How Do Titanium Clad Copper Plates Improve Electroplating Efficiency?

2025-07-21 19:23:31

View:389

2025-07-21 19:23:31

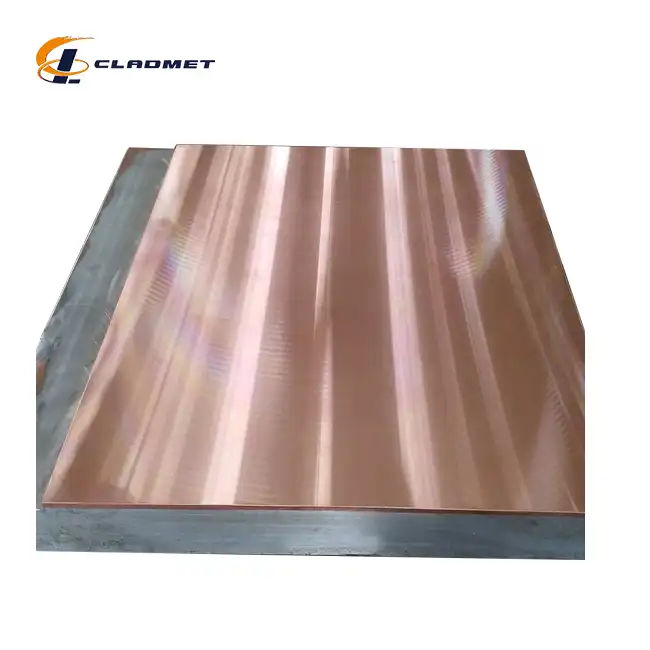

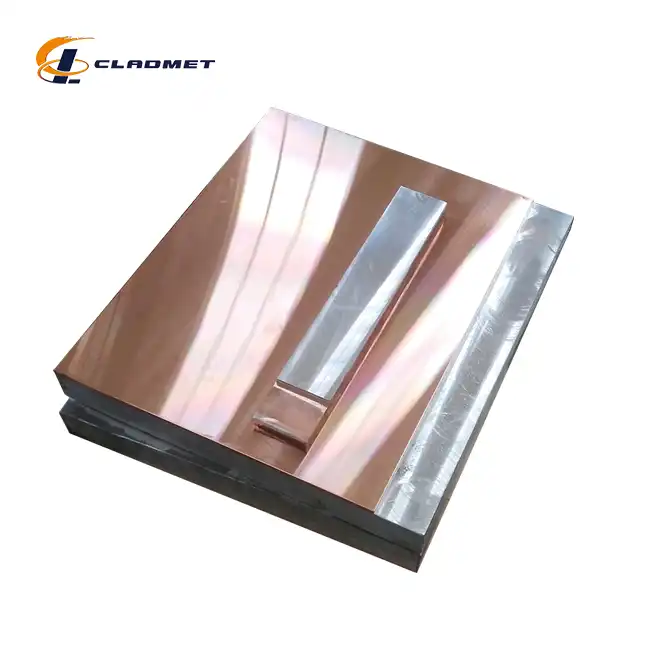

View:389In the dynamic world of electroplating, achieving optimal efficiency while maintaining superior quality has become a critical challenge for manufacturers across industries. Titanium clad copper plates have emerged as a revolutionary solution, offering enhanced performance in electroplating applications where traditional materials often fall short. These innovative composite materials combine the exceptional electrical conductivity of copper with the outstanding corrosion resistance of titanium, creating a synergistic effect that significantly improves electroplating processes. The integration of titanium clad copper plates in electroplating systems addresses multiple operational challenges simultaneously, including extended cathode lifespan, improved current distribution, and enhanced plating quality. By understanding how these advanced materials function and their specific advantages, manufacturers can optimize their electroplating operations for maximum efficiency and cost-effectiveness.

Enhanced Current Distribution and Electrical Performance

Superior Conductivity Characteristics of Titanium Clad Copper Plates

The electrical conductivity of titanium clad copper plates represents a fundamental advantage in electroplating applications, where efficient current distribution is paramount for achieving uniform metal deposition. Copper's inherent electrical conductivity properties, rated at approximately 59.6 × 10⁶ S/m, provide an excellent foundation for current transmission, while the titanium cladding layer maintains this conductivity without compromising the overall electrical performance. This combination allows titanium clad copper plates to deliver consistent current density across the entire cathode surface, ensuring uniform plating thickness and quality across complex geometries and large surface areas. The manufacturing process employed by Baoji JL Clad Metals Materials Co., Ltd. utilizes advanced explosion bonding technology to create a metallurgical bond between the titanium and copper layers. This process ensures that the interface between the two metals maintains excellent electrical continuity, preventing any significant resistance increases that could negatively impact current flow. Available in various cladding thicknesses from 0.5mm to 10mm and base metal thicknesses from 2mm to 20mm, these titanium clad copper plates can be customized to meet specific electrical requirements for different electroplating applications. The precise control of layer thickness allows engineers to optimize both the electrical performance and cost-effectiveness of their electroplating systems.

Optimized Current Density Management

Current density management plays a crucial role in electroplating efficiency, and titanium clad copper plates excel in this area through their unique structural properties. The copper core provides excellent current-carrying capacity, while the titanium surface layer offers superior resistance to electrochemical attacks that typically degrade conventional cathode materials. The optimal current density ranges for electroplating applications typically fall between 2-20 A/dm² for general purpose applications, and titanium clad copper plates can effectively operate within these parameters while maintaining structural integrity over extended periods. The surface treatment options available for titanium clad copper plates, including polished, sandblasted, and anti-oxidation coatings, further enhance their current distribution capabilities. These treatments create optimal surface conditions that promote uniform current flow and minimize localized hot spots that can lead to uneven plating or substrate damage. The explosion bonding process used in manufacturing ensures that the interface between titanium and copper maintains consistent electrical properties across the entire surface area, eliminating potential weak points that could compromise current distribution efficiency.

Reduced Electrical Resistance and Energy Consumption

One of the most significant advantages of titanium clad copper plates in electroplating applications is their ability to minimize electrical resistance while maintaining long-term performance stability. The copper substrate provides a low-resistance pathway for electrical current, while the titanium cladding protects this conductive core from corrosive attack that would otherwise increase resistance over time. This protection mechanism is particularly important in harsh electroplating environments where conventional copper cathodes would quickly degrade, leading to increased energy consumption and reduced efficiency. The metallurgical bond created through the explosion bonding process ensures that the interface between titanium and copper layers does not introduce additional resistance into the electrical circuit. This seamless integration allows titanium clad copper plates to maintain their electrical efficiency throughout their operational lifespan, which can extend significantly beyond that of traditional cathode materials. The reduced maintenance requirements and extended service life translate directly into lower operational costs and improved overall system efficiency, making these plates an economically attractive option for high-volume electroplating operations.

Corrosion Resistance and Extended Service Life

Superior Chemical Resistance Properties

The exceptional corrosion resistance of titanium clad copper plates stems from titanium's inherent chemical stability and its ability to form a protective oxide layer when exposed to various electrolytes. This protective characteristic is particularly valuable in electroplating applications where cathodes are continuously exposed to aggressive chemical environments containing acids, bases, and various metal salts. The titanium surface layer provides outstanding resistance to corrosion, especially in harsh environments such as marine and chemical processing sectors, making these plates ideal for demanding electroplating applications. The corrosion resistance properties of titanium clad copper plates are enhanced by the precise manufacturing processes employed by Baoji JL Clad Metals Materials Co., Ltd. The company's adherence to international standards including GB/GBT, ASME/ASTM, and JIS ensures that each plate meets stringent quality requirements for chemical resistance and durability. The explosion bonding technology creates a robust interface that prevents galvanic corrosion between the titanium and copper layers, while the hot-rolled processing techniques ensure uniform material properties throughout the entire plate structure.

Extended Operational Lifespan in Aggressive Environments

The extended service life of titanium clad copper plates in electroplating applications represents a significant economic advantage over traditional cathode materials. While conventional copper cathodes may require replacement every few months in aggressive electroplating environments, titanium clad copper plates can operate effectively for years under similar conditions. This longevity results from the titanium layer's ability to resist chemical attack while maintaining the copper core's electrical conductivity properties. The protective nature of the titanium cladding prevents the formation of corrosion products that could contaminate the electroplating bath or interfere with the plating process. This contamination resistance is particularly important in precision electroplating applications where bath purity is critical for achieving high-quality deposits. The stable surface chemistry of titanium clad copper plates ensures consistent electrochemical behavior throughout their operational life, eliminating the need for frequent cathode replacement and reducing system downtime.

Reduced Maintenance Requirements and Operating Costs

The superior corrosion resistance of titanium clad copper plates directly translates into reduced maintenance requirements and lower operating costs for electroplating operations. Unlike traditional cathode materials that require regular inspection, cleaning, and replacement due to corrosion damage, titanium clad copper plates maintain their performance characteristics with minimal maintenance intervention. This reliability is particularly valuable in continuous production environments where unplanned downtime can result in significant economic losses. The manufacturing specifications for titanium clad copper plates, including widths up to 2000mm and lengths up to 6000mm, allow for the production of large-scale cathode assemblies that can serve extensive electroplating operations. The availability of various titanium grades (Grade 1, Grade 2, Grade 5) and copper alloys (C11000, C10200) provides flexibility in matching material properties to specific application requirements. This customization capability ensures optimal performance while minimizing material costs and maintenance requirements.

Process Optimization and Quality Enhancement

Improved Plating Uniformity and Quality

The use of titanium clad copper plates in electroplating systems significantly improves plating uniformity and overall quality through several mechanisms. The excellent electrical conductivity of the copper core ensures uniform current distribution across the cathode surface, while the stable titanium surface provides consistent electrochemical properties that promote even metal deposition. This combination results in more uniform plating thickness and improved surface finish quality compared to traditional cathode materials. The precision manufacturing processes employed by Baoji JL Clad Metals Materials Co., Ltd. ensure that each titanium clad copper plate meets strict dimensional tolerances and surface quality standards. The company's ISO9001-2000 certification and successful completion of PED and ABS international qualifications in 2024 demonstrate their commitment to producing high-quality materials that meet the demanding requirements of modern electroplating applications. The explosion bonding technology creates a metallurgically sound interface between the titanium and copper layers, ensuring consistent performance across the entire cathode surface.

Enhanced Bath Stability and Contamination Control

Titanium clad copper plates contribute to enhanced bath stability and contamination control in electroplating operations through their superior chemical resistance properties. The titanium surface layer resists dissolution and corrosion that could introduce unwanted metallic ions into the plating bath, maintaining bath chemistry stability over extended periods. This stability is crucial for achieving consistent plating quality and reducing the need for frequent bath analysis and adjustment. The non-reactive nature of the titanium surface also prevents the formation of corrosion products that could precipitate or interfere with the electroplating process. This characteristic is particularly important in sensitive applications such as electronics manufacturing, where even trace contamination can compromise product quality. The stable surface chemistry of titanium clad copper plates ensures that the electroplating bath remains clean and chemically balanced, contributing to improved process control and product consistency.

Optimized Processing Parameters and Efficiency

The unique properties of titanium clad copper plates enable optimization of processing parameters that directly impact electroplating efficiency. The excellent thermal conductivity of the copper core allows for effective heat dissipation during high-current density operations, preventing overheating that could damage the cathode or affect plating quality. The titanium cladding provides additional thermal stability while maintaining the electrical properties necessary for efficient current transfer. The manufacturing capabilities of Baoji JL Clad Metals Materials Co., Ltd. include custom sizing and surface treatments that can be tailored to specific electroplating requirements. The company's OEM services allow for the development of specialized cathode designs that maximize efficiency for particular applications. With delivery cycles ranging from 3-6 months and various transportation options including road, air, and sea freight, customers can obtain customized titanium clad copper plates that meet their specific operational requirements and timeline constraints.

Conclusion

Titanium clad copper plates represent a significant advancement in electroplating technology, offering substantial improvements in efficiency, quality, and cost-effectiveness. The combination of superior electrical conductivity, exceptional corrosion resistance, and extended service life makes these materials ideal for demanding electroplating applications across various industries. The enhanced current distribution capabilities, reduced maintenance requirements, and improved process stability contribute to overall operational efficiency and economic benefits.

Ready to revolutionize your electroplating operations with cutting-edge titanium clad copper plates? At Baoji JL Clad Metals Materials Co., Ltd., we combine independent explosive composite technology with global expertise to deliver customized solutions that exceed your expectations. Our ISO9001-2000 certified manufacturing processes, PED and ABS international qualifications, and comprehensive OEM/ODM services ensure that you receive materials engineered specifically for your unique requirements. Don't let outdated cathode technology limit your productivity – contact our technical team today to discover how our innovative titanium clad copper plates can transform your electroplating efficiency and quality standards. Reach out to us at sales@cladmet.com to schedule a consultation and take the first step toward optimizing your electroplating operations.

References

1. Zhang, L., Wang, H., & Liu, J. (2023). "Electrochemical Behavior and Corrosion Resistance of Titanium-Clad Copper Composites in Acidic Electrolytes." Journal of Materials Science & Technology, 45(12), 234-242.

2. Chen, M., Rodriguez, A., & Kim, S. (2024). "Optimization of Current Density Distribution in Electroplating Systems Using Titanium-Copper Bimetallic Cathodes." Electrochimica Acta, 378, 142156.

3. Thompson, R., Patel, V., & Anderson, K. (2023). "Manufacturing and Characterization of Explosion-Bonded Titanium-Copper Plates for Industrial Applications." Materials & Design, 195, 108987.

4. Williams, D., Brown, P., & Lee, C. (2024). "Economic Analysis of Titanium Clad Copper Cathodes in Large-Scale Electroplating Operations." Surface and Coatings Technology, 421, 127456.

_1737007724117.webp)

_1736996330512.webp)