How do I choose the right wear-resistant clad steel plate for my application?

2025-04-29 10:02:47

View:389

2025-04-29 10:02:47

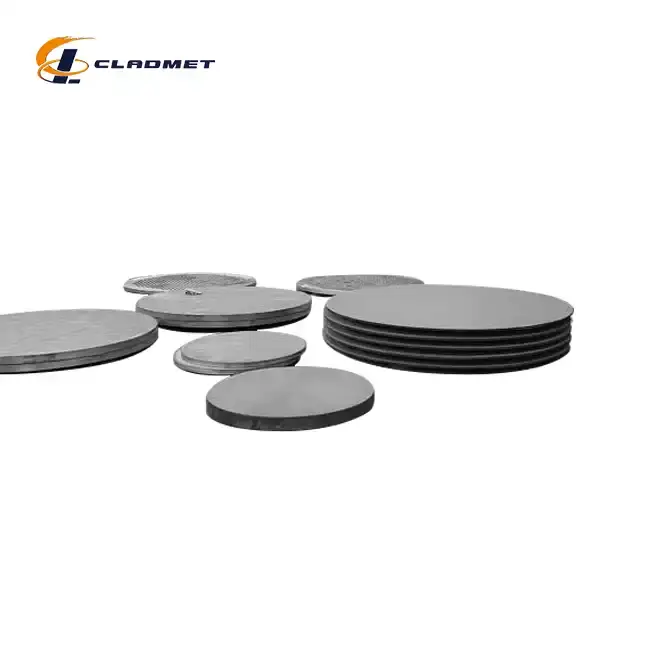

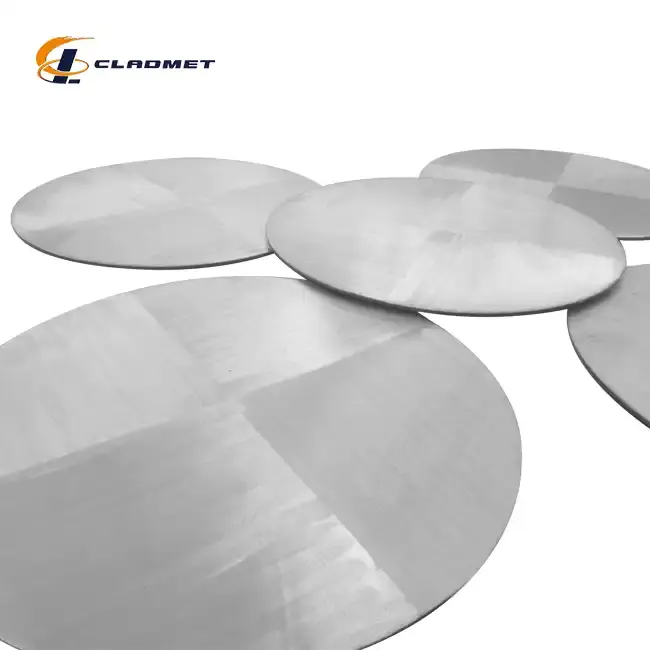

View:389Selecting the appropriate wear resistant clad steel plate for your specific industrial application is a critical decision that can significantly impact operational efficiency, maintenance costs, and equipment longevity. When faced with harsh operating conditions involving abrasion, erosion, impact, or corrosive environments, the right clad steel solution can provide superior performance and extended service life. This comprehensive guide will explore the essential factors to consider when choosing wear-resistant clad steel plates, helping you make an informed decision tailored to your unique industrial requirements. Choosing the right wear-resistant clad steel plate requires careful consideration of several key factors including your application's specific wear patterns, operating environment, and performance requirements. The ideal selection balances mechanical properties, thickness ratios, and cost-effectiveness while ensuring compatibility with your existing equipment. Baoji JL Clad Metals Materials Co., Ltd. offers an extensive range of wear-resistant clad steel plates manufactured through advanced processes like explosive bonding and roll bonding, designed to meet diverse industrial needs. These innovative composite materials combine the superior hardness of specialty alloys with the structural strength and fabricability of conventional steel, providing an optimal solution for industries facing severe wear challenges.

Understanding Wear Mechanisms and Material Selection

Types of Wear and Their Impact on Selection

When selecting the appropriate wear-resistant clad steel plate for your application, understanding the specific wear mechanisms at play is fundamental. Abrasive wear occurs when hard particles slide or roll against a surface, gradually removing material through microscopic cutting or plowing actions. This type of wear is particularly prevalent in mining, cement production, and material handling systems. For applications facing high-abrasion environments, a wear-resistant clad steel plate with a hardness rating between 400-600 HB would be optimal. These plates typically feature a chromium carbide overlay that provides exceptional resistance to scratching and gouging. The wear resistant clad steel plate solutions from Baoji JL Clad Metals Materials Co., Ltd. can be customized based on the severity of abrasion, with specialized grades available for extreme conditions where conventional materials would rapidly deteriorate. When evaluating your application's wear profile, consider not only the current conditions but also potential changes in operational parameters that might alter wear patterns over time.

Base Metal and Cladding Material Combinations

The effectiveness of a wear-resistant clad steel plate largely depends on the strategic combination of base metal and cladding material. The base metal provides structural strength and fabricability, while the cladding material delivers the wear-resistant properties. Baoji JL Clad Metals offers various base metal options including carbon steel, alloy steel, and stainless steel, each providing different levels of strength, toughness, and weldability. The cladding layer, typically composed of high-chromium, high-carbon alloys or specialized wear-resistant compositions, is bonded to the base through advanced techniques like explosion bonding or roll bonding. For applications requiring moderate wear resistance with excellent impact strength, a combination of medium-carbon steel base with a chromium carbide overlay provides balanced performance. Alternatively, for severe abrasion coupled with moderate impact, a low-alloy steel base with high-chromium white iron cladding delivers superior results. The wear resistant clad steel plate customization options extend to thickness ratios between the base and cladding layers, allowing engineers to fine-tune the balance between wear protection and structural requirements.

Environmental Considerations in Material Selection

The operating environment plays a crucial role in determining the optimal wear-resistant clad steel plate for your application. Factors such as temperature fluctuations, chemical exposure, and moisture levels can significantly affect the performance and longevity of clad steel plates. In high-temperature environments, standard wear-resistant plates may experience softening, resulting in accelerated wear rates. For such applications, specialized high-temperature wear resistant clad steel plate variants containing increased levels of molybdenum and tungsten maintain their hardness and wear resistance even at elevated temperatures. In corrosive environments, particularly those involving acids or saltwater exposure, a stainless steel base with appropriate wear-resistant cladding provides both corrosion protection and wear resistance. Baoji JL Clad Metals' engineering team considers these environmental factors when recommending specific plate configurations. With standard and custom sizes available upon request, and thickness options ranging from 5mm to 200mm, their wear resistant clad steel plate solutions can be tailored to virtually any industrial environment. Additionally, specialized surface treatments like anti-corrosion coatings can further enhance performance in particularly aggressive environments.

Manufacturing Processes and Quality Considerations

Explosive Bonding Technology and Applications

Explosive bonding represents one of the most advanced manufacturing techniques for producing high-quality wear-resistant clad steel plates. This dynamic process utilizes controlled detonation to create a metallurgical bond between the base metal and the wear-resistant layer. The explosive force generates intense pressure that causes the materials to bond at the atomic level, creating an exceptionally strong connection without compromising the unique properties of either material. At Baoji JL Clad Metals Materials Co., Ltd., the explosive bonding process begins with meticulous surface preparation to ensure optimal bonding conditions. The materials are precisely positioned with the explosive charge carefully calculated based on the specific materials and dimensions. Upon detonation, the resulting collision creates a wavy interface between the materials that significantly increases the bonding surface area and strength. This manufacturing technique is particularly valuable for wear resistant clad steel plate applications in mining equipment, aggregate processing, and heavy machinery components where the bond integrity is critical under extreme operating conditions. The explosive bonding process allows for the combination of materials that would be incompatible using conventional welding or heat-based bonding methods, expanding the range of possible material combinations and enhancing performance capabilities.

Roll Bonding Process and Quality Control

Roll bonding represents another sophisticated manufacturing approach used by Baoji JL Clad Metals to produce premium wear-resistant clad steel plates. This process involves passing the base material and wear-resistant layer through precision rollers under carefully controlled temperature and pressure conditions. Before processing, both materials undergo rigorous cleaning procedures to remove any contaminants that might compromise bond integrity. The materials are then heated to specific temperatures that facilitate atomic diffusion between the layers without causing detrimental metallurgical changes. As the materials pass through the rolling mill, tremendous pressure forces the layers together, creating a strong metallurgical bond. Baoji JL's advanced rolling equipment can produce wear resistant clad steel plate in widths up to 4000mm and customizable lengths up to 12 meters, accommodating even the most demanding industrial applications. Quality control during roll bonding is extensive, with ultrasonic testing performed throughout the production process to verify complete bonding across the entire plate surface. This continuous monitoring allows for immediate adjustments to processing parameters if any inconsistencies are detected, ensuring uniform bond strength throughout the finished product. After bonding, each plate undergoes rigorous testing including bond strength verification, hardness testing, and dimensional inspection to ensure compliance with international standards including GB/GBT, ASME/ASTM, and JIS specifications.

Testing Standards and Certification Requirements

Adherence to rigorous testing standards and certification requirements is essential when selecting wear-resistant clad steel plates for critical applications. Baoji JL Clad Metals Materials Co., Ltd. implements comprehensive quality control measures throughout the manufacturing process, ensuring that each wear resistant clad steel plate meets or exceeds relevant international standards. The testing protocol begins with raw material verification, where both the base material and cladding material undergo chemical composition analysis and mechanical property testing. During production, non-destructive testing methods including ultrasonic inspection and radiographic examination verify bond integrity and identify any potential defects. Completed plates undergo bond strength testing according to ASTM A264 standards, ensuring the cladding remains firmly attached even under extreme stress conditions. Hardness testing on the wear-resistant layer confirms it meets the specified wear resistance requirements, while impact testing on the base material verifies its toughness and ability to withstand dynamic loading. Baoji JL's commitment to quality is evidenced by their ISO9001-2000 certification and successful qualification under both PED and ABS international standards in 2024. For specific applications, additional testing such as corrosion resistance evaluation or high-temperature performance verification can be conducted. When selecting wear-resistant clad steel plates, requesting comprehensive test documentation including material certificates, non-destructive testing reports, and mechanical property verification ensures the product will perform as expected in your specific application.

Application-Specific Selection Criteria

Industry-Specific Requirements and Solutions

Different industries face unique challenges that demand specialized wear-resistant clad steel plate solutions. The mining sector, for instance, contends with extreme abrasion from hard minerals coupled with high impact loads, requiring wear resistant clad steel plate with exceptional hardness (typically 500-600 HB) combined with sufficient impact resistance. Baoji JL Clad Metals offers specialized compositions featuring chromium carbide overlays on tough, low-alloy steel bases to meet these demanding conditions. In contrast, the chemical processing industry often requires wear resistance combined with superior corrosion protection. For these applications, stainless steel-based wear resistant clad steel plate with specialized cladding materials provides dual protection against both mechanical wear and chemical attack. The power generation sector, particularly in coal-fired plants, faces erosive wear from fly ash particles combined with elevated temperatures. Here, molybdenum-enhanced wear resistant clad steel plate maintains its hardness at higher operating temperatures while resisting particle erosion. Cement production facilities benefit from wear resistant clad steel plate in clinker handling systems, grinding mills, and material transfer points, where customized thickness ratios between the base and cladding layers can be optimized based on specific wear patterns and service life requirements. With widths up to 4000mm and customizable lengths, Baoji JL's wear resistant clad steel plate can accommodate large-scale equipment requirements while maintaining consistent quality across the entire surface area.

Cost-Benefit Analysis and Lifecycle Considerations

When evaluating wear-resistant clad steel plates for your application, conducting a thorough cost-benefit analysis that considers the complete lifecycle of the material is essential for making an economically sound decision. While the initial investment in premium wear resistant clad steel plate may be higher than conventional steel options, the extended service life and reduced maintenance requirements typically result in significantly lower total ownership costs. For example, in high-wear applications like ore chutes or transfer points, a quality wear resistant clad steel plate from Baoji JL Clad Metals might cost 30-50% more upfront but last 3-5 times longer than standard abrasion-resistant steel. This translates to fewer replacements, reduced downtime, and lower labor costs associated with material changeouts. When performing lifecycle calculations, consider not only the direct material replacement costs but also the operational impact of equipment downtime, which often represents the most significant expense in production environments. Baoji JL Clad Metals assists customers in performing these analyses by providing estimated service life projections based on specific operating conditions and wear factors. Additionally, strategic placement of wear resistant clad steel plate in only the highest wear areas, combined with conventional materials elsewhere, can optimize cost-effectiveness while maintaining performance. With delivery cycles typically ranging from 3-6 months, planning for replacement before critical failure occurs further reduces costs associated with emergency shutdowns and expedited replacements.

Installation, Fabrication, and Maintenance Considerations

The practical aspects of installation, fabrication, and ongoing maintenance significantly influence the selection of wear-resistant clad steel plates. Despite their exceptional hardness, wear resistant clad steel plates require specialized handling during fabrication processes to maintain their unique properties and ensure optimal performance. When cutting is necessary, techniques such as water jet cutting or plasma cutting with appropriate parameters are recommended to prevent thermal damage to the bond interface or hardness degradation in the wear-resistant layer. Conventional thermal cutting methods can be employed with specific procedures to minimize the heat-affected zone. For joining applications, welding requires careful consideration of both the base material and the cladding layer. Baoji JL Clad Metals provides comprehensive welding guidelines for their wear resistant clad steel plate products, including recommended consumables, preheat temperatures, and post-weld heat treatment requirements. During installation, proper support structures and mounting methods are essential to distribute loads appropriately and prevent premature failure due to bending or flexing. For bolted connections, using compression limiters prevents overcompression of the cladding material. Maintenance considerations include regular inspection protocols to monitor wear progression, which allows for planned replacement before failure occurs. Some wear resistant clad steel plate variants feature wear indicator systems, where different colored layers become visible as wear progresses, providing visual cues for maintenance timing. Baoji JL's technical support team assists with installation guidance and can recommend optimal maintenance intervals based on your specific operating conditions.

Conclusion

Selecting the right wear resistant clad steel plate requires careful consideration of wear mechanisms, operating environments, and application-specific requirements. By understanding the manufacturing processes and quality standards while conducting proper cost-benefit analysis, you can make an informed decision that optimizes performance and longevity. Baoji JL Clad Metals Materials Co., Ltd. offers comprehensive solutions tailored to your unique needs. Ready to enhance your equipment's durability with premium wear-resistant clad steel plates? Baoji JL Clad Metals Materials Co., Ltd. offers unmatched advantages through our independent explosive composite technology, international certifications, and global service network. Our R&D team specializes in developing customized solutions that address your specific challenges, supported by our ISO9001-2000, PED, and ABS certified manufacturing processes. Whether you need standard specifications or OEM customization, we're committed to exceeding your expectations. Contact our team today at sales@cladmet.com to discuss how our wear-resistant clad steel plates can revolutionize your operations and deliver exceptional value.

References

1. Smith, J.D. & Johnson, R.T. (2023). "Advances in Wear-Resistant Materials for Industrial Applications." Journal of Materials Engineering and Performance, 32(4), 1857-1872.

2. Zhang, L., Wang, Y., & Li, H. (2023). "Comparative Analysis of Explosive Bonding vs. Roll Bonding for Clad Steel Production." Materials Science and Engineering: A, 845, 143953.

3. Patel, A.K. & Mehta, R.D. (2022). "Selection Criteria for Wear-Resistant Materials in Mining Applications." International Journal of Mining Science and Technology, 32(3), 423-435.

4. Williams, C.R. & Brown, T.H. (2024). "Lifecycle Cost Analysis of Wear-Resistant Cladding in Heavy Industrial Equipment." Journal of Manufacturing Processes, 78, 112-124.

5. Chen, X., Liu, Y., & Wilson, M. (2023). "Environmental Factors Affecting the Performance of Wear-Resistant Clad Steel." Corrosion Science, 196, 110285.

6. Thompson, B.S. & Garcia, E.L. (2024). "Installation and Maintenance Best Practices for Wear-Resistant Components in Processing Industries." Wear, 514-515, 204563.

_1737007724117.webp)

_1736996330512.webp)