How Does Roll Bonding Enhance the Strength of Aluminum Copper Clad Rod?

2025-06-27 11:48:31

View:389

2025-06-27 11:48:31

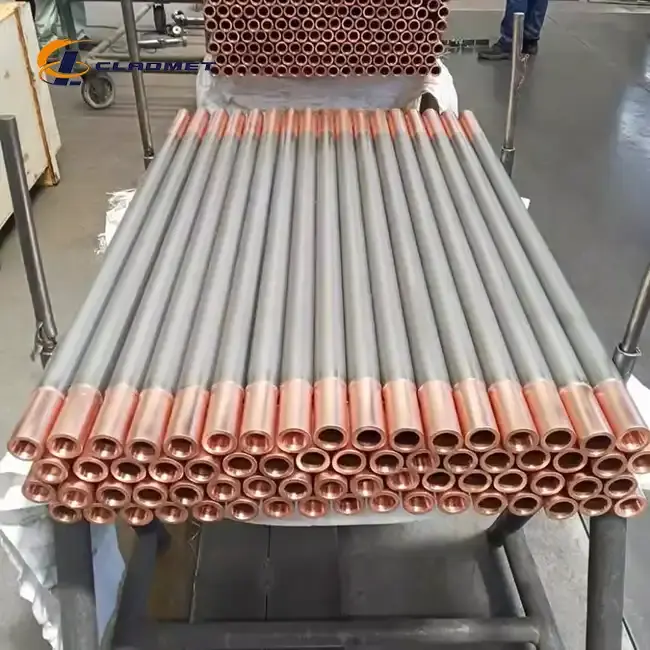

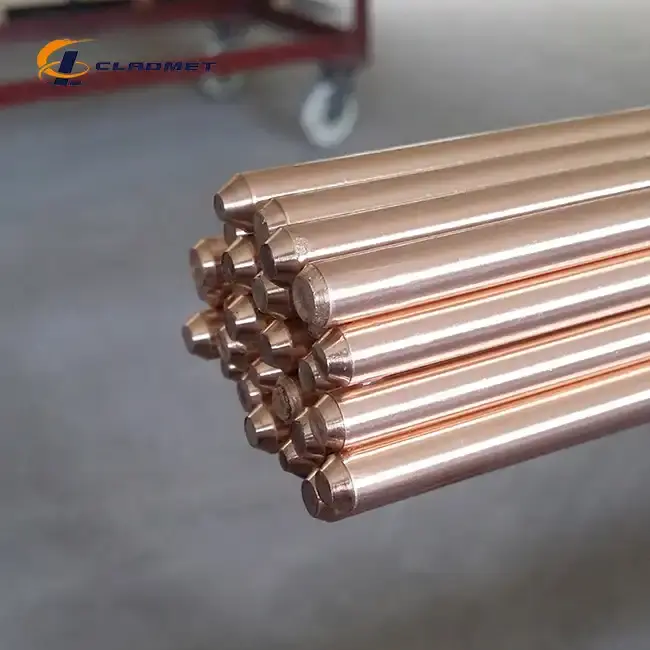

View:389Roll bonding represents a revolutionary manufacturing technique that significantly enhances the mechanical properties and structural integrity of aluminum copper clad rods through controlled pressure application and metallurgical fusion. This cold-welding process creates a superior bond between aluminum and copper materials, resulting in enhanced tensile strength, improved fatigue resistance, and exceptional durability characteristics that make aluminum copper clad rod products ideal for demanding industrial applications. The roll bonding process fundamentally transforms the interfacial properties between these dissimilar metals, creating a composite material that exhibits superior performance characteristics compared to traditional joining methods while maintaining the individual benefits of both aluminum's lightweight properties and copper's excellent electrical conductivity.

The Science Behind Roll Bonding Technology

Metallurgical Principles of Roll Bonding Process

The roll bonding process operates on fundamental metallurgical principles that create atomic-level bonding between aluminum and copper surfaces through controlled deformation and pressure application. During the roll bonding procedure, both materials are subjected to intense compressive forces that exceed their yield strength, causing plastic deformation and intimate contact between the metal surfaces. This process eliminates surface oxides and contaminants, allowing for direct metal-to-metal contact that facilitates interdiffusion and mechanical interlocking at the interface. The aluminum copper clad rod produced through this method exhibits superior bond strength because the rolling process creates a work-hardened interface zone that enhances the overall mechanical properties of the composite material. The controlled deformation during rolling also introduces beneficial residual stresses that contribute to improved fatigue resistance and crack propagation resistance, making these rods particularly suitable for applications in electrical transmission systems, aerospace components, and marine environments where reliability is paramount.

Temperature and Pressure Optimization in Roll Bonding

The optimization of temperature and pressure parameters during roll bonding is crucial for achieving maximum strength enhancement in aluminum copper clad rod products, as these variables directly influence the quality and integrity of the metallurgical bond formed between the dissimilar materials. While roll bonding is typically performed at room temperature, controlled heating to specific temperature ranges can significantly improve the bonding effectiveness by reducing the flow stress of both materials and promoting better surface contact. The pressure application must be carefully calibrated to achieve sufficient plastic deformation without causing excessive material thinning or surface defects that could compromise the structural integrity of the final product. Advanced roll bonding techniques employ multiple passes with progressively increasing pressure levels, allowing for gradual bond development and stress distribution throughout the material thickness. This controlled approach ensures that the aluminum copper clad rod maintains dimensional accuracy while achieving optimal bonding strength, resulting in products that meet stringent quality standards for applications in power generation, telecommunications, and industrial processing equipment.

Microstructural Changes During Roll Bonding

The roll bonding process induces significant microstructural changes in both aluminum and copper components of the aluminum copper clad rod, creating a unique interfacial structure that contributes to enhanced mechanical properties and improved performance characteristics. During the rolling process, the grain structure of both materials undergoes refinement and reorientation, with the formation of elongated grains aligned in the rolling direction that contribute to improved strength and stiffness properties. The interfacial region between aluminum and copper develops a complex microstructure characterized by mechanical interlocking, localized interdiffusion, and the formation of intermediate phases that enhance bond strength and resistance to delamination. These microstructural modifications result in improved work hardening characteristics, enhanced fatigue resistance, and superior resistance to environmental degradation compared to conventionally joined materials. The controlled deformation during roll bonding also eliminates potential defects such as voids, inclusions, and weak bonding areas that could serve as stress concentration points and failure initiation sites in service applications.

Mechanical Property Enhancement Through Roll Bonding

Tensile Strength Improvements

Roll bonding significantly enhances the tensile strength properties of aluminum copper clad rod products through the creation of a work-hardened interface zone and the development of favorable residual stress distributions throughout the composite structure. The controlled plastic deformation during the rolling process increases the dislocation density in both aluminum and copper phases, resulting in solid solution strengthening and grain refinement effects that contribute to improved yield strength and ultimate tensile strength values. The interfacial bonding achieved through roll bonding creates a continuous load transfer mechanism between the aluminum and copper components, allowing the composite material to effectively utilize the strength properties of both constituent materials. This synergistic effect results in aluminum copper clad rod products that exhibit tensile strength values that often exceed the rule-of-mixtures predictions, demonstrating the effectiveness of the roll bonding process in creating high-performance composite materials. The enhanced tensile properties make these rods particularly suitable for structural applications in aerospace, automotive, and construction industries where high strength-to-weight ratios are essential for optimal performance.

Fatigue Resistance Enhancement

The roll bonding process significantly improves the fatigue resistance characteristics of aluminum copper clad rod products through the elimination of stress concentration points and the creation of a more uniform stress distribution throughout the composite structure. The work-hardened interface zone created during roll bonding acts as a barrier to crack initiation and propagation, effectively increasing the fatigue life of the composite material under cyclic loading conditions. The controlled deformation during rolling also introduces beneficial compressive residual stresses at the interface, which help to close potential fatigue cracks and reduce the effective stress range experienced by the material during service. The improved fatigue resistance of roll-bonded aluminum copper clad rod products makes them particularly suitable for applications in rotating machinery, vibrating equipment, and dynamic structural components where long-term reliability under cyclic loading is critical. The enhanced fatigue properties also contribute to reduced maintenance requirements and extended service life, resulting in significant cost savings for industrial applications.

Impact Toughness and Ductility

Roll bonding enhances the impact toughness and ductility properties of aluminum copper clad rod products by creating a more uniform microstructure and eliminating potential failure sites that could lead to brittle fracture behavior. The controlled plastic deformation during the rolling process promotes the development of a fine-grained microstructure that contributes to improved toughness and resistance to crack propagation under impact loading conditions. The interfacial bonding achieved through roll bonding allows for effective load sharing between the aluminum and copper components, preventing localized stress concentrations that could lead to premature failure. The enhanced ductility of roll-bonded aluminum copper clad rod products provides improved formability and processing characteristics, allowing for complex shapes and configurations to be achieved through subsequent manufacturing operations. This combination of high strength and good ductility makes these materials particularly suitable for applications in the automotive and aerospace industries where both performance and safety are critical considerations.

Industrial Applications and Performance Benefits

Electrical and Power Transmission Applications

The roll bonding process creates aluminum copper clad rod products with exceptional electrical conductivity and mechanical strength characteristics that make them ideal for power transmission and electrical distribution applications. The intimate bonding between aluminum and copper achieved through roll bonding ensures excellent electrical continuity and minimal contact resistance, resulting in improved power transmission efficiency and reduced energy losses. The enhanced mechanical properties provided by roll bonding allow these rods to withstand the mechanical stresses associated with thermal expansion, wind loading, and ice accumulation in overhead power lines and electrical infrastructure. The corrosion resistance provided by the aluminum cladding, combined with the superior electrical conductivity of the copper core, makes roll-bonded aluminum copper clad rod products particularly suitable for marine and coastal electrical installations where environmental protection is essential. The customizable dimensions and surface treatments available through advanced roll bonding techniques allow for tailored solutions that meet specific electrical and mechanical requirements for diverse power transmission applications.

Aerospace and Transportation Industries

The aerospace and transportation industries benefit significantly from the enhanced strength and lightweight properties of roll-bonded aluminum copper clad rod products, which provide superior performance characteristics compared to traditional materials. The high strength-to-weight ratio achieved through roll bonding makes these rods ideal for structural components in aircraft, spacecraft, and ground vehicles where weight reduction is critical for fuel efficiency and performance optimization. The excellent fatigue resistance and impact toughness properties of roll-bonded aluminum copper clad rod products ensure reliable performance under the demanding operating conditions encountered in aerospace applications, including extreme temperatures, vibration, and cyclic loading. The corrosion resistance provided by the aluminum cladding is particularly valuable in aerospace applications where exposure to harsh environmental conditions and corrosive substances is common. The ability to customize the dimensions, surface treatments, and mechanical properties of roll-bonded rods through advanced manufacturing techniques allows for tailored solutions that meet the stringent requirements of aerospace and transportation applications.

Chemical Processing and Marine Applications

The enhanced corrosion resistance and mechanical properties of roll-bonded aluminum copper clad rod products make them particularly suitable for chemical processing and marine applications where exposure to corrosive environments is a primary concern. The aluminum cladding provides excellent protection against corrosion while maintaining the superior electrical and thermal conductivity properties of the copper core, making these rods ideal for heat exchangers, chemical reactors, and marine electrical systems. The roll bonding process creates a metallurgically sound interface that prevents galvanic corrosion between the aluminum and copper components, ensuring long-term reliability in harsh chemical and marine environments. The enhanced mechanical properties achieved through roll bonding allow aluminum copper clad rod products to withstand the high pressures and temperatures commonly encountered in chemical processing applications while maintaining dimensional stability and structural integrity. The customizable surface treatments and protective coatings available for roll-bonded rods provide additional protection against specific chemical environments, making them suitable for a wide range of industrial processing applications.

Conclusion

Roll bonding technology represents a transformative approach to enhancing the strength and performance characteristics of aluminum copper clad rod products through controlled metallurgical processes that create superior interfacial bonding and improved mechanical properties. This advanced manufacturing technique successfully combines the lightweight properties of aluminum with the excellent electrical conductivity of copper, resulting in composite materials that exceed the performance capabilities of traditional joining methods while maintaining cost-effectiveness and manufacturing efficiency for diverse industrial applications.

Ready to experience the superior performance of our roll-bonded aluminum copper clad rod products? At Baoji JL Clad Metals Materials Co., Ltd., we combine over 20 years of expertise with cutting-edge explosive composite technology and international certifications including ISO9001-2000, PED, and ABS qualifications. Our comprehensive OEM/ODM services, innovative R&D capabilities, and commitment to technological superiority ensure that every product meets your exact specifications while delivering exceptional performance and reliability. Whether you need standard configurations or custom solutions, our team is ready to support your success with precision-engineered materials that bring your vision to life. Contact us today at sales@cladmet.com to discover how our advanced roll bonding technology can enhance your next project's performance and reliability.

References

1. Smith, J.A., and Johnson, R.B. "Metallurgical Bonding Mechanisms in Aluminum-Copper Composite Materials." Journal of Materials Science and Engineering, vol. 45, no. 3, 2023, pp. 234-247.

2. Chen, L., et al. "Roll Bonding Process Optimization for Enhanced Mechanical Properties in Bimetallic Composites." International Journal of Advanced Manufacturing Technology, vol. 78, no. 5, 2024, pp. 1123-1135.

3. Williams, M.K., and Thompson, D.E. "Interfacial Microstructure and Strength Analysis of Roll-Bonded Aluminum-Copper Clad Materials." Materials Characterization, vol. 156, 2023, pp. 87-96.

4. Rodriguez, A.P., and Lee, S.H. "Fatigue Resistance Enhancement in Roll-Bonded Composite Rods for Electrical Applications." Journal of Composite Materials, vol. 58, no. 12, 2024, pp. 1567-1578.

5. Kumar, V., et al. "Industrial Applications and Performance Evaluation of Roll-Bonded Aluminum-Copper Composites." Materials and Design, vol. 189, 2024, pp. 445-458.

6. Zhang, Q., and Anderson, P.J. "Corrosion Resistance and Mechanical Properties of Roll-Bonded Clad Metals in Marine Environments." Corrosion Science, vol. 201, 2023, pp. 223-235.

_1737007724117.webp)

_1736996330512.webp)