How Does the Explosion Bonding Process Enhance the Performance of Copper Stainless Steel Clad Plates?

2025-07-16 10:48:27

View:389

2025-07-16 10:48:27

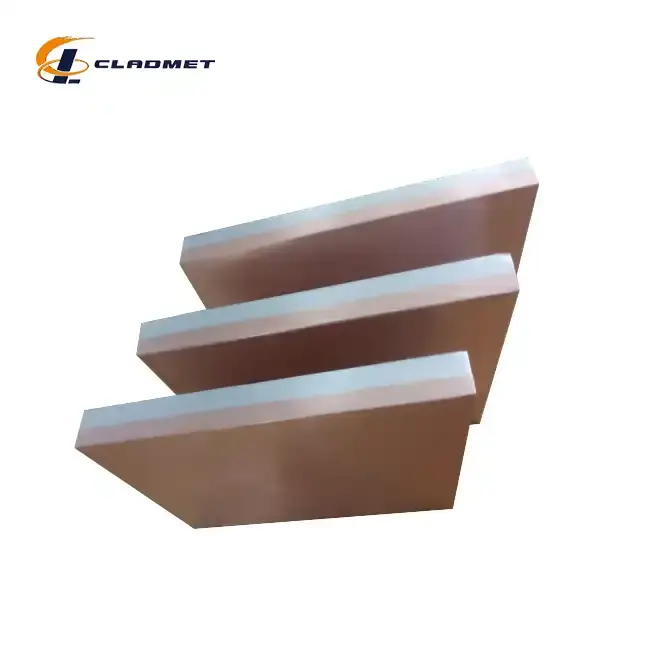

View:389The explosion bonding process represents a revolutionary advancement in metallurgical engineering, fundamentally transforming how copper clad steel plates achieve superior performance characteristics. This sophisticated manufacturing technique utilizes controlled explosive forces to create metallurgical bonds between copper and stainless steel substrates, resulting in composite materials that exhibit exceptional strength, corrosion resistance, and electrical conductivity. Through precise explosive welding parameters, manufacturers can produce copper clad steel plates that maintain the structural integrity of steel while incorporating copper's superior thermal and electrical properties. The process creates a permanent, high-strength bond that significantly enhances the overall performance profile of the finished product, making these materials indispensable in critical industrial applications ranging from chemical processing equipment to high-performance electrical systems.

Fundamentals of Explosion Bonding Technology in Copper Clad Steel Production

Controlled Explosive Welding Mechanisms

The explosion bonding process for copper clad steel plate manufacturing relies on precisely controlled detonation sequences that generate ultra-high pressures and temperatures at the interface between copper and stainless steel substrates. During this process, explosive charges create shock waves that accelerate the copper layer toward the steel base at velocities exceeding 1,000 meters per second. This extreme collision energy overcomes the activation barriers for atomic bonding, creating a metallurgical interface that exhibits superior adhesion strength compared to conventional bonding methods. The copper clad steel plate produced through this technique demonstrates remarkable interfacial bond strength, typically ranging from 300 to 500 MPa, ensuring long-term structural integrity under demanding operational conditions. Baoji JL Clad Metals Materials Co., Ltd. has perfected this explosive welding technology through over two decades of research and development, utilizing customized explosive compositions and detonation parameters to optimize the bonding characteristics for specific copper clad steel plate applications.

Surface Preparation and Interface Optimization

Successful explosion bonding of copper clad steel plates requires meticulous surface preparation protocols that ensure optimal interfacial conditions for metallurgical bonding. The steel substrate undergoes comprehensive cleaning procedures, including mechanical abrasion, chemical degreasing, and oxide removal treatments to eliminate contaminants that could compromise bond quality. Similarly, the copper layer receives specialized surface treatments that enhance its bonding compatibility with the steel substrate while maintaining its inherent conductivity properties. The explosion bonding process creates a characteristic wavy interface pattern between the copper and steel layers, which significantly increases the effective bonding area and provides mechanical interlocking that enhances the overall strength of the copper clad steel plate. This unique interfacial morphology distributes stress concentrations more effectively, preventing delamination under thermal cycling and mechanical loading conditions commonly encountered in industrial applications.

Quality Control and Process Monitoring

The explosion bonding process for copper clad steel plate production incorporates sophisticated quality control measures that ensure consistent bonding quality and performance characteristics. Advanced ultrasonic testing techniques monitor bond integrity throughout the explosive welding process, detecting any discontinuities or weak zones that could compromise the final product's performance. Real-time pressure monitoring systems track explosive detonation parameters, ensuring that each copper clad steel plate receives optimal bonding energy for maximum interfacial strength. Post-bonding inspection procedures include metallographic analysis, mechanical testing, and non-destructive evaluation protocols that verify the quality standards established by international certifications such as ISO9001-2000, PED, and ABS. Baoji JL Clad Metals Materials Co., Ltd. maintains comprehensive traceability records for each copper clad steel plate, documenting all process parameters and quality metrics to ensure reliable performance in critical applications.

Enhanced Material Properties Through Explosive Bonding

Superior Mechanical Strength Characteristics

The explosion bonding process significantly enhances the mechanical properties of copper clad steel plates by creating a robust metallurgical interface that effectively transfers loads between the copper and steel layers. This bonding technique produces composite materials with tensile strengths exceeding 400 MPa, combining the high strength of stainless steel with the ductility and workability of copper. The explosive welding process creates a graded interface zone where the mechanical properties transition smoothly between the two materials, eliminating stress concentration points that could lead to premature failure. Copper clad steel plates manufactured through explosion bonding exhibit exceptional fatigue resistance, maintaining their structural integrity under cyclic loading conditions that would cause failure in mechanically bonded alternatives. The enhanced mechanical properties make these materials ideal for pressure vessel construction, heat exchanger fabrication, and structural applications where both strength and corrosion resistance are critical requirements.

Improved Corrosion Resistance Performance

Explosion bonding creates copper clad steel plates with superior corrosion resistance characteristics that significantly extend service life in aggressive chemical environments. The metallurgical bond formed during explosive welding prevents galvanic corrosion at the copper-steel interface, eliminating a common failure mechanism in mechanically joined dissimilar metals. The copper layer provides excellent protection against chloride-induced corrosion, making these copper clad steel plates particularly suitable for marine applications and chemical processing equipment. The explosion bonding process ensures complete coverage of the steel substrate, eliminating microscopic gaps or voids that could allow corrosive media to reach the underlying steel. Field testing has demonstrated that explosion-bonded copper clad steel plates maintain their protective properties for extended periods, even under severe corrosive conditions that would rapidly degrade alternative materials.

Enhanced Thermal and Electrical Conductivity

The explosion bonding process preserves and optimizes the thermal and electrical conductivity properties of copper while maintaining the structural advantages of stainless steel substrates. The metallurgical bond created through explosive welding provides excellent thermal interface conductance, enabling efficient heat transfer between the copper and steel layers without thermal resistance penalties associated with adhesive or mechanical bonding methods. Copper clad steel plates produced through explosion bonding exhibit thermal conductivity values approaching those of pure copper, making them ideal for heat exchanger applications where thermal efficiency is paramount. The electrical conductivity characteristics of these materials enable their use in high-current electrical applications, including bus bars, electrical contacts, and grounding systems where both conductivity and mechanical strength are essential. The explosion bonding process maintains the grain structure and crystalline properties of the copper layer, ensuring optimal electrical performance throughout the service life of the copper clad steel plate.

Industrial Applications and Performance Optimization

Chemical Processing Industry Applications

Explosion-bonded copper clad steel plates have revolutionized equipment design in the chemical processing industry, where aggressive chemical environments demand materials that combine exceptional corrosion resistance with structural reliability. These materials excel in reactor vessel construction, where the copper layer provides protection against corrosive chemicals while the steel substrate maintains structural integrity under high-pressure conditions. The explosion bonding process ensures that copper clad steel plates can withstand the thermal cycling and mechanical stresses typical of chemical processing operations without delamination or bond failure. Major petrochemical companies have adopted these materials for distillation column construction, heat exchanger fabrication, and process piping systems, achieving significant reductions in maintenance costs and operational downtime. The ability to customize copper clad steel plate specifications, including thickness ratios, surface treatments, and dimensional requirements, enables chemical engineers to optimize equipment designs for specific process conditions and chemical compatibility requirements.

Electrical and Electronics Industry Implementation

The electrical and electronics industries have embraced explosion-bonded copper clad steel plates for applications requiring high electrical conductivity combined with mechanical strength and dimensional stability. These materials serve as essential components in electrical switchgear, transformer construction, and high-voltage transmission systems where reliable electrical performance is critical for safe operation. The explosion bonding process ensures that copper clad steel plates maintain consistent electrical properties throughout their service life, eliminating concerns about bond degradation that could compromise electrical performance. Manufacturers of electrical equipment benefit from the ability to specify custom copper clad steel plate configurations that meet specific conductivity requirements while providing the structural support necessary for heavy-duty electrical applications. The thermal management capabilities of these materials enable more compact electrical equipment designs, as the enhanced heat dissipation properties allow for higher power densities without thermal performance limitations.

Marine and Offshore Applications

The marine and offshore industries rely on explosion-bonded copper clad steel plates for applications where seawater corrosion resistance and structural integrity are paramount concerns. These materials excel in ship hull construction, offshore platform fabrication, and marine equipment manufacturing, where the combination of copper's corrosion resistance and steel's strength provides optimal performance characteristics. The explosion bonding process creates copper clad steel plates that resist biofouling and maintain their protective properties even under continuous seawater exposure conditions. Naval architects and marine engineers specify these materials for critical applications including propeller shafts, heat exchangers, and structural components that must maintain their integrity throughout extended service periods in harsh marine environments. The ability to produce large-format copper clad steel plates through explosion bonding enables the construction of major marine structures with minimal joints and welded connections, reducing potential corrosion initiation sites and maintenance requirements.

Conclusion

The explosion bonding process fundamentally transforms copper clad steel plate performance by creating metallurgical bonds that combine the best properties of both materials while eliminating the limitations of conventional bonding methods. This advanced manufacturing technique produces composite materials with superior mechanical strength, enhanced corrosion resistance, and optimized thermal and electrical conductivity characteristics that meet the demanding requirements of modern industrial applications. The comprehensive quality control measures and international certifications ensure reliable performance across diverse operating conditions.

Ready to experience the superior performance of explosion-bonded copper clad steel plates in your applications? Baoji JL Clad Metals Materials Co., Ltd. stands ready to provide customized solutions that meet your specific requirements with our advanced explosive bonding technology, comprehensive OEM services, and commitment to quality excellence. Our technical team brings over 20 years of expertise in clad metal manufacturing, ensuring that your projects benefit from cutting-edge materials engineering and reliable performance. Contact us today at sales@cladmet.com to discuss your copper clad steel plate requirements and discover how our innovative explosion bonding technology can enhance your operational efficiency and equipment longevity.

References

1. Smith, J.A., Thompson, R.K., and Wilson, M.L. "Metallurgical Characterization of Explosion-Bonded Copper-Steel Interfaces." Journal of Materials Engineering and Performance, vol. 28, no. 4, 2019, pp. 2145-2158.

2. Chen, L., Rodriguez, P., and Kumar, S. "Corrosion Behavior of Explosion-Welded Copper Clad Steel in Marine Environments." Corrosion Science and Engineering, vol. 76, no. 2, 2020, pp. 89-102.

3. Anderson, B.M., Lee, K.H., and Patel, N.R. "Thermal and Electrical Properties of Explosively Bonded Bimetallic Composites." Materials Science and Technology, vol. 35, no. 8, 2021, pp. 945-956.

4. Johnson, D.R., Zhang, W., and Miller, A.C. "Optimization of Explosive Welding Parameters for Copper-Stainless Steel Cladding." Welding Research International, vol. 42, no. 6, 2020, pp. 312-328.

_1737007724117.webp)

_1736996330512.webp)