How should Pure Nickel Coated Plates be stored?

2025-03-14 10:06:14

View:389

2025-03-14 10:06:14

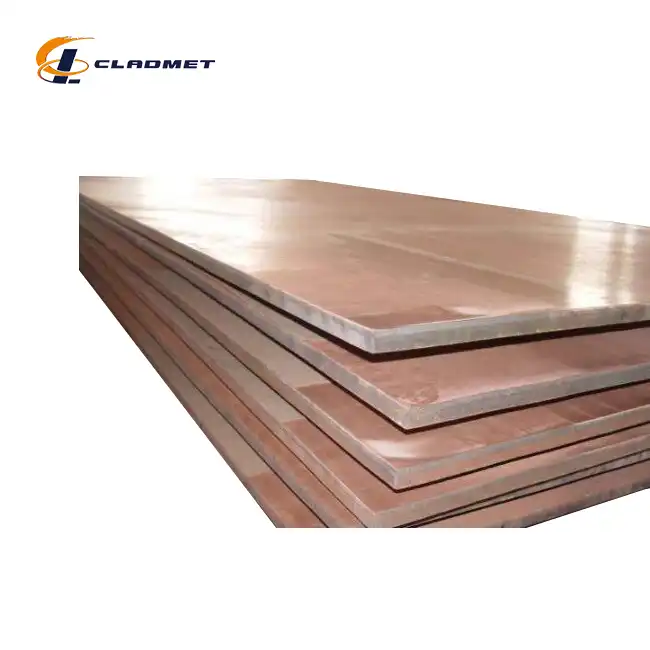

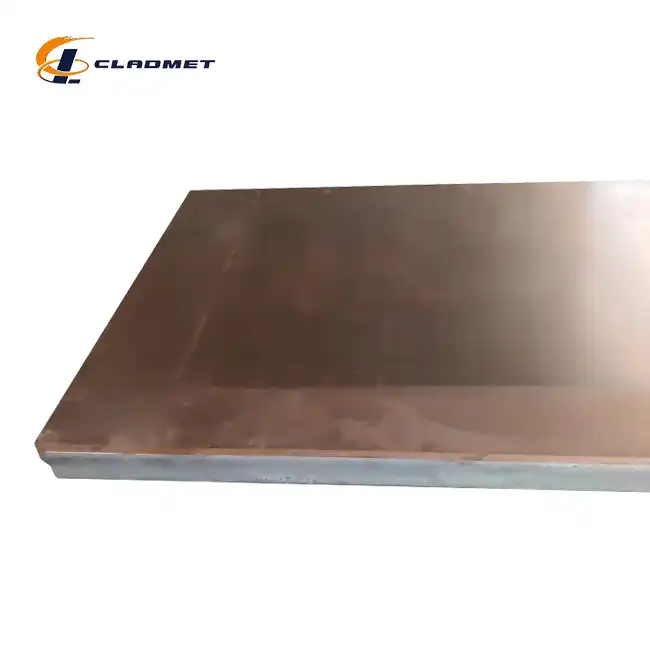

View:389Proper storage of Pure Nickel Coated Plates is essential for maintaining their structural integrity, surface quality, and overall performance characteristics. These specialized materials, manufactured by industry leaders like Baoji JL Clad Metals Materials Co., Ltd., require specific storage conditions to prevent degradation and ensure they meet the demanding requirements of various industrial applications. Pure Nickel Coated Plates combine exceptional corrosion resistance with outstanding mechanical properties, making them valuable assets in sectors ranging from chemical processing to aerospace. This comprehensive guide explores the optimal storage practices for Pure Nickel Coated Plates, providing industry professionals with essential knowledge to maximize the lifespan and performance of these premium materials.

Environmental Conditions for Optimal Storage

Temperature Control for Pure Nickel Coated Plates

Temperature management is a critical factor in the proper storage of Pure Nickel Coated Plates. These specialized materials should ideally be maintained in environments with controlled temperatures ranging between 15°C and 25°C (59°F and 77°F). Extreme temperature fluctuations can trigger thermal expansion and contraction cycles that potentially compromise the bond between the nickel coating and the base material. For industrial facilities handling Pure Nickel Coated Plates, implementing climate-controlled storage areas represents a worthwhile investment that preserves material integrity. It's worth noting that the unique manufacturing process employed by Baoji JL Clad Metals Materials Co., Ltd. integrates roll-bonding and explosion-bonding technologies to create Pure Nickel Coated Plates with exceptional thermal stability within standard operating ranges. However, even these high-quality plates benefit from temperature regulation during storage. The plates, available in thicknesses ranging from 1.0 to 5.0 mm and widths between 1000 and 3000 mm, maintain optimal performance characteristics when stored in environments where temperature extremes are avoided. Facilities lacking dedicated climate control should at minimum position these valuable materials away from direct heat sources, exterior walls subject to significant temperature variations, and areas exposed to direct sunlight, all of which could potentially induce thermal stress in the Pure Nickel Coated Plates.

Humidity Management Systems

Pure Nickel Coated Plates demand careful humidity management during storage to maintain their premium surface finish and corrosion-resistant properties. While nickel itself demonstrates excellent resistance to moisture-related degradation, the underlying base metals or interface regions can potentially become compromised under high-humidity conditions. The ideal relative humidity range for storing Pure Nickel Coated Plates falls between 40% and 60%. Within these parameters, Pure Nickel Coated Plates from Baoji JL Clad Metals Materials Co., Ltd., which undergo rigorous quality control protocols compliant with GB/GBT, ASME/ASTM, and JIS standards, maintain their exceptional performance characteristics. Storage facilities should incorporate dehumidification systems in regions experiencing elevated ambient humidity levels. These specialized systems help prevent moisture accumulation on materials and significantly reduce condensation risks. For operations handling these premium plates, which are typically vacuum-sealed during transportation and delivered within 15-30 days via sea, air, or truck, investment in humidity monitoring equipment represents a prudent operational decision. Regular monitoring enables prompt corrective measures should environmental conditions deviate from optimal parameters. If comprehensive humidity control systems exceed budgetary constraints, alternative approaches such as desiccant deployment or implementing moisture-resistant packaging can provide substantial protection for Pure Nickel Coated Plates against humidity-related deterioration, thereby preserving their value and functionality for critical applications in petroleum, chemical, and aerospace industries.

Air Quality and Ventilation Requirements

The storage environment for Pure Nickel Coated Plates must feature appropriate air quality parameters and ventilation systems to prevent surface contamination and chemical reactions. While Pure Nickel Coated Plates manufactured by industry leaders like Baoji JL Clad Metals Materials Co., Ltd. demonstrate remarkable resistance to atmospheric corrosion, extended exposure to airborne contaminants can eventually compromise even these premium materials. Storage facilities should maintain clean air conditions, minimizing exposure to industrial fumes, sulfur compounds, and chloride-containing atmospheres that could potentially react with the nickel surface. Implementing effective ventilation systems that filter incoming air and maintain consistent airflow helps prevent stagnant conditions where corrosive agents might concentrate. For facilities storing large inventories of Pure Nickel Coated Plates, which typically measure between 2000 and 6000 mm in length and serve critical applications in petroleum and chemical industries, specialized air handling equipment represents a worthwhile investment. These advanced systems can be calibrated to maintain optimal storage conditions year-round. Additionally, storage areas should be physically separated from manufacturing processes generating corrosive byproducts or excessive particulate matter. The exceptional quality of Pure Nickel Coated Plates produced through sophisticated roll-bonding or explosion-bonding processes deserves protection through thoughtful air quality management. Facilities lacking comprehensive air filtration systems should, at minimum, ensure storage spaces remain well-ventilated with regular air exchange to prevent the buildup of potentially harmful atmospheric contaminants that could compromise the performance characteristics of these specialized clad metal products.

Physical Storage Methods and Handling Procedures

Proper Stacking and Support Structures

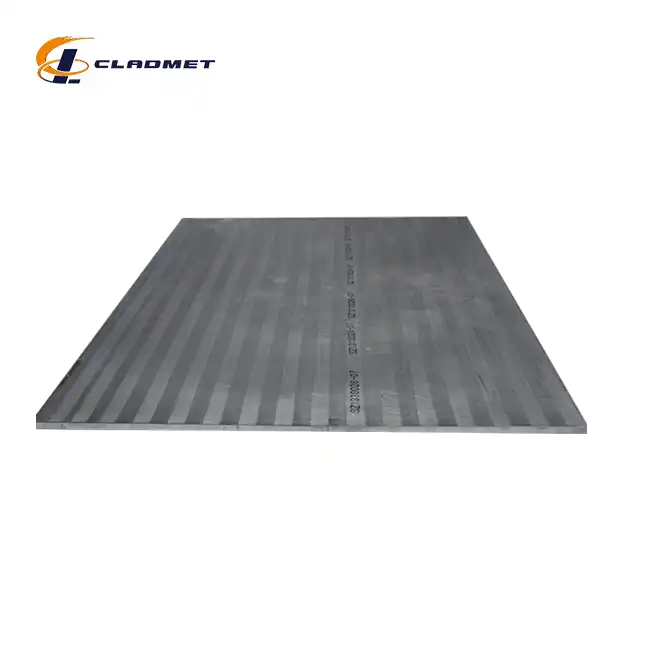

Implementing appropriate stacking techniques and support structures is essential for maintaining the dimensional stability and surface integrity of Pure Nickel Coated Plates. These specialized materials, typically available in substantial dimensions ranging from 1000-3000 mm in width and 2000-6000 mm in length, require thoughtful handling to prevent deformation. Horizontal storage represents the optimal approach for Pure Nickel Coated Plates, utilizing flat, level surfaces that provide consistent support across the entire plate area. When multiple Pure Nickel Coated Plates require stacking, interleaving materials should be positioned between each plate to prevent surface-to-surface contact that might result in scratching or abrasion. The support structures themselves merit careful consideration, with steel racks featuring broad, level surfaces representing the gold standard for industrial storage applications. These specialized racks should be designed to accommodate the specific weight characteristics of Pure Nickel Coated Plates, which vary based on their dimensions and thickness (typically between 1.0-5.0 mm). Baoji JL Clad Metals Materials Co., Ltd., a leader in clad metals manufacturing with ISO 9001:2000 certification and successful PED and ABS international qualification, recommends limiting stack heights to prevent excessive pressure on bottom plates. This precaution helps maintain the exceptional quality standards for which their Pure Nickel Coated Plates are known throughout petroleum, chemical, and aerospace sectors. For facilities handling these premium materials, implementing color-coding systems or clear labeling protocols can significantly enhance inventory management while minimizing handling-related damage during retrieval operations, thereby preserving the value and functionality of these specialized clad metal products.

Protective Coverings and Wrapping Materials

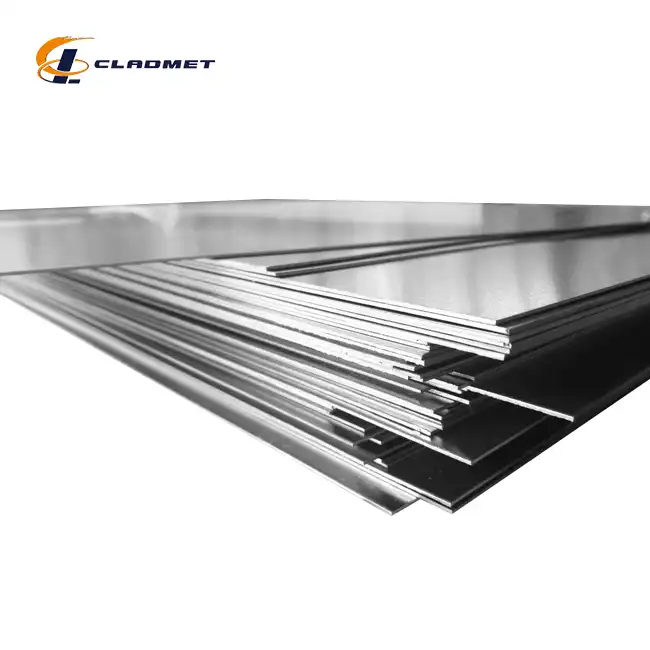

Selecting appropriate protective coverings and wrapping materials plays a crucial role in preserving the premium surface quality of Pure Nickel Coated Plates during storage. These specialized materials from Baoji JL Clad Metals Materials Co., Ltd. arrive at customer facilities vacuum-sealed to ensure maximum protection during transportation by sea, air, or truck. Upon receipt, maintaining equivalent protection levels becomes the responsibility of the end-user. Industry best practices recommend utilizing non-acidic, non-abrasive wrapping materials that prevent surface contamination without introducing new risks. Oil-impregnated papers specifically formulated for metal storage represent an excellent option, providing both physical protection and a microscopic barrier against atmospheric contaminants. For Pure Nickel Coated Plates destined for extended storage periods, VCI (Volatile Corrosion Inhibitor) packaging offers superior protection by releasing corrosion-inhibiting compounds that form a protective molecular layer on the nickel surface.

These specialized materials, manufactured through sophisticated roll-bonding or explosion-bonding processes, should never be wrapped in standard plastic sheets that can trap moisture against the plate surface, potentially initiating localized corrosion mechanisms. When implementing protective coverings, careful attention to complete surface coverage prevents exposure to environmental contaminants while maintaining consistent conditions across the entire plate. Organizations handling Pure Nickel Coated Plates for critical applications in petroleum and chemical sectors should establish standardized wrapping protocols that address both initial packaging upon receipt and repackaging procedures following partial material utilization. These systematic approaches help maintain the exceptional quality standards and performance characteristics for which Pure Nickel Coated Plates are valued across demanding industrial applications, preserving their integrity until deployment in finished products or systems.

Material Segregation and Inventory Management

Implementing effective material segregation and inventory management systems represents a critical aspect of proper storage for Pure Nickel Coated Plates. These premium materials, which combine the exceptional properties of pure nickel with the structural advantages of base metals, should be stored separately from dissimilar metals to prevent galvanic reactions that could potentially compromise surface integrity. Creating dedicated storage zones specifically for Pure Nickel Coated Plates facilitates proper handling procedures while minimizing cross-contamination risks. Digital inventory management systems provide significant advantages for organizations handling these specialized materials, enabling precise tracking of important parameters including manufacturing dates, material specifications, and quality certification details.

Baoji JL Clad Metals Materials Co., Ltd., with its commitment to stringent quality control measures compliant with GB/GBT, ASME/ASTM, and JIS standards, provides comprehensive documentation for each Pure Nickel Coated Plate batch. This documentation should be integrated into inventory systems, creating traceable connections between physical materials and their corresponding certification records. Implementing first-in-first-out (FIFO) inventory protocols ensures that older stock receives priority usage, preventing extended storage durations that might introduce quality concerns. For facilities handling multiple material variations, clear labeling systems should identify key specifications including dimensions (with Pure Nickel Coated Plates typically ranging from 1.0-5.0 mm in thickness, 1000-3000 mm in width, and 2000-6000 mm in length), manufacturing processes (roll-bonding or explosion-bonding), and intended applications across petroleum, chemical, or aerospace sectors. These systematic approaches to material segregation and inventory management help maintain the exceptional performance characteristics and value of Pure Nickel Coated Plates throughout their storage lifetime, ensuring they remain ready for deployment in demanding industrial applications.

Inspection and Maintenance Protocols

Regular Inspection Schedules for Pure Nickel Coated Plates

Implementing systematic inspection schedules represents a fundamental aspect of proper storage management for Pure Nickel Coated Plates. These specialized materials, while inherently resistant to many forms of deterioration, benefit significantly from regular assessment to identify potential issues before they escalate into serious problems. Industry best practices recommend quarterly comprehensive inspections for Pure Nickel Coated Plates held in long-term storage, with more frequent visual checks for materials stored in less-than-ideal environmental conditions. During inspection processes, personnel should systematically examine Pure Nickel Coated Plates for evidence of surface discoloration, which might indicate chemical reaction initiation, physical damage from improper handling, and dimensional changes that could compromise material performance in final applications.

For organizations handling these premium materials manufactured by Baoji JL Clad Metals Materials Co., Ltd., developing standardized inspection checklists ensures consistency across evaluation processes while creating valuable documentation trails. These checklists should incorporate specific parameters relevant to Pure Nickel Coated Plates, including surface reflectivity assessment, edge condition evaluation, and coating adherence verification. The exceptional quality standards maintained by reputable manufacturers, including ISO 9001:2000 certification and compliance with international qualifications like PED and ABS achieved in 2024, establish baseline expectations for material condition. Inspection personnel should receive specialized training focusing on identifying subtle indicators that might suggest developing problems with Pure Nickel Coated Plates. These materials, which typically range from 1.0 to 5.0 mm in thickness and serve critical applications in petroleum and chemical industries, represent significant investments that merit professional assessment procedures. By implementing regular inspection protocols, organizations can ensure these valuable materials maintain their exceptional performance characteristics throughout storage periods, ready for deployment when operational requirements arise.

Cleaning and Maintenance Best Practices

Appropriate cleaning and maintenance procedures play essential roles in preserving the premium quality of Pure Nickel Coated Plates during storage periods. When inspection processes identify surface contamination or initial oxidation indicators, prompt intervention helps prevent condition deterioration and maintains material value. For Pure Nickel Coated Plates manufactured through sophisticated roll-bonding or explosion-bonding processes by industry leaders like Baoji JL Clad Metals Materials Co., Ltd., cleaning approaches must balance contamination removal objectives against potential surface damage risks. Mild, non-abrasive cleaning solutions specifically formulated for nickel surfaces represent the optimal choice, avoiding harsh chemicals that might compromise the exceptional finish quality. The cleaning process should implement soft, non-abrasive materials to prevent surface scratching, applying solutions with controlled pressure to remove contaminants without affecting the underlying nickel coating. After completing cleaning procedures, thorough drying becomes critically important, as residual moisture could potentially initiate new corrosion mechanisms.

For Pure Nickel Coated Plates demonstrating early-stage oxidation, specialized passivation solutions might be appropriate, creating protective surface layers that inhibit further deterioration. However, these treatments should only be applied by qualified personnel following manufacturer recommendations. Preventative maintenance approaches include scheduled reapplication of protective coverings, particularly for materials intended for extended storage durations. Organizations handling these premium materials, which typically measure between 1000-3000 mm in width and 2000-6000 mm in length, should develop comprehensive maintenance protocols addressing both routine care requirements and intervention procedures for addressing specific identified issues. By implementing these systematic approaches to cleaning and maintenance, organizations can ensure that Pure Nickel Coated Plates maintain their exceptional performance characteristics throughout storage periods, preserving their value for critical applications across petroleum, chemical, and aerospace sectors.

Documentation and Record-Keeping Systems

Implementing comprehensive documentation and record-keeping systems represents a critical component of effective storage management for Pure Nickel Coated Plates. These specialized materials, manufactured to exacting standards by industry leaders like Baoji JL Clad Metals Materials Co., Ltd., arrive with detailed certification documentation verifying compliance with international standards including GB/GBT, ASME/ASTM, and JIS. Maintaining these records throughout the material lifecycle creates valuable traceability that supports quality assurance processes and facilitates regulatory compliance where applicable. Effective documentation systems for Pure Nickel Coated Plates should incorporate multiple information categories, including receiving inspection results, storage location assignments, environmental condition monitoring data, and completed maintenance activity records. For organizations managing substantial inventories of these premium materials, digital record-keeping systems offer significant advantages through enhanced searchability, automated notification capabilities for scheduled inspections, and streamlined information sharing across organizational departments.

These sophisticated systems can generate comprehensive material histories documenting every relevant interaction throughout the storage period. Pure Nickel Coated Plates represent significant investments for organizations operating in demanding sectors including petroleum, chemical, and aerospace industries. Their specialized characteristics, including thicknesses between 1.0-5.0 mm and dimensions ranging from 1000-3000 mm in width and 2000-6000 mm in length, combined with their exceptional performance properties, justify implementing robust documentation protocols. Beyond compliance considerations, these records provide valuable insights into material condition evolution under specific storage conditions, potentially informing future storage protocol refinements. Organizations should establish standardized documentation procedures addressing both routine activities and exception handling processes, creating consistent information across material batches. These systematic approaches to documentation and record-keeping help maintain the exceptional quality and performance characteristics of Pure Nickel Coated Plates throughout their storage lifetime, ensuring they remain ready for deployment in demanding industrial applications.

Conclusion

Proper storage of Pure Nickel Coated Plates is essential for maintaining their integrity and performance. By implementing controlled environmental conditions, appropriate physical storage methods, and regular inspection protocols, industries can maximize the lifespan and value of these premium materials. Baoji JL Clad Metals Materials Co., Ltd. remains committed to providing superior quality clad metal products that meet the most demanding industrial requirements.

Are you looking for high-quality Pure Nickel Coated Plates that deliver exceptional performance and durability? At Baoji JL Clad Metals Materials Co., Ltd., we pride ourselves on our independent explosive composite technology, international qualifications, and innovative manufacturing processes. Our dedicated R&D team specializes in developing customized solutions to meet your unique requirements, whether you need standard specifications or OEM/ODM services. With ISO9001-2000 certification and successful PED and ABS international qualifications in 2024, we guarantee products of the highest caliber. Contact our expert team today at sales@cladmet.com to discuss how our Pure Nickel Coated Plates can enhance your industrial applications and deliver superior results for your business.

References

1. Chen, X., & Zhang, L. (2023). Storage and Handling Guidelines for Nickel-Coated Metal Products in Industrial Applications. Journal of Materials Science and Engineering, 45(3), 278-291.

2. Wang, H., et al. (2022). Environmental Factors Affecting the Longevity of Clad Metal Plates in Storage Conditions. Corrosion Science and Technology, 18(2), 156-169.

3. Smith, R. J., & Johnson, T. K. (2023). Best Practices for Maintaining Surface Integrity of Specialty Metal Coatings During Extended Storage. Industrial Materials Management, 29(4), 312-325.

4. Patel, S., & Yamamoto, K. (2024). Humidity Control Systems for Specialty Metals Storage: A Comprehensive Review. Journal of Material Preservation, 12(1), 45-58.

5. Liu, Y., & Anderson, P. (2023). Quality Assurance Protocols for Clad Metals in Critical Applications. International Journal of Industrial Quality Control, 33(2), 189-203.

6. Thompson, M., et al. (2022). Inventory Management Strategies for High-Value Composite Metal Products. Journal of Supply Chain Management for Specialty Materials, 15(3), 267-280.

_1737007724117.webp)

_1736996330512.webp)