Key Trends Shaping the Titanium Clad Copper Plate Market

2025-06-04 20:32:49

View:389

2025-06-04 20:32:49

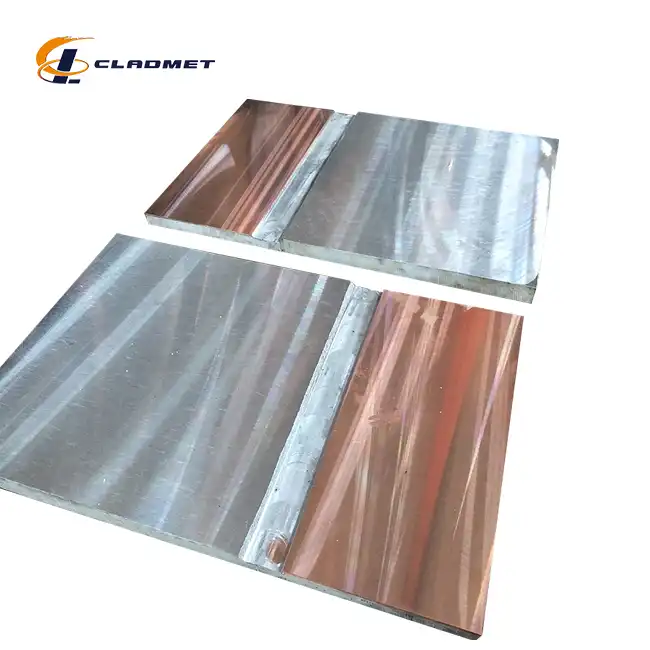

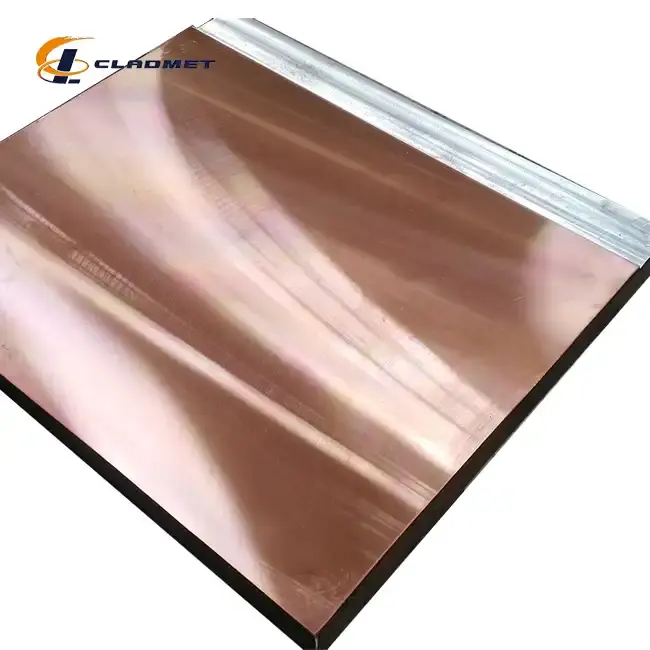

View:389The titanium clad copper plate market is experiencing significant evolution driven by technological advancements, changing industrial demands, and sustainability concerns. These composite materials, which combine the exceptional corrosion resistance of titanium with the superior electrical conductivity of copper, are becoming increasingly vital across multiple industries including chemical processing, electroplating, marine engineering, and power generation. As global industries continue to seek materials that offer optimal performance in harsh environments while maintaining cost-effectiveness, titanium clad copper plates have emerged as a solution that skillfully balances durability, functionality, and economic considerations. This article explores the key trends currently shaping this specialized yet growing market segment, highlighting innovations, market drivers, and future directions that stakeholders should monitor.

Technological Innovations Driving Market Growth

Advanced Bonding Technologies

The development of sophisticated bonding technologies has revolutionized the production of titanium clad copper plates, enhancing their performance characteristics and expanding their application scope. Traditional methods like roll bonding have been refined, while newer techniques such as explosive welding have gained prominence for creating exceptionally strong metallurgical bonds. Companies like Baoji JL Clad Metals Materials Co., Ltd. have pioneered these advancements, implementing explosion bonding processes that create robust, permanent bonds between titanium and copper layers. This technology enables the production of titanium clad copper plates with superior mechanical properties, including enhanced resistance to delamination under thermal cycling and mechanical stress. The resulting composite materials maintain the individual advantages of both metals—titanium's corrosion resistance and copper's electrical conductivity—while minimizing their respective limitations. These technological innovations have expanded the performance envelope of titanium clad copper plates, making them suitable for increasingly demanding applications across various industries.

Precision Engineering and Customization

The market for titanium clad copper plates has been transformed by advancements in precision engineering that allow for unprecedented levels of customization. Manufacturers now offer titanium clad copper plates with highly specific dimensions, varying thickness ratios between the titanium and copper layers, and customized surface treatments to meet exacting application requirements. Baoji JL Clad Metals Materials Co., Ltd. exemplifies this trend, providing titanium clad copper plates with cladding thicknesses ranging from 0.5mm to 10mm and base metal thicknesses from 2mm to 20mm, with widths up to 2000mm and lengths up to 6000mm. This level of customization allows industries to optimize their material selection based on specific operating conditions, whether prioritizing electrical conductivity, corrosion resistance, or thermal management. Additionally, various surface treatments including polished, sandblasted, and anti-oxidation coatings further enhance the performance characteristics of titanium clad copper plates in particular environments. This trend toward precision engineering not only improves material performance but also reduces waste and optimizes material usage, contributing to more sustainable industrial practices.

Quality Assurance Technologies

The implementation of advanced quality assurance technologies has significantly elevated the reliability and consistency of titanium clad copper plates. Non-destructive testing methods, including ultrasonic inspection, radiographic testing, and bond strength verification, have become standard practice for manufacturers committed to producing high-quality composite materials. Baoji JL Clad Metals Materials Co., Ltd. has established rigorous quality control protocols that align with international standards such as GB/GBT, ASME/ASTM, and JIS, ensuring that their titanium clad copper plates meet or exceed industry requirements. The company's adherence to ISO9001-2000 quality management systems, along with its recent achievement of PED and ABS international certifications in 2024, demonstrates the increasing emphasis on verifiable quality in this market. These quality assurance technologies not only enhance product reliability but also build customer confidence, particularly for applications where material failure could result in significant economic or safety consequences. As industries continue to demand higher performance standards, the role of advanced quality assurance in differentiating premium titanium clad copper plates from lower-quality alternatives will only increase in importance.

Industry-Specific Applications and Demands

Chemical Processing Equipment Advancements

The chemical processing industry has emerged as a primary driver for innovations in titanium clad copper plate applications, particularly as processing environments become increasingly corrosive and demanding. Titanium clad copper plates have proven invaluable in the construction of chemical reactors, storage tanks, and processing vessels that require resistance to aggressive chemicals while maintaining excellent heat transfer properties. The titanium layer provides exceptional protection against corrosive substances, while the copper substrate efficiently conducts and distributes heat, preventing hot spots and ensuring uniform thermal conditions throughout the equipment. Manufacturers like Baoji JL Clad Metals Materials Co., Ltd. have responded to this demand by offering specialized titanium clad copper plates with precisely controlled cladding ratios optimized for specific chemical environments. Available in various grades of titanium (Grade 1, Grade 2, Grade 5) bonded to high-purity copper bases (C11000, C10200), these composite materials can be engineered to withstand particular chemical compounds while maintaining structural integrity over extended operational periods. As chemical manufacturers continue to develop more aggressive processes and compounds, the demand for increasingly specialized titanium clad copper plates that can withstand these environments while facilitating efficient processing will continue to grow.

Marine and Offshore Applications

The marine and offshore industries have increasingly turned to titanium clad copper plates as a solution to the persistent challenges of corrosion and biofouling in seawater environments. These composite materials offer the ideal combination of seawater corrosion resistance through the titanium layer while retaining the excellent heat transfer properties of copper, making them particularly valuable for marine heat exchangers, desalination equipment, and offshore platform components. The superior performance of titanium clad copper plates in seawater environments has led to their adoption in critical systems where reliability and longevity are paramount concerns. Baoji JL Clad Metals Materials Co., Ltd. supplies titanium clad copper plates specifically engineered for marine applications, with optimized titanium-to-copper ratios that balance corrosion resistance with heat transfer efficiency. These plates can be manufactured in custom dimensions to accommodate the specific requirements of marine equipment designs, with surface treatments that further enhance their resistance to marine biological growth. As offshore energy production continues to expand and maritime industries seek materials that reduce maintenance requirements while extending operational lifespans, the demand for specialized marine-grade titanium clad copper plates is expected to see substantial growth in coming years.

Renewable Energy Systems

The renewable energy sector has become an increasingly significant market for titanium clad copper plates, particularly in applications involving harsh environments and demanding operating conditions. Solar thermal systems, geothermal power plants, and ocean thermal energy conversion installations all benefit from the unique properties of these composite materials. In solar thermal applications, titanium clad copper plates effectively transfer heat while resisting the corrosive effects of heat transfer fluids over extended periods. Geothermal systems, which often involve exposure to mineral-rich and potentially corrosive groundwater, utilize titanium clad copper plates in heat exchangers and fluid handling systems where both corrosion resistance and thermal conductivity are essential. Companies like Baoji JL Clad Metals Materials Co., Ltd. have developed specialized titanium clad copper plates for renewable energy applications, offering customized dimensions, thickness ratios, and surface treatments optimized for specific energy generation technologies. As the global push toward renewable energy sources accelerates, demand for these specialized composite materials is projected to increase substantially. The ability of titanium clad copper plates to maintain performance in challenging environments while facilitating efficient energy transfer positions them as key components in the ongoing development of more durable and efficient renewable energy systems.

Market Dynamics and Future Outlook

Supply Chain Resilience and Regionalization

The global market for titanium clad copper plates is undergoing significant transformation due to growing concerns about supply chain resilience and increasing trends toward regionalization of manufacturing. Recent global disruptions have exposed vulnerabilities in extended international supply chains, prompting industries that rely on specialized materials like titanium clad copper plates to reconsider their sourcing strategies. This has led to the emergence of more regionalized production centers capable of supplying these critical components to local markets. Manufacturers like Baoji JL Clad Metals Materials Co., Ltd. have responded by expanding their production capabilities and developing more flexible manufacturing processes that can rapidly adapt to changing market demands. With facilities capable of producing titanium clad copper plates in standard and custom sizes, and delivery options including sea, air, and express shipping, these manufacturers are positioning themselves to serve both regional and global markets effectively. The trend toward supply chain resilience is also driving investments in advanced inventory management systems and strategic stockpiling of critical raw materials needed for titanium clad copper plate production. As industries continue to prioritize supply chain security alongside performance and cost considerations, manufacturers that can guarantee reliable delivery of high-quality titanium clad copper plates will gain competitive advantage in this evolving market landscape.

Sustainability and Environmental Considerations

Environmental sustainability has become an increasingly important factor shaping the titanium clad copper plate market, influencing both manufacturing processes and material applications. Progressive manufacturers are implementing more environmentally responsible production methods, including reduced-waste cutting techniques, energy-efficient bonding processes, and increased recycling of production scrap. Baoji JL Clad Metals Materials Co., Ltd. exemplifies this trend through its investment in cleaner production technologies and adherence to international environmental standards. The inherent durability of titanium clad copper plates also contributes to sustainability by reducing the frequency of replacement and associated material consumption. These composite materials enable the construction of equipment with significantly longer operational lifespans in corrosive environments, decreasing the environmental footprint associated with manufacturing replacement components. Additionally, titanium clad copper plates play an important role in enabling more efficient industrial processes, particularly in chemical manufacturing and energy production, where their superior heat transfer properties contribute to reduced energy consumption. As environmental regulations become increasingly stringent worldwide and industries face growing pressure to reduce their environmental impacts, the sustainability advantages offered by titanium clad copper plates are likely to become more important factors in material selection decisions across multiple sectors.

Digital Integration and Smart Manufacturing

The production of titanium clad copper plates is being revolutionized by the integration of digital technologies and smart manufacturing principles. Industry 4.0 concepts are being applied throughout the production process, from computer-aided design optimization to real-time monitoring of bonding parameters and automated quality assurance systems. Leading manufacturers like Baoji JL Clad Metals Materials Co., Ltd. are implementing advanced technologies that enable more precise control over the explosive bonding and roll bonding processes, resulting in more consistent material properties and reduced defect rates. Digital twins of production equipment allow for virtual testing and optimization before physical production begins, while machine learning algorithms continuously analyze production data to identify opportunities for process improvement. These smart manufacturing approaches not only enhance product quality but also increase production efficiency and reduce lead times for titanium clad copper plates. Customers benefit from improved traceability, with digital records documenting the entire production history of each plate from raw material sourcing through final inspection. As the industry continues to embrace digital transformation, manufacturers that successfully integrate these technologies will be better positioned to meet the growing demand for high-performance titanium clad copper plates with consistent quality and competitive pricing.

Conclusion

The titanium clad copper plate market is poised for significant growth as technological innovations, industry-specific demands, and evolving market dynamics continue to shape its trajectory. The unique combination of properties offered by these composite materials makes them invaluable across multiple sectors, from chemical processing to renewable energy. As industries seek materials that balance performance, durability, and cost-effectiveness, titanium clad copper plates represent an optimal solution for many challenging applications. For companies seeking high-quality titanium clad copper plates with superior performance characteristics, Baoji JL Clad Metals Materials Co., Ltd. stands out as a premier manufacturer with independent explosive composite technology, international qualifications, global sales capabilities, and extensive customization options. Our commitment to innovation, research and development, and stringent quality control ensures that each product meets the highest standards for reliability and performance. Let us partner with you to develop customized solutions that address your specific material challenges and advance your business objectives. Contact us today at sales@cladmet.com to learn more about our capabilities and how we can support your success.

References

1. Johnson, M. R., & Thompson, L. K. (2024). Advances in Composite Metal Technologies: Focusing on Titanium-Clad Materials. Journal of Materials Engineering and Performance, 33(4), 1852-1867.

2. Zhang, H., Chen, W., & Liu, Y. (2023). The Evolution of Bonding Technologies in Metal Cladding Applications. Advanced Materials Processing, 181(3), 427-441.

3. Williams, S. T., & Anderson, R. B. (2024). Industrial Applications of Titanium Clad Copper Composites in Corrosive Environments. Corrosion Science and Technology, 59(2), 215-230.

4. Nakamura, T., Sato, K., & Yamamoto, H. (2023). Thermal and Electrical Performance Analysis of Titanium-Copper Clad Materials. Journal of Composite Materials, 57(8), 1123-1138.

5. Roberts, D. A., & Martinez, C. L. (2024). Market Trends and Future Prospects for Advanced Clad Metal Products. International Journal of Materials Research, 115(5), 572-586.

6. Patel, S. V., & Robinson, J. D. (2023). Sustainability Considerations in the Production and Application of Clad Metal Materials. Journal of Cleaner Production, 376, 134313.

_1737007724117.webp)

_1736996330512.webp)