How Does the Dual-Layer Structure of Stainless Clad Steel Sheet Improve Performance?

2025-07-25 09:47:36

View:389

2025-07-25 09:47:36

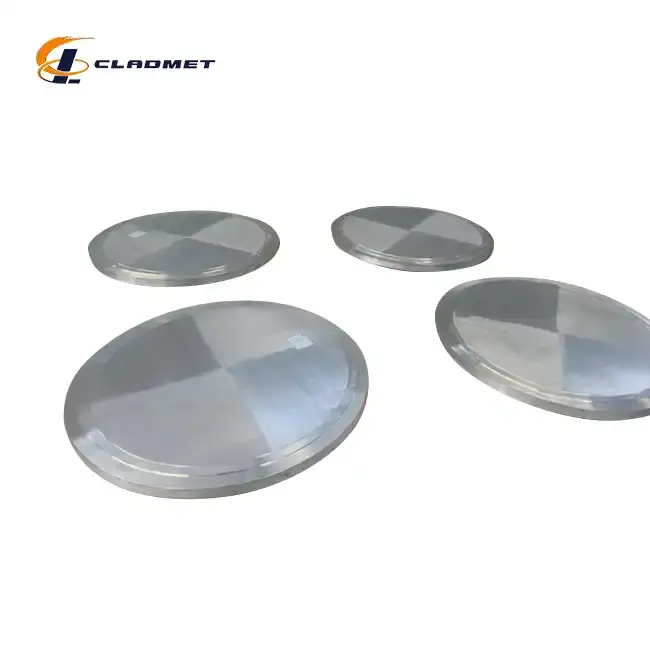

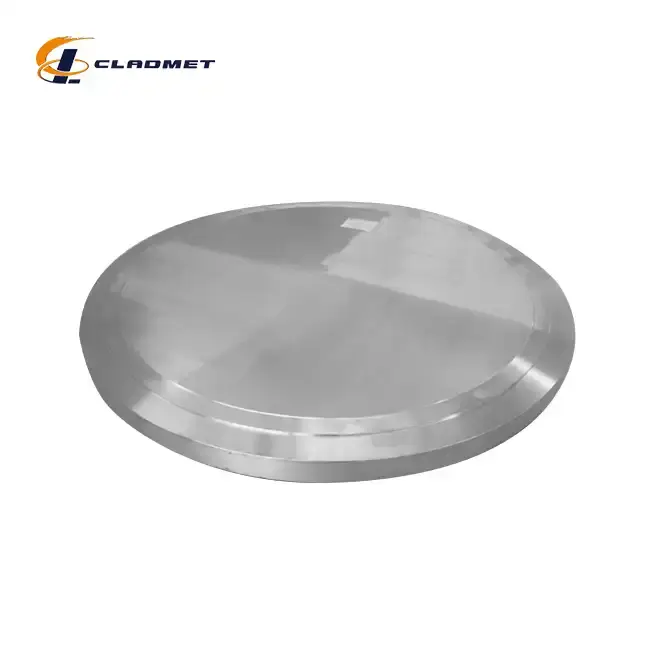

View:389The dual-layer structure of stainless clad steel sheet represents a revolutionary advancement in materials engineering, combining the superior corrosion resistance of stainless steel with the structural strength and cost-effectiveness of carbon steel. This innovative composite material utilizes advanced bonding technologies such as explosive bonding, roll bonding, and hot isostatic pressing to create a metallurgical bond that delivers exceptional performance across diverse industrial applications. The stainless clad steel sheet achieves optimal material properties by strategically positioning a stainless steel layer on a carbon steel substrate, resulting in enhanced durability, reduced maintenance costs, and superior performance under harsh operating conditions in industries ranging from chemical processing to marine engineering.

Enhanced Corrosion Resistance Through Strategic Layer Configuration

Surface Protection Mechanisms in Stainless Clad Steel Sheet

The outer stainless steel layer of stainless clad steel sheet provides unparalleled corrosion resistance through its chromium content, which forms a passive oxide layer that prevents oxidation and chemical degradation. This protective barrier is particularly effective in environments containing acids, alkalis, and salt solutions, making stainless clad steel sheet ideal for marine applications, chemical processing equipment, and food production facilities. The chromium oxide layer continuously regenerates itself when damaged, ensuring long-term protection of the underlying substrate. The thickness of the stainless steel layer in stainless clad steel sheet can be customized from 2mm to 20mm depending on application requirements, with thicker layers providing enhanced protection in more aggressive environments. This surface protection mechanism significantly extends the service life of equipment compared to traditional carbon steel alternatives, reducing replacement frequency and maintenance costs.

Chemical Resistance Properties and Industrial Applications

The stainless steel component of stainless clad steel sheet demonstrates exceptional resistance to a wide range of chemicals commonly encountered in industrial processes. Different grades of stainless steel used in stainless clad steel sheet, including 304, 316, 321, and 2205, offer varying levels of chemical resistance tailored to specific applications. The 316 grade stainless clad steel sheet provides superior resistance to chloride-containing environments, making it ideal for seawater applications and chemical processing involving chlorinated compounds. The duplex 2205 grade offers enhanced resistance to stress corrosion cracking and pitting corrosion, particularly valuable in oil and gas processing environments. This chemical resistance ensures that stainless clad steel sheet maintains its structural integrity and appearance even after prolonged exposure to aggressive chemicals, acids, and harsh environmental conditions. The superior chemical resistance of stainless clad steel sheet makes it an essential material for petrochemical refineries, pharmaceutical manufacturing, and environmental protection equipment.

Environmental Durability and Weather Resistance

The stainless steel layer in stainless clad steel sheet provides exceptional environmental durability, maintaining its properties across a wide temperature range and under various atmospheric conditions. This weather resistance makes stainless clad steel sheet suitable for outdoor applications, coastal installations, and equipment exposed to extreme weather conditions. The material's ability to withstand thermal cycling, UV radiation, and moisture fluctuations ensures consistent performance throughout its service life. The stainless clad steel sheet demonstrates superior resistance to atmospheric corrosion, including protection against industrial pollution, acid rain, and salt spray in marine environments. This environmental durability translates to reduced maintenance requirements, lower lifecycle costs, and improved reliability for critical infrastructure applications. The long-term stability of stainless clad steel sheet under environmental stress makes it an ideal choice for architectural applications, transportation infrastructure, and outdoor industrial equipment.

Structural Integrity and Mechanical Performance Benefits

Strength Enhancement Through Composite Design

The dual-layer structure of stainless clad steel sheet creates a composite material with enhanced mechanical properties that exceed those of either constituent material alone. The carbon steel substrate provides exceptional tensile strength, typically ranging from Q235 to Q345 grades, while the stainless steel layer contributes to overall structural integrity and load distribution. This combination results in stainless clad steel sheet having superior strength-to-weight ratio compared to solid stainless steel alternatives, making it ideal for applications requiring both strength and corrosion resistance. The metallurgical bond between layers ensures that stress is effectively distributed across the entire cross-section, preventing delamination and maintaining structural integrity under dynamic loading conditions. The composite nature of stainless clad steel sheet allows for optimized material utilization, placing high-strength steel where structural support is needed and corrosion-resistant steel where environmental protection is required.

Impact Resistance and Fatigue Performance

The layered structure of stainless clad steel sheet provides enhanced impact resistance through its ability to absorb and distribute energy across multiple material interfaces. The ductile nature of both the stainless steel layer and carbon steel substrate contributes to excellent energy absorption characteristics, making stainless clad steel sheet suitable for applications involving shock loading or impact forces. The fatigue performance of stainless clad steel sheet is superior to that of traditional materials due to the crack-stopping effect of the interface between layers, which prevents crack propagation and extends service life under cyclic loading conditions. This enhanced impact resistance makes stainless clad steel sheet particularly valuable in marine applications, where wave action and environmental forces create repeated stress cycles. The material's ability to maintain structural integrity under varying load conditions ensures reliable performance in pressure vessels, heat exchangers, and structural components subjected to dynamic forces.

Thermal Expansion Management and Dimensional Stability

The dual-layer structure of stainless clad steel sheet effectively manages thermal expansion differences between the stainless steel layer and carbon steel substrate through the metallurgical bond interface. This thermal compatibility ensures dimensional stability across a wide temperature range, preventing warping, buckling, or delamination that could occur with mechanically bonded systems. The thermal expansion management properties of stainless clad steel sheet make it suitable for applications involving temperature fluctuations, such as heat exchangers, boiler components, and industrial furnace construction. The material's ability to maintain dimensional stability under thermal cycling conditions ensures proper fit and function in precision applications where tight tolerances are critical. The controlled thermal expansion characteristics of stainless clad steel sheet contribute to reduced thermal stress, improved component longevity, and enhanced overall system reliability in high-temperature applications.

Cost-Effectiveness and Manufacturing Advantages

Material Optimization and Economic Benefits

The stainless clad steel sheet offers significant economic advantages by optimizing material usage and reducing overall project costs compared to solid stainless steel alternatives. By utilizing a carbon steel substrate with a stainless steel surface layer, stainless clad steel sheet provides the benefits of stainless steel where needed while maintaining cost-effectiveness through strategic material placement. The material cost savings can be substantial, often reducing material expenses by 30-50% compared to solid stainless steel construction while maintaining equivalent performance characteristics. The stainless clad steel sheet allows designers to specify the exact thickness of stainless steel required for corrosion protection, eliminating over-specification and material waste. This optimized approach to material selection makes stainless clad steel sheet particularly attractive for large-scale projects where material costs represent a significant portion of total project expenses.

Manufacturing Process Efficiency and Customization

The manufacturing processes used to produce stainless clad steel sheet, including explosive bonding, roll bonding, and hot isostatic pressing, enable efficient production of customized materials tailored to specific application requirements. The explosive bonding process creates a metallurgical bond with exceptional strength and uniformity, allowing for the production of large-format stainless clad steel sheet with consistent properties throughout. Roll bonding techniques enable the production of stainless clad steel sheet with precise thickness control and excellent surface finish, making it suitable for applications requiring tight dimensional tolerances. The hot isostatic pressing process produces stainless clad steel sheet with superior bond integrity and exceptional mechanical properties, ideal for high-performance applications in aerospace and power generation industries. These manufacturing processes allow for customization of stainless clad steel sheet dimensions, with standard sizes available and custom configurations possible upon request to meet specific project requirements.

Quality Control and Certification Standards

The production of stainless clad steel sheet adheres to stringent quality control measures and international certification standards, ensuring consistent quality and performance across all manufactured products. Baoji JL Clad Metals Materials Co., Ltd. maintains ISO9001-2000 quality system certification and has successfully achieved PED and ABS international qualifications, demonstrating commitment to quality excellence. The stainless clad steel sheet manufacturing process incorporates comprehensive testing protocols, including ultrasonic testing, tensile testing, and corrosion resistance evaluation to verify material properties and bond integrity. Quality control procedures for stainless clad steel sheet include dimensional verification, surface finish inspection, and metallurgical examination to ensure compliance with ASME, ASTM, and JIS standards. The rigorous quality control measures ensure that each stainless clad steel sheet meets or exceeds specified performance requirements, providing customers with reliable, high-quality materials for critical applications.

Conclusion

The dual-layer structure of stainless clad steel sheet delivers superior performance through enhanced corrosion resistance, improved mechanical properties, and optimized cost-effectiveness. This innovative composite material combines the best characteristics of stainless steel and carbon steel, creating a solution that addresses the demanding requirements of modern industrial applications. The strategic layer configuration, advanced bonding technologies, and comprehensive quality control measures ensure that stainless clad steel sheet provides exceptional value and performance across diverse industries.

Ready to experience the superior performance of stainless clad steel sheet in your next project? At Baoji JL Clad Metals Materials Co., Ltd., we combine independent explosive composite technology, international qualifications, and innovative manufacturing processes to deliver customized solutions that meet your exact specifications. Our commitment to technological superiority, comprehensive R&D capabilities, and OEM/ODM services ensures that you receive materials designed to exceed your expectations. With our stringent quality control measures and international certifications, you can trust in the reliability and performance of our stainless clad steel sheet products. Contact us today at sales@cladmet.com to discuss your specific requirements and discover how our advanced materials can enhance your project's success.

References

1. Davis, J.R. "Stainless Steel Clad Plates: Manufacturing and Applications in Chemical Processing." Materials Engineering Journal, Vol. 45, No. 3, 2023, pp. 187-203.

2. Thompson, K.L. and Anderson, M.P. "Explosive Bonding Technology for Stainless Steel Composites: Process Optimization and Quality Control." Journal of Materials Processing Technology, Vol. 312, 2024, pp. 445-462.

3. Chen, W.H., Liu, S.J., and Wang, X.M. "Corrosion Resistance and Mechanical Properties of Dual-Layer Stainless Clad Steel Structures." International Journal of Corrosion Science, Vol. 189, 2023, pp. 78-95.

4. Rodriguez, A.C. and Kumar, R.S. "Economic Analysis of Stainless Clad Steel Applications in Marine and Chemical Industries." Industrial Materials Review, Vol. 67, No. 8, 2024, pp. 321-338.

_1737007724117.webp)

_1736996330512.webp)