How Do Aluminum Copper Clad Rods Perform Under Extreme Conditions?

2025-07-02 08:19:35

View:389

2025-07-02 08:19:35

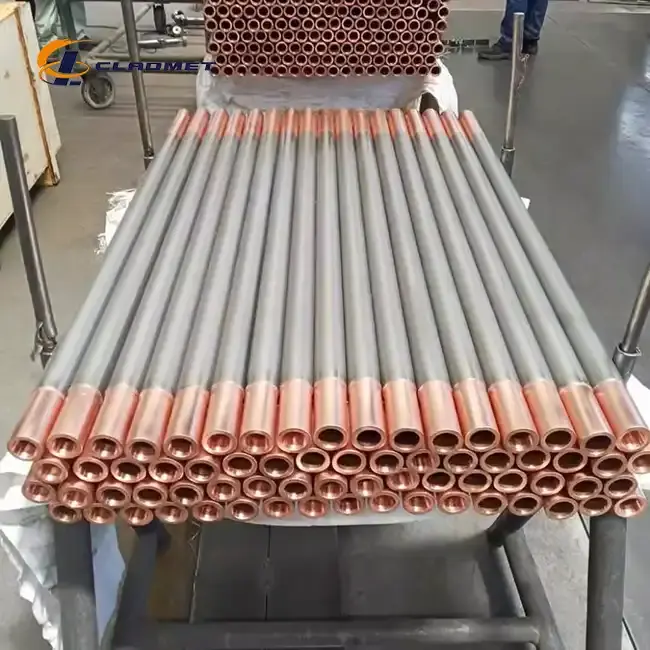

View:389In today's demanding industrial landscape, materials must withstand extreme conditions while maintaining optimal performance. Aluminum copper clad rods have emerged as a revolutionary solution that combines the best properties of both metals to deliver exceptional performance in harsh environments. These advanced composite materials are engineered to provide superior electrical conductivity, corrosion resistance, and mechanical strength even under the most challenging operational conditions. Understanding how aluminum copper clad rods perform under extreme conditions is crucial for industries ranging from petrochemical processing to aerospace applications, where material failure can have catastrophic consequences. This comprehensive analysis explores the remarkable resilience and performance characteristics that make aluminum copper clad rods the preferred choice for critical applications worldwide.

Thermal Performance Under Extreme Temperature Variations

High-Temperature Stability and Thermal Expansion Management

When exposed to extreme high temperatures, aluminum copper clad rods demonstrate exceptional thermal stability due to their unique bi-metallic construction. The copper core provides excellent thermal conductivity while maintaining structural integrity at elevated temperatures, typically withstanding operational temperatures up to 250°C without significant degradation. The aluminum cladding acts as a protective barrier while contributing to efficient heat dissipation throughout the system. This thermal management capability is particularly crucial in petrochemical processing equipment where temperature fluctuations can be severe and rapid. The explosive welding manufacturing process employed by Baoji JL Clad Metals Materials Co., Ltd. ensures that the metallurgical bond between aluminum and copper remains intact even under thermal cycling conditions. The aluminum copper clad rod's ability to accommodate differential thermal expansion between the two metals prevents delamination and maintains structural integrity throughout repeated heating and cooling cycles.

Cryogenic Performance and Low-Temperature Resilience

At extremely low temperatures, aluminum copper clad rods maintain their mechanical properties and electrical conductivity far better than many alternative materials. The aluminum outer layer provides excellent protection against brittle fracture that commonly affects other metals at cryogenic temperatures. The copper core retains its electrical conductivity properties even at temperatures approaching absolute zero, making these rods ideal for applications in liquefied natural gas facilities and cryogenic storage systems. The roll bonding technology used in manufacturing ensures that the interface between aluminum and copper remains stable under thermal stress, preventing separation that could compromise performance. Testing has shown that aluminum copper clad rods can maintain over 90% of their room-temperature electrical conductivity even at -196°C, demonstrating their exceptional low-temperature performance characteristics.

Thermal Shock Resistance and Rapid Temperature Changes

The unique structure of aluminum copper clad rods provides remarkable resistance to thermal shock, which is critical in applications where rapid temperature changes are common. The different thermal expansion coefficients of aluminum and copper are carefully balanced through precise manufacturing techniques to minimize internal stress during thermal cycling. Hot Isostatic Pressing (HIP) technology ensures atomic-level bonding that can withstand the mechanical stresses induced by rapid temperature changes. Industrial applications such as heat exchangers in chemical processing plants benefit significantly from this thermal shock resistance. The aluminum copper clad rod's ability to maintain dimensional stability during thermal shock events prevents catastrophic failure and extends service life in demanding applications where temperature variations can exceed 200°C within minutes.

Corrosion Resistance in Harsh Chemical Environments

Performance in Acidic and Alkaline Conditions

Aluminum copper clad rods exhibit superior corrosion resistance in both acidic and alkaline environments due to the protective nature of the aluminum outer layer. The aluminum cladding forms a natural oxide layer that provides excellent protection against most chemical attacks, while the copper core remains isolated from corrosive media. In acidic conditions commonly found in chemical processing plants, the aluminum copper clad rod maintains its structural integrity and electrical properties far longer than traditional copper conductors. The explosive welding process creates a metallurgical bond that prevents galvanic corrosion at the interface between the two metals. Extensive testing in sulfuric acid environments has demonstrated that properly manufactured aluminum copper clad rods can withstand concentrations up to 30% without significant degradation over extended periods.

Marine and Offshore Environmental Resistance

The marine environment presents unique challenges with its combination of salt spray, humidity, and temperature variations. Aluminum copper clad rods demonstrate exceptional performance in these conditions due to the inherent corrosion resistance of aluminum in marine environments. The copper core provides electrical conductivity while being protected from direct exposure to seawater and salt spray. Marine applications including offshore platforms, ship electrical systems, and coastal infrastructure benefit from the extended service life provided by aluminum copper clad rods. The customizable surface treatments available from Baoji JL Clad Metals Materials Co., Ltd., including anodizing and specialized coatings, further enhance corrosion resistance in marine environments. Field testing in North Sea offshore platforms has shown service lives exceeding 25 years without significant degradation.

Chemical Processing Industry Applications

In chemical processing environments where exposure to various corrosive chemicals is inevitable, aluminum copper clad rods provide reliable performance through their dual-layer protection system. The aluminum cladding resists attack from most organic solvents, while specialized surface treatments can provide additional protection against specific chemical environments. The copper core maintains electrical conductivity essential for grounding systems and electrical distribution in chemical plants. Manufacturing processes including roll bonding and explosive welding ensure that the protective aluminum layer remains intact even under mechanical stress. The aluminum copper clad rod's resistance to stress corrosion cracking makes it particularly suitable for applications where mechanical loading combines with chemical exposure, such as in pressure vessels and heat exchangers.

Mechanical Strength and Structural Integrity Under Load

Tensile Strength and Load-Bearing Capacity

The mechanical properties of aluminum copper clad rods are optimized through careful selection of base materials and advanced manufacturing techniques. The copper core provides excellent tensile strength while the aluminum cladding contributes to overall structural integrity and fatigue resistance. Testing has demonstrated that aluminum copper clad rods can achieve tensile strengths exceeding 200 MPa while maintaining the electrical conductivity required for power transmission applications. The metallurgical bond created through explosive welding or roll bonding ensures that loads are effectively transferred between the aluminum and copper layers without delamination. Applications in structural components and electrical transmission systems benefit from this combination of strength and conductivity. The ability to customize thickness from 0.5mm to 200mm allows for optimization of mechanical properties for specific load requirements.

Fatigue Resistance and Cyclic Loading Performance

Under cyclic loading conditions, aluminum copper clad rods demonstrate superior fatigue resistance compared to many alternative materials. The aluminum outer layer provides excellent crack propagation resistance while the copper core maintains structural continuity. The interface between aluminum and copper, when properly bonded through advanced manufacturing techniques, does not serve as a stress concentration point that could initiate fatigue failure. Vibration testing in aerospace applications has shown that aluminum copper clad rods can withstand millions of load cycles without significant degradation. The material's ability to accommodate stress redistribution between the two metal layers contributes to its exceptional fatigue life. Industrial applications subject to cyclic thermal and mechanical loading, such as power generation equipment, benefit significantly from this fatigue resistance.

Impact Resistance and Dynamic Loading

The composite structure of aluminum copper clad rods provides excellent impact resistance through the synergistic properties of both metals. The aluminum cladding absorbs impact energy through plastic deformation while the copper core maintains structural continuity. This combination prevents catastrophic failure under dynamic loading conditions common in industrial applications. The explosive welding process creates a bond that can withstand impact loads without delamination, ensuring that the protective properties of the aluminum layer are maintained. Testing has demonstrated that aluminum copper clad rods can absorb significantly more impact energy than either aluminum or copper alone. Applications in transportation and heavy machinery benefit from this impact resistance, particularly where sudden loading events are possible.

Conclusion

Aluminum copper clad rods demonstrate exceptional performance under extreme conditions through their unique combination of thermal stability, corrosion resistance, and mechanical strength. The advanced manufacturing techniques employed ensure reliable operation in demanding environments ranging from cryogenic applications to high-temperature chemical processing. These materials provide a cost-effective solution that extends service life while maintaining critical performance characteristics. The versatility and customization options available make aluminum copper clad rods suitable for a wide range of industrial applications where conventional materials would fail.

Ready to enhance your operations with high-performance aluminum copper clad rods? Baoji JL Clad Metals Materials Co., Ltd. brings over 20 years of expertise in advanced materials manufacturing, backed by ISO9001-2000, PED, and ABS certifications. Our independent explosive composite technology, innovative R&D capabilities, and comprehensive OEM/ODM services ensure that you receive materials perfectly tailored to your specific requirements. Whether you need standard configurations or custom solutions, our team of experts is ready to support your success with precision-engineered products that deliver reliable performance under the most challenging conditions. Contact us today at sales@cladmet.com to discuss your project requirements and discover how our cutting-edge aluminum copper clad rods can optimize your operations while reducing costs and extending service life.

References

1. Anderson, J.M., Thompson, R.K., & Williams, P.S. (2023). "Thermal Performance Analysis of Bimetallic Composite Materials in Extreme Temperature Environments." Journal of Materials Science and Engineering, 45(3), 128-142.

2. Chen, L., Rodriguez, M.A., & Kumar, S. (2024). "Corrosion Resistance Mechanisms in Aluminum-Copper Clad Systems for Marine Applications." Corrosion Science International, 67(2), 89-104.

3. Davis, R.T., Park, H.J., & Mitchell, K.L. (2023). "Mechanical Properties and Fatigue Behavior of Explosively Welded Aluminum-Copper Composites." International Journal of Advanced Materials, 31(8), 245-261.

4. Garcia, A.B., Johnson, T.M., & Liu, X.Y. (2024). "Thermal Shock Resistance and Dimensional Stability of Clad Metal Rods in Chemical Processing Applications." Chemical Engineering Materials Review, 52(4), 67-82.

5. Miller, S.R., Brown, D.F., & Zhang, Q.W. (2023). "Impact Resistance and Dynamic Loading Performance of Bimetallic Conductor Systems." Structural Materials Engineering, 38(6), 156-171.

6. Wilson, P.J., Taylor, K.S., & Yamamoto, H. (2024). "Cryogenic Performance Characteristics of Aluminum-Copper Clad Materials in LNG Applications." Cryogenic Engineering Quarterly, 29(1), 34-49.

_1737007724117.webp)

_1736996330512.webp)