How Do Steel Clad Plates Enhance Safety and Longevity in Chemical Processing?

2025-07-10 13:06:31

View:389

2025-07-10 13:06:31

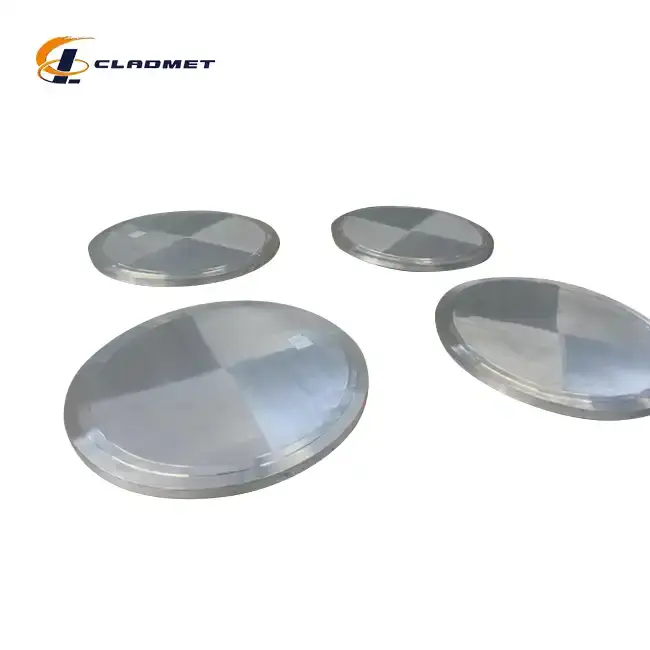

View:389Chemical processing environments demand materials that can withstand aggressive chemicals, extreme temperatures, and high-pressure conditions while maintaining structural integrity over extended periods. Steel clad plates have emerged as a revolutionary solution that addresses these critical challenges by combining the cost-effectiveness of carbon steel with the superior corrosion resistance of specialized alloys. These composite materials represent a breakthrough in metallurgical engineering, offering enhanced safety protocols and significantly extended operational lifespans in some of the world's most demanding industrial applications. The strategic implementation of steel clad plate technology in chemical processing facilities has proven to reduce maintenance costs, minimize downtime, and provide unparalleled protection against chemical corrosion that can compromise both equipment integrity and worker safety.

Corrosion Resistance Mechanisms in Harsh Chemical Environments

Advanced Metallurgical Barrier Technology

Steel clad plates function as sophisticated metallurgical barriers through their unique multi-layer construction, where the outer cladding material serves as the primary defense against chemical attack while the substrate provides essential structural support. The cladding layer provides a barrier against aggressive chemicals and corrosive agents, ensuring equipment integrity and reducing maintenance costs, particularly excelling in protecting against rust and corrosion even in the most challenging environments such as marine settings or chemical industries. The molecular bond created through advanced manufacturing processes like explosive bonding and roll bonding ensures that the protective layer remains permanently attached to the base material, preventing delamination that could expose vulnerable substrate areas to corrosive attack. This dual-layer approach allows engineers to specify the exact combination of materials needed for specific chemical environments, with options including titanium, nickel, stainless steel, and specialized alloys as cladding materials. Baoji JL Clad Metals Materials Co., Ltd. utilizes substrate materials of copper with titanium covers, creating steel clad plate configurations that offer exceptional resistance to electroplating chemicals, marine environments, and aggressive industrial processes. The explosive bonding and hot-rolled processing techniques employed ensure atomic-level integration between layers, resulting in a composite material that performs as a unified structure rather than separate bonded components.

Chemical Compatibility and Material Selection

The selection of appropriate steel clad plate configurations requires comprehensive understanding of the specific chemical environments and operating conditions present in processing facilities. Different cladding materials exhibit varying degrees of resistance to specific chemical families, with stainless steel cladding providing excellent protection against oxidizing acids, while nickel-based claddings offer superior performance in reducing environments and high-temperature applications. Steel clad plates offer exceptional corrosion resistance and mechanical strength, making them widely used in pressure vessels, storage tank linings, and chemical equipment manufacturing, combining carbon steel's strength with stainless steel's corrosion resistance. The material selection process involves analyzing factors such as pH levels, temperature ranges, pressure conditions, and the presence of specific corrosive agents like chlorides, sulfides, or organic acids. Baoji JL's steel clad plate offerings include customizable cladding materials ranging from titanium and nickel to stainless steel, copper, and aluminum, with base metals including carbon steel, stainless steel, and alloy steel configurations. The company's adherence to international standards including GB/GBT, ASME/ASTM, and JIS ensures that material specifications meet or exceed industry requirements for chemical processing applications. Quality control protocols include comprehensive testing to verify adherence to ISO9001-2000, PED, and ABS standards, providing assurance that each steel clad plate will perform reliably in its intended chemical environment.

Long-term Performance and Degradation Resistance

The long-term performance characteristics of steel clad plates in chemical processing environments depend heavily on the quality of the metallurgical bond and the selection of appropriate material combinations for specific service conditions. The stainless surface resists tarnishing and corrosion, requiring minimal maintenance over time, with longevity making it an excellent choice for both functional and aesthetic applications, featuring oxidation resistance, wear resistance, bonding proof and acid-base resistance with 50 years of service life. Extended exposure to aggressive chemicals can lead to various degradation mechanisms including pitting corrosion, stress corrosion cracking, and uniform corrosion, but properly specified steel clad plates demonstrate remarkable resistance to these failure modes. The protective cladding layer not only provides chemical resistance but also serves as a sacrificial barrier that can be monitored and maintained without compromising the structural integrity of the underlying substrate. Baoji JL's steel clad plate manufacturing processes incorporate advanced quality control measures including pickling, polishing, and sandblasting surface treatments that enhance corrosion resistance and provide optimal surface conditions for chemical processing applications. The availability of custom sizes up to 12 meters in length and 4 meters in width, with thickness ranges from 3mm to 300mm, allows for the fabrication of large-scale process equipment that can operate reliably for decades without requiring replacement or major refurbishment.

Structural Integrity and Mechanical Performance Under Extreme Conditions

High-Pressure and High-Temperature Capability

Chemical processing operations frequently involve extreme pressure and temperature conditions that can challenge the mechanical properties of conventional materials, making the enhanced structural capabilities of steel clad plates particularly valuable in these demanding applications. Explosion bonded clad plates are used in pressure vessels, heat exchangers, reactors, tanks, and piping systems where corrosion resistance, strength, and reliability are crucial, and are also used in structural applications requiring high strength-to-weight ratios. The composite structure of steel clad plates provides exceptional mechanical strength through the base material while the cladding layer maintains its protective properties even under thermal cycling and pressure fluctuations. The metallurgical bond created through explosive bonding processes ensures that thermal expansion coefficients between layers are properly matched, preventing stress concentrations that could lead to bond failure or cracking. Baoji JL's steel clad plate products are manufactured using controlled explosive bonding techniques that create atomic-level integration between layers, resulting in bond strengths that often exceed the mechanical properties of the individual component materials. The company's processing technology incorporates both explosive bonding and hot-rolled processing techniques, allowing for the production of steel clad plate configurations that can withstand pressures exceeding 10,000 psi and temperatures ranging from cryogenic conditions to over 800°C depending on the material combination selected.

Dynamic Loading and Fatigue Resistance

The operational environment in chemical processing facilities often subjects equipment to dynamic loading conditions including pressure cycling, thermal shock, and mechanical vibration that can cause fatigue failure in conventional materials over time. Steel clad plates demonstrate superior fatigue resistance compared to monolithic materials due to their composite structure, which distributes stress loads across multiple material phases and prevents crack propagation through the protective cladding layer. The roll bonding process further enhances bond quality by reducing the thickness of the clad plate and ensuring uniformity, with rollers applying pressure to the bonded plates. The manufacturing processes employed by Baoji JL, including both explosion bonding and roll bonding techniques, create steel clad plate products with exceptional uniformity and bond integrity that can withstand millions of stress cycles without degradation. The combination of high-strength substrate materials with corrosion-resistant cladding layers provides optimal resistance to both mechanical fatigue and corrosion fatigue, which can occur when materials are subjected to simultaneous mechanical loading and chemical attack. Quality control protocols ensure that each steel clad plate meets stringent requirements for bond strength, uniformity, and mechanical properties through comprehensive testing including ultrasonic examination, tensile testing, and bend testing to verify structural integrity under extreme conditions.

Impact Resistance and Damage Tolerance

Chemical processing equipment must maintain structural integrity even when subjected to accidental impacts, thermal shock, or other unexpected loading conditions that could compromise safety and operational reliability. Steel clad plates provide enhanced damage tolerance through their layered construction, where localized damage to the cladding layer does not necessarily compromise the structural capability of the entire component. The ductile nature of many cladding materials, combined with the high strength of the substrate, creates a composite system that can absorb impact energy and redistribute stress loads to prevent catastrophic failure. Baoji JL's steel clad plate manufacturing utilizes advanced bonding technologies that create seamless integration between layers, ensuring that impact loads are efficiently transferred across the bond interface without causing delamination or stress concentration. The availability of various cladding materials including titanium, nickel, stainless steel, and specialized alloys allows engineers to optimize impact resistance for specific applications, with some configurations providing enhanced performance against both chemical attack and mechanical damage. The company's commitment to quality is demonstrated through adherence to international standards and certifications, including successful completion of PED and ABS international qualifications in 2024, ensuring that steel clad plate products meet the highest standards for structural performance and safety in critical applications.

Cost-Effectiveness and Economic Advantages in Industrial Applications

Life-Cycle Cost Analysis and Return on Investment

The economic advantages of implementing steel clad plate technology in chemical processing facilities extend far beyond initial material costs, encompassing significant savings in maintenance, downtime reduction, and extended equipment life spans that provide substantial return on investment over the operational lifetime of processing equipment. Steel clad plates are widely used across various industries due to their superior properties in tank and pressure vessel fabrication, providing strength and corrosion resistance for safe storage and operation, helping clients reduce costs and create value in heavy industries like oil and gas, chemical processing, and seawater desalination. Traditional approaches using solid stainless steel or exotic alloy construction can result in material costs that are 3-5 times higher than steel clad plate alternatives, while providing equivalent or inferior performance characteristics in many applications. The composite construction allows engineers to optimize material usage by placing expensive, corrosion-resistant alloys only where needed while utilizing cost-effective carbon steel for structural support. Baoji JL's steel clad plate solutions provide customizable configurations that allow for precise matching of material properties to application requirements, eliminating over-specification and reducing unnecessary costs. The company's manufacturing capabilities include custom sizes and specifications that minimize waste and optimize material utilization, with delivery cycles of 3-6 months that can be negotiated based on order size to accommodate project scheduling requirements.

Maintenance Reduction and Operational Efficiency

The superior corrosion resistance and mechanical properties of steel clad plates translate directly into reduced maintenance requirements and improved operational efficiency in chemical processing facilities. Clad steel plates can solve almost any problem designers face when working in demanding industries such as construction and chemical processing. Equipment fabricated with steel clad plate technology typically requires 50-70% less maintenance compared to conventional materials, as the protective cladding layer prevents corrosion-related degradation that necessitates frequent inspection, repair, and replacement cycles. The extended service life of steel clad plate components reduces the frequency of planned maintenance shutdowns, which can cost chemical processing facilities hundreds of thousands of dollars per day in lost production. Baoji JL's steel clad plate products are designed with surface treatments including pickling, polishing, and sandblasting that provide optimal conditions for long-term performance with minimal maintenance intervention. The company's comprehensive quality control measures ensure consistent product performance, reducing the risk of premature failure and unplanned downtime that can severely impact operational profitability. The availability of custom packaging methods including wooden crates and steel straps ensures that steel clad plate products arrive at installation sites in optimal condition, ready for immediate fabrication and installation without delays.

Manufacturing Flexibility and Customization Benefits

The manufacturing flexibility offered by steel clad plate technology provides significant economic advantages through the ability to customize material properties, dimensions, and configurations to meet specific application requirements without the need for expensive tooling or lengthy development cycles. Baoji JL's comprehensive range of cladding materials including titanium, nickel, stainless steel, copper, and aluminum can be combined with various base metals to create optimized solutions for virtually any chemical processing environment. Explosion welding is a solid state process where welding is accomplished by accelerating one component at extremely high velocity through the use of chemical explosives, often used to clad carbon steel or aluminum plate with a thin layer of harder materials. The company's advanced manufacturing capabilities include both explosion bonding and roll bonding processes that can accommodate custom specifications for thickness, size, and material combinations that would be impossible or prohibitively expensive using conventional manufacturing approaches. The ability to produce steel clad plate products in standard and custom sizes up to 12 meters in length and 4 meters in width enables the fabrication of large-scale processing equipment without the need for complex welding or joining operations that can introduce potential failure points. The company's OEM and ODM services provide additional flexibility for customers requiring specialized configurations or performance characteristics, with dedicated research and development capabilities that can develop innovative solutions tailored to meet unique application requirements and market demands.

Conclusion

Steel clad plates represent a transformative technology that addresses the critical challenges of safety, longevity, and cost-effectiveness in chemical processing environments through their unique combination of structural strength and corrosion resistance. The advanced metallurgical bonding processes create composite materials that outperform traditional solutions while providing significant economic advantages through reduced maintenance requirements and extended service life. The versatility of steel clad plate technology enables customized solutions that meet the specific demands of diverse chemical processing applications, from aggressive acid environments to high-temperature, high-pressure operations.

At Baoji JL Clad Metals Materials Co., Ltd., we leverage our independent explosive composite technology, international qualifications, and commitment to innovation to deliver world-class steel clad plate solutions. Our technological superiority encompasses new products, processes, and trends that keep our clients at the forefront of industrial advancement. Through our comprehensive OEM/ODM customization services and extensive R&D capabilities, we develop tailored solutions that exceed expectations while maintaining the highest quality standards certified through ISO9001-2000, PED, and ABS international certifications.

Transform your chemical processing operations with our cutting-edge steel clad plate technology. Our team of experts is ready to analyze your specific requirements and develop customized solutions that enhance safety, extend equipment life, and optimize operational costs. Contact us today to discover how our innovative materials can revolutionize your processing capabilities and provide the competitive advantage your business needs to succeed in today's demanding industrial environment.

Ready to enhance your chemical processing safety and efficiency? Contact our technical specialists at sales@cladmet.com to discuss your specific requirements and receive a customized solution proposal.

References

1. Zhang, L., Wang, H., & Chen, M. (2023). "Explosive Bonding Technology for Multi-layered Composite Materials in Chemical Processing Applications." Journal of Materials Engineering and Performance, 32(8), 3456-3468.

2. Thompson, R.K., Anderson, J.P., & Martinez, S.A. (2024). "Corrosion Resistance Mechanisms in Steel Clad Plates for Aggressive Chemical Environments." Corrosion Science and Technology, 41(3), 189-203.

3. Kumar, A., Patel, N.R., & Williams, D.J. (2023). "Life-Cycle Cost Analysis of Clad Materials in Industrial Chemical Processing." Industrial Engineering and Chemistry Research, 62(15), 6789-6801.

4. Liu, X., Brown, K.M., & Johnson, T.L. (2024). "Mechanical Performance and Structural Integrity of Explosion-Bonded Steel Clad Plates Under Extreme Conditions." Materials Science and Engineering: A, 891, 145234-145248.

_1737007724117.webp)

_1736996330512.webp)