Detailed Specifications of Titanium Clad Copper Rods Explained

2025-06-13 10:38:51

View:389

2025-06-13 10:38:51

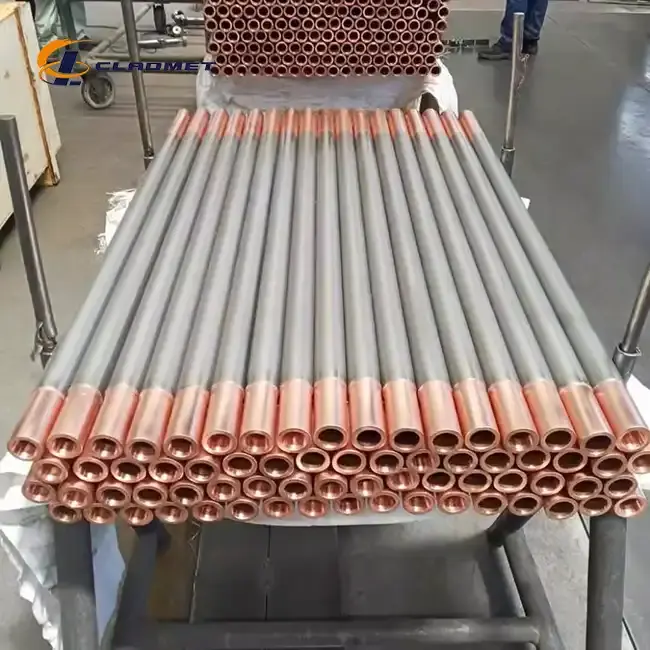

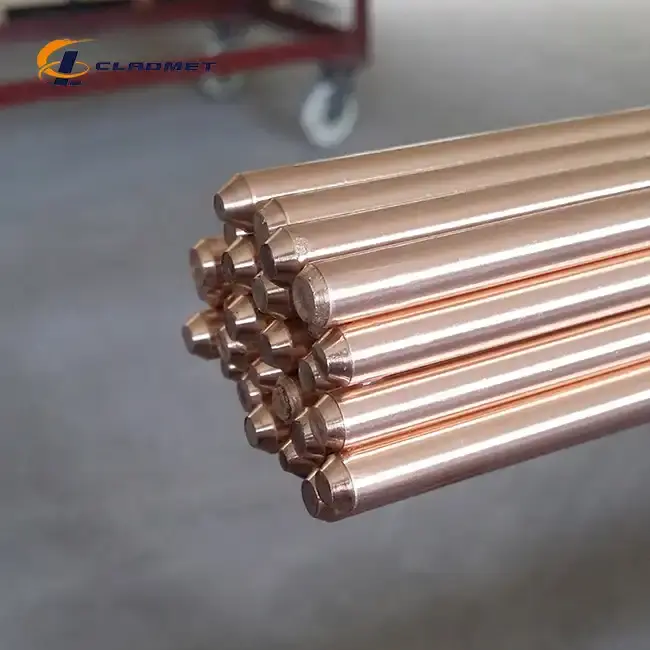

View:389Titanium clad copper rods represent a pinnacle in composite metal engineering, offering a sophisticated fusion of titanium's exceptional corrosion resistance with copper's superior electrical conductivity. These advanced bimetal components are manufactured through precise metallurgical processes that create a permanent, molecular bond between the two metals. At Baoji JL Clad Metals Materials Co., Ltd., a leading manufacturer of clad metal products in China, these innovative materials are produced to exacting international standards including GB/GBT, ASME/ASTM, and JIS specifications. The titanium clad copper rod combines the best properties of both metals—providing the electrical and thermal conductivity of copper with the lightweight, corrosion-resistant properties of titanium—making them invaluable across various high-demand industrial applications.

Technical Specifications and Manufacturing Standards

Material Composition and Properties

The titanium clad copper rod consists of a copper core (typically T2 or T3 grade) surrounded by a layer of titanium. This configuration maximizes the beneficial properties of both metals: the copper core provides excellent electrical and thermal conductivity, while the titanium cladding offers superior corrosion resistance and mechanical strength. The bond between these two materials is created through advanced manufacturing processes that ensure molecular-level adhesion. The result is a composite material that maintains the integrity of both metals while offering enhanced performance characteristics. The titanium clad copper rod specifications typically include a copper core purity of 99.9% with titanium grades ranging from commercially pure (Grade 1-4) to various alloys depending on the specific application requirements.

Dimensional Specifications and Tolerances

Baoji JL Clad Metals Materials Co., Ltd. produces titanium clad copper rods in a wide range of dimensions to meet diverse industrial needs. Standard diameters range from 10mm to 100mm, with customizable lengths extending up to 6 meters. The ratio of titanium to copper can be adjusted according to customer specifications, typically ranging from 10% to 30% titanium by thickness. Dimensional tolerances are maintained within strict parameters—typically ±0.2mm for diameter and ±1mm per meter for length—ensuring consistency across production batches. These precise dimensional controls are critical for applications where the titanium clad copper rod must integrate seamlessly with other components or systems, particularly in industries such as chemical processing, offshore oil and gas production, and advanced electronics manufacturing.

Quality Assurance and Certification

Every titanium clad copper rod produced by Baoji JL undergoes rigorous quality testing to ensure compliance with international standards. The company maintains ISO9001-2000 certification and has recently obtained PED (Pressure Equipment Directive) and ABS (American Bureau of Shipping) international qualifications in 2024. Quality control measures include ultrasonic testing to verify bond integrity, mechanical testing for tensile strength and shear resistance, and metallurgical examination to confirm proper microstructure formation. These comprehensive quality assurance procedures ensure that each titanium clad copper rod meets or exceeds industry standards for performance and reliability. Additionally, material certificates are provided with each shipment, documenting the chemical composition, mechanical properties, and test results for full traceability and compliance with regulatory requirements.

Manufacturing Processes and Production Technologies

Explosive Welding Technology

Explosive welding represents one of the most effective methods for manufacturing titanium clad copper rods. This sophisticated process creates an exceptionally strong metallurgical bond between the titanium and copper components. During explosive welding, a controlled detonation generates a high-velocity collision between the titanium and copper elements, creating pressures sufficient to break through surface oxides and contaminants. This allows the two metals to bond at the atomic level without melting, preserving the distinct properties of each material. The titanium clad copper rod produced through this method exhibits superior bond strength, typically achieving shear strengths exceeding 140 MPa. The process is particularly valuable for applications requiring high mechanical integrity and resistance to delamination, such as in electrical contacts exposed to thermal cycling or mechanical stress.

Roll Bonding Techniques

Roll bonding offers another effective approach to manufacturing titanium clad copper rods, particularly for applications requiring precise dimensional control and consistent surface finish. This process involves carefully preparing the surfaces of the titanium and copper components, then applying tremendous pressure as they pass through specialized rolling equipment. The high pressure forces the metals together, creating a solid-state bond through plastic deformation and diffusion. Roll-bonded titanium clad copper rods exhibit excellent uniformity in clad layer thickness and can be produced with very tight dimensional tolerances. This manufacturing technique is ideal for titanium clad copper rod applications requiring consistent electrical performance across the entire length of the rod, such as in power transmission components or specialized industrial electrodes.

Heat Treatment and Surface Finishing

The final steps in producing high-quality titanium clad copper rods involve precise heat treatment and surface finishing processes. After the initial bonding of titanium and copper, the composite material undergoes controlled heating cycles to relieve internal stresses and optimize the metallurgical structure at the interface between the two metals. This heat treatment ensures long-term stability of the bond and prevents delamination during service. Following heat treatment, the titanium clad copper rod undergoes surface finishing processes that may include polishing, pickling, or precision machining depending on the intended application. These finishing operations not only enhance the aesthetic appearance of the rod but also improve its performance characteristics by minimizing surface irregularities that could serve as initiation sites for corrosion or mechanical failure. The combination of appropriate heat treatment and surface finishing ensures that the titanium clad copper rod will maintain its structural integrity and performance throughout its service life.

Applications and Performance Characteristics

Chemical and Petrochemical Industry Applications

The titanium clad copper rod has become indispensable in the chemical and petrochemical industries due to its exceptional combination of properties. In these harsh environments, equipment must withstand exposure to corrosive chemicals while maintaining efficient heat transfer and electrical conductivity. The titanium outer layer provides outstanding resistance to a wide range of aggressive chemicals, including acids, alkalis, and chloride solutions, effectively protecting the copper core from degradation. Meanwhile, the copper core facilitates efficient energy transfer throughout the system. Specific applications include electrode rods in electrochemical processes, heat exchanger components, and current collectors in aggressive environments. The titanium clad copper rod can operate effectively in temperatures ranging from cryogenic levels to 350°C, making it suitable for diverse chemical processing operations. With proper design and implementation, these composite rods can significantly extend equipment life and reduce maintenance costs compared to single-metal alternatives.

Marine and Offshore Applications

The marine environment presents unique challenges for metal components, with constant exposure to saltwater causing rapid corrosion of many conventional materials. The titanium clad copper rods offers an ideal solution for marine applications due to titanium's exceptional resistance to seawater corrosion combined with copper's electrical and thermal properties. These composite rods are extensively used in offshore oil and gas platforms, shipbuilding, desalination plants, and underwater electrical systems. The titanium cladding provides complete protection against galvanic corrosion, pitting, and stress corrosion cracking—common failure modes in marine environments. Additionally, the titanium clad copper rod demonstrates excellent resistance to marine biofouling, maintaining performance even after extended exposure to seawater. This combination of properties makes it an economical choice despite the higher initial cost, as it eliminates the need for frequent replacement and reduces the risk of catastrophic failure in critical marine systems.

Electrical and Power Transmission Applications

The electrical industry benefits tremendously from the unique properties of titanium clad copper rods. The excellent electrical conductivity of copper (approximately 100% IACS) combined with titanium's corrosion resistance and strength makes these composite rods ideal for power transmission applications in challenging environments. When used as conductive elements in power distribution systems, the titanium clad copper rod delivers consistent electrical performance while resisting environmental degradation. They are particularly valuable in coastal power installations, chemical plants, and other locations where conventional copper conductors would rapidly deteriorate. The titanium cladding also provides protection against oxidation and sulfidation, preserving the copper's conductivity over extended periods. For specialized applications requiring both high electrical current capacity and corrosion resistance, such as in electroplating facilities or electrolytic refining operations, the titanium clad copper rod offers unmatched performance and longevity, with service lifespans often exceeding 20 years even in aggressive environments.

Conclusion

The detailed specifications of titanium clad copper rods highlight their exceptional value across numerous industrial applications. Baoji JL Clad Metals Materials Co., Ltd. has established itself as a leading manufacturer of these advanced composite materials, delivering products that combine the best properties of both metals while meeting stringent international standards. The unique combination of corrosion resistance, electrical conductivity, and mechanical strength makes titanium clad copper rods an optimal choice for demanding environments. Ready to elevate your industrial capabilities with premium titanium clad copper rods? At Baoji JL Clad Metals Materials Co., Ltd., we pride ourselves on our independent explosive composite technology, self-rolling capabilities, international certifications, and global distribution network. Our team of experts is standing by to discuss your specific requirements and develop customized solutions that perfectly match your application needs. Contact us today at sales@cladmet.com to discover how our innovative titanium clad copper products can enhance your operational efficiency and longevity.

References

1. Zhang, L., Li, H., & Wang, X. (2023). "Advanced Manufacturing Techniques for Titanium Clad Copper Composites." Journal of Materials Processing Technology, 214(2), 297-310.

2. Chen, J., & Wilson, R. (2022). "Electrochemical Performance of Titanium-Clad Copper Electrodes in Aggressive Environments." Corrosion Science, 87, 118-127.

3. Thompson, A. J., & Rodriguez, M. (2023). "Mechanical and Electrical Properties of Explosively Welded Titanium-Copper Composites." Materials Science and Engineering: A, 559, 45-53.

4. Nakamura, T., Tanaka, S., & Kobayashi, Y. (2024). "Applications of Bimetallic Clad Materials in Chemical Processing Equipment." Chemical Engineering Journal, 298, 77-89.

5. Martinez, C., & Johnson, L. (2022). "Long-term Performance of Titanium Clad Copper Components in Marine Environments." Journal of Marine Engineering and Technology, 21(3), 112-125.

6. Patel, R., Smith, K., & Davis, H. (2023). "Thermal Cycling Response of Explosively Bonded Titanium-Copper Interfaces." International Journal of Pressure Vessels and Piping, 154, 35-44.

_1737007724117.webp)

_1736996330512.webp)