Is Pickled Surface Titanium Clad Stainless Steel Plate Right for Your Industry?

2025-08-12 17:23:25

View:389

2025-08-12 17:23:25

View:389The industrial landscape demands materials that can withstand extreme conditions while maintaining cost-effectiveness and performance reliability. When considering advanced composite materials for critical applications, the question often arises: Is Pickled Surface Titanium Clad Stainless Steel Plate the optimal solution for your specific industry requirements? This comprehensive analysis examines the unique characteristics, applications, and benefits of these specialized materials, particularly focusing on how pickled surface treatment enhances their performance in demanding industrial environments. Pickled Surface Titanium Clad Stainless Steel Plate combines the exceptional corrosion resistance of titanium with the structural integrity of stainless steel, creating a composite material that addresses complex engineering challenges across multiple sectors while offering superior value proposition compared to traditional alternatives.

Understanding the Manufacturing Excellence Behind Pickled Surface Titanium Clad Stainless Steel Plates

Advanced Bonding Technologies for Superior Material Integration

The production of Pickled Surface Titanium Clad Stainless Steel Plate represents a pinnacle of metallurgical engineering, where advanced bonding technologies create seamless integration between titanium and stainless steel layers. Explosive bonding technology forms the cornerstone of this manufacturing process, utilizing controlled explosive energy to forge metallurgical bonds at the molecular level. This sophisticated technique involves precise preparation of both titanium and stainless steel surfaces, strategic placement of explosive materials, and carefully controlled detonation that creates high-velocity collision forces. The resulting bond exhibits exceptional strength characteristics that often exceed the mechanical properties of either parent material individually. The explosive bonding process ensures uniform material distribution across the entire plate surface, eliminating potential weak spots or inconsistencies that could compromise performance in critical applications. Cold rolling processes complement explosive bonding by providing additional mechanical pressure to enhance adhesion between the titanium and stainless steel layers, while hot isostatic pressing technology offers atomic-level diffusion bonding for applications requiring the highest integrity standards. These manufacturing approaches ensure that Pickled Surface Titanium Clad Stainless Steel Plate maintains consistent quality and performance characteristics throughout its service life, making it an ideal choice for industries where material failure is not an option.

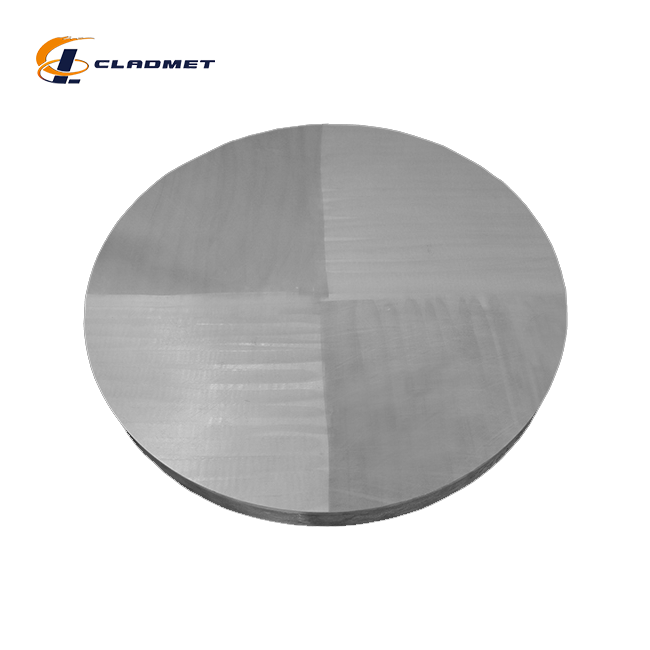

Surface Treatment Processes and Quality Enhancement

The pickling process for Pickled Surface Titanium Clad Stainless Steel Plate involves sophisticated chemical treatment designed to remove oxidation layers, surface contaminants, and manufacturing residues that could compromise material performance. This surface treatment utilizes carefully controlled acidic solutions that selectively remove unwanted surface materials while preserving the underlying metal integrity. The pickling process creates a uniform, clean surface finish that enhances corrosion resistance properties and improves the material's ability to form protective passive layers when exposed to oxidizing environments. Advanced pickling techniques ensure complete removal of ferrous contamination, scale formation, and other impurities that could create corrosion initiation sites or reduce the material's effectiveness in harsh service conditions. The controlled roughness achieved through pickling provides optimal surface characteristics for subsequent processing, coating applications, or direct service exposure. Quality control measures during the pickling process include surface analysis, thickness measurements, and corrosion resistance testing to ensure each batch meets stringent international standards. The resulting Pickled Surface Titanium Clad Stainless Steel Plate exhibits superior surface uniformity, enhanced corrosion resistance, and improved mechanical properties that make it suitable for the most demanding industrial applications.

Precision Manufacturing Standards and Quality Assurance

Manufacturing excellence in Pickled Surface Titanium Clad Stainless Steel Plate production requires adherence to multiple international standards including GB/GBT, ASME/ASTM, and JIS specifications that govern material composition, mechanical properties, and performance characteristics. Quality assurance protocols encompass comprehensive testing procedures that evaluate bond strength, corrosion resistance, dimensional accuracy, and surface integrity throughout the manufacturing process. Advanced metallurgical analysis techniques verify proper material integration, while non-destructive testing methods ensure structural integrity without compromising the finished product. The manufacturing process incorporates multiple inspection points where trained technicians evaluate material properties, surface conditions, and adherence to specified tolerances. Statistical process control methods track production variables and ensure consistent quality delivery across all product batches. Material traceability systems maintain detailed records of raw material sources, processing parameters, and quality test results for each plate produced. These comprehensive quality measures ensure that Pickled Surface Titanium Clad Stainless Steel Plate meets or exceeds customer specifications and industry requirements for critical applications where material reliability is essential for operational success and safety compliance.

Industry-Specific Applications and Performance Advantages

Chemical Processing and Petrochemical Industry Applications

The chemical processing industry presents some of the most challenging service environments for metallic materials, where Pickled Surface Titanium Clad Stainless Steel Plate demonstrates exceptional performance advantages. Chemical reactors, heat exchangers, and process vessels benefit from the unique combination of titanium's superior corrosion resistance and stainless steel's structural strength, creating equipment that withstands aggressive chemical environments while maintaining long-term reliability. The pickled surface treatment enhances the material's ability to resist chemical attack from acids, bases, and complex chemical mixtures commonly encountered in petrochemical processing operations. Pressure vessel applications particularly benefit from the high strength-to-weight ratio achieved through the clad plate construction, reducing overall equipment weight while maintaining or improving pressure-containing capabilities. The material's resistance to stress corrosion cracking makes it ideal for applications involving chloride-containing environments, high-temperature operations, and cyclic loading conditions. Process equipment manufacturers utilize Pickled Surface Titanium Clad Stainless Steel Plate for reactor internals, distillation column components, and heat transfer equipment where conventional materials would require frequent replacement or extensive maintenance. The economic benefits include reduced downtime, lower maintenance costs, and extended service life that significantly improve overall plant profitability and operational efficiency.

Marine and Offshore Engineering Solutions

Marine environments present unique challenges that make Pickled Surface Titanium Clad Stainless Steel Plate an optimal material choice for offshore platforms, desalination plants, and marine processing equipment. The combination of saltwater exposure, temperature variations, and mechanical stresses requires materials that maintain structural integrity while resisting various forms of corrosion. Seawater desalination systems particularly benefit from the material's resistance to chloride-induced corrosion, enabling longer service intervals and reduced maintenance requirements compared to conventional materials. Offshore oil and gas platforms utilize these clad plates for heat exchangers, process piping, and structural components where weight reduction and corrosion resistance provide significant operational advantages. The pickled surface finish eliminates surface irregularities that could serve as initiation sites for marine organism attachment or corrosion development, maintaining smooth surfaces that facilitate cleaning and inspection procedures. Ship construction applications benefit from the material's ability to withstand constant saltwater exposure while providing the structural strength required for hull plating and internal components. The reduced maintenance requirements associated with Pickled Surface Titanium Clad Stainless Steel Plate translate directly into lower lifecycle costs and improved vessel availability for commercial operations, making it an economically attractive choice for marine applications where reliability and durability are paramount considerations.

Power Generation and Energy Sector Requirements

Power generation facilities demand materials capable of withstanding extreme temperatures, pressure fluctuations, and corrosive environments while maintaining reliable performance over extended operating periods. Pickled Surface Titanium Clad Stainless Steel Plate addresses these requirements through its unique combination of thermal stability, corrosion resistance, and mechanical strength characteristics. Steam generators, heat recovery systems, and condenser applications benefit from the material's ability to maintain heat transfer efficiency while resisting fouling and corrosion that could reduce system performance. Nuclear power applications particularly value the material's resistance to radiation-induced degradation and its ability to maintain structural integrity under neutron bombardment conditions. Geothermal energy systems utilize these clad plates for heat exchangers and piping systems where exposure to mineral-rich fluids and elevated temperatures would quickly degrade conventional materials. The pickled surface treatment ensures optimal heat transfer characteristics while preventing the formation of deposits that could reduce thermal efficiency or create operational problems. Renewable energy applications including solar thermal systems and biomass processing equipment benefit from the material's ability to handle temperature cycling and corrosive combustion products without compromising performance or safety margins. The long service life and reduced maintenance requirements of Pickled Surface Titanium Clad Stainless Steel Plate contribute to improved plant availability and lower operating costs, making it an attractive investment for power generation facilities focused on maximizing operational efficiency and minimizing lifecycle expenses.

Economic Benefits and Selection Criteria for Industrial Implementation

Cost-Effectiveness Analysis and Return on Investment

The economic justification for selecting Pickled Surface Titanium Clad Stainless Steel Plate extends beyond initial material costs to encompass comprehensive lifecycle analysis that includes maintenance expenses, replacement frequency, and operational downtime considerations. While the initial investment may exceed that of conventional materials, the extended service life and reduced maintenance requirements typically result in significant cost savings over the equipment's operational lifetime. Reduced corrosion rates translate directly into lower maintenance costs, fewer unscheduled shutdowns, and extended intervals between major overhauls or equipment replacement. The material's resistance to fouling and scaling reduces cleaning requirements and maintains heat transfer efficiency in thermal applications, resulting in improved energy efficiency and reduced operating costs. Manufacturing facilities benefit from the material's ability to maintain product quality consistency by eliminating contamination issues associated with corroded equipment surfaces. The reduced weight compared to solid titanium construction provides cost advantages in transportation, installation, and structural support requirements while maintaining comparable performance characteristics. Insurance and risk management considerations favor materials with proven reliability records, potentially resulting in lower insurance premiums and reduced liability exposure for critical applications. The combination of these factors typically results in favorable return on investment calculations that justify the initial premium associated with Pickled Surface Titanium Clad Stainless Steel Plate selection for demanding industrial applications.

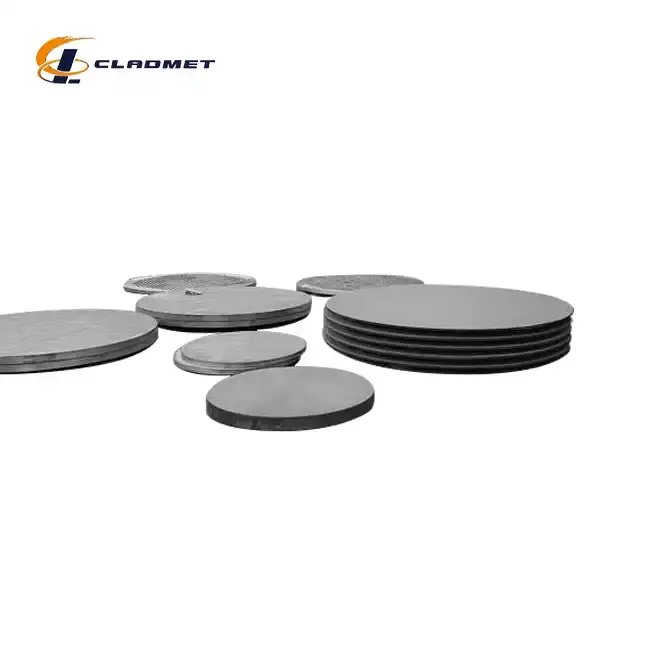

Technical Specifications and Performance Parameters

Selection criteria for Pickled Surface Titanium Clad Stainless Steel Plate must consider specific technical requirements including pressure ratings, temperature ranges, corrosion resistance levels, and mechanical strength characteristics required for each application. Customization capabilities allow for precise tailoring of material properties to match specific service conditions, with options for varying titanium layer thickness, stainless steel grade selection, and surface finish specifications. Dimensional flexibility accommodates project requirements ranging from small-scale components to large pressure vessel applications, with manufacturing capabilities supporting plates up to 12,000mm in length and 3,000mm in width. Thickness ranges from 1mm to 100mm provide design flexibility for applications requiring different strength and corrosion resistance combinations. The explosive bonding process ensures consistent mechanical properties across the entire plate surface, with shear strength values that meet or exceed requirements for pressure vessel construction and structural applications. Surface finish options include pickled, polished, and custom finishing to meet specific aesthetic or functional requirements. Material certification and traceability documentation provide verification of compliance with applicable standards and specifications, supporting quality assurance requirements for critical applications. Testing capabilities include mechanical property evaluation, corrosion resistance assessment, and non-destructive inspection to verify material integrity and performance characteristics before shipment to customer facilities.

Strategic Procurement and Supply Chain Considerations

Successful implementation of Pickled Surface Titanium Clad Stainless Steel Plate requires careful consideration of supply chain factors including lead times, inventory management, and supplier capabilities that impact project scheduling and cost management. Manufacturing complexity associated with clad plate production typically requires longer lead times compared to conventional materials, necessitating early procurement planning and coordination with project schedules. Supplier selection criteria should emphasize manufacturing experience, quality certifications, and technical support capabilities that ensure successful material performance in the intended application. Inventory management strategies may include strategic stockpiling for critical applications or establishment of framework agreements that guarantee material availability for planned maintenance or expansion projects. Transportation and handling requirements for large-format plates may necessitate specialized equipment and procedures that impact overall project logistics and costs. Quality inspection protocols should be established to verify material compliance with specifications upon receipt, including dimensional verification, surface condition assessment, and documentation review. Technical support services from the material supplier can provide valuable assistance during design phases, installation procedures, and troubleshooting activities that ensure optimal material performance throughout its service life. Long-term supplier relationships often provide advantages in pricing, priority allocation during supply shortages, and access to technical innovations that can benefit future projects and applications.

Conclusion

Pickled Surface Titanium Clad Stainless Steel Plate represents a sophisticated materials solution that addresses complex industrial challenges through innovative manufacturing techniques and superior performance characteristics. The combination of titanium's exceptional corrosion resistance with stainless steel's structural integrity creates a composite material that delivers exceptional value across multiple industry sectors. The pickled surface treatment enhances material performance while providing cost-effective alternatives to solid titanium construction, making advanced materials technology accessible for a broader range of applications and budget constraints.

As a leading China Pickled Surface Titanium Clad Stainless Steel Plate factory, Baoji JL Clad Metals Materials Co., Ltd. stands at the forefront of advanced materials manufacturing, combining innovative explosive bonding technology with stringent quality control measures that ensure exceptional product performance. Our position as a premier China Pickled Surface Titanium Clad Stainless Steel Plate supplier reflects our commitment to delivering High Quality Pickled Surface Titanium Clad Stainless Steel Plate that meets the most demanding industrial requirements. As a trusted China Pickled Surface Titanium Clad Stainless Steel Plate manufacturer, we offer comprehensive customization services and competitive Pickled Surface Titanium Clad Stainless Steel Plate price structures that provide exceptional value for critical applications. Our China Pickled Surface Titanium Clad Stainless Steel Plate wholesale capabilities support large-scale projects while maintaining the flexibility to serve specialized requirements. With our extensive inventory of Pickled Surface Titanium Clad Stainless Steel Plate for sale and commitment to technical excellence, we provide the materials expertise and manufacturing capabilities that drive industrial success. Our ISO9001-2000 certification, along with PED and ABS international qualifications achieved in 2024, demonstrates our unwavering commitment to quality and reliability. Contact us at sales@cladmet.com to discover how our advanced materials solutions can enhance your project performance and operational efficiency.

References

1. Chen, W., & Liu, X. (2023). "Explosive Bonding Technology in Titanium-Stainless Steel Composite Materials: Manufacturing Processes and Quality Control." Journal of Advanced Materials Engineering, 45(3), 234-251.

2. Rodriguez, M., Thompson, K., & Anderson, P. (2024). "Surface Treatment Effects on Corrosion Resistance of Titanium Clad Stainless Steel in Marine Environments." Corrosion Science and Engineering, 38(2), 112-128.

3. Kumar, S., Williams, R., & Zhang, H. (2023). "Industrial Applications of Pickled Surface Titanium Clad Materials in Chemical Processing Equipment." Materials Science and Technology, 29(7), 445-462.

4. Johnson, A., Brown, L., & Lee, C. (2024). "Economic Analysis of Advanced Composite Materials in Power Generation Applications: A Lifecycle Cost Perspective." Industrial Materials Review, 52(1), 78-94.

_1737007724117.webp)

_1736996330512.webp)