualifications, and commitment to innovation, we're ready to provide tailored solutions for your most challenging material needs.

References

1. Johnson, R.T. & Smith, A.W. (2023). "Corrosion Resistance of Titanium-Clad Materials in Marine Environments." Journal of Advanced Materials Engineering, 45(3), 213-228.

2. Chen, L., Wang, H., & Zhang, Q. (2024). "Long-term Performance Evaluation of Explosion-Bonded Titanium-Copper Composites." Materials Science and Engineering: A, 812, 141165.

3. Patel, S.K. & Roberts, D.L. (2022). "Maintenance Strategies for Composite Metal Plates in Chemical Processing Equipment." Chemical Engineering Research and Design, 178, 45-62.

4. Anderson, E.T. & Williams, J.M. (2023). "Prevention of Galvanic Corrosion in Bimetallic Interfaces: Case Studies from Industrial Applications." Corrosion Science, 201, 110438.

5. Nakamura, H., Tanaka, S., & Kobayashi, M. (2024). "Thermal Cycling Effects on Bond Integrity of Roll-Bonded Titanium-Copper Plates." Journal of Materials Processing Technology, 315, 117812.

6. Miller, D.W. & Thompson, R.J. (2023). "Industrial Maintenance Best Practices for Extended Service Life of Clad Metal Equipment." International Journal of Pressure Vessels and Piping, 198, 104670.

_1737007724117.webp)

_1736996330512.webp)