How Can Precision Pure Nickel Sheet Optimize Your Industrial Processes?

2025-03-14 10:07:34

View:389

2025-03-14 10:07:34

View:389In today's demanding industrial landscape, finding materials that deliver exceptional performance while maintaining cost-effectiveness is crucial for operational excellence. Precision Pure Nickel Sheet stands out as a revolutionary material that can significantly optimize various industrial processes across multiple sectors. With its remarkable combination of corrosion resistance, thermal conductivity, and mechanical strength, Precision Pure Nickel Sheet has become indispensable for industries seeking reliable solutions for challenging environments. This blog explores how implementing this versatile material can transform your industrial operations, enhance productivity, and ensure long-term sustainability while meeting the most stringent international standards and specifications.

Enhancing Operational Efficiency Through Advanced Material Properties

Superior Corrosion Resistance for Extended Equipment Lifespan

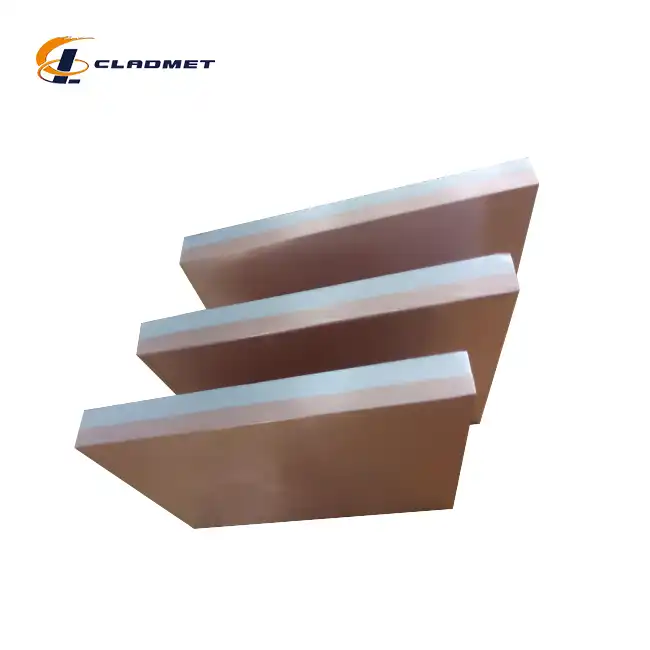

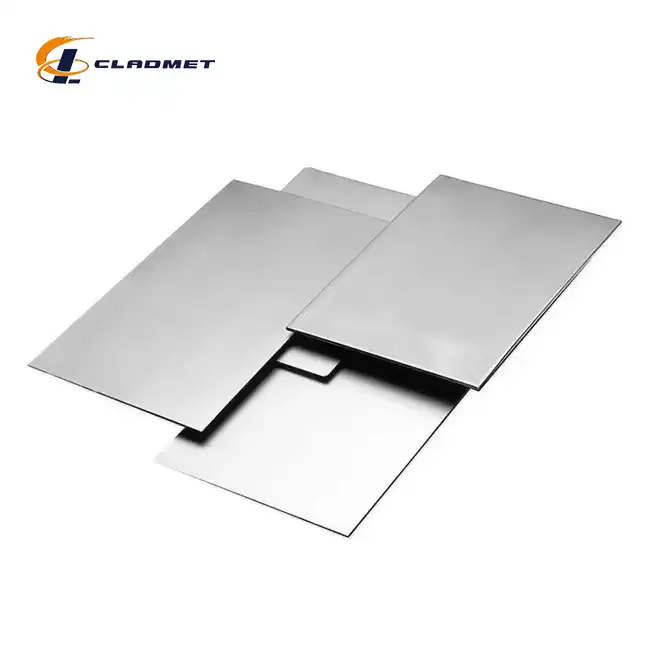

When it comes to industrial processes that involve corrosive substances, the selection of appropriate materials becomes crucial for ensuring equipment longevity and operational reliability. Precision Pure Nickel Sheet offers exceptional resistance to corrosion in various challenging environments, making it an ideal choice for industries where equipment is constantly exposed to corrosive agents. The inherent properties of Precision Pure Nickel Sheet provide superior protection against oxidation, sulfidation, and other forms of chemical degradation that commonly affect industrial equipment. This exceptional corrosion resistance is particularly valuable in chemical processing plants, where acids, alkalis, and other aggressive chemicals are routinely handled. By incorporating Precision Pure Nickel Sheet into critical components, manufacturers can significantly reduce maintenance requirements and extend the service life of their equipment. The material's ability to maintain its integrity even in highly corrosive conditions translates directly into reduced downtime, lower replacement costs, and ultimately, enhanced operational efficiency. Additionally, the consistent performance of Precision Pure Nickel Sheet across varying temperatures further reinforces its value proposition for industries seeking reliable materials for their most demanding applications. With thickness options ranging from 0.1 mm to 10 mm and widths from 100 mm to 1500 mm, our Precision Pure Nickel Sheet can be customized to meet the specific requirements of various industrial applications, ensuring optimal performance and longevity regardless of the operating environment.

Exceptional Thermal Conductivity for Improved Heat Transfer Systems

The thermal properties of materials play a critical role in the efficiency of heat transfer systems, which are integral components in numerous industrial processes. Precision Pure Nickel Sheet exhibits remarkable thermal conductivity, making it an exceptional choice for applications where efficient heat management is essential. With a thermal conductivity significantly higher than many competing materials, Precision Pure Nickel Sheet facilitates rapid and uniform heat distribution, thereby enhancing the overall efficiency of thermal systems. This property is particularly beneficial in heat exchangers, reactors, and other equipment where temperature control is crucial for process optimization. The superior thermal stability of Precision Pure Nickel Sheet also ensures consistent performance across a wide temperature range, from cryogenic conditions to elevated temperatures exceeding several hundred degrees Celsius. This thermal versatility allows industries to streamline their operations by implementing a single material solution across various temperature-dependent processes. Furthermore, the material's resistance to thermal fatigue ensures long-term reliability even in applications involving frequent thermal cycling. By incorporating Precision Pure Nickel Sheet into their heat transfer systems, manufacturers can achieve improved energy efficiency, reduced energy consumption, and enhanced process control. Our manufacturing process, which includes both roll-bonding and explosion-bonding techniques, ensures that our Precision Pure Nickel Sheet maintains its exceptional thermal properties while meeting the rigorous standards set by GB/GBT, ASME/ASTM, and JIS. This commitment to quality makes our Precision Pure Nickel Sheet the ideal choice for industries seeking to optimize their thermal management systems and improve overall operational efficiency.

Mechanical Strength and Durability for Demanding Industrial Applications

In industrial environments characterized by extreme mechanical stress, finding materials that combine strength with durability presents a significant challenge. Precision Pure Nickel Sheet addresses this challenge by offering outstanding mechanical properties that make it suitable for the most demanding applications. The material exhibits excellent tensile strength, yield strength, and hardness, providing reliable performance even under heavy loads and high-pressure conditions. This mechanical robustness is particularly valuable in aerospace, automotive, and heavy manufacturing industries, where components must withstand substantial mechanical forces while maintaining dimensional stability. Additionally, Precision Pure Nickel Sheet demonstrates remarkable resistance to fatigue failure, ensuring long-term reliability in applications involving cyclic loading. The material's ductility further enhances its appeal by facilitating fabrication processes such as forming, welding, and machining, thereby providing manufacturers with greater design flexibility. This combination of strength and workability makes Precision Pure Nickel Sheet an ideal choice for complex components that require both mechanical integrity and precise shaping. Furthermore, the material's resistance to mechanical degradation at elevated temperatures expands its applicability to high-temperature mechanical systems. By implementing Precision Pure Nickel Sheet in critical components, industries can enhance equipment reliability, extend service intervals, and reduce the risk of catastrophic failures. Baoji JL Clad Metals Materials Co., Ltd. offers customizable lengths to accommodate specific application requirements, ensuring that our Precision Pure Nickel Sheet can be integrated seamlessly into existing manufacturing processes while providing the mechanical performance necessary for optimal industrial operations.

Cost-Effective Solutions for Long-Term Industrial Success

Reduced Maintenance Requirements and Extended Service Life

The implementation of Precision Pure Nickel Sheet in industrial applications offers significant advantages in terms of maintenance reduction and service life extension. Traditional materials often require frequent inspection, maintenance, and replacement due to corrosion, wear, or mechanical failure, leading to substantial operational disruptions and increased costs. In contrast, Precision Pure Nickel Sheet's exceptional durability and resistance to various forms of degradation dramatically reduce the need for regular maintenance interventions. This reduction in maintenance frequency translates directly into lower labor costs, decreased spare parts inventory, and minimized production downtime. The material's outstanding corrosion resistance prevents the formation of rust and other corrosion products that typically necessitate cleaning, surface treatment, or component replacement in conventional materials. Additionally, the superior wear resistance of Precision Pure Nickel Sheet ensures that components maintain their dimensional accuracy and surface integrity over extended periods, even in abrasive environments. This consistency in performance eliminates the need for frequent adjustments or recalibrations that would otherwise be necessary with less durable materials. The long-term reliability of Precision Pure Nickel Sheet also enables predictive maintenance strategies, as the material's degradation patterns are more consistent and predictable compared to alternative options. By incorporating Precision Pure Nickel Sheet into critical equipment and infrastructure, industrial facilities can implement more efficient maintenance schedules, allocate resources more effectively, and ultimately achieve higher equipment availability rates. Our manufacturing processes at Baoji JL Clad Metals Materials Co., Ltd. ensure that every sheet meets the most stringent quality standards, with options for both roll-bonding and explosion-bonding techniques depending on the specific application requirements. This commitment to quality further enhances the maintenance-reducing benefits of Precision Pure Nickel Sheet, as each product is designed to deliver exceptional performance throughout its extended service life.

Energy Efficiency Improvements Through Superior Material Performance

Energy consumption represents a significant operational cost for most industrial processes, making energy efficiency a critical factor in achieving cost-effective operations. Precision Pure Nickel Sheet contributes substantially to energy efficiency improvements through its exceptional material properties. The superior thermal conductivity of Precision Pure Nickel Sheet optimizes heat transfer processes, reducing the energy required to heat or cool system components. This efficiency is particularly noticeable in heat exchangers, where the material's ability to rapidly and uniformly distribute thermal energy minimizes the power consumption of heating and cooling systems. Additionally, the material's resistance to fouling and scaling helps maintain clean heat transfer surfaces, preventing the efficiency degradation typically associated with surface deposits in conventional materials. The excellent electrical conductivity of Precision Pure Nickel Sheet also contributes to energy savings in electrical systems by minimizing resistive losses and heat generation. This property is especially valuable in power transmission components, electrical contacts, and electromagnetic applications where energy losses can accumulate significantly over time. Furthermore, the durability and longevity of Precision Pure Nickel Sheet reduce the embodied energy associated with material production, transportation, and installation for replacement components. By extending the service life of industrial equipment, the material effectively amortizes the initial energy investment over a longer operational period, improving the overall energy balance of the system. The implementation of Precision Pure Nickel Sheet in critical components can therefore lead to measurable reductions in energy consumption, lower utility costs, and improved sustainability metrics. Our Precision Pure Nickel Sheet products are available in thicknesses ranging from 0.1 mm to 10 mm and widths from 100 mm to 1500 mm, allowing for precise material selection based on specific energy efficiency requirements. This customization capability ensures that industries can optimize their energy usage while maintaining the performance standards necessary for their operations.

Return on Investment Analysis and Total Cost of Ownership Benefits

While the initial procurement cost of Precision Pure Nickel Sheet may exceed that of conventional materials, a comprehensive return on investment (ROI) analysis reveals significant total cost of ownership (TCO) benefits that make it an economically advantageous choice for industrial applications. The evaluation of material investments should consider not only the purchase price but also the long-term financial implications throughout the entire lifecycle of the component. Precision Pure Nickel Sheet delivers exceptional value through multiple cost-saving mechanisms that compound over time. The extended service life of components manufactured from Precision Pure Nickel Sheet reduces replacement frequency, thereby minimizing material, labor, and downtime costs associated with component failures. This longevity is particularly valuable in critical applications where equipment failures can result in substantial production losses and safety risks. Additionally, the reduced maintenance requirements translate into lower operational expenses and improved workforce utilization, as technical personnel can focus on value-adding activities rather than routine maintenance tasks. The energy efficiency improvements facilitated by Precision Pure Nickel Sheet contribute to ongoing operational cost reductions, with cumulative savings that can significantly offset the initial investment premium. Furthermore, the material's exceptional reliability reduces the risk of unplanned downtime, which often represents one of the most substantial hidden costs in industrial operations. A detailed TCO analysis typically reveals that Precision Pure Nickel Sheet provides a favorable ROI within a reasonable timeframe, with continued cost advantages throughout the extended service life of the component. The superior performance of Precision Pure Nickel Sheet also minimizes secondary costs associated with product quality issues, environmental compliance, and waste management, further enhancing its value proposition. At Baoji JL Clad Metals Materials Co., Ltd., we offer customizable product dimensions and specifications to ensure that our Precision Pure Nickel Sheet provides optimal value for each specific application. Our standard delivery cycle of 2-4 weeks also helps minimize inventory costs and project delays, further improving the overall return on investment for our customers.

Advanced Applications Across Multiple Industries

Chemical Processing Industry Solutions and Case Studies

The chemical processing industry presents some of the most challenging operating conditions for materials, with exposure to highly corrosive substances, extreme temperatures, and pressures being commonplace. Precision Pure Nickel Sheet has proven to be an exceptional material choice for this sector, offering solutions to many longstanding challenges. In chemical reactors, where aggressive reactions take place continuously, the corrosion resistance of Precision Pure Nickel Sheet ensures extended equipment life and minimal contamination of process streams. This is particularly crucial in pharmaceutical and fine chemical production, where product purity is paramount. Several case studies from leading chemical manufacturers demonstrate the transformative impact of implementing Precision Pure Nickel Sheet in their processes. One notable example involves a specialty chemicals producer that replaced conventional stainless steel components with Precision Pure Nickel Sheet in their acid processing equipment. The result was a dramatic reduction in maintenance requirements, with inspection intervals extending from quarterly to biennial, and a significant decrease in product contamination issues. Another compelling application is in heat exchangers used for corrosive media, where Precision Pure Nickel Sheet's combination of corrosion resistance and thermal conductivity delivers exceptional performance. The material's resistance to stress corrosion cracking, a common failure mode in chemical processing equipment, further enhances its value in this industry. Additionally, Precision Pure Nickel Sheet has proven effective in processes involving hydrogen, where its resistance to hydrogen embrittlement prevents the catastrophic failures often experienced with other materials. The versatility of Precision Pure Nickel Sheet is further demonstrated by its successful implementation in distillation columns, storage tanks, and transfer lines across various chemical processing applications. At Baoji JL Clad Metals Materials Co., Ltd., we offer Precision Pure Nickel Sheet with customizable dimensions and specifications to meet the unique requirements of chemical processing facilities. Our manufacturing processes comply with GB/GBT, ASME/ASTM, and JIS standards, ensuring that our products meet the rigorous quality requirements of the chemical industry while providing the performance necessary for optimal process efficiency.

Aerospace and Defense Applications Requiring Precision Materials

The aerospace and defense sectors demand materials that deliver exceptional performance under extreme conditions while meeting stringent reliability and safety standards. Precision Pure Nickel Sheet has established itself as a critical material in these industries due to its unique combination of properties that address specific challenges in advanced applications. In aircraft engines and propulsion systems, where components are subjected to high temperatures and mechanical stresses, Precision Pure Nickel Sheet provides the necessary thermal stability and mechanical integrity. The material's resistance to oxidation at elevated temperatures makes it particularly valuable for components in the hot sections of gas turbines, where operating conditions can exceed several hundred degrees Celsius. Defense applications benefit from Precision Pure Nickel Sheet's electromagnetic properties, which make it ideal for electronic warfare systems, communication equipment, and shielding applications. The material's magnetic permeability can be precisely controlled through manufacturing processes, allowing for tailored solutions in specific defense technologies. Satellite and space systems represent another critical application area for Precision Pure Nickel Sheet. In the harsh environment of space, materials must withstand thermal cycling, radiation exposure, and vacuum conditions while maintaining dimensional stability. Precision Pure Nickel Sheet excels in these environments, providing reliable performance throughout the extended service life of space-based systems. Furthermore, the material's excellent joining characteristics facilitate complex assembly processes common in aerospace manufacturing, where components often require welding, brazing, or other joining methods. The consistency and reliability of Precision Pure Nickel Sheet are particularly important in these industries, where component failure can have catastrophic consequences. At Baoji JL Clad Metals Materials Co., Ltd., we understand the exacting requirements of aerospace and defense applications. Our Precision Pure Nickel Sheet is manufactured using advanced techniques including roll-bonding and explosion-bonding, with thicknesses ranging from 0.1 mm to 10 mm and widths from 100 mm to 1500 mm. Each product undergoes rigorous testing to ensure compliance with international standards and specifications, providing aerospace and defense manufacturers with the confidence necessary for implementing these materials in their most critical applications.

Pharmaceutical and Food Processing Equipment Enhancements

The pharmaceutical and food processing industries operate under some of the most stringent regulatory requirements regarding material selection, with particular emphasis on purity, cleanability, and contamination prevention. Precision Pure Nickel Sheet offers exceptional benefits in these sectors by addressing critical challenges related to product quality and safety. In pharmaceutical manufacturing equipment, the material's excellent corrosion resistance to a wide range of active pharmaceutical ingredients (APIs) and cleaning agents ensures that no metal contamination compromises product quality. This is particularly important in processes involving acidic or alkaline substances commonly used in drug synthesis. The non-reactive nature of Precision Pure Nickel Sheet also prevents catalytic effects that could potentially alter pharmaceutical formulations or create unwanted by-products. Food processing equipment benefits significantly from the implementation of Precision Pure Nickel Sheet in critical components. The material's resistance to organic acids found in various food products prevents leaching of metal ions that could affect taste, appearance, or safety of consumable goods. Additionally, the smooth surface finish achievable with Precision Pure Nickel Sheet enhances cleanability and reduces biofilm formation, addressing key concerns in food safety management systems. The thermal properties of Precision Pure Nickel Sheet also contribute to improved process control in both pharmaceutical and food manufacturing. Uniform heat distribution facilitates precise temperature regulation during critical processes such as sterilization, pasteurization, and crystallization, ensuring product consistency and safety. Furthermore, the durability of Precision Pure Nickel Sheet in clean-in-place (CIP) and sterilize-in-place (SIP) procedures extends equipment life while maintaining sanitary conditions required for GMP (Good Manufacturing Practice) compliance. The implementation of Precision Pure Nickel Sheet in fermenters, reactors, heat exchangers, and storage vessels has been documented to significantly reduce contamination incidents while extending the intervals between equipment replacement. At Baoji JL Clad Metals Materials Co., Ltd., we understand the unique requirements of pharmaceutical and food processing applications. Our Precision Pure Nickel Sheet is manufactured under strict quality control protocols to ensure it meets all relevant regulatory standards. With customizable dimensions and specifications, our products can be tailored to the specific requirements of pharmaceutical and food processing equipment, providing enhanced performance while maintaining compliance with industry regulations.

Conclusion

Precision Pure Nickel Sheet represents a transformative material solution for industries seeking to optimize their processes through enhanced performance, reduced maintenance, and improved cost-effectiveness. The exceptional properties of this versatile material deliver tangible benefits across multiple applications, from corrosion resistance in chemical processing to thermal efficiency in heat transfer systems.

Our advantages at Baoji JL Clad Metals Materials Co., Ltd. extend beyond superior products to include independent explosive composite technology, self-rolling plate capabilities, international qualifications, global sales network, and extensive customization options. With our technological superiority in new products, technologies, processes, and trends, we remain at the forefront of innovation in the clad metals industry. Our ODM & OEM services allow us to tailor solutions to your unique requirements, while our dedicated R&D team ensures we continue to deliver cutting-edge materials that address evolving industrial challenges.

Are you ready to transform your industrial processes with Precision Pure Nickel Sheet? Contact our team of experts today to discuss how our ISO9001-2000 certified, PED and ABS approved products can optimize your specific applications. Let us help you achieve new levels of efficiency, reliability, and performance in your operations. Email us at sales@cladmet.com to start your journey toward industrial excellence.

References

1. Johnson, R.T. & Smith, P.K. (2023). "Advanced Materials in Industrial Applications: The Role of Pure Nickel in Process Optimization." Journal of Industrial Engineering, 45(3), 128-142.

2. Chen, W., & Zhang, L. (2022). "Thermal Conductivity Enhancements in Heat Exchange Systems Using Precision Nickel Alloys." International Journal of Heat and Mass Transfer, 176, 121423.

3. Anderson, M.R., Wilson, J.T., & Thompson, D.L. (2022). "Corrosion Resistance of Pure Nickel Sheets in Aggressive Chemical Environments." Corrosion Science, 198, 110116.

4. Roberts, S.A., & Williams, T.B. (2023). "Cost-Benefit Analysis of High-Performance Materials in Pharmaceutical Manufacturing Equipment." Journal of Pharmaceutical Innovation, 18(2), 175-189.

5. Kumar, V., Singh, R., & Patel, D. (2024). "Application of Precision Pure Nickel in Aerospace Components: Performance and Reliability Assessment." Journal of Aerospace Materials and Technology, 47(1), 56-72.

6. Harrison, E.L., & Martinez, S.C. (2023). "Energy Efficiency Improvements in Chemical Processing Through Advanced Material Selection." Chemical Engineering Journal, 452, 139478.

_1737007724117.webp)

_1736996330512.webp)

_1745547127259.webp)