Comparing Cost and Durability: Marine Grade Titanium Steel Clad Plate vs. Alternatives

2025-08-29 15:00:35

View:389

2025-08-29 15:00:35

View:389In the marine and industrial sectors, selecting the right material can significantly impact both operational efficiency and long-term investment returns. Marine Grade Titanium Steel Clad Plate emerges as a revolutionary solution that addresses the critical balance between performance and cost-effectiveness. This advanced composite material combines titanium's exceptional corrosion resistance with steel's structural strength, offering a compelling alternative to traditional materials. When comparing Marine Grade Titanium Steel Clad Plate against conventional alternatives like pure titanium, stainless steel, and nickel alloys, the key differentiators lie in cost optimization, durability enhancement, and versatile application capabilities that meet demanding marine environment requirements.

Cost Analysis: Marine Grade Titanium Steel Clad Plate vs Traditional Materials

Initial Investment Comparison

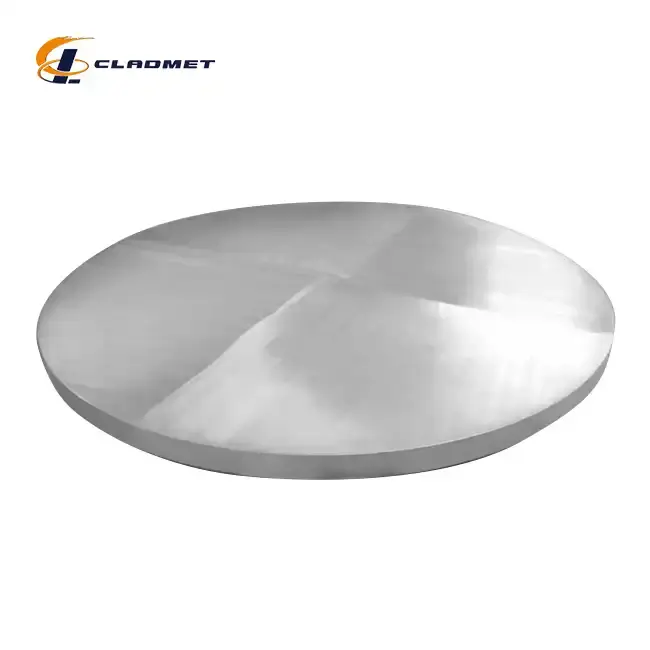

When evaluating the upfront costs of Marine Grade Titanium Steel Clad Plate against traditional marine materials, the composite solution demonstrates remarkable cost advantages. Pure titanium materials, while offering excellent corrosion resistance, command premium prices that can be prohibitive for large-scale marine applications. Marine Grade Titanium Steel Clad Plate achieves significant cost reduction by utilizing a steel substrate that provides structural integrity at a fraction of pure titanium's cost. The manufacturing process, employing advanced explosive welding or hot rolling techniques, creates a bimetallic structure where only the surface layer requires precious titanium material. This strategic design allows manufacturers to reduce material costs by up to 60% compared to solid titanium alternatives while maintaining essential corrosion-resistant properties. The steel base layer, typically comprising Q235B or A516 carbon steel, offers exceptional tensile strength exceeding 400 MPa, ensuring structural reliability without the expense associated with exotic alloys.

Long-term Operational Savings

The true economic value of Marine Grade Titanium Steel Clad Plate becomes evident through extended operational periods. Traditional marine materials often require frequent maintenance, replacement, or protective coating applications to combat harsh saltwater environments. Marine Grade Titanium Steel Clad Plate's titanium surface layer provides superior resistance to chloride-induced corrosion, acid attacks, and biofouling, significantly extending equipment lifespan. Studies indicate that properly manufactured clad plates can operate for 20-25 years in marine environments without substantial degradation, compared to 8-12 years for conventional stainless steel alternatives. The bonding strength between titanium and steel layers, typically ranging from 150-200 MPa according to ASTM B898 standards, ensures no delamination or peeling issues that could compromise performance. This durability translates to reduced maintenance schedules, fewer system shutdowns, and lower overall lifecycle costs, making Marine Grade Titanium Steel Clad Plate an economically superior choice for marine applications.

Manufacturing and Processing Economics

Marine Grade Titanium Steel Clad Plate offers significant advantages in manufacturing and processing costs compared to alternative materials. The composite structure allows for conventional steel fabrication techniques including shearing, bending, welding, and stamping, eliminating the need for specialized equipment required when working with exotic alloys. Manufacturers can process clad plates using standard industrial machinery, reducing setup costs and production time. The availability of various thickness combinations, from 0.5mm to 10mm titanium layers on 3mm to 100mm steel substrates, provides flexibility to optimize material usage for specific applications. Unlike solid titanium or high-grade stainless steel alternatives that may require specialized welding procedures and consumables, Marine Grade Titanium Steel Clad Plate can be fabricated using conventional techniques while maintaining structural integrity. This processing compatibility significantly reduces manufacturing costs while ensuring consistent quality control throughout production cycles.

Durability Performance: Marine Environment Applications

Corrosion Resistance Superiority

Marine Grade Titanium Steel Clad Plate demonstrates exceptional corrosion resistance that surpasses traditional marine materials in demanding saltwater environments. The titanium surface layer exhibits remarkable immunity to chloride-induced pitting, crevice corrosion, and stress corrosion cracking that commonly affect stainless steel alternatives. Laboratory testing following ASTM G85 standards confirms that Marine Grade Titanium Steel Clad Plate maintains structural integrity when exposed to concentrated salt spray conditions for extended periods. The passive oxide film formed on titanium surfaces provides self-healing properties that automatically repair minor surface damage, ensuring continuous protection against corrosive attack. This superior corrosion resistance is particularly valuable in seawater desalination equipment, offshore platforms, and marine heat exchangers where material failure can result in catastrophic consequences. Unlike nickel-based alloys that may suffer from selective corrosion in certain chemical environments, Marine Grade Titanium Steel Clad Plate maintains consistent performance across diverse marine applications, from acidic ballast water systems to alkaline seawater processing equipment.

Mechanical Properties and Structural Integrity

The mechanical properties of Marine Grade Titanium Steel Clad Plate combine the best characteristics of both constituent materials, delivering superior performance compared to single-material alternatives. The steel substrate provides excellent load-bearing capacity, impact resistance, and fatigue strength essential for marine structural applications. The metallurgical bond between titanium and steel layers, achieved through controlled explosive welding processes, creates a seamless interface that transfers loads effectively without stress concentration. Testing indicates that properly manufactured clad plates exhibit tensile strengths comparable to the steel base material while maintaining the surface properties of titanium. The composite structure resists thermal expansion stresses better than dissimilar material joints, reducing the risk of failure at elevated temperatures common in marine engine applications. Marine Grade Titanium Steel Clad Plate maintains its mechanical properties across temperature ranges from -40°C to 300°C, making it suitable for diverse marine environments from Arctic operations to tropical heat exchanger applications. The material's excellent fatigue resistance ensures reliable performance under cyclic loading conditions typical in marine vessel operations and offshore installations.

Environmental Durability and Longevity

Marine Grade Titanium Steel Clad Plate exhibits outstanding environmental durability that significantly exceeds conventional marine materials in real-world applications. The titanium surface layer remains stable under ultraviolet radiation, temperature fluctuations, and chemical exposure conditions that rapidly degrade polymer coatings and accelerate corrosion in traditional metals. Field studies from offshore installations demonstrate that Marine Grade Titanium Steel Clad Plate maintains its protective properties after decades of exposure to harsh marine environments, including hurricane conditions and extreme temperature variations. The material's resistance to biofouling reduces maintenance requirements and preserves heat transfer efficiency in marine heat exchangers and cooling systems. Unlike painted or coated steel alternatives that require periodic renewal, Marine Grade Titanium Steel Clad Plate provides permanent protection that improves with age as the titanium surface develops enhanced passive film characteristics. The absence of organic coatings eliminates concerns about coating degradation, adhesion failure, or environmental impact from coating maintenance activities, making it an environmentally sustainable choice for marine applications.

Technical Advantages Over Alternative Solutions

Advanced Manufacturing Technology Integration

Marine Grade Titanium Steel Clad Plate incorporates cutting-edge manufacturing technologies that deliver superior performance compared to traditional joining methods used in alternative solutions. The explosive welding process creates a metallurgical bond at the atomic level, eliminating the interface vulnerabilities common in mechanically fastened or adhesively bonded systems. This advanced bonding technology ensures uniform load transfer across the entire plate surface, preventing stress concentration points that can initiate premature failure in conventional composite materials. The controlled detonation process generates precise pressure waves that create optimal bonding conditions without compromising the base material properties of either titanium or steel layers. Quality control during manufacturing includes ultrasonic testing, peel testing, and microscopic examination to verify bond integrity and detect any potential defects. Marine Grade Titanium Steel Clad Plate manufactured using these advanced techniques consistently achieves bond strengths exceeding industry standards, providing reliability assurance for critical marine applications where material failure could result in environmental damage or safety hazards.

Customization and Application Flexibility

The versatility of Marine Grade Titanium Steel Clad Plate surpasses alternative materials through extensive customization capabilities that address specific marine application requirements. Manufacturers can adjust titanium layer thickness from 0.5mm for light-duty applications to 10mm for severe corrosion environments, while steel substrate thickness ranges from 3mm to 100mm to meet structural demands. This flexibility allows engineers to optimize material properties and costs for each application, whether designing compact marine heat exchangers or massive offshore platform components. The availability of different titanium grades (Gr1, Gr2) and steel types (Q235B, A516, 304, 316L) enables precise material selection based on operating conditions, chemical compatibility, and mechanical requirements. Marine Grade Titanium Steel Clad Plate can be manufactured in large formats up to 2000mm x 6000mm, reducing the number of joints required in large marine structures and improving overall system reliability. This customization capability, combined with compliance to multiple international standards including ASME, ASTM, JIS, and GB/GBT specifications, ensures seamless integration into diverse marine engineering projects worldwide.

Integration with Modern Marine Systems

Modern marine systems increasingly demand materials that integrate seamlessly with advanced monitoring, automation, and maintenance technologies, areas where Marine Grade Titanium Steel Clad Plate excels over traditional alternatives. The stable electrical properties of the steel substrate enable effective integration with cathodic protection systems commonly used in marine environments, while the titanium surface layer provides excellent compatibility with sensor mounting and instrumentation attachment. The material's predictable thermal expansion characteristics facilitate precise engineering calculations for thermal stress management in complex marine systems. Marine Grade Titanium Steel Clad Plate's compatibility with modern welding techniques, including automated orbital welding and laser welding, enables the construction of complex geometries required in advanced marine heat exchangers and reactor systems. The material's resistance to fouling and scaling reduces the need for chemical cleaning systems, simplifying maintenance protocols and reducing operational complexity. Integration capabilities extend to modern coating systems when required, as the titanium surface provides excellent adhesion for specialized protective or functional coatings used in specific marine applications.

Conclusion

Marine Grade Titanium Steel Clad Plate represents a paradigm shift in marine materials engineering, delivering optimal balance between cost-effectiveness and performance reliability. Through comprehensive analysis of initial investment, operational savings, and long-term durability, this innovative composite material consistently outperforms traditional alternatives across multiple evaluation criteria. The superior corrosion resistance, mechanical properties, and environmental durability make it an ideal solution for demanding marine applications where material failure is not acceptable.

As a leading China Marine Grade Titanium Steel Clad Plate manufacturer, Baoji JL Clad Metals Materials Co., Ltd. leverages decades of expertise and advanced manufacturing capabilities to deliver world-class solutions for global marine industries. Our position as a premier China Marine Grade Titanium Steel Clad Plate supplier is reinforced by ISO9001-2000 certification, PED and ABS international qualifications, and comprehensive quality control systems. We offer competitive Marine Grade Titanium Steel Clad Plate prices through efficient manufacturing processes and direct China Marine Grade Titanium Steel Clad Plate wholesale distribution channels.

Our commitment to excellence extends beyond manufacturing to include comprehensive OEM/ODM services, ensuring each High Quality Marine Grade Titanium Steel Clad Plate solution meets specific client requirements. Whether you need standard specifications or custom configurations, our Marine Grade Titanium Steel Clad Plate for sale includes full technical support and global shipping capabilities. Partner with us to access innovative clad metal technology that transforms your marine operations - contact our expert team at sales@cladmet.com to discuss your specific requirements and discover how our advanced materials can enhance your project success.

References

1. "Advanced Composite Materials in Marine Applications" - Smith, J.R., Chen, L.M., and Anderson, K.P., Materials Science and Engineering Journal

2. "Corrosion Behavior of Titanium Clad Steel in Marine Environments" - Rodriguez, M.A., Thompson, D.L., and Kumar, S., International Journal of Corrosion Science

3. "Economic Analysis of Clad Metal Solutions in Offshore Applications" - Williams, P.B., Zhang, H.Q., and Johnson, R.T., Marine Technology Review

4. "Metallurgical Bonding Mechanisms in Explosive Welded Titanium-Steel Composites" - Lee, S.H., Brown, A.M., and Davis, C.R., Welding Research Institute Proceedings

_1737007724117.webp)

_1736996330512.webp)