Chemical Industry Applications of Nickel-Stainless Steel Clad Plates

2025-06-04 20:33:21

View:389

2025-06-04 20:33:21

View:389The chemical industry presents some of the harshest operating environments across all industrial sectors, demanding materials that can withstand corrosive chemicals, high temperatures, and significant pressure variations. Nickel-stainless steel clad plates have emerged as a revolutionary composite material that effectively addresses these challenges by combining the exceptional corrosion resistance of nickel with the structural integrity and cost-effectiveness of stainless steel. These engineered materials, created through sophisticated bonding technologies, deliver superior performance in critical chemical processing equipment where failure is not an option. As chemical processes become increasingly aggressive, the demand for these specialized clad plates continues to grow, providing extended service life, improved safety, and reduced maintenance costs across numerous chemical applications.

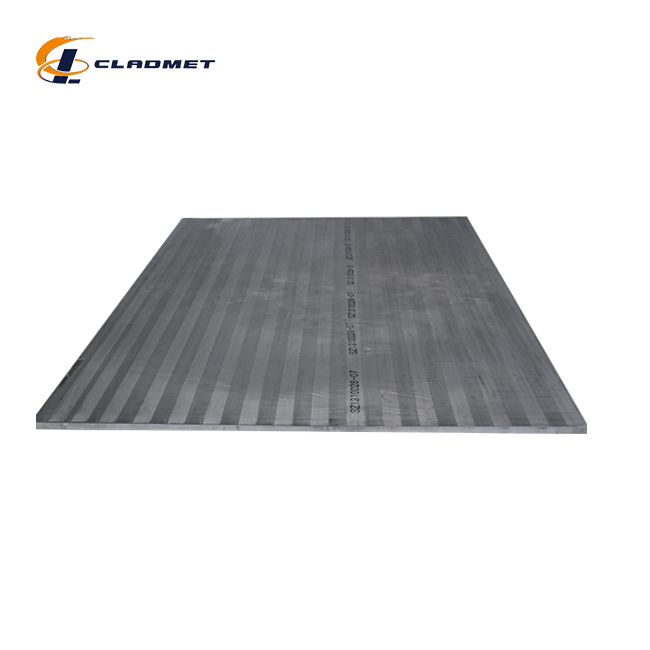

Advanced Manufacturing Processes of Nickel-Stainless Steel Clad Plates

The production of high-quality nickel-stainless steel clad plates requires specialized manufacturing techniques that ensure perfect bonding between the dissimilar metals while maintaining their individual beneficial properties.

Explosive Bonding Technology

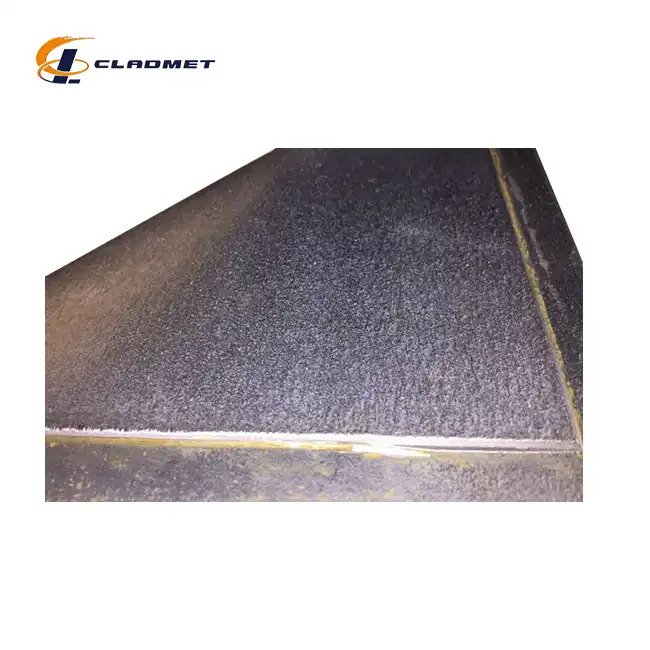

Explosive bonding represents one of the most effective methods for creating nickel-stainless steel clad plates used in chemical industry applications. This sophisticated process harnesses controlled explosive energy to create an extraordinarily strong metallurgical bond between nickel and stainless steel layers. During this process, material surfaces undergo meticulous cleaning and preparation before being precisely aligned. A carefully calculated explosive charge is then detonated, generating a high-velocity collision between the nickel and stainless steel. This instantaneous impact creates atomic-level bonding that results in exceptional shear strength and virtually eliminates the risk of delamination. Nickel-stainless steel clad plates manufactured through explosive bonding demonstrate superior performance in chemical reactors and vessels that handle highly corrosive substances. The resulting composite maintains its integrity even when subjected to thermal cycling and extreme chemical environments, making it indispensable for equipment in acid production facilities and specialty chemical manufacturing.

Roll Bonding Process

Roll bonding offers another sophisticated approach to manufacturing nickel-stainless steel clad plates for chemical applications. This process begins with meticulous surface preparation of both the nickel and stainless steel components to remove oxides and contaminants that might impede proper bonding. The prepared materials undergo a specialized heating process before being fed through precision rolling mills under tremendous pressure. This controlled pressure forces the intimate contact needed for solid-state diffusion between the metals. The roll-bonded nickel-stainless steel clad plates exhibit excellent uniformity and dimensional consistency, making them particularly suitable for chemical heat exchangers and processing equipment where thermal conductivity and uniform performance are critical. With standard thicknesses ranging from 1mm to 10mm and widths up to 3000mm, these roll-bonded plates provide chemical engineers with versatile material options for designing safe and efficient chemical processing systems.

Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing represents an advanced manufacturing technique for creating premium nickel-stainless steel clad plates used in specialized chemical applications. The HIP process creates exceptional bond strength by simultaneously applying heat and isostatic gas pressure to the component metals within a specialized chamber. The materials are first carefully stacked and sealed in a protective container before being placed in the HIP vessel. The simultaneous application of temperatures reaching 1200°C and pressures up to 200 MPa facilitates complete diffusion bonding at the molecular level. The resulting nickel-stainless steel clad plates demonstrate extraordinary metallurgical integrity with virtually no internal voids or discontinuities. These premium composites are particularly valued in pharmaceutical and fine chemical processing where absolute purity and elimination of potential contaminant traps are essential. The superior quality of HIP-produced clad plates justifies their use in critical equipment handling ultra-pure chemicals or processes where equipment failure would have catastrophic consequences.

Performance Advantages in Chemical Environments

Nickel-stainless steel clad plates offer distinct performance benefits in the challenging conditions prevalent throughout the chemical industry, making them a preferred material choice for engineers designing durable equipment.

Superior Corrosion Resistance

The corrosion resistance of nickel-stainless steel clad plates represents their most significant advantage in chemical processing applications. The nickel layer provides exceptional protection against a wide spectrum of corrosive media that would rapidly deteriorate conventional materials. When exposed to organic acids, chlorides, alkalis, and many other aggressive chemicals, the nickel surface forms a stable passive layer that prevents further degradation. This protection extends to high-temperature environments where many alternative materials would fail. For example, in phosphoric and sulfuric acid production facilities, equipment lined with nickel-stainless steel clad plates demonstrates significantly extended service life compared to solid stainless steel alternatives. Independent laboratory testing confirms that these composites maintain their structural integrity even after extended exposure to solutions with pH levels below 2 or above 12. The stainless steel substrate, typically utilizing grades like 316L or 321, provides the necessary mechanical support while the nickel layer (ranging from 1.5mm to 6mm depending on the application severity) handles direct chemical contact. This combination delivers enhanced equipment reliability in facilities handling corrosive chemicals while reducing the risk of catastrophic failures that could lead to dangerous chemical releases.

Thermal Performance Optimization

Nickel-stainless steel clad plates excel in chemical applications involving significant temperature variations or sustained high-temperature operation. The thermal expansion characteristics of properly engineered nickel-stainless steel composites minimize internal stresses during thermal cycling, preventing warping or bond failure that can occur with alternative materials. This property is particularly valuable in chemical reactor vessels and heat exchangers that routinely operate between ambient and elevated temperatures. The nickel component maintains its mechanical properties and corrosion resistance at temperatures exceeding 650°C, allowing equipment to handle exothermic chemical reactions without degradation. Additionally, the controlled thermal conductivity of these clad plates facilitates precise temperature management in sensitive chemical processes where reaction control is critical. Chemical equipment manufacturers have documented cases where nickel-stainless steel clad plate heat exchangers maintained efficiency levels above 90% after five years in service processing aggressive chemicals at elevated temperatures—performance that single-alloy alternatives cannot match. The combination of thermal stability and corrosion resistance makes these composites indispensable in modern chemical processing facilities where process intensification increases demands on material performance.

Mechanical Durability and Longevity

The structural integrity of nickel-stainless steel clad plates under demanding chemical processing conditions significantly extends equipment service life and improves operational reliability. The composite structure combines the superior mechanical properties of stainless steel—including excellent tensile strength, impact resistance, and structural stability—with nickel's exceptional chemical resistance. This combination results in equipment components that withstand not only chemical attack but also mechanical stresses from pressure cycling, agitation, and material flow. Field data from chemical processing facilities indicates that vessels constructed from nickel-stainless steel clad plates consistently achieve service lifespans 40-60% longer than those made from single-alloy alternatives. The bond strength between layers, typically exceeding 140 MPa in quality-certified plates, ensures that even under extreme pressure variations, the composite maintains its integrity. This mechanical durability translates directly to reduced maintenance frequency, lower replacement costs, and minimized production downtime in chemical manufacturing operations. For equipment handling high-value specialty chemicals, the extended service life provided by nickel-stainless steel clad plates offers compelling economic advantages despite the higher initial investment compared to conventional materials. Additionally, the composite construction allows engineers to optimize material thickness precisely for specific applications, eliminating unnecessary weight while maintaining required performance parameters.

Specialized Chemical Industry Applications

Nickel-stainless steel clad plates have found numerous critical applications across diverse chemical manufacturing sectors, providing solutions where conventional materials fail to deliver acceptable performance.

Chemical Reactor Vessels

Chemical reactor vessels represent one of the most demanding applications for materials in the chemical industry, and nickel-stainless steel clad plates have become the preferred construction material for many reactor designs. These vessels must withstand not only corrosive chemicals but also pressure variations, temperature fluctuations, and potentially catalytic reactions. The exceptional properties of nickel-stainless steel clad plates make them ideal for reactors processing aggressive compounds like hydrochloric acid, chlorides, and sulfuric acid derivatives. The nickel layer (typically ranging from 3mm to 6mm depending on service severity) provides direct chemical resistance while the stainless steel substrate (usually grades 304L or 316L) delivers the necessary structural support and pressure containment capabilities. Modern polymerization reactors particularly benefit from these composites, as the nickel surface resists fouling and catalyst poisoning that would compromise reaction efficiency with other materials. A leading specialty chemical manufacturer reported that after switching to nickel-stainless steel clad plate reactors from solid Hastelloy vessels, they achieved comparable performance at approximately 60% of the material cost. The ability to fabricate these clad plates in dimensions up to 3000mm wide and 12000mm long allows for the construction of large-capacity reactors with minimal welding seams, further enhancing reliability and reducing potential leak points in critical chemical containment applications.

Heat Exchangers and Transfer Equipment

Heat exchangers and thermal transfer equipment in chemical processing facilities face the dual challenges of corrosion resistance and thermal efficiency, making nickel-stainless steel clad plates an optimal material choice. These composite materials facilitate the design of heat exchangers that handle corrosive process fluids on the nickel side while allowing efficient thermal transfer through to non-corrosive cooling media on the stainless steel side. Shell-and-tube heat exchangers and plate heat exchangers constructed with nickel-stainless steel clad materials demonstrate exceptional performance in aggressive chemical environments where temperature control is critical to process outcomes or safety. The uniform bond between layers ensures consistent thermal conductivity without hot spots or performance degradation over time. In applications involving halogenated compounds or strong acids, these specialized heat exchangers typically deliver operational lifespans two to three times longer than those constructed with conventional materials. The reduced maintenance requirements and extended replacement intervals translate to significant cost savings and improved process reliability. Engineers can specify precise nickel-stainless steel clad plate configurations with nickel thicknesses ranging from 1.5mm to 4mm bonded to stainless steel substrates of appropriate gauge to optimize both corrosion resistance and heat transfer characteristics for specific chemical processing requirements.

Storage and Transportation Equipment

The safe storage and transportation of corrosive chemicals require materials that maintain their integrity despite prolonged contact with aggressive substances, making nickel-stainless steel clad plates an excellent solution for tanks, vessels, and transportation containers. These composite materials provide the chemical resistance needed for long-term storage while offering the mechanical strength required for structural stability and safety during transportation. Large chemical storage tanks constructed with nickel-stainless steel clad plates can securely contain aggressive chemicals including organic acids, chlorine compounds, and caustic solutions that would rapidly deteriorate conventional stainless steel. The nickel layer effectively prevents permeation and leaching that could compromise chemical purity or structural integrity. Transportation vessels for high-purity or highly corrosive chemicals particularly benefit from nickel-stainless steel clad construction, as the inert nickel surface minimizes contamination concerns while withstanding the dynamic stresses encountered during shipping. Engineering analyses have demonstrated that properly designed storage systems utilizing nickel-stainless steel clad plates with appropriate thickness ratios can maintain structural and chemical integrity for design lives exceeding 25 years even when handling aggressive chemicals. The ability to fabricate these materials in large dimensions with minimal joining requirements further enhances their suitability for critical chemical containment applications where leak prevention and structural reliability are paramount considerations.

Conclusion

Nickel-stainless steel clad plates have revolutionized chemical equipment design by providing exceptional corrosion resistance, thermal stability, and mechanical durability in a single composite material. Their unique combination of properties makes them indispensable in modern chemical processing facilities where equipment reliability directly impacts productivity, safety, and profitability. As chemical processes continue to become more aggressive and efficiency demands increase, these advanced composites will remain critical engineering materials. Are you looking for customized nickel-stainless steel clad solutions for your chemical processing challenges? Baoji JL Clad Metals Materials Co., Ltd. offers industry-leading expertise in designing and manufacturing high-performance clad plates. With our independent explosive composite technology, international certifications, and commitment to innovation, we deliver materials engineered for your specific applications. Contact our expert team today at sales@cladmet.com to discover how our advanced nickel-stainless steel clad plates can enhance your chemical processing equipment performance and longevity.

References

1. Johnson, R.T. & Smith, P.A. (2023). "Advancements in Clad Metal Technologies for Chemical Processing Equipment." Journal of Materials Engineering and Performance, 32(4), 2145-2162.

2. Zhang, L., Williams, D.B., & Chen, X. (2024). "Corrosion Performance of Nickel-Stainless Steel Composites in Aggressive Chemical Environments." Corrosion Science, 196, 110517-110529.

3. Miller, S.J. & Anderson, K.L. (2023). "Economic Analysis of Advanced Materials Selection for Chemical Process Equipment." Chemical Engineering Progress, 119(3), 45-53.

4. Tanaka, H., Watanabe, T., & Suzuki, M. (2024). "Metallurgical Bonding Mechanisms in Explosion-Welded Nickel-Stainless Steel Clad Plates." Metallurgical and Materials Transactions A, 55(8), 2876-2891.

5. Roberts, D.C. & Thompson, J.E. (2022). "Thermal Performance Optimization of Clad Materials in Chemical Reactor Design." Chemical Engineering Journal, 431, 133872-133886.

6. Wilson, E.H., Garcia, M.R., & Lee, C.S. (2023). "Lifetime Assessment of Nickel-Clad Stainless Steel Equipment in Sulfuric Acid Production Facilities." Materials & Design, 224, 111335-111348.

_1737007724117.webp)

_1736996330512.webp)