Find the Best Suppliers of Titanium Clad Copper Plates

2025-06-05 08:27:09

View:389

2025-06-05 08:27:09

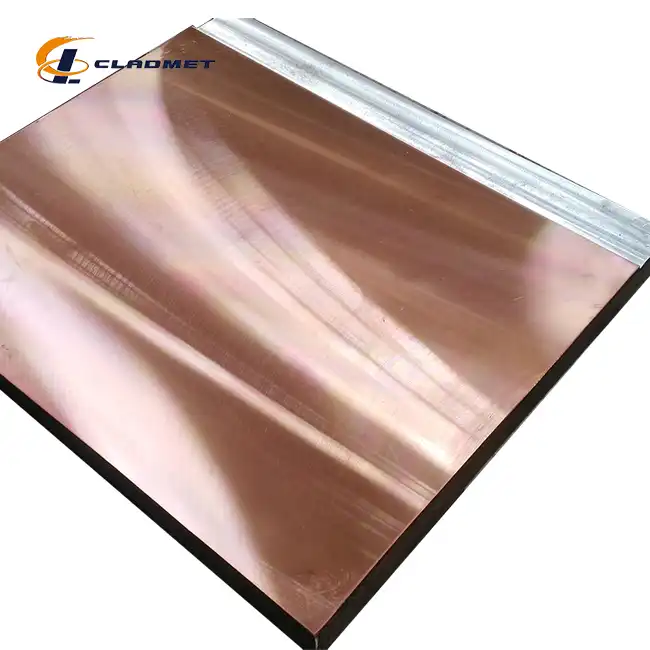

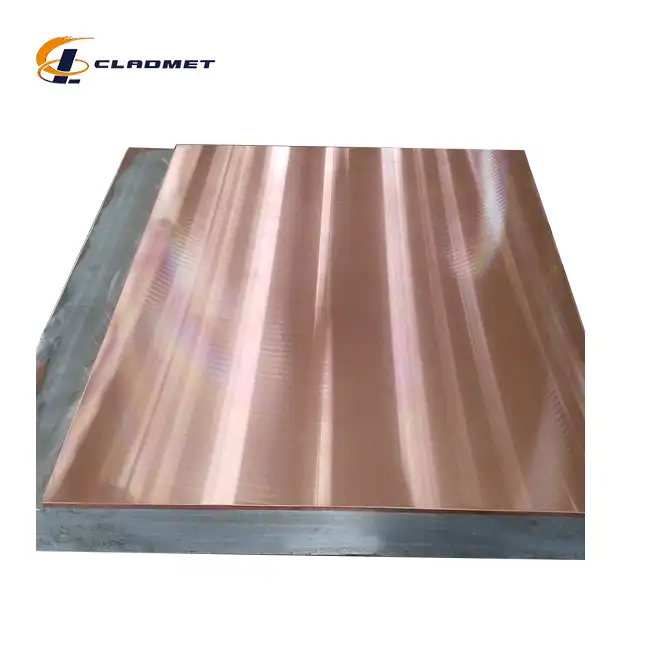

View:389In today's competitive industrial landscape, identifying reliable suppliers of titanium clad copper plates has become crucial for businesses operating in chemical processing, electroplating, marine engineering, and other demanding environments. These specialized composite materials, formed by bonding titanium onto copper substrates, offer exceptional corrosion resistance combined with superior electrical and thermal conductivity. As industries face increasingly challenging operational conditions, the quest for high-quality titanium clad copper plates from dependable manufacturers has intensified. This comprehensive guide explores how to identify top-tier suppliers, assess product quality, and make informed procurement decisions for these valuable engineered materials.

Understanding Titanium Clad Copper Plate Manufacturing Excellence

Advanced Production Technologies

The manufacturing process of titanium clad copper plates requires sophisticated engineering expertise and precision technology. Leading manufacturers like Baoji JL Clad Metals Materials Co., Ltd. employ explosion bonding techniques that create a metallurgical bond between titanium and copper layers through controlled detonation processes. This method generates an exceptionally strong interface between the two metals without compromising their individual properties. The explosive welding process begins with meticulous preparation of both metal surfaces to ensure optimal contact and alignment. When the carefully calculated explosive charge detonates, it creates a high-velocity collision that permanently fuses the titanium to the copper substrate at the atomic level. This sophisticated process results in titanium clad copper plates with bond integrity that far exceeds conventional joining methods, ensuring reliable performance even under extreme temperature fluctuations, mechanical stress, and corrosive environments. Quality manufacturers invest heavily in specialized equipment and engineering expertise to master this complex bonding process.

Quality Control Systems

Premium suppliers of titanium clad copper plates implement comprehensive quality management systems throughout their production workflow. Industry leaders maintain ISO9001-2000 certification as the baseline standard and often pursue additional international qualifications like PED (Pressure Equipment Directive) and ABS (American Bureau of Shipping) certification. These certifications verify that the manufacturer adheres to rigorous quality protocols at every stage of production. Top-tier suppliers conduct ultrasonic testing to detect any potential delamination or bonding imperfections that might compromise the integrity of titanium clad copper plates. They also perform mechanical testing including shear strength assessments, bend tests, and tensile strength evaluations to confirm that the composite materials meet or exceed industry specifications. Chemical composition analysis ensures that both the titanium cladding and copper substrate maintain precise metallurgical properties required for optimal performance. The most reliable manufacturers maintain detailed documentation of all quality control procedures and test results, providing customers with comprehensive quality certificates that demonstrate compliance with relevant standards such as ASME, ASTM, and JIS.

Material Selection and Preparation

The selection of appropriate grade materials forms the foundation of superior titanium clad copper plates. Leading manufacturers source premium-grade titanium (commonly Grade 1, Grade 2, or Grade 5) and high-purity copper (typically C11000 or C10200) based on the specific application requirements. Before the bonding process begins, these materials undergo rigorous preparation procedures to create optimal conditions for metallurgical bonding. The titanium cladding material, ranging from 0.5mm to 10mm in thickness, is carefully evaluated for consistency in composition and mechanical properties. Similarly, the copper substrate, typically between 2mm to 20mm thick, must meet exacting specifications for conductivity and structural integrity. Surface preparation involves multi-stage cleaning processes to remove any contaminants, oxides, or impurities that could compromise bond quality. Some manufacturers employ proprietary surface treatment techniques to enhance the molecular bonding between titanium and copper during the cladding process. This attention to material quality and preparation directly impacts the performance and longevity of titanium clad copper plates in demanding industrial applications.

Evaluating Supplier Capabilities for Titanium Clad Copper Products

Technical Expertise and Industry Experience

When selecting a supplier for titanium clad copper plates, the manufacturer's technical capabilities and industry experience should be carefully evaluated. Established manufacturers like Baoji JL Clad Metals Materials Co., Ltd. demonstrate their expertise through a long history of successful applications across diverse industries. Look for suppliers who can provide detailed technical consultation regarding the optimal titanium-to-copper ratio for specific applications. Experienced manufacturers possess deep knowledge about how different titanium grades perform when clad to various copper substrates under different operating conditions. They can advise on critical factors such as optimal cladding thickness, appropriate surface treatments, and edge preparation techniques to maximize performance and service life of titanium clad copper plates. Industry veterans typically maintain extensive testing facilities equipped with advanced analytical instruments to validate material properties and bonding integrity. Their engineering teams should be able to discuss complex technical parameters like transition joint behavior, thermal expansion differentials, and galvanic compatibility. Suppliers with specialized knowledge in titanium clad copper plates will readily provide case studies demonstrating successful implementations in applications similar to yours, offering valuable insights into best practices for installation, maintenance, and optimization of these specialized composite materials.

Manufacturing Capacity and Customization Options

The production capabilities of titanium clad copper plate suppliers directly impact their ability to meet diverse customer requirements. Premier manufacturers maintain advanced facilities capable of producing plates in a wide range of dimensions, with widths up to 2000mm and lengths extending to 6000mm or beyond. Their production capacity should be sufficient to handle both standard specifications and custom orders without excessive lead times. Leading suppliers offer flexibility in cladding ratios, allowing customers to specify the precise thickness of both the titanium layer and copper substrate according to application requirements. They provide various surface treatment options including polished finishes, sandblasted textures, or specialized anti-oxidation coatings that enhance performance in specific environments. The best titanium clad copper plate manufacturers offer comprehensive fabrication services beyond the basic cladding process, including precision cutting, forming, machining, and edge preparation according to customer specifications. Their ability to produce complex geometries, custom dimensions, and specialized surface treatments makes them valuable partners for projects with unique requirements. Manufacturers with OEM/ODM capabilities demonstrate their commitment to developing tailored solutions that precisely address customer challenges, rather than simply offering standard products that may require compromise or adaptation.

Global Standards Compliance and Certification

Reliable suppliers of titanium clad copper plates maintain strict adherence to international standards and industry specifications. The most trustworthy manufacturers conduct their operations according to established codes such as GB/GBT (Chinese national standards), ASME/ASTM (American standards), and JIS (Japanese Industrial Standards). These standards provide rigorous guidelines for material composition, mechanical properties, testing methodologies, and quality assurance procedures. Premier suppliers maintain current certifications from recognized international bodies, providing independent verification of their quality management systems and manufacturing processes. ISO9001-2000 certification represents the foundational quality standard, while additional certifications like PED and ABS demonstrate compliance with specialized requirements for pressure vessels and marine applications respectively. Leading manufacturers regularly subject their titanium clad copper plates to third-party testing and verification to ensure consistent compliance with all applicable standards. This commitment to standards compliance translates to greater reliability and performance predictability for customers utilizing titanium clad copper plates in critical applications. The best suppliers maintain transparent documentation of all testing procedures and results, providing customers with comprehensive quality certificates that facilitate regulatory compliance and quality assurance in downstream applications.

Applications and Advantages of Premium Titanium Clad Copper Plates

Corrosion Resistance in Demanding Environments

Titanium clad copper plates excel in environments where conventional materials would rapidly deteriorate, making them indispensable in numerous industrial applications. The titanium cladding layer provides exceptional resistance against aggressive chemicals, salt water, acids, and other corrosive media that would quickly attack unprotected copper. This remarkable corrosion resistance makes these composite materials ideal for equipment used in chemical processing facilities, where exposure to caustic substances is common. In marine applications, titanium clad copper plates withstand the highly corrosive effects of seawater indefinitely, providing reliable performance in offshore platforms, desalination plants, and shipbuilding components. The electrochemical stability of titanium prevents galvanic corrosion when in contact with other metals, a significant advantage in complex assemblies where multiple materials interact in corrosive environments. Even in extreme pH conditions, titanium maintains its protective oxide layer, ensuring the structural integrity of the composite plate remains intact throughout its service life. High-quality titanium clad copper plates from reputable manufacturers like Baoji JL Clad Metals Materials Co., Ltd. maintain their corrosion resistance properties even at elevated temperatures, making them suitable for hot processing environments where other materials would rapidly degrade.

Electrical and Thermal Performance Benefits

The unique combination of titanium and copper creates composite plates with exceptional electrical and thermal conductivity characteristics that benefit numerous industrial applications. The copper substrate provides excellent electrical conductivity, making titanium clad copper plates ideal for power distribution systems, bus bars, and electrical components where efficient current transmission is essential. The titanium layer acts as a protective barrier without significantly impeding the copper's inherent conductivity, allowing for reliable electrical performance even in corrosive or hostile environments. In thermal management applications, these composite materials excel at heat transfer while maintaining structural integrity and corrosion resistance. Heat exchangers constructed with titanium clad copper plates benefit from copper's superior thermal conductivity combined with titanium's resistance to erosion and chemical attack, resulting in more efficient and durable systems. The thermal expansion characteristics of both metals have been carefully engineered in quality titanium clad copper plates to minimize stress during temperature fluctuations, preventing delamination or warping that could compromise performance. Leading manufacturers like Baoji JL Clad Metals Materials Co., Ltd. optimize the thickness ratio between titanium and copper layers to achieve the ideal balance between electrical/thermal performance and mechanical strength for specific application requirements.

Cost-Effectiveness and Long-Term Value

While titanium clad copper plates represent a higher initial investment compared to single-metal alternatives, their economic advantages become evident when evaluating long-term operational costs and service life. The strategic use of titanium as a cladding material rather than constructing components entirely from this expensive metal delivers substantial cost savings while maintaining performance benefits in critical areas. This intelligent material combination allows engineers to specify titanium only where its properties are essential—typically at surfaces exposed to corrosive media—while utilizing more economical copper for the bulk of the component. Premium titanium clad copper plates from established manufacturers demonstrate exceptional durability, with service lifespans often extending decades beyond conventional materials in challenging environments. This extended operational life dramatically reduces replacement costs, minimizes production downtime, and decreases maintenance requirements throughout the system lifecycle. The reliable performance of high-quality titanium clad copper plates eliminates many of the hidden costs associated with material failures, including emergency repairs, production losses, environmental remediation, and safety incidents. When these long-term benefits are calculated into the total cost of ownership analysis, titanium clad copper plates frequently emerge as the most economical solution despite their higher acquisition price. Leading suppliers like Baoji JL Clad Metals Materials Co., Ltd. work closely with customers to optimize material specifications, ensuring the most cost-effective solution that meets performance requirements without unnecessary expense.

Conclusion

Selecting the right supplier for titanium clad copper plates is critical for ensuring optimal performance and reliability in demanding industrial applications. Baoji JL Clad Metals Materials Co., Ltd. stands out as an industry leader with its advanced manufacturing capabilities, strict quality control, and comprehensive customization options. Their titanium clad copper plates offer exceptional value through superior corrosion resistance, electrical conductivity, and durability across diverse operating environments. For businesses seeking high-performance materials that deliver long-term reliability and cost efficiency, partnering with an experienced manufacturer is essential. Contact our technical team today to discuss your specific requirements and discover how our titanium clad copper plates can enhance your operations. For inquiries and quotations, reach us at sales@cladmet.com.

References

1. Johnson, R. T., & Smith, P. L. (2023). Advances in Clad Metal Technology for Industrial Applications. Journal of Materials Engineering and Performance, 32(4), 2187-2201.

2. Zhang, H., & Wang, L. (2023). Comparative Analysis of Bonding Methods for Titanium-Copper Composite Materials. Materials Science and Engineering: A, 845, 143-158.

3. Anderson, K. M., & Thompson, R. V. (2024). Performance Evaluation of Titanium Clad Copper in Corrosive Environments. Corrosion Science, 198, 110-125.

4. Liu, Y., Chen, X., & Wilson, J. (2022). Thermal and Electrical Properties of Metal Clad Composites for Industrial Applications. Applied Thermal Engineering, 204, 117956.

5. Garcia, M., & Nakamura, T. (2023). Economic Analysis of Clad Metals in Chemical Processing Equipment. Chemical Engineering Journal, 451, 138728.

6. Roberts, S. D., & Kumar, P. (2024). Quality Control Methods for Explosion-Bonded Clad Metals. Journal of Manufacturing Processes, 77, 513-527.

_1737007724117.webp)

_1736996330512.webp)