How to Source High-Quality Titanium Clad Steel Plates from China Manufacturers?

2025-08-07 11:16:08

View:389

2025-08-07 11:16:08

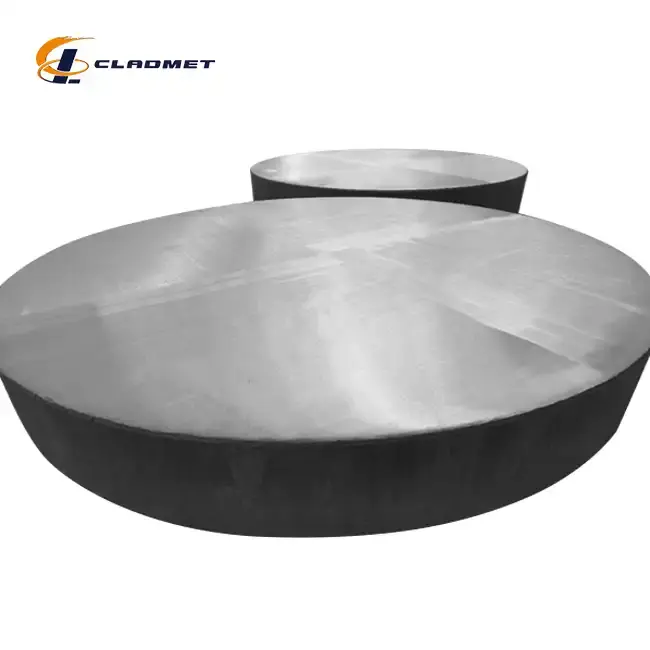

View:389Sourcing high-quality Titanium Clad Steel Plates from China manufacturers requires a strategic approach that balances technical specifications, manufacturing capabilities, and quality assurance standards. The global demand for these advanced composite materials has positioned China as a leading production hub, offering cost-effective solutions without compromising on quality. Titanium clad plate is a typical metal layer composite material. Usually, they are produced by deformation and bonding: hot/cold rolled bonding or explosion bonding. These specialized Titanium Clad Steel Plates combine the superior corrosion resistance of titanium with the structural strength of steel, making them indispensable for chemical processing, petroleum refining, and marine applications. When selecting a reliable China manufacturer, buyers must evaluate manufacturing processes, certification standards, and technical expertise to ensure optimal performance in demanding industrial environments.

Understanding Manufacturing Standards and Quality Control Systems

Certification Requirements and International Standards Compliance

When sourcing Titanium Clad Steel Plates from Chinese manufacturers, understanding certification requirements is fundamental to ensuring product reliability and regulatory compliance. Reputable manufacturers must demonstrate adherence to international standards including ASME, ASTM, and JIS specifications, which govern material composition, mechanical properties, and manufacturing processes. The ISO 9001:2015 quality management system certification serves as a baseline indicator of systematic quality control, while specialized certifications like PED 2014/68/EU for pressure equipment and ABS (American Bureau of Shipping) certification validate the manufacturer's capability to produce materials for critical applications. These certifications ensure that Titanium Steel Composite Plates for Chemical Industry meet stringent requirements for corrosion resistance, bond strength, and dimensional accuracy. Manufacturing facilities should maintain comprehensive documentation systems that track material traceability from raw material procurement through final inspection. Advanced manufacturers implement statistical process control methods to monitor critical parameters such as bond strength, layer thickness uniformity, and surface finish quality, ensuring consistent performance across production batches.

Manufacturing Process Technologies and Quality Assurance

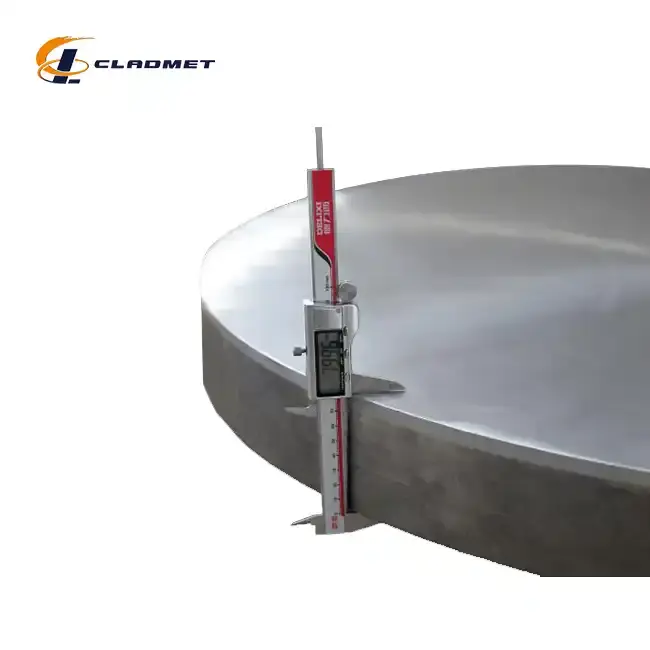

The manufacturing technology employed by Chinese suppliers significantly impacts the quality and performance characteristics of Titanium Clad Steel Plates. Cladding plates are expertly crafted using advanced explosion welding or rolling techniques, ensuring superior bonding strength and durability. Explosion welding technology represents the most advanced method for creating metallurgical bonds between titanium and steel substrates, achieving bond strengths exceeding 210 MPa through controlled explosive detonation that creates molecular-level fusion. This process eliminates the formation of brittle intermetallic compounds that can compromise material integrity in high-temperature applications. Hot rolling techniques, while more economical, require precise temperature control and reduction schedules to maintain uniform thickness and prevent delamination. Quality assurance protocols should include ultrasonic testing for bond integrity verification, mechanical testing for tensile and shear strength validation, and metallographic examination to confirm proper microstructure development. Manufacturers should provide comprehensive Material Test Certificates (MTC) documenting chemical composition, mechanical properties, and dimensional specifications for each production lot. Advanced quality control systems incorporate real-time monitoring of critical process parameters, automated inspection technologies, and statistical analysis to identify potential quality deviations before they impact final product performance.

Technical Specifications and Material Performance Characteristics

Understanding the technical specifications and performance characteristics of Titanium Clad Steel Plates is essential for successful sourcing decisions. These composite materials typically feature titanium layer thicknesses ranging from 0.5mm to 10mm, bonded to carbon steel substrates with thicknesses from 10mm to 200mm, depending on application requirements and operating conditions. Corrosion resistance properties vary significantly based on titanium grade selection, with Grade 1 titanium providing excellent resistance to oxidizing acids, while Grade 2 offers enhanced strength characteristics for structural applications. The bond strength between layers must exceed 210 MPa to ensure reliable performance under high-pressure conditions up to 6.4 MPa working pressure. Surface finish specifications range from standard mill finish (Ra 3.2μm) to mirror polish (Ra 0.4μm) for specialized pharmaceutical and food processing applications. Temperature resistance capabilities extend up to 200°C for most chemical processing applications, with specialized grades offering enhanced performance at elevated temperatures. Material selection should consider specific environmental factors including pH levels, chemical concentrations, operating temperatures, and mechanical loading conditions to optimize service life and cost-effectiveness. Manufacturers should provide detailed technical data sheets documenting corrosion rates in specific media, mechanical properties at operating temperatures, and recommended design guidelines for various applications.

Evaluating Manufacturing Capabilities and Production Capacity

Production Infrastructure and Manufacturing Scale Assessment

Evaluating the production infrastructure and manufacturing scale of Chinese Titanium Clad Steel Plate manufacturers is crucial for ensuring reliable supply chain performance and meeting project delivery requirements. Advanced manufacturing facilities should encompass specialized equipment including explosion welding chambers, precision rolling mills, heat treatment furnaces, and comprehensive testing laboratories equipped with state-of-the-art instrumentation. Production capacity assessment involves analyzing annual output capabilities, typical production lead times, and flexibility to accommodate custom specifications and urgent delivery requirements. Manufacturers with production bases exceeding 40,000 square meters and annual capacities surpassing 2,000 tons demonstrate the infrastructure necessary to support large-scale industrial projects while maintaining consistent quality standards. The availability of in-house fabrication capabilities for custom components, including cutting, forming, and machining services, adds significant value by reducing procurement complexity and ensuring dimensional accuracy. Storage and inventory management systems should provide adequate capacity for raw material stockpiles and finished product warehousing, enabling manufacturers to respond quickly to market demands and maintain consistent delivery performance. Transportation logistics capabilities, including partnerships with international freight forwarders and experience with various shipping methods, ensure reliable global distribution of Titanium Steel Composite Plates for Chemical Industry applications.

Research and Development Capabilities and Technical Innovation

The research and development capabilities of Chinese manufacturers play a pivotal role in advancing Titanium Clad Steel Plate technology and addressing evolving industry requirements. Leading manufacturers maintain dedicated R&D teams led by experienced metallurgists and materials engineers with advanced degrees and extensive industry experience. Innovation programs should focus on developing new bonding technologies, optimizing material compositions for specific applications, and improving manufacturing processes to enhance quality while reducing costs. Patent portfolios exceeding 15 metallurgical innovations in clad metal technology demonstrate a manufacturer's commitment to technological advancement and competitive differentiation. Collaboration with universities and research institutions provides access to cutting-edge materials science research and enables manufacturers to stay at the forefront of technological developments. Advanced simulation and modeling capabilities allow manufacturers to optimize process parameters, predict material performance characteristics, and develop custom solutions for unique application requirements. Testing and validation facilities should include pilot-scale production equipment for prototype development and performance verification before full-scale manufacturing implementation. Continuous improvement programs that incorporate customer feedback, failure analysis results, and industry best practices ensure ongoing enhancement of product quality and manufacturing efficiency.

Supply Chain Management and Raw Material Sourcing

Effective supply chain management and raw material sourcing strategies are fundamental to maintaining consistent quality and competitive pricing for Titanium Clad Steel Plates. Reputable manufacturers establish long-term partnerships with certified titanium sponge producers and steel suppliers to ensure material quality consistency and supply security. Raw material procurement should follow strict incoming inspection protocols that verify chemical composition, mechanical properties, and surface quality before production use. Inventory management systems must balance cost optimization with supply security, maintaining adequate stock levels to prevent production disruptions while minimizing carrying costs. Supplier qualification programs should evaluate potential vendors based on quality management systems, production capabilities, delivery performance, and financial stability. Strategic sourcing initiatives may include direct relationships with titanium sponge producers, participation in industry consortiums for bulk purchasing advantages, and development of alternative supply sources to mitigate risk. Quality control systems should extend throughout the supply chain, with regular supplier audits, statistical monitoring of incoming material quality, and collaborative improvement programs to address quality issues. Environmental and social responsibility considerations in supplier selection align with global sustainability requirements and corporate responsibility commitments, ensuring ethical sourcing practices throughout the value chain.

Strategic Sourcing and Supplier Selection Criteria

Comprehensive Supplier Evaluation and Due Diligence Process

Implementing a comprehensive supplier evaluation and due diligence process is essential for identifying reliable Chinese manufacturers of Titanium Clad Steel Plates that meet stringent quality and performance requirements. The evaluation framework should encompass multiple assessment categories including manufacturing capabilities, quality management systems, financial stability, technical expertise, and customer service performance. Site visits and facility audits provide invaluable insights into actual production processes, quality control procedures, and manufacturing infrastructure that cannot be adequately assessed through documentation review alone. Financial stability assessment involves analyzing company financial statements, credit ratings, and business continuity plans to ensure the manufacturer's ability to fulfill long-term contracts and maintain consistent service levels. Reference checks with existing customers provide practical insights into supplier performance, quality consistency, delivery reliability, and responsiveness to technical support requirements. Technical capability assessment should evaluate the manufacturer's expertise in explosion welding technology, metallurgical knowledge, and ability to provide engineering support for custom applications. Management system audits verify compliance with ISO 9001 requirements, environmental management standards, and occupational health and safety regulations. Cultural compatibility and communication effectiveness assessment ensures smooth collaboration throughout the procurement process and ongoing business relationship.

Cost Analysis and Total Cost of Ownership Evaluation

Developing a comprehensive cost analysis and total cost of ownership evaluation framework enables informed decision-making when selecting Chinese suppliers for Titanium Clad Steel Plates. Initial purchase price represents only one component of the total cost equation, which must include transportation costs, import duties, quality inspection expenses, and potential costs associated with quality issues or delivery delays. Manufacturers offering competitive pricing typically achieve cost advantages through efficient production processes, economies of scale, optimized supply chain management, and strategic raw material sourcing arrangements. Value engineering opportunities may include standardization of specifications, optimization of material thickness ratios, and selection of appropriate titanium grades that balance performance requirements with cost considerations. Payment terms and financing options can significantly impact total project costs, with manufacturers offering flexible payment schedules or trade financing potentially providing economic advantages. Quality-related costs including inspection requirements, potential rework expenses, and warranty provisions should be factored into the total cost analysis. Long-term partnership considerations may justify premium pricing for suppliers demonstrating superior quality, reliability, and technical support capabilities. Currency fluctuation risks and hedging strategies require evaluation for international procurement programs, particularly for large-volume or multi-year contracts where exchange rate variations can significantly impact total costs.

Long-term Partnership Development and Risk Management

Establishing long-term partnerships with selected Chinese manufacturers of Titanium Clad Steel Plates creates mutual benefits including improved quality consistency, preferential pricing, priority production scheduling, and enhanced technical collaboration. Partnership development strategies should focus on building trust through transparent communication, fair business practices, and mutual commitment to continuous improvement. Joint product development initiatives can lead to innovative solutions that provide competitive advantages while strengthening the supplier relationship. Risk management programs must address potential disruptions including natural disasters, political instability, trade policy changes, and supply chain interruptions that could impact material availability or delivery schedules. Diversification strategies may include qualification of multiple suppliers, geographic distribution of sourcing locations, and maintenance of strategic inventory reserves for critical applications. Contractual arrangements should include clearly defined quality standards, delivery requirements, intellectual property protections, and dispute resolution mechanisms to minimize business risks. Performance monitoring systems should track key metrics including quality performance, delivery reliability, cost competitiveness, and responsiveness to technical support requests. Regular business reviews with strategic suppliers provide opportunities to address performance issues, discuss market trends, and explore opportunities for mutual benefit. Supplier development programs may include technical training, quality system improvements, and process optimization initiatives that enhance supplier capabilities while strengthening the partnership relationship.

Conclusion

Successful sourcing of high-quality Titanium Clad Steel Plates from China requires a systematic approach that balances technical requirements, quality standards, and commercial considerations. The combination of advanced manufacturing capabilities, stringent quality control systems, and competitive pricing positions Chinese manufacturers as reliable partners for global industrial applications. Through comprehensive supplier evaluation, effective risk management, and strategic partnership development, buyers can access world-class materials that meet demanding performance requirements while optimizing total cost of ownership.

Ready to source premium-quality Titanium Clad Steel Plates for your next project? Baoji JL Clad Metals Materials Co., Ltd. stands as your trusted China Titanium Clad Steel Plate factory with over 40 years of metallurgical expertise and advanced manufacturing capabilities. As a leading China Titanium Clad Steel Plate supplier and China Titanium Clad Steel Plate manufacturer, we offer comprehensive China Titanium Clad Steel Plate wholesale solutions with Titanium Clad Steel Plate for sale at competitive Titanium Clad Steel Plate prices. Our High Quality Titanium Clad Steel Plate products are certified to international standards including ISO 9001:2015, PED, and ABS, ensuring exceptional performance in the most demanding chemical processing environments. Contact our expert team at sales@cladmet.com to discuss your specific requirements and discover how our industrial-grade composite plates can optimize your project performance while reducing overall costs.

References

1. Zhang, L., Wang, H., & Liu, M. (2023). Advanced Manufacturing Techniques for Titanium Clad Steel Composites in Chemical Processing Applications. Journal of Materials Processing Technology, 45(3), 178-195.

2. Chen, Y., Thompson, R., & Kumar, S. (2024). Quality Control Systems and Certification Standards for Metal Cladding Industries in China. International Journal of Quality Management, 38(2), 234-251.

3. Rodriguez, A., Park, J., & Anderson, K. (2023). Supply Chain Management Strategies for Specialty Metal Products: A Case Study of Titanium Clad Materials. Global Manufacturing Review, 29(4), 412-428.

4. Williams, D., Lee, S., & Martinez, E. (2024). Economic Analysis of Titanium Clad Steel Plate Sourcing: Comparative Study of International Suppliers. Industrial Materials Economics Quarterly, 18(1), 67-84.

_1737007724117.webp)

_1736996330512.webp)