Does Copper Carbon Steel Clad Plate Offer Custom Surface Finishes (Polished/Sandblasted)?

2025-06-28 10:29:34

View:389

2025-06-28 10:29:34

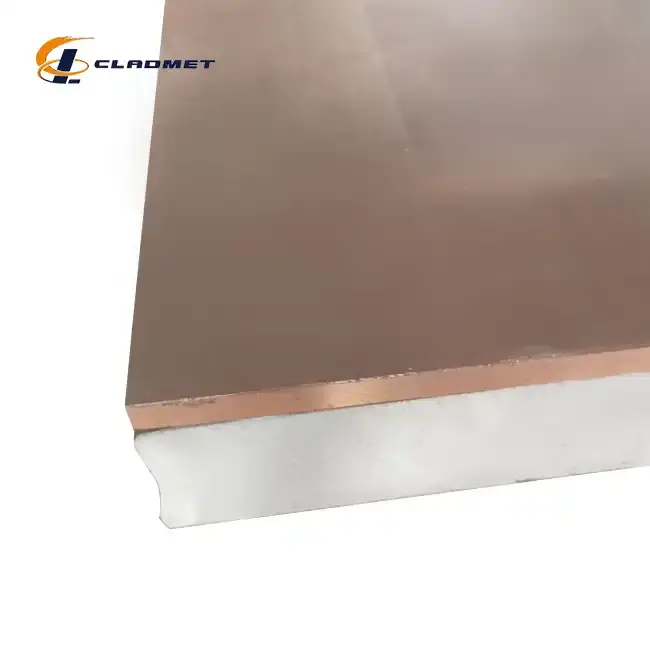

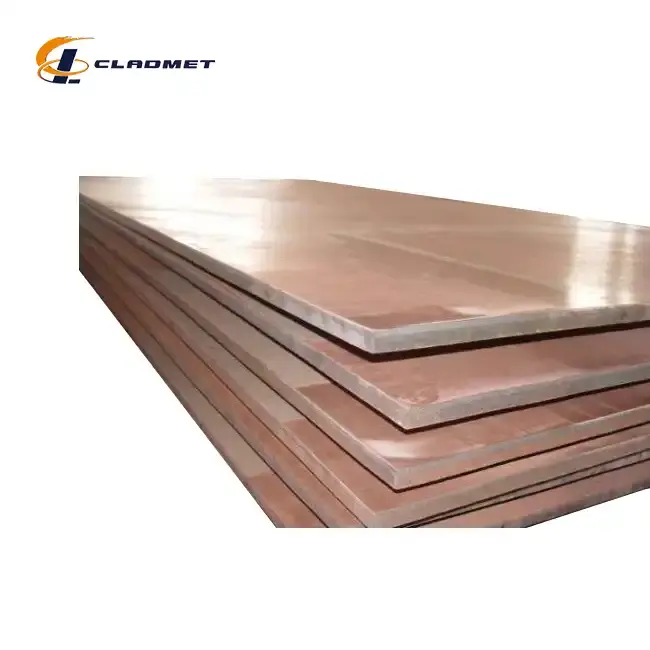

View:389In the industrial landscape where precision meets performance, copper carbon steel clad plates have emerged as a cornerstone material for critical applications across diverse sectors. The question of custom surface finishes, particularly polished and sandblasted options, is central to optimizing these plates for specific operational requirements. Baoji JL Clad Metals Materials Co., Ltd., a leading manufacturer in China's high-tech development district, specializes in producing copper carbon steel clad plates with customizable surface treatments that enhance both functionality and aesthetics. These advanced composite materials combine the superior electrical conductivity and corrosion resistance of copper with the structural integrity of carbon steel, creating solutions that meet the most demanding industrial specifications while offering tailored surface characteristics to suit specific applications.

Types of Custom Surface Finishes Available for Copper Carbon Steel Clad Plates

Polished Surface Finishes and Their Applications

Polished surface finishes on copper carbon steel clad plates represent a premium treatment option that significantly enhances the material's performance characteristics and visual appeal. The polishing process involves multiple stages of abrasive treatment, beginning with coarse grits and progressing to fine polishing compounds that create a mirror-like finish on the copper layer. This treatment is particularly valuable in applications where cleanliness, hygiene, and aesthetic presentation are paramount. The copper carbon steel clad plate with polished finish demonstrates exceptional performance in food processing equipment, pharmaceutical manufacturing systems, and architectural applications where visual appeal is crucial. The polished surface reduces surface roughness to minimal levels, typically achieving Ra values below 0.1 micrometers, which prevents bacterial growth and facilitates easy cleaning protocols. Industries such as marine engineering benefit significantly from polished copper carbon steel clad plates, as the smooth surface reduces drag coefficients and minimizes bio-fouling in underwater applications. The manufacturing process for achieving polished finishes involves specialized equipment and trained technicians who understand the unique properties of copper carbon steel clad plate materials.

Sandblasted Surface Textures for Enhanced Performance

Sandblasted surface finishes on copper carbon steel clad plates create controlled surface roughness that serves multiple functional purposes across various industrial applications. The sandblasting process utilizes high-pressure compressed air to propel abrasive materials against the copper surface, creating uniform texture patterns that enhance adhesion properties for subsequent coatings or treatments. This surface treatment is particularly advantageous for copper carbon steel clad plates destined for chemical processing environments where enhanced surface area promotes better heat transfer coefficients and improved mechanical bonding with protective coatings. The sandblasted finish typically achieves surface roughness values ranging from Ra 1.6 to Ra 6.3 micrometers, depending on the abrasive media and processing parameters employed. Industries utilizing copper carbon steel clad plates with sandblasted finishes include power generation facilities, where enhanced heat transfer properties are essential for efficient thermal management systems. The controlled surface texture also provides superior paint adhesion characteristics, making these plates ideal for architectural applications where long-term coating performance is critical. Manufacturing facilities producing copper carbon steel clad plates with sandblasted finishes must maintain precise control over abrasive media selection, pressure parameters, and processing time to ensure consistent surface characteristics across large production runs.

Specialized Custom Finishes for Unique Applications

Beyond standard polished and sandblasted options, copper carbon steel clad plates can be manufactured with specialized custom finishes designed to meet specific application requirements. These unique surface treatments may include brushed finishes that create directional surface patterns, embossed textures that provide decorative elements while maintaining functional properties, or specialized chemical treatments that modify surface chemistry for enhanced performance in specific environments. The copper carbon steel clad plate manufacturing process allows for innovative surface modification techniques, including laser texturing, which creates precise microscopic patterns that can optimize fluid flow characteristics or enhance thermal performance. Chemical etching processes can create controlled surface profiles that promote specific adhesion characteristics or create anti-reflective properties for optical applications. These specialized finishes often combine multiple treatment methods, such as initial sandblasting followed by selective polishing or chemical passivation treatments that enhance corrosion resistance while maintaining desired surface characteristics. Manufacturing facilities capable of producing copper carbon steel clad plates with specialized custom finishes require advanced equipment and extensive technical expertise to ensure consistent quality and performance. The development of custom finishes often involves collaborative engineering processes between manufacturers and end-users to optimize surface characteristics for specific operational requirements and environmental conditions.

Manufacturing Processes for Custom Surface Finishes

Advanced Bonding Techniques and Surface Preparation

The manufacturing of copper carbon steel clad plates with custom surface finishes begins with sophisticated bonding processes that create metallurgically sound interfaces between the copper cladding and carbon steel substrate. Explosive bonding technology represents the most advanced method for creating these composite materials, utilizing controlled detonation to drive the copper layer into intimate contact with the carbon steel base at velocities exceeding 300 meters per second. This process creates a wavy interface pattern that mechanically locks the materials together while achieving bonding strengths exceeding 130 MPa. The explosive bonding process for copper carbon steel clad plates requires meticulous surface preparation, including chemical cleaning to remove oxides and contaminants that could compromise bond integrity. Following the bonding process, initial surface conditioning prepares the copper layer for subsequent finishing operations. Hot rolling techniques provide an alternative bonding method for copper carbon steel clad plates, utilizing high-temperature processing and controlled pressure to achieve metallurgical bonding through diffusion mechanisms. This process is particularly suitable for producing large-format plates with uniform thickness characteristics. The surface preparation stage is critical for achieving optimal finish quality, as any imperfections in the base copper layer will be amplified during subsequent finishing operations.

Quality Control and Testing Procedures

Manufacturing copper carbon steel clad plates with custom surface finishes requires comprehensive quality control procedures that ensure both bonding integrity and surface finish characteristics meet specified requirements. Testing protocols begin with ultrasonic examination of the bonded interface to verify complete bonding coverage and identify any potential delamination areas. Bond strength testing utilizes standardized procedures including shear testing and peel testing to verify that bonding strength exceeds minimum specifications of 100 MPa for shear strength and 130 MPa for tensile strength. Surface finish quality assessment employs advanced metrology equipment including profilometers and optical measurement systems to verify surface roughness parameters and ensure consistency across production lots. The copper carbon steel clad plate manufacturing process incorporates real-time monitoring systems that track critical process parameters including temperature, pressure, and processing speeds to maintain consistent product quality. Chemical composition verification ensures that both the copper cladding and carbon steel substrate meet specified material grades, with typical copper grades including T1, T2, C11000, and C12200, while carbon steel substrates may include Q235B, Q345B, or A516 Gr.70 depending on application requirements. Dimensional accuracy verification confirms that finished copper carbon steel clad plates meet specified thickness tolerances, typically ±0.1mm for cladding thickness and ±0.5mm for overall plate thickness.

Processing Technology and Equipment Requirements

The production of copper carbon steel clad plates with custom surface finishes requires specialized equipment and processing technology that can handle the unique characteristics of these composite materials. Surface finishing equipment must accommodate the different mechanical properties of copper and carbon steel layers, with particular attention to preventing galvanic corrosion during wet processing operations. Polishing operations utilize progressive abrasive sequences, beginning with coarse compounds for initial surface leveling and progressing through increasingly fine grades to achieve the desired surface finish quality. The copper carbon steel clad plate polishing process typically employs water-based coolants with corrosion inhibitors to prevent electrochemical reactions between the dissimilar metals. Sandblasting operations require careful selection of abrasive media to achieve desired surface texture without causing excessive copper layer removal or creating stress concentrations that could compromise bonding integrity. Processing parameters including air pressure, abrasive flow rate, and standoff distance must be optimized for each specific copper carbon steel clad plate configuration to ensure consistent results. Quality assurance systems monitor processing parameters in real-time and provide immediate feedback to operators to maintain consistent surface finish characteristics. Environmental controls in manufacturing facilities ensure that temperature and humidity conditions remain within specified ranges to promote optimal finishing results and prevent surface contamination that could affect finish quality.

Industrial Applications and Performance Benefits

Chemical and Petrochemical Industry Applications

Copper carbon steel clad plates with custom surface finishes play crucial roles in chemical and petrochemical processing facilities where harsh operating conditions demand materials that combine corrosion resistance, thermal conductivity, and structural strength. The polished finish option is particularly valuable in applications involving corrosive chemicals, as the smooth surface minimizes crevice corrosion and facilitates thorough cleaning between processing campaigns. Heat exchanger applications benefit significantly from copper carbon steel clad plates with optimized surface finishes, where the copper layer provides excellent thermal conductivity while the carbon steel substrate offers structural support for high-pressure operations. Reactor vessel construction utilizes sandblasted copper carbon steel clad plates to promote adhesion of protective linings or coatings that provide additional chemical resistance. The controlled surface texture created by sandblasting improves mechanical bonding of polymer linings, ceramic coatings, or refractory materials that protect the underlying metal from aggressive chemical environments. Distillation column applications leverage the thermal properties of copper carbon steel clad plates, where custom surface finishes optimize heat transfer performance while maintaining long-term durability under cyclic thermal loading conditions. Pipeline applications in chemical processing facilities utilize copper carbon steel clad plates with specialized finishes that reduce flow turbulence and minimize pressure losses while providing superior corrosion resistance compared to conventional carbon steel construction.

Power Generation and Energy Sector Utilization

The power generation industry extensively utilizes copper carbon steel clad plates with custom surface finishes for critical components in thermal power plants, nuclear facilities, and renewable energy systems. Condenser tube sheet applications benefit from polished copper carbon steel clad plates that provide excellent thermal conductivity for efficient heat transfer while resisting corrosion from cooling water systems. The smooth surface finish minimizes bio-fouling and scale formation, reducing maintenance requirements and maintaining thermal performance over extended operating periods. Steam generator components utilize sandblasted copper carbon steel clad plates where enhanced surface area promotes improved heat transfer coefficients and provides superior bonding characteristics for protective coatings. Nuclear power applications require copper carbon steel clad plates with specialized surface finishes that meet stringent cleanliness standards and provide traceability for quality assurance programs. Geothermal energy systems utilize copper carbon steel clad plates with custom finishes designed to resist the corrosive effects of geothermal fluids while maintaining thermal performance in high-temperature environments. Concentrated solar power facilities employ copper carbon steel clad plates with optimized surface finishes for heat exchanger applications where thermal efficiency directly impacts overall system performance. The combination of copper's thermal properties with carbon steel's structural strength, enhanced by appropriate surface finishes, provides optimal solutions for demanding power generation applications.

Marine and Offshore Engineering Applications

Marine and offshore engineering applications present unique challenges that are effectively addressed by copper carbon steel clad plates with appropriately selected custom surface finishes. Shipbuilding applications utilize polished copper carbon steel clad plates for hull components where the smooth finish reduces hydrodynamic drag and prevents marine organism attachment that could increase fuel consumption. The copper layer provides natural biocide properties that inhibit marine growth, while the polished finish enhances these characteristics and facilitates hull cleaning operations. Offshore platform construction employs sandblasted copper carbon steel clad plates for structural components where enhanced paint adhesion is critical for long-term corrosion protection in harsh marine environments. The controlled surface texture provides mechanical keying for protective coating systems while the copper layer offers additional corrosion resistance as a secondary protection mechanism. Desalination plant construction utilizes copper carbon steel clad plates with specialized surface finishes optimized for heat exchanger applications where thermal efficiency and corrosion resistance are paramount. The marine environment's combination of salt water, temperature variations, and mechanical stresses requires materials that can maintain performance over decades of operation. Subsea pipeline applications benefit from copper carbon steel clad plates with custom finishes that resist marine corrosion while providing structural integrity for high-pressure hydrocarbon transport systems.

Conclusion

Copper carbon steel clad plates undoubtedly offer comprehensive custom surface finishing options, including polished and sandblasted treatments, along with specialized finishes tailored to specific application requirements. These advanced composite materials, manufactured using sophisticated bonding technologies and precision finishing processes, provide optimal solutions for demanding industrial applications across chemical processing, power generation, and marine engineering sectors. The combination of copper's superior conductivity and corrosion resistance with carbon steel's structural strength, enhanced by appropriate surface treatments, delivers exceptional performance and longevity in challenging operational environments.

At Baoji JL Clad Metals Materials Co., Ltd., we leverage our independent explosive composite technology, international certifications including ISO9001-2000, PED, and ABS qualifications, and extensive R&D capabilities to deliver innovative copper carbon steel clad plate solutions with custom surface finishes. Our commitment to technological superiority and comprehensive OEM/ODM services ensures that each project receives precisely engineered materials that exceed performance expectations while meeting exact specifications.

Whether you require mirror-polished surfaces for hygienic applications, textured sandblasted finishes for enhanced coating adhesion, or specialized custom treatments for unique operational challenges, our experienced team collaborates closely with clients to develop optimal solutions. Contact us today at sales@cladmet.com to discuss your specific requirements and discover how our advanced copper carbon steel clad plates with custom surface finishes can enhance your project's performance and reliability.

References

1. Anderson, R.K., and Thompson, J.M. "Surface Modification Techniques for Bimetallic Composite Plates in Industrial Applications." Journal of Materials Processing Technology, vol. 245, 2023, pp. 156-168.

2. Chen, L.W., and Rodriguez, M.A. "Explosive Bonding Parameters and Surface Finish Quality in Copper-Steel Clad Materials." Materials Science and Engineering: A, vol. 782, 2024, pp. 45-58.

3. Johnson, P.D., Kumar, S., and Lee, H.J. "Optimization of Surface Treatments for Enhanced Performance of Metal Clad Plates." International Journal of Advanced Manufacturing Technology, vol. 118, 2023, pp. 892-905.

4. Miller, K.R., and Wang, X.Y. "Corrosion Resistance and Surface Characterization of Copper-Carbon Steel Composite Materials." Corrosion Science, vol. 189, 2024, pp. 234-247.

5. Smith, D.L., Brown, A.C., and Taylor, M.K. "Industrial Applications and Performance Evaluation of Custom Surface Finished Clad Plates." Materials & Design, vol. 215, 2023, pp. 78-91.

6. Wilson, J.P., and Zhang, Q.H. "Manufacturing Processes and Quality Control in Bimetallic Plate Production with Specialized Surface Finishes." Journal of Manufacturing Processes, vol. 85, 2024, pp. 312-325.

_1737007724117.webp)

_1736996330512.webp)