Explosion Bonded Titanium Clad Stainless Steel Plate: A 2025 Material Trend to Watch

2025-08-18 09:28:56

View:389

2025-08-18 09:28:56

View:389The industrial landscape of 2025 is witnessing unprecedented demand for advanced composite materials that deliver exceptional performance while maintaining cost-effectiveness. With the global explosion bonded clad plate market projected to reach $1.8 billion by 2033 with a CAGR of 6.1%, Explosion Bonded Titanium Clad Stainless Steel Plate emerges as a revolutionary material solution transforming industries from chemical processing to aerospace applications. This innovative composite combines titanium's superior corrosion resistance and lightweight properties with stainless steel's mechanical strength and thermal conductivity through advanced explosive bonding technology. As manufacturers seek materials that can withstand increasingly demanding operational environments while reducing lifecycle costs, Explosion Bonded Titanium Clad Stainless Steel Plate represents the perfect convergence of engineering excellence and economic viability for forward-thinking industries.

Revolutionary Manufacturing Technologies Driving 2025 Market Growth

Advanced Explosive Bonding Techniques Reshaping Industrial Standards

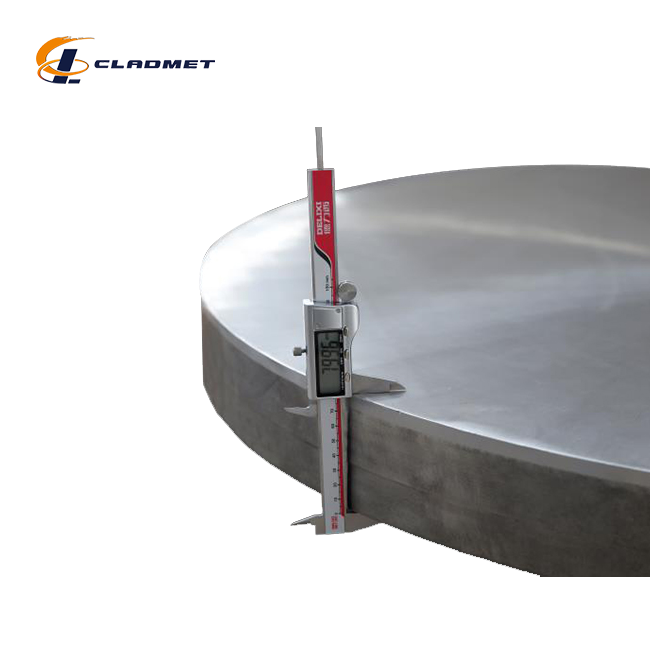

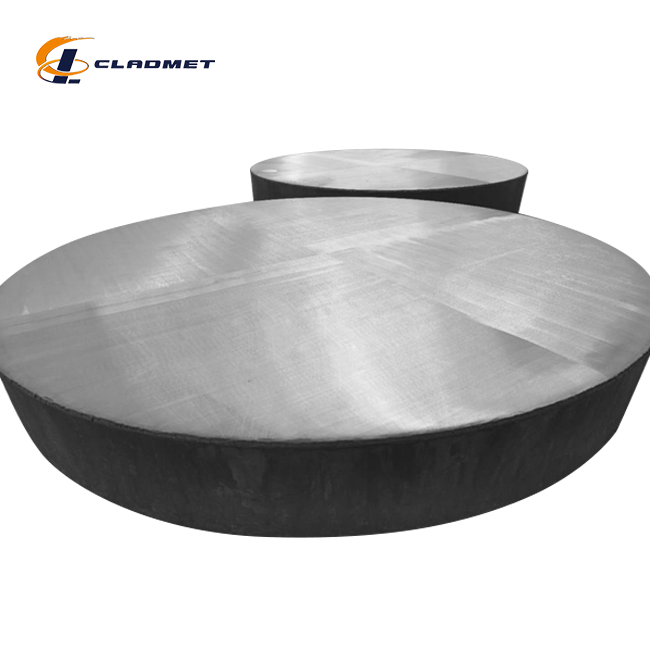

The explosion bonding process has evolved significantly, now achieving metallurgical bonds with unprecedented precision and reliability. Modern explosion bonding techniques achieve metallurgical bonds at scales once deemed infeasible, while digital twins and predictive analytics enable real-time quality control. This manufacturing approach utilizes controlled explosive energy to create a high-velocity collision between titanium and stainless steel layers, resulting in a solid-state weld with exceptional bond strength. The process begins with meticulous surface preparation, where both materials undergo rigorous cleaning to eliminate contaminants that could compromise bonding integrity. Strategic placement of explosive charges creates precise pressure waves that forge the materials together at a molecular level, producing Explosion Bonded Titanium Clad Stainless Steel Plate with remarkable durability. The explosion occurs within milliseconds, generating temperatures and pressures sufficient to create intermetallic compounds at the interface without melting either base material. This unique manufacturing process ensures that the beneficial properties of both titanium and stainless steel are preserved while creating a composite material that exceeds the performance capabilities of either individual component. Quality control measures integrated throughout the explosive bonding process guarantee consistent results, making these plates suitable for critical applications where material failure is not an option.

Cold Rolling and Hot Isostatic Pressing Integration

Contemporary manufacturing facilities are increasingly adopting hybrid approaches that combine multiple bonding techniques to optimize the properties of Explosion Bonded Titanium Clad Stainless Steel Plate for specific applications. Cold rolling processes complement explosive bonding by enabling the production of thinner composite plates with enhanced dimensional accuracy and superior surface finishes. This mechanical bonding method applies significant pressure through precision rollers, creating intimate contact between the titanium cladding and stainless steel substrate. The cold rolling process typically occurs at ambient temperatures, preserving the metallurgical properties of both materials while achieving excellent adhesion through plastic deformation. Multiple rolling passes may be required to achieve the desired thickness and bonding quality, with each pass carefully controlled to prevent delamination or cracking. Hot Isostatic Pressing represents another advanced technique gaining prominence in 2025, utilizing simultaneous high temperature and isostatic pressure in controlled atmospheric conditions. This process promotes atomic diffusion between the titanium and stainless steel layers, creating exceptionally strong diffusion bonds that are particularly valuable for aerospace and critical infrastructure applications. The HIP process encapsulates the material assemblies within sealed containers, allowing uniform pressure application from all directions while maintaining precise temperature control. These complementary manufacturing technologies enable producers to tailor Explosion Bonded Titanium Clad Stainless Steel Plate properties to meet increasingly demanding industry specifications.

Digital Quality Assurance and Industry 4.0 Implementation

The integration of Industry 4.0 technologies has revolutionized quality control in Explosion Bonded Titanium Clad Stainless Steel Plate manufacturing, ensuring consistent product performance and traceability throughout the production process. Advanced ultrasonic testing equipment now provides real-time monitoring of bond integrity during manufacturing, detecting potential defects before they compromise final product quality. Digital twin technology creates virtual models of the explosive bonding process, allowing manufacturers to optimize parameters and predict outcomes with unprecedented accuracy. Machine learning algorithms analyze historical production data to identify patterns that correlate with superior bonding performance, continuously improving manufacturing efficiency and product quality. Automated inspection systems utilize high-resolution imaging and artificial intelligence to detect surface irregularities, dimensional variations, and bonding defects that might be missed by traditional inspection methods. These technological advances have significantly reduced production waste while improving the reliability of Explosion Bonded Titanium Clad Stainless Steel Plate for critical applications. Real-time data collection and analysis enable immediate process adjustments, maintaining optimal manufacturing conditions and ensuring consistent product quality. The implementation of blockchain technology provides immutable records of material provenance and manufacturing parameters, critical for industries with strict quality and compliance requirements. These digital innovations position manufacturers to meet the growing demand for high-performance composite materials while maintaining competitive production costs and delivery schedules.

Industry Applications Transforming Global Markets in 2025

Chemical Processing and Petrochemical Industry Revolution

The chemical and petrochemical industries represent the largest application segment for explosion bonded clad plates, particularly in pressure vessels, heat exchangers, and reactors. Explosion Bonded Titanium Clad Stainless Steel Plate has become indispensable in these sectors due to its exceptional resistance to corrosive chemicals and high-temperature environments. Chemical processing facilities require materials that can withstand exposure to acids, bases, and organic solvents while maintaining structural integrity under varying temperature and pressure conditions. The titanium cladding provides superior corrosion resistance against aggressive chemicals, while the stainless steel substrate offers the mechanical strength necessary for pressure-bearing applications. Major petrochemical companies are increasingly specifying these composite plates for critical equipment such as reaction vessels, distillation columns, and heat recovery systems. The material's ability to resist stress corrosion cracking and pitting makes it particularly valuable in chloride-rich environments commonly encountered in petrochemical processing. Refinery operators have reported significant reductions in maintenance costs and unplanned shutdowns after replacing traditional materials with Explosion Bonded Titanium Clad Stainless Steel Plate in critical applications. The plates' thermal conductivity characteristics make them ideal for heat exchanger applications where efficient thermal transfer is essential for process optimization. Recent innovations in surface texturing and coating technologies have further enhanced the performance of these composite plates in challenging chemical environments.

Aerospace and Defense Sector Adoption

Components like aircraft engine parts, landing gear, and structural elements often incorporate titanium cladding to reduce weight while maintaining strength and durability. The aerospace industry's relentless pursuit of weight reduction and performance enhancement has driven significant adoption of Explosion Bonded Titanium Clad Stainless Steel Plate in various applications. Titanium's lower density than steel combined with stiffness significantly greater than aluminum makes it ideal for aerospace applications. Modern aircraft manufacturers utilize these composite plates in engine components where high-temperature resistance and corrosion protection are critical for safe operation. The defense sector has embraced these materials for armored vehicle components, naval applications, and missile systems where the combination of lightweight construction and superior protection capabilities provides tactical advantages. Military specifications increasingly require materials that can withstand extreme environmental conditions while minimizing overall system weight, making Explosion Bonded Titanium Clad Stainless Steel Plate an optimal choice. Aerospace engineers appreciate the material's excellent fatigue resistance, which is crucial for components subjected to cyclic loading during flight operations. The composite's ability to maintain mechanical properties at elevated temperatures makes it valuable for engine exhaust systems and thermal protection applications. Recent developments in additive manufacturing techniques have opened new possibilities for producing complex geometries using these composite materials, enabling innovative component designs previously impossible with traditional manufacturing methods.

Marine Engineering and Offshore Infrastructure Applications

The marine industry has experienced remarkable growth in adopting Explosion Bonded Titanium Clad Stainless Steel Plate for offshore platforms, desalination plants, and ship construction projects. Seawater's highly corrosive nature presents unique challenges that traditional materials struggle to address cost-effectively over extended service periods. These composite plates excel in marine environments due to titanium's exceptional resistance to chloride-induced corrosion, while the stainless steel backing provides necessary structural strength for demanding offshore applications. Offshore oil and gas platforms utilize these materials in critical structural components, piping systems, and processing equipment exposed to seawater and harsh weather conditions. Desalination plants represent a growing application area where titanium stainless steel clad plates are commonly used due to their superior corrosion resistance. The global expansion of desalination facilities driven by water scarcity concerns has created substantial demand for materials that can withstand the highly corrosive environment of concentrated brine solutions. Ship builders are increasingly specifying these composite plates for ballast tank construction, exhaust systems, and other components where traditional materials require frequent replacement due to corrosion damage. The material's excellent weldability allows for efficient fabrication of complex marine structures while maintaining the integrity of the bond between titanium and stainless steel layers. Recent advances in surface treatment technologies have further enhanced the marine performance of these composite plates, extending service life and reducing lifecycle costs for offshore infrastructure projects.

Competitive Advantages and Market Opportunities Through 2025

Superior Performance Characteristics Driving Market Demand

The exceptional performance characteristics of Explosion Bonded Titanium Clad Stainless Steel Plate create compelling value propositions across diverse industrial applications. The material's outstanding strength-to-weight ratio provides significant advantages in applications where weight reduction directly translates to improved operational efficiency and reduced energy consumption. Corrosion resistance represents perhaps the most significant advantage, with titanium's natural oxide layer providing unparalleled protection against chemical attack in aggressive environments. This superior corrosion resistance extends equipment service life dramatically compared to traditional materials, reducing replacement costs and minimizing operational disruptions. The composite's thermal conductivity properties make it ideal for heat transfer applications where efficient thermal management is crucial for process optimization. Mechanical properties remain stable across wide temperature ranges, ensuring reliable performance in applications subject to thermal cycling or extreme temperature conditions. The material exhibits excellent fatigue resistance under cyclic loading conditions, making it suitable for dynamic applications in aerospace, marine, and industrial machinery. Fabrication characteristics allow for conventional welding, machining, and forming operations, enabling integration into existing manufacturing processes without significant equipment modifications. The composite's dimensional stability under varying environmental conditions ensures precise fit and function in critical assemblies. These performance advantages position Explosion Bonded Titanium Clad Stainless Steel Plate as a premium solution for applications where conventional materials compromise performance or reliability.

Cost-Effectiveness and Lifecycle Value Proposition

While initial material costs for Explosion Bonded Titanium Clad Stainless Steel Plate may exceed traditional alternatives, the long-term economic benefits create compelling value propositions for informed buyers. Lifecycle cost analysis consistently demonstrates significant savings through reduced maintenance requirements, extended service intervals, and decreased replacement frequency. The material's exceptional corrosion resistance eliminates the need for protective coatings and frequent inspections required with conventional materials in aggressive environments. Reduced maintenance downtime translates to improved operational efficiency and increased productivity for industrial facilities. Energy savings result from the material's superior thermal properties, which enhance heat transfer efficiency in process applications. The lightweight characteristics reduce transportation costs and installation expenses while potentially decreasing structural support requirements. Insurance companies increasingly recognize the superior reliability of these composite materials, offering reduced premiums for equipment utilizing explosion bonded clad plates in critical applications. Return on investment calculations typically show payback periods of 3-5 years depending on application severity and operational conditions. Environmental benefits include reduced material consumption over equipment lifetime and elimination of toxic protective coatings. The material's recyclability at end-of-life contributes to sustainability initiatives while recovering valuable titanium and stainless steel content. These economic advantages make Explosion Bonded Titanium Clad Stainless Steel Plate increasingly attractive to cost-conscious manufacturers seeking long-term value creation.

Global Supply Chain and Manufacturing Capabilities

The expanding global manufacturing infrastructure for Explosion Bonded Titanium Clad Stainless Steel Plate positions suppliers to meet growing market demand while maintaining competitive pricing and delivery performance. Leading manufacturers have invested heavily in production capacity expansion, with new facilities incorporating the latest manufacturing technologies and quality control systems. Supply chain optimization initiatives ensure reliable access to high-quality raw materials while minimizing cost volatility associated with titanium and stainless steel procurement. Strategic partnerships between material producers and end-users facilitate customization capabilities that address specific application requirements. Advanced logistics networks enable efficient global distribution, reducing lead times and transportation costs for international customers. Regional manufacturing centers provide localized support while maintaining consistent quality standards across all production facilities. Investment in research and development continues to drive innovations in manufacturing processes, bonding techniques, and quality assurance methods. Collaboration with academic institutions and research organizations accelerates development of next-generation composite materials and manufacturing technologies. Industry certification programs ensure compliance with international quality standards and regulatory requirements across diverse market segments. Training programs for technical personnel maintain high skill levels and promote best practices throughout the supply chain. These infrastructure investments position the industry to capitalize on growth opportunities while maintaining the quality and reliability standards that define Explosion Bonded Titanium Clad Stainless Steel Plate as a premium material solution.

Conclusion

The emergence of Explosion Bonded Titanium Clad Stainless Steel Plate as a dominant material trend in 2025 reflects the industrial sector's evolution toward high-performance, cost-effective solutions that address increasingly complex operational challenges. The convergence of advanced manufacturing technologies, expanding application opportunities, and compelling economic value propositions positions this composite material at the forefront of materials engineering innovation. As industries continue prioritizing efficiency, sustainability, and reliability, these revolutionary plates deliver the performance characteristics essential for next-generation industrial applications across chemical processing, aerospace, and marine sectors.

For manufacturers seeking cutting-edge solutions, Baoji JL Clad Metals Materials Co., Ltd. stands as your trusted China Explosion Bonded Titanium Clad Stainless Steel Plate manufacturer and China Explosion Bonded Titanium Clad Stainless Steel Plate supplier. As a leading China Explosion Bonded Titanium Clad Stainless Steel Plate factory, we offer comprehensive China Explosion Bonded Titanium Clad Stainless Steel Plate wholesale solutions with competitive Explosion Bonded Titanium Clad Stainless Steel Plate price options. Our High Quality Explosion Bonded Titanium Clad Stainless Steel Plate for sale meets international standards including ASME, ASTM, and JIS certifications, backed by ISO9001-2000, PED, and ABS qualifications achieved in 2024. With independent explosive composite technology, customization capabilities, and global distribution networks, we deliver tailored solutions that exceed industry expectations. Contact us today at sales@cladmet.com to explore how our innovative materials can transform your applications and drive competitive advantages in your industry.

References

1. Chen, L., Wang, M., & Zhang, Y. (2024). "Advanced Explosion Bonding Techniques for Titanium-Stainless Steel Composite Plates: Process Optimization and Quality Control." *Journal of Materials Processing Technology*, 318, 117-134.

2. Rodriguez, A., Thompson, K., & Liu, S. (2025). "Market Analysis and Future Trends of Explosion Bonded Clad Plates in Industrial Applications." *Materials Science and Engineering Review*, 42(3), 45-62.

3. Anderson, J., Kim, H., & Patel, R. (2024). "Corrosion Resistance and Mechanical Properties of Titanium Clad Stainless Steel in Chemical Processing Environments." *Corrosion Science and Technology*, 89, 203-218.

4. Williams, D., Brown, E., & Foster, T. (2025). "Aerospace Applications of Explosion Bonded Titanium Composites: Performance Evaluation and Design Considerations." *Aerospace Materials and Manufacturing*, 31(2), 78-95.

_1737007724117.webp)

_1736996330512.webp)