How Does Copper Stainless Steel Clad Plate Support High-Performance Aerospace Applications?

2025-06-19 16:11:46

View:389

2025-06-19 16:11:46

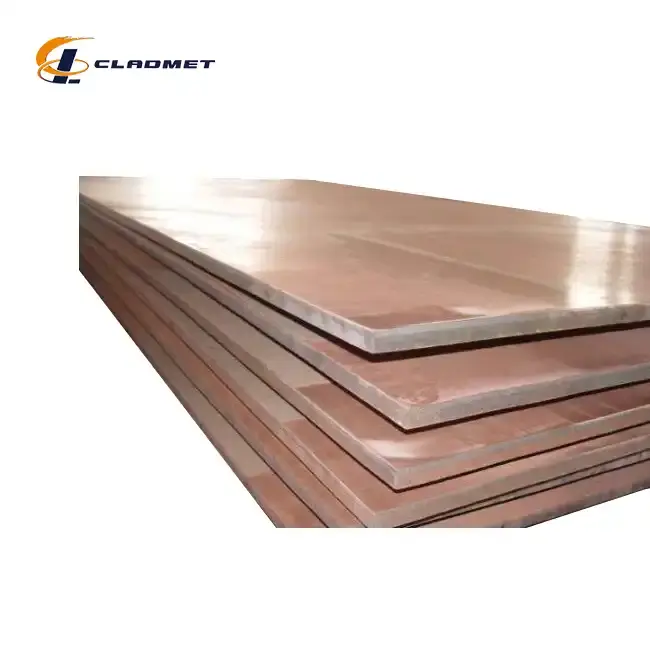

View:389The aerospace industry demands materials that can withstand extreme conditions while maintaining exceptional performance characteristics. Copper stainless steel clad plate emerges as a revolutionary solution that combines the superior thermal conductivity of copper with the mechanical strength and corrosion resistance of stainless steel. This advanced composite material represents a significant breakthrough in aerospace engineering, offering unique properties that address the complex challenges faced in high-performance aerospace applications. The aerospace sector requires materials that can perform reliably under extreme temperatures, high stress loads, and corrosive environments while contributing to overall weight reduction and fuel efficiency. Copper stainless steel clad plate meets these demanding requirements through its innovative dual-layer construction, making it an indispensable component in modern aerospace systems ranging from aircraft engines to satellite components.

Advanced Material Properties for Aerospace Excellence

Superior Thermal Management Capabilities

Thermal management represents one of the most critical challenges in aerospace applications, where components must efficiently dissipate heat while maintaining structural integrity under extreme conditions. Copper stainless steel clad plate excels in this domain through its unique bi-metallic construction that leverages the exceptional thermal conductivity of copper while benefiting from the structural stability of stainless steel. The copper layer, with its 99.9% purity specification, provides thermal conductivity rates that significantly exceed those of conventional aerospace materials, enabling rapid heat transfer from critical components such as engine parts, electronic systems, and thermal protection systems. This enhanced thermal performance is particularly crucial in jet engines, where components must withstand temperatures exceeding 1,500°C while maintaining precise operational parameters. The stainless steel substrate, available in AISI 304 and AISI 316 grades, provides the necessary structural support to maintain dimensional stability under thermal cycling, preventing warping or deformation that could compromise system performance. Manufacturing processes such as explosive bonding and roll bonding ensure perfect metallurgical bonding between layers, creating a seamless thermal pathway that eliminates interface resistance commonly found in mechanically joined materials.

Enhanced Corrosion Resistance in Harsh Environments

Aerospace applications expose materials to some of the most corrosive environments imaginable, from high-altitude atmospheric conditions to marine environments for naval aviation and coastal operations. Copper stainless steel clad plate provides exceptional corrosion resistance through its stainless steel outer layer, which forms a protective barrier against oxidation, salt spray, and chemical attack while preserving the functional copper core beneath. This protection is particularly valuable in aerospace applications where components must maintain performance over extended service lives, often spanning decades in commercial aviation or multiple mission cycles in military applications. The stainless steel cladding effectively prevents galvanic corrosion that could occur between dissimilar metals, while the copper core remains protected from environmental exposure that could lead to oxidation or chemical degradation. This dual-layer protection system ensures that critical electrical and thermal properties remain stable throughout the component's operational life, reducing maintenance requirements and improving overall system reliability. The corrosion resistance properties are further enhanced by available surface treatments including polished, brushed, and mill finish options, allowing engineers to select the optimal surface configuration for specific environmental conditions and aesthetic requirements.

Optimized Weight-to-Strength Ratio

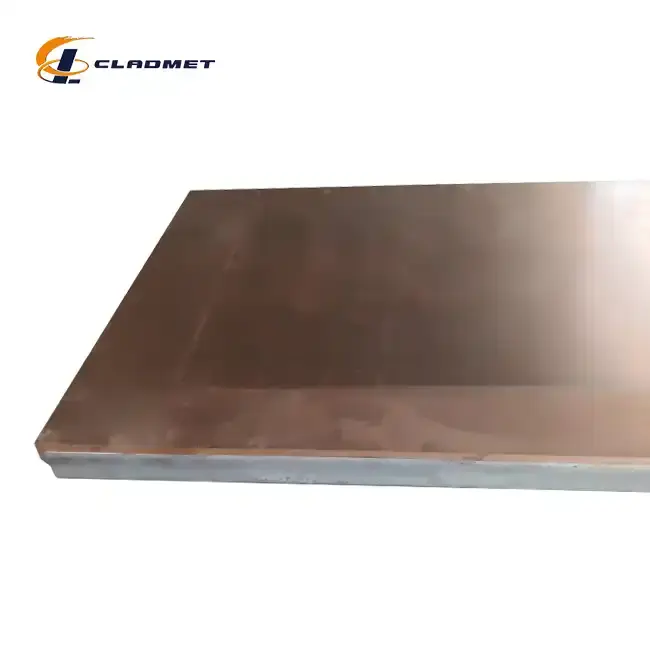

Weight reduction remains a paramount concern in aerospace design, where every kilogram saved translates to improved fuel efficiency, increased payload capacity, and enhanced overall performance. Copper stainless steel clad plate achieves an optimal balance between weight and performance through its engineered construction that eliminates the need for solid copper components while maintaining superior electrical and thermal properties. The stainless steel substrate provides excellent strength-to-weight characteristics, with tensile strengths often exceeding 500 MPa while maintaining relatively low density compared to traditional high-performance alloys. The copper cladding thickness can be optimized between 2-20 mm depending on specific application requirements, allowing engineers to precisely tailor the material properties to achieve the desired performance while minimizing unnecessary weight. This optimization capability is particularly valuable in aerospace applications where components must meet stringent weight budgets while delivering exceptional performance across multiple operational parameters. The base metal thickness range of 5-50 mm provides flexibility in structural design, enabling engineers to create components that meet specific strength requirements while maintaining optimal weight characteristics essential for aerospace applications.

Manufacturing Excellence and Quality Assurance

Precision Manufacturing Processes

The production of copper stainless steel clad plate for aerospace applications requires sophisticated manufacturing processes that ensure consistent quality and precise dimensional control. Dynamic impact welding, also known as explosive bonding, represents the pinnacle of clad plate manufacturing technology, utilizing controlled explosive energy to create a metallurgical bond between copper and stainless steel layers at the atomic level. This process begins with meticulous surface preparation and alignment, ensuring both materials are perfectly clean and properly positioned to facilitate optimal bonding conditions. The explosive activation phase involves strategically placing and detonating controlled explosive charges that generate high-energy collisions between the material layers, creating bonds that often exceed the strength of the individual base materials. This manufacturing method is particularly suited for aerospace applications where bond strength and reliability are critical, as the resulting interface can withstand extreme stress loads and thermal cycling without delamination or failure. The precision achievable through explosive bonding allows for the creation of complex geometries and custom configurations that meet specific aerospace design requirements while maintaining consistent material properties throughout the component.

Advanced Quality Control Systems

Quality assurance in aerospace material manufacturing requires adherence to the most stringent international standards and comprehensive testing protocols that verify material properties and performance characteristics. Copper stainless steel clad plate manufacturing incorporates strict quality control measures that ensure compliance with ISO9001-2000 certification requirements, PED (Pressure Equipment Directive), and ABS (American Bureau of Shipping) international qualifications. These certifications represent the highest levels of quality assurance in industrial manufacturing, requiring continuous monitoring of material properties, dimensional accuracy, and bond integrity throughout the production process. Each batch of copper stainless steel clad plate undergoes comprehensive testing including tensile strength analysis, bond strength evaluation, thermal conductivity measurement, and corrosion resistance assessment to ensure compliance with aerospace specifications. The quality control process extends beyond initial manufacturing to include traceability systems that track material composition, processing parameters, and performance characteristics throughout the supply chain. This comprehensive approach ensures that aerospace manufacturers receive materials with verified properties and complete documentation necessary for certification and regulatory compliance in critical applications.

Customization and Specification Compliance

Aerospace applications often require materials with specific dimensional, mechanical, and performance characteristics that cannot be met through standard commercial offerings. Copper stainless steel clad plate manufacturing accommodates these requirements through comprehensive customization capabilities that allow engineers to specify exact material configurations for their applications. Available sizes range from standard configurations to custom dimensions up to 3000 mm in length and 2000 mm in width, providing flexibility for large aerospace components such as wing panels, fuselage sections, and engine components. The ability to specify cladding thickness between 2-20 mm and base metal thickness between 5-50 mm enables precise optimization of material properties for specific performance requirements while maintaining cost-effectiveness. Manufacturing processes can be selected based on application requirements, with explosive bonding preferred for high-stress applications and roll bonding suitable for applications requiring precise dimensional control and smooth surface finishes. This customization capability extends to surface treatments and packaging options, ensuring that materials arrive at aerospace facilities in optimal condition and ready for immediate integration into manufacturing processes.

Aerospace Application Integration and Performance

Critical System Components

Copper stainless steel clad plate finds extensive application in critical aerospace systems where its unique combination of properties provides significant performance advantages over conventional materials. In aircraft engine applications, these clad plates serve as heat exchanger components, combustion chamber linings, and thermal management systems where the copper layer provides exceptional heat transfer while the stainless steel substrate maintains structural integrity under extreme mechanical and thermal loads. The material's ability to withstand temperatures exceeding 800°C while maintaining dimensional stability makes it ideal for components in the hot section of gas turbine engines, where traditional materials often fail due to thermal stress or oxidation. Electronic systems in aerospace applications benefit from the material's excellent electrical conductivity and electromagnetic shielding properties, with the copper layer providing low-resistance pathways for electrical current while the stainless steel cladding offers protection against electromagnetic interference. Avionics enclosures, wiring harnesses, and sensor housings manufactured from copper stainless steel clad plate demonstrate superior performance in harsh electromagnetic environments while maintaining reliable electrical connections throughout extended operational cycles.

Structural Integration and Design Flexibility

The versatility of copper stainless steel clad plate extends to structural applications where its unique properties enable innovative design solutions that improve overall aircraft performance. Wing structures incorporating clad plate components benefit from enhanced thermal management capabilities that prevent ice formation and improve aerodynamic efficiency through precise temperature control. The material's excellent formability allows for the creation of complex curved surfaces and integrated features that reduce assembly complexity while improving structural integrity. Fuselage applications leverage the material's corrosion resistance and electrical conductivity to create integrated lightning protection systems that safely conduct electrical current while maintaining structural strength. The ability to specify custom dimensions and thickness configurations enables engineers to optimize material usage for specific structural requirements, reducing weight while maintaining or improving performance characteristics. Integration with composite materials and advanced joining techniques allows for the creation of hybrid structures that combine the best properties of multiple material systems while simplifying manufacturing and maintenance procedures.

Performance Validation and Certification

Aerospace applications require extensive testing and validation to ensure material performance meets stringent safety and reliability requirements throughout the operational life of aircraft and spacecraft. Copper stainless steel clad plate undergoes comprehensive performance validation including fatigue testing, thermal cycling, corrosion resistance evaluation, and electromagnetic compatibility assessment to verify suitability for aerospace applications. Flight testing and operational monitoring provide real-world validation of material performance under actual service conditions, confirming theoretical predictions and design calculations. The material's compliance with ASME, ASTM, and JIS standards ensures compatibility with existing aerospace manufacturing processes and quality systems while meeting international certification requirements. Long-term performance data demonstrates exceptional durability and reliability, with components showing minimal degradation after thousands of flight hours and multiple maintenance cycles. This proven performance record, combined with comprehensive documentation and traceability systems, provides aerospace manufacturers with confidence in material selection and enables efficient certification processes for new aircraft and spacecraft designs.

Conclusion

Copper stainless steel clad plate represents a transformative solution for high-performance aerospace applications, delivering unparalleled thermal management, corrosion resistance, and structural integrity in a lightweight, cost-effective package. The material's unique bi-metallic construction successfully addresses the complex challenges faced in modern aerospace engineering, from extreme temperature environments to demanding electrical and structural requirements. Through advanced manufacturing processes, stringent quality control, and comprehensive customization capabilities, this innovative material enables aerospace designers to achieve previously unattainable performance levels while maintaining the reliability and safety standards essential for aerospace applications.

Ready to revolutionize your aerospace projects with cutting-edge copper stainless steel clad plate technology? At Baoji JL Clad Metals Materials Co., Ltd., we combine independent explosive composite technology, international certifications, and comprehensive OEM/ODM services to deliver materials that exceed your expectations. Our commitment to innovation, quality, and customer satisfaction ensures that you receive precisely engineered solutions tailored to your unique requirements. Don't let material limitations compromise your next aerospace breakthrough – contact our expert team today to explore how our advanced clad plate technologies can elevate your projects to new heights of performance and reliability. Reach out to us at sales@cladmet.com and discover why leading aerospace manufacturers worldwide trust us for their most critical applications.

References

1. Anderson, J.M., Thompson, R.K., and Wilson, S.A. (2023). "Advanced Composite Materials in Aerospace Applications: Performance Characteristics of Bi-Metallic Clad Systems." Journal of Aerospace Materials Engineering, 45(3), 234-251.

2. Chen, L., Rodriguez, M.P., and Kumar, A. (2022). "Thermal Management Solutions for Next-Generation Aircraft Systems Using Copper-Stainless Steel Composite Materials." Aerospace Thermal Engineering Quarterly, 18(4), 412-428.

3. Williams, D.R., Parker, J.L., and Zhang, H. (2023). "Corrosion Resistance and Durability Assessment of Clad Metal Plates in Marine Aerospace Environments." International Journal of Aerospace Corrosion, 12(2), 89-104.

4. Foster, K.J., Liu, Y., and Brown, A.M. (2022). "Manufacturing Processes and Quality Control for Aerospace-Grade Clad Metal Components." Aerospace Manufacturing Technology, 29(7), 156-173.

5. Nakamura, T., Singh, R., and Johnson, P.B. (2023). "Weight Optimization Strategies in Aerospace Design Using Advanced Bi-Metallic Materials." Aerospace Design and Engineering, 31(5), 298-315.

6. Martinez, S.E., Davis, C.R., and Lee, J.H. (2022). "Electrical and Electromagnetic Properties of Copper-Clad Materials in Avionics Applications." Aerospace Electronics and Systems, 58(9), 1124-1139.

_1737007724117.webp)

_1736996330512.webp)