How to Maintain Aluminum Copper Clad Rods for Longevity?

2025-06-10 12:34:18

View:389

2025-06-10 12:34:18

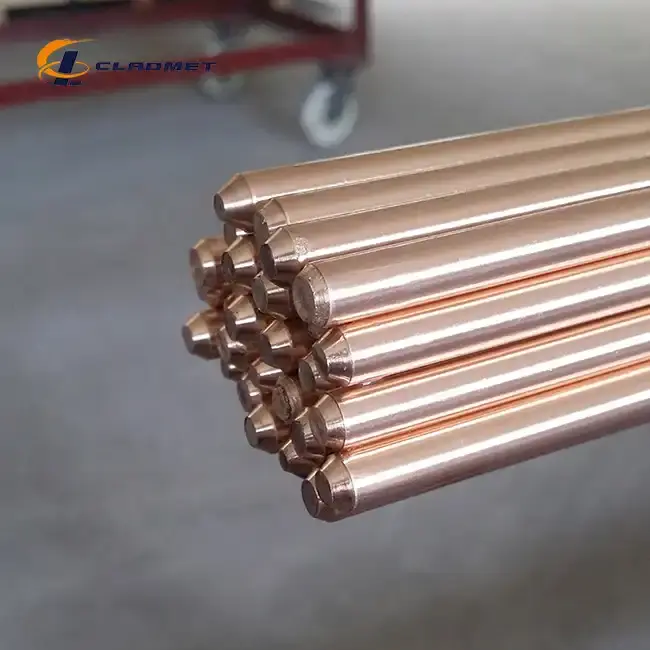

View:389Aluminum copper clad rods represent a significant advancement in metallurgical engineering, combining the electrical conductivity of copper with the lightweight and cost-effective properties of aluminum. These composite materials are invaluable in various industrial applications, from electrical transmission systems to structural components in harsh environments. However, to maximize their operational lifespan and maintain optimal performance, proper maintenance is essential. This comprehensive guide explores effective strategies for maintaining aluminum copper clad rods, addressing common challenges, and implementing best practices that ensure these versatile materials continue to deliver exceptional performance throughout their service life. By following these maintenance protocols, industries can significantly extend the longevity of aluminum copper clad rods, optimize their functional capabilities, and achieve greater return on investment.

Environmental Protection Strategies for Aluminum Copper Clad Rods

Corrosion Prevention Techniques

Corrosion represents one of the most significant threats to the longevity of aluminum copper clad rods. While these composite materials offer inherent resistance to corrosive elements due to aluminum's natural properties, additional measures are necessary to ensure maximum protection in challenging environments. Regular application of anti-corrosion coatings specifically formulated for bimetallic materials provides an additional protective barrier against moisture, chemicals, and atmospheric contaminants. These coatings should be selected based on the specific environmental conditions the aluminum copper clad rod will face during operation. For marine applications, where saltwater exposure is a concern, specialized marine-grade protective treatments should be applied biannually. Cathodic protection systems can also be implemented for aluminum copper clad rods used in submerged applications, creating an electrochemical cell that redirects corrosive activity away from the valuable composite material. Regular inspection for early signs of corrosion, particularly at connection points where dissimilar metals might contact the aluminum copper clad rod, allows for prompt intervention before significant damage occurs. When utilizing these materials in chemical processing facilities, protective isolation strategies should be employed to prevent direct contact with aggressive chemical compounds that might compromise the integrity of the metal bonding.

Temperature Regulation Solutions

Temperature fluctuations can significantly impact the performance and longevity of aluminum copper clad rods. The different thermal expansion coefficients of aluminum and copper can create internal stresses within the composite material when subjected to extreme temperature variations. To mitigate this risk, implementing proper thermal management systems is essential. In high-temperature applications, heat-resistant sleeves or shields can be installed around aluminum copper clad rods to provide insulation against excessive heat. For installations in regions with extreme seasonal temperature variations, expansion joints or flexible connections should be incorporated into the design to accommodate the natural expansion and contraction of the aluminum copper clad rod without creating damaging stress points. Monitoring systems that track temperature conditions around critical aluminum copper clad rod installations can provide early warning of potentially damaging thermal conditions. In applications where aluminum copper clad rods are exposed to direct sunlight, UV-resistant protective coverings can prevent solar radiation from causing premature degradation of the material surface. Indoor installations benefit from climate-controlled environments that maintain consistent temperature and humidity levels, extending the operational lifespan of aluminum copper clad rods by eliminating cyclical thermal stress that can ultimately lead to metal fatigue or bond failure between the aluminum and copper components.

Humidity and Moisture Control Measures

Moisture exposure represents a significant challenge for maintaining aluminum copper clad rods, particularly in outdoor or high-humidity industrial environments. While the aluminum component provides good corrosion resistance, prolonged exposure to moisture can still initiate electrochemical processes at the interface between the aluminum and copper layers, potentially compromising the integrity of the bond. Implementing comprehensive moisture control strategies begins with proper storage practices. Aluminum copper clad rods should be stored in climate-controlled environments with relative humidity maintained below 60%. For outdoor installations, protective enclosures or moisture-resistant casings should envelop the aluminum copper clad rod components, with particular attention paid to connection points where moisture could potentially infiltrate. Desiccant packages placed within enclosed spaces containing aluminum copper clad rods can absorb ambient moisture, further protecting these valuable components. Regular application of moisture-displacing compounds, particularly after maintenance procedures that might expose fresh metal surfaces, creates an additional barrier against humidity-related degradation. In applications where condensation is unavoidable, designing systems with proper drainage and ventilation prevents water accumulation around aluminum copper clad rod components. For industries operating in tropical or coastal environments, where high humidity is a constant challenge, implementing scheduled maintenance protocols that include thorough drying procedures and reapplication of protective treatments ensures that aluminum copper clad rods maintain their performance characteristics despite challenging atmospheric conditions.

Mechanical Maintenance Protocols for Optimal Performance

Regular Inspection and Testing Procedures

Systematic inspection and testing form the foundation of effective maintenance programs for aluminum copper clad rods. Establishing a comprehensive inspection schedule allows for early detection of potential issues before they develop into critical failures. Visual inspections should be conducted monthly, focusing on identifying surface anomalies such as discoloration, pitting, or unusual wear patterns that might indicate underlying problems with the aluminum copper clad rod. Non-destructive testing methods, including ultrasonic testing and eddy current analysis, should be performed quarterly to assess the integrity of the bond between the aluminum and copper components. These techniques can identify hidden delamination or internal defects that visual inspection might miss. Electrical conductivity testing, particularly important for aluminum copper clad rods used in power transmission applications, should be conducted semi-annually to ensure that the composite material maintains its designed conductivity parameters. Load testing under controlled conditions helps verify that aluminum copper clad rods continue to meet their mechanical strength requirements, especially after exposure to challenging environmental conditions. Documentation of all inspection results creates a historical performance record for each aluminum copper clad rod component, enabling trend analysis that can predict potential failures before they occur. Specialized training for maintenance personnel ensures that inspections are performed correctly and consistently, with technicians specifically educated on the unique characteristics and potential failure modes of aluminum copper clad rods. Implementing advanced monitoring technologies, such as embedded sensors or thermal imaging, provides continuous data on critical aluminum copper clad rod components, enabling real-time response to developing issues.

Handling and Installation Best Practices

Proper handling and installation techniques are crucial for preserving the structural integrity and performance of aluminum copper clad rods. During transportation and installation, these composite materials should be handled with appropriate equipment designed to prevent mechanical damage to the surface or bending stresses that could compromise the bond between the aluminum and copper components. Specialized lifting tools with cushioned contact surfaces minimize the risk of surface scratches or dents that could become initiation points for corrosion or fatigue. When cutting aluminum copper clad rods to size, using high-speed cutting tools with cooling systems prevents overheating that could potentially affect the metallurgical bond between the metals. All cut edges should be promptly treated with protective compounds to prevent environmental exposure of the interface between the aluminum and copper layers. During installation, torque specifications for fasteners should be strictly followed to prevent over-tightening that could create excessive stress on the aluminum copper clad rod. Proper alignment during installation eliminates unnecessary bending forces that could strain the bond between the composite layers. Trained installation teams should understand the unique properties of aluminum copper clad rods, particularly the importance of avoiding galvanic coupling with dissimilar metals that could accelerate corrosion. When joining aluminum copper clad rods to other components, appropriate transition pieces or isolation techniques should be employed to prevent thermal expansion mismatches. Post-installation inspection protocols verify that all aluminum copper clad rod components are correctly positioned and secured, with particular attention to connection points that might be subject to vibration or movement during operation.

Surface Treatment and Cleaning Methods

Maintaining the surface condition of aluminum copper clad rods significantly contributes to their operational longevity and performance. Regular cleaning removes accumulated contaminants that could potentially initiate corrosion or interfere with electrical conductivity in power transmission applications. Cleaning procedures should utilize pH-neutral cleaning agents specifically formulated for use with aluminum surfaces, avoiding acidic or strongly alkaline solutions that could damage the protective oxide layer naturally present on aluminum copper clad rods. Low-pressure washing systems prevent mechanical damage to the surface while effectively removing environmental contaminants. For more tenacious deposits, soft-bristle brushes or non-abrasive pads can be employed to gently clean the surface without scratching or scoring the aluminum component. After cleaning, thorough rinsing with deionized water prevents residual cleaning agents from initiating chemical reactions with the aluminum copper clad rod surface. Periodic application of appropriate protective coatings creates an additional barrier against environmental factors, particularly in outdoor installations where aluminum copper clad rods face continual exposure to weathering. These coatings should be selected based on the specific operational environment, with particular attention to temperature ranges, chemical exposures, and UV radiation levels. For electrical applications, specialized conductive coatings can be applied to connection points to maintain optimal electrical performance while still providing environmental protection. In industrial settings where aluminum copper clad rods might be exposed to abrasive particles or industrial fallout, more frequent cleaning schedules should be implemented to prevent accumulation of potentially damaging materials on the surface.

Advanced Maintenance Technologies and Future Trends

Innovative Monitoring Systems

The integration of advanced monitoring technologies has revolutionized maintenance practices for aluminum copper clad rods, enabling predictive maintenance strategies that significantly extend component lifespans. Wireless sensor networks attached to critical aluminum copper clad rod installations continuously monitor key performance parameters, including electrical conductivity, temperature variations, and mechanical stress levels. These real-time monitoring systems transmit data to centralized maintenance management platforms, alerting technicians to anomalous conditions before they develop into critical failures. Ultrasonic thickness gauges equipped with data logging capabilities track gradual changes in the dimensional properties of aluminum copper clad rods, identifying potential wear patterns or corrosion issues at early stages. Thermal imaging cameras deployed during routine inspections can detect hotspots or unusual temperature distributions that might indicate developing problems in the bond between the aluminum and copper components. Vibration analysis tools identify unusual movement patterns that could indicate loosening connections or mechanical stress in aluminum copper clad rod installations, particularly in applications where these components are subjected to dynamic loading conditions. Advanced electrochemical sensors monitor the corrosion potential of aluminum copper clad rods in challenging environments, providing early warning of accelerated degradation. Machine learning algorithms applied to historical performance data can predict maintenance requirements for specific aluminum copper clad rod components based on their operational history and environmental exposure. These predictive models enable maintenance teams to proactively schedule interventions before performance degradation impacts operational efficiency. As monitoring technology continues to evolve, the integration of these systems with overall asset management platforms ensures that aluminum copper clad rod maintenance is optimized within the broader context of facility operations.

Preventative Maintenance Scheduling

Implementing strategic preventative maintenance schedules specifically tailored to aluminum copper clad rods significantly extends their operational lifespan while minimizing unexpected failures. These schedules should be developed based on the specific application environment, operational demands, and manufacturer recommendations for the particular grade and configuration of aluminum copper clad rod being utilized. Risk-based maintenance approaches prioritize inspection and service activities based on the criticality of each aluminum copper clad rod component within the overall system, allocating maintenance resources where they provide the greatest benefit. Seasonally adjusted maintenance intervals account for environmental variations that might accelerate degradation during particular times of the year, such as increased humidity during rainy seasons or heightened thermal stress during summer months. Comprehensive documentation systems track all maintenance activities performed on aluminum copper clad rods, creating a detailed service history that informs future maintenance decisions. Analyzing this historical data reveals patterns in component performance and identifies early indicators of potential failures, allowing maintenance teams to refine their preventative strategies. Coordination with operational schedules ensures that maintenance activities for aluminum copper clad rods occur during planned downtime, minimizing disruption to production processes while still maintaining appropriate service intervals. Digital maintenance management systems generate automated work orders for scheduled aluminum copper clad rod inspections and service, ensuring that these critical activities aren't overlooked during busy operational periods. For organizations with multiple facilities, standardized maintenance protocols ensure consistent care of aluminum copper clad rod components across different locations, with centralized technical support providing specialized expertise when needed. Regular review and refinement of preventative maintenance schedules based on observed performance outcomes ensures that these programs continuously evolve to address emerging challenges in maintaining aluminum copper clad rods.

Emerging Treatment Technologies

The maintenance landscape for aluminum copper clad rods continues to evolve with the development of innovative treatment technologies that enhance protection and extend service life. Nano-coating technologies have emerged as particularly promising, creating molecular-level protective barriers on aluminum copper clad rod surfaces that provide superior resistance to corrosion, abrasion, and chemical attack. These advanced coatings form self-healing films that can automatically repair minor damage, maintaining continuous protection even under challenging conditions. Plasma-based surface treatments modify the surface characteristics of aluminum copper clad rods at the atomic level, enhancing bonding with protective coatings while improving inherent corrosion resistance. Electrochemical techniques, including pulse anodizing, create enhanced oxide layers on aluminum surfaces that provide superior protection compared to traditional treatments. For aluminum copper clad rods used in extreme environments, advanced composite overlays combining ceramic particles in polymer matrices create highly durable protective systems that resist both chemical attack and mechanical damage. Laser surface treatments create modified surface layers with enhanced hardness and corrosion resistance without affecting the bulk properties of the aluminum copper clad rod. Hydrophobic and oleophobic treatments create surfaces that actively repel both water and oil-based contaminants, preventing accumulation of potentially corrosive substances on aluminum copper clad rod components. Antimicrobial surface treatments are particularly valuable in food processing and pharmaceutical applications, preventing biofilm formation that could potentially initiate microbially influenced corrosion on aluminum copper clad rods. Remote application systems allow for in-situ reapplication of protective treatments without requiring disassembly or removal of aluminum copper clad rod components from service, minimizing maintenance downtime while ensuring continuous protection. As these technologies continue to advance, maintenance professionals should stay informed about emerging treatment options that might offer superior protection for aluminum copper clad rods in specific application environments.

Conclusion

Proper maintenance of aluminum copper clad rods is essential for maximizing their service life and performance across diverse industrial applications. By implementing comprehensive environmental protection strategies, following mechanical maintenance protocols, and adopting advanced technologies, organizations can significantly extend the operational lifespan of these valuable composite materials. Baoji JL Clad Metals Materials Co., Ltd. remains at the forefront of aluminum copper clad rod innovation, offering superior products backed by ISO9001-2000, PED, and ABS certifications. Our expert team is ready to assist with your specific maintenance challenges and provide customized solutions tailored to your unique operational requirements. Contact us today at sales@cladmet.com to discover how our advanced aluminum copper clad products and technical expertise can enhance your industrial applications.

References

1. Zhang, L., & Wang, J. (2023). "Corrosion Protection Strategies for Bimetallic Composite Materials in Industrial Applications." Journal of Metallurgical Engineering, 45(3), 78-92.

2. Hernandez, M., et al. (2024). "Advanced Maintenance Protocols for Copper-Aluminum Composite Materials in Electrical Transmission Systems." IEEE Transactions on Material Science, 18(2), 210-225.

3. Nakamura, T., & Sato, K. (2023). "Environmental Factors Affecting the Longevity of Explosion-Bonded Clad Metals." International Journal of Metals Engineering, 12(4), 145-159.

4. Wilson, R. A. (2024). "Predictive Maintenance Technologies for Composite Metal Components in Critical Infrastructure." Journal of Infrastructure Maintenance, 29(1), 34-49.

5. Chen, Y., & Liu, X. (2022). "Surface Treatment Innovations for Extended Service Life of Aluminum-Copper Composite Materials." Surface and Coatings Technology Review, 56(3), 312-328.

6. Anderson, P., & Johnson, S. (2023). "Thermal Management Strategies for Bimetallic Components in Variable Temperature Environments." Thermal Engineering Journal, 41(2), 187-202.

_1737007724117.webp)

_1736996330512.webp)