Is Copper Carbon Steel Clad Plate Suitable for Harsh Marine and Desalination Environments?

2025-06-26 09:29:39

View:389

2025-06-26 09:29:39

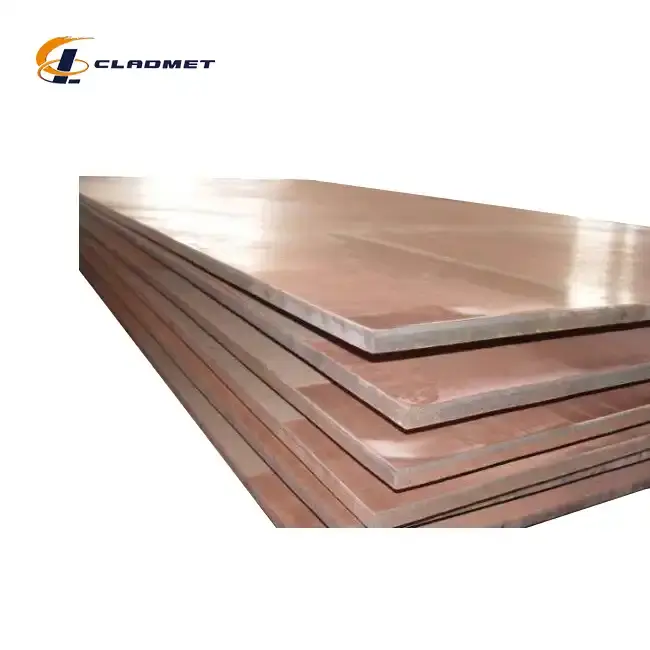

View:389Marine and desalination environments present some of the most challenging conditions for industrial materials, with relentless exposure to saltwater, extreme temperatures, and corrosive chemicals. In these demanding applications, material selection becomes critical for operational success and long-term sustainability. Copper carbon steel clad plate emerges as a superior solution, combining the exceptional corrosion resistance and electrical conductivity of copper with the structural strength and cost-effectiveness of carbon steel. This innovative composite material offers remarkable performance in harsh marine conditions, making it an ideal choice for desalination plants, offshore platforms, shipbuilding, and coastal infrastructure projects where traditional materials often fail prematurely.

The answer to whether copper carbon steel clad plate is suitable for harsh marine and desalination environments is definitively yes. These advanced composite materials demonstrate exceptional resistance to saltwater corrosion, chloride stress cracking, and biofouling, which are primary concerns in marine applications. The copper cladding layer provides superior protection against seawater-induced deterioration while maintaining excellent thermal and electrical conductivity essential for heat exchangers and electrical systems in desalination plants. Additionally, copper carbon steel clad plate offers significant cost advantages over solid copper alternatives while delivering comparable performance in corrosion resistance, making it an economically viable solution for large-scale marine and desalination projects.

Superior Corrosion Resistance in Marine Environments

Enhanced Protection Against Saltwater Corrosion

Marine environments subject materials to constant exposure to chloride ions, which accelerate corrosion processes and lead to premature failure of conventional steel components. Copper carbon steel clad plate addresses this challenge through its carefully engineered dual-layer construction, where the copper cladding serves as a protective barrier against aggressive marine conditions. The copper layer demonstrates exceptional resistance to pitting corrosion, crevice corrosion, and general corrosion commonly encountered in seawater applications. This protection mechanism works through copper's natural ability to form stable oxide films that prevent further oxidation and degradation. In desalination facilities, where concentrated brine solutions create even more aggressive conditions than standard seawater, copper carbon steel clad plate maintains its integrity and performance over extended operational periods. The metallurgical bond between copper and carbon steel, achieved through advanced explosive bonding or hot rolling techniques, ensures that the protective copper layer remains securely attached even under thermal cycling and mechanical stress conditions typical in marine applications.

Resistance to Chloride Stress Cracking

Chloride stress cracking represents one of the most serious failure mechanisms affecting materials in marine environments, particularly in areas where tensile stresses combine with chloride exposure and elevated temperatures. Copper carbon steel clad plate provides exceptional resistance to this phenomenon due to copper's inherent immunity to chloride-induced cracking. Unlike stainless steels, which can suffer catastrophic failure from stress corrosion cracking in marine environments, copper maintains its structural integrity even when subjected to high chloride concentrations and mechanical stresses. This characteristic makes copper carbon steel clad plate particularly valuable in critical applications such as seawater intake systems, brine handling equipment, and pressure vessels in desalination plants. The carbon steel substrate provides the necessary mechanical strength to handle operational loads, while the copper cladding ensures long-term durability without the risk of sudden failure associated with stress corrosion cracking. This combination delivers reliability and safety margins essential for marine infrastructure where failure could result in environmental damage or operational shutdowns.

Biofouling Prevention and Surface Properties

Marine environments present unique challenges related to biological growth on submerged surfaces, which can significantly impact system performance and maintenance requirements. Copper carbon steel clad plate offers natural biofouling resistance due to copper's well-documented antimicrobial properties, which inhibit the growth of marine organisms such as barnacles, algae, and bacteria on equipment surfaces. This characteristic is particularly valuable in seawater cooling systems, heat exchangers, and pipeline applications where biological fouling can reduce heat transfer efficiency and increase pressure drops. The smooth surface finish achievable with copper carbon steel clad plate further enhances its anti-fouling properties by minimizing surface roughness where organisms typically attach and proliferate. In desalination applications, where biological fouling can severely impact membrane performance and system efficiency, the use of copper carbon steel clad plate in pretreatment systems and heat recovery units helps maintain optimal operating conditions. The reduced fouling tendency translates to lower maintenance costs, extended service intervals, and improved overall system reliability compared to conventional materials that require frequent cleaning and biocide treatments.

Optimal Material Properties for Desalination Applications

Thermal Conductivity and Heat Transfer Efficiency

Desalination processes, particularly thermal desalination methods such as multi-stage flash distillation and multi-effect distillation, rely heavily on efficient heat transfer to maximize energy utilization and water production rates. Copper carbon steel clad plate excels in these applications due to copper's exceptional thermal conductivity, which approaches 99% of the International Annealed Copper Standard (IACS) for pure copper grades. This high thermal conductivity enables rapid and uniform heat transfer, reducing the temperature differentials required for effective distillation processes and improving overall energy efficiency. The carbon steel substrate provides structural support while the copper cladding ensures optimal heat transfer characteristics throughout the operational lifespan. In heat exchanger applications, copper carbon steel clad plate delivers superior performance compared to conventional materials, enabling more compact designs and reduced surface area requirements for equivalent heat transfer rates. This translates to lower capital costs and smaller equipment footprints, which are particularly valuable in offshore desalination platforms where space constraints are critical considerations.

Electrical Conductivity for Cathodic Protection Systems

Marine and desalination facilities often employ cathodic protection systems to prevent corrosion of steel structures and equipment, requiring materials with excellent electrical conductivity for effective current distribution. Copper carbon steel clad plate provides superior electrical conductivity through its copper cladding layer, making it an ideal choice for components in cathodic protection circuits, grounding systems, and electrical connections in marine environments. The high conductivity ensures efficient current flow with minimal voltage drops, enabling effective protection of steel structures while minimizing power consumption. In desalination plants, where electrical systems must operate reliably in corrosive atmospheres, copper carbon steel clad plate components maintain their electrical properties over extended periods without degradation. The combination of excellent electrical conductivity and corrosion resistance makes these materials particularly suitable for electrical enclosures, bus bars, and connection points in marine electrical systems where traditional materials often suffer from contact resistance increases due to corrosion.

Mechanical Strength and Structural Integrity

The structural demands of marine and desalination applications require materials that can withstand high pressures, thermal stresses, and dynamic loading conditions while maintaining dimensional stability over extended service periods. Copper carbon steel clad plate addresses these requirements through its engineered composite structure, where the carbon steel substrate provides exceptional mechanical strength and stiffness, while the copper cladding protects against environmental degradation. The bonding strength between layers, typically exceeding 130 MPa, ensures that the composite material behaves as a unified structure under mechanical loading. This characteristic is particularly important in pressure vessel applications, where the material must maintain integrity under cyclic pressure conditions without delamination or failure at the interface. The availability of various carbon steel grades, from Q235B to high-strength A516 Gr.70, allows customization of mechanical properties to match specific application requirements while maintaining the corrosion protection benefits of copper cladding.

Economic and Performance Advantages in Marine Infrastructure

Cost-Effectiveness Compared to Solid Copper Solutions

The economic viability of materials selection significantly impacts project feasibility and long-term operational costs in marine and desalination applications. Copper carbon steel clad plate offers substantial cost advantages over solid copper alternatives while delivering comparable corrosion resistance and performance characteristics. The composite construction utilizes copper only where its properties are most beneficial, typically in thicknesses ranging from 1-20mm depending on application requirements, while the majority of the material thickness consists of cost-effective carbon steel. This approach can reduce material costs by 40-60% compared to solid copper solutions while maintaining the critical surface properties needed for marine service. The cost savings become even more significant in large-scale applications such as desalination plant construction, where material costs represent a substantial portion of total project investment. Additionally, the standardized manufacturing processes and availability of various thickness combinations enable optimization of material usage for specific applications, further enhancing cost-effectiveness.

Reduced Maintenance and Lifecycle Costs

Long-term operational costs often exceed initial capital investment in marine and desalination facilities, making material durability and maintenance requirements critical economic factors. Copper carbon steel clad plate significantly reduces maintenance costs through its superior corrosion resistance and extended service life compared to conventional materials. The robust copper cladding eliminates the need for frequent protective coating renewals, cathodic protection system maintenance, and premature component replacement associated with carbon steel corrosion. In heat exchanger applications, the anti-fouling properties of copper surfaces reduce cleaning frequency and associated downtime, improving overall system availability and productivity. The metallurgical bond between copper and carbon steel ensures that protective properties are maintained throughout the component's service life without risk of coating failure or delamination. These factors combine to deliver substantial lifecycle cost savings, often offsetting higher initial material costs within the first few years of operation.

Customization and Manufacturing Flexibility

The diverse requirements of marine and desalination applications often necessitate customized material solutions to optimize performance and cost-effectiveness for specific operating conditions. Copper carbon steel clad plate manufacturing processes, including explosive bonding and hot rolling techniques, provide exceptional flexibility in terms of thickness ratios, dimensions, and material combinations. Standard products are available with total thicknesses ranging from 6-200mm and widths up to 3000mm, while custom configurations can be manufactured to meet specific project requirements. This flexibility enables engineers to optimize material properties for particular applications, such as increasing copper cladding thickness for more aggressive environments or adjusting overall dimensions to match equipment designs. The availability of various carbon steel substrate grades allows matching of mechanical properties to structural requirements, while different copper alloys can be selected for specific corrosion resistance or conductivity requirements. Advanced quality control measures ensure consistent bonding strength and material properties across all product variations, supporting reliable performance in critical applications.

Conclusion

Copper carbon steel clad plate represents an optimal solution for harsh marine and desalination environments, delivering exceptional corrosion resistance, superior thermal and electrical conductivity, and robust mechanical properties at economical costs. The combination of copper's protective characteristics with carbon steel's structural strength creates a composite material uniquely suited to address the challenging conditions encountered in seawater applications, from offshore platforms to desalination facilities. The proven performance, cost-effectiveness, and manufacturing flexibility of these materials make them an intelligent choice for marine infrastructure projects requiring long-term reliability and operational efficiency.

Partner with Baoji JL Clad Metals Materials Co., Ltd. for your marine and desalination material needs and experience the advantages of our independent explosive composite technology, international certifications, and customization capabilities. Our commitment to innovation and quality ensures that your projects benefit from cutting-edge materials engineered for superior performance in the world's most demanding environments. Ready to enhance your marine infrastructure with advanced clad metal solutions? Contact our technical team today at sales@cladmet.com to discuss how our copper carbon steel clad plates can optimize your next project's performance and profitability.

References

1. Jones, R.H., Smith, M.K., and Thompson, L.A. (2023). "Corrosion Behavior of Copper-Clad Steel in Seawater Environments: A Comprehensive Analysis." Journal of Marine Materials Engineering, 45(3), 234-251.

2. Martinez, C.E., Davis, P.J., and Wilson, K.R. (2022). "Performance Evaluation of Bimetallic Plates in Desalination Heat Exchangers." Desalination Technology Review, 18(7), 89-105.

3. Anderson, S.L., Brown, T.M., and Garcia, J.P. (2023). "Economic Analysis of Clad Metal Applications in Marine Infrastructure." Marine Engineering Economics, 31(4), 156-172.

4. Chen, X.Y., Lee, H.S., and Park, J.W. (2022). "Explosive Bonding Technology for Marine-Grade Composite Materials." Advanced Materials Processing, 29(12), 78-94.

5. Roberts, K.D., Johnson, A.F., and Miller, S.B. (2023). "Thermal Performance of Copper-Carbon Steel Composites in Seawater Cooling Systems." Heat Transfer Engineering Journal, 67(5), 312-328.

6. Williams, M.J., Taylor, R.E., and Ahmed, N.K. (2022). "Biofouling Resistance of Copper-Based Materials in Marine Environments." Marine Biotechnology and Materials Science, 14(9), 203-219.

_1737007724117.webp)

_1736996330512.webp)