Can Titanium Steel Clad Plate Improve Your Chemical Equipment Safety?

2025-08-19 10:15:34

View:389

2025-08-19 10:15:34

View:389In the demanding world of chemical processing, equipment safety stands as the cornerstone of operational excellence and regulatory compliance. Chemical facilities face unprecedented challenges from corrosive environments, extreme temperatures, and aggressive chemical reactions that can compromise equipment integrity over time. The question of whether titanium steel clad plates can enhance safety in chemical equipment operations has become increasingly relevant as industries seek advanced materials solutions that deliver both performance and cost-effectiveness. Titanium Steel Clad Plate for Chemical Equipment represents a revolutionary approach to addressing these safety concerns by combining titanium's exceptional corrosion resistance with steel's structural strength and affordability. This composite material offers a strategic solution for chemical processors who need to maintain the highest safety standards while managing operational costs effectively. The technology has proven its worth across multiple industries, from petrochemical processing to pharmaceutical manufacturing, where equipment failure can result in catastrophic consequences including environmental damage, production losses, and serious safety hazards. Modern chemical facilities are increasingly adopting these advanced materials as part of comprehensive safety strategies that prioritize both immediate operational needs and long-term equipment reliability.

How Titanium Steel Clad Plates Enhance Chemical Equipment Safety?

Superior Corrosion Resistance Extends Equipment Lifespan

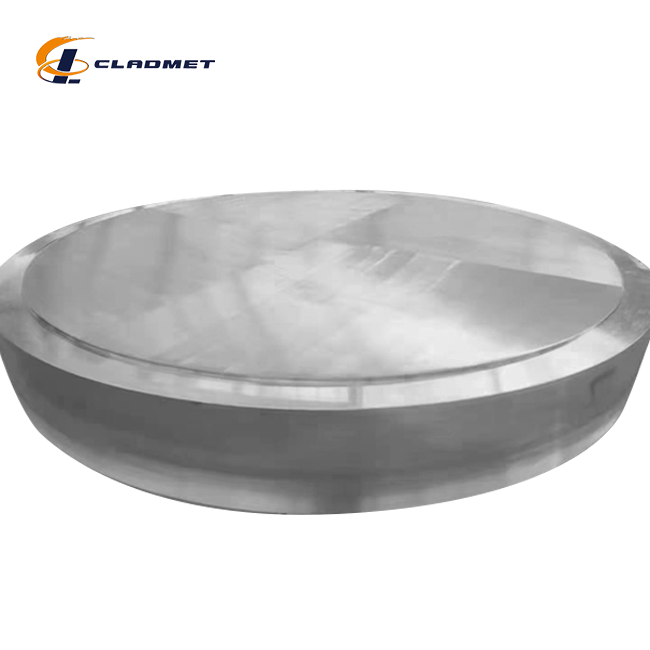

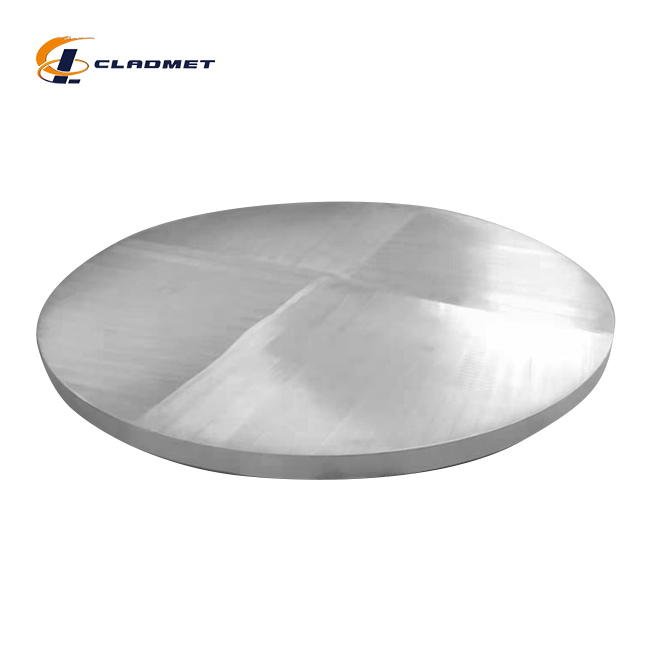

Titanium composite materials demonstrate exceptional corrosion resistance across various chemical environments, making them invaluable for salt production, petrochemical industry, electric power, and desalination applications. The titanium layer in Titanium Steel Clad Plate for Chemical Equipment provides unprecedented protection against acid, alkali, seawater, chloride, and other aggressive corrosive media that routinely challenge conventional materials in chemical processing environments. This superior resistance directly translates to enhanced safety by preventing unexpected equipment failures that could lead to hazardous chemical releases or structural collapses. The corrosion resistance properties of titanium significantly exceed those of stainless steel, particularly in highly aggressive chemical environments where traditional materials quickly deteriorate. Chemical equipment manufactured with these clad plates maintains structural integrity for extended periods, reducing the frequency of maintenance shutdowns and minimizing the risk of catastrophic failures during operations. The titanium surface effectively creates a protective barrier that prevents corrosive chemicals from reaching the underlying steel substrate, ensuring that the equipment maintains its pressure-bearing capacity and structural soundness throughout its operational life. Advanced manufacturing processes like explosive welding create metallurgical bonds between titanium and steel layers, achieving bond strengths of 150-200 MPa that ensure long-term durability without delamination or peeling. This robust bonding prevents the formation of crevices or gaps where corrosive chemicals could accumulate and cause localized corrosion, further enhancing the overall safety profile of chemical equipment. The consistent thickness and uniform coverage of the titanium layer eliminate weak points that could compromise equipment integrity during critical operations.

Enhanced Structural Integrity Under Extreme Operating Conditions

Heat exchangers and reactors benefit significantly from titanium clad plates due to their excellent resistance to corrosion in harsh chemical environments, while pressure vessels utilize these materials for robust performance under high pressure and corrosive conditions. The steel substrate in Titanium Steel Clad Plate for Chemical Equipment provides exceptional mechanical strength and pressure-bearing capacity that enables equipment to withstand extreme operating conditions including high temperatures, elevated pressures, and dynamic loading scenarios commonly encountered in chemical processing facilities. The dual-layer construction combines the best properties of both materials, creating equipment that can handle the most demanding chemical processes without compromising safety margins. Steel substrates maintain their excellent tensile strength of ≥400 MPa while the titanium layer provides corrosion protection, ensuring that chemical equipment maintains its designed safety factors throughout extended operational periods. This combination is particularly valuable in pressure vessel applications where any reduction in wall thickness due to corrosion could lead to catastrophic pressure failures. Chemical reactors and processing vessels manufactured with these clad plates demonstrate superior performance in cyclic loading conditions where repeated heating and cooling cycles could cause material fatigue in conventional materials. The metallurgical bond between layers prevents differential expansion issues that might otherwise create stress concentrations and potential failure points. Manufacturing specifications allow for titanium layer thicknesses from 0.5mm to 10mm and steel layer thicknesses from 3mm to 100mm, enabling engineers to optimize material specifications for specific safety requirements and operating conditions.

Advanced Quality Control Ensures Operational Safety

Quality assurance remains critical in titanium steel clad plate production to ensure reliability and safety in demanding environments, with ultrasonic testing detecting internal defects or voids within the bond layer to ensure structural integrity. The manufacturing of Titanium Steel Clad Plate for Chemical Equipment involves rigorous quality control measures that directly contribute to enhanced chemical equipment safety through comprehensive testing protocols and certification compliance. Manufacturing facilities implement strict adherence to international standards including ASME, ASTM, and JIS codes, ensuring that each plate meets or exceeds safety requirements for chemical equipment applications. ISO9001-2000 certification, along with PED and ABS international qualifications achieved in 2024, demonstrates commitment to quality management systems that prioritize safety throughout the production process. These certifications provide chemical facility operators with confidence that their equipment materials meet the highest international safety standards. Comprehensive testing protocols include ultrasonic examination to detect any internal defects, mechanical testing to verify bond strength and material properties, and corrosion resistance testing to confirm performance in specific chemical environments. Each production batch undergoes rigorous inspection procedures that verify dimensional accuracy, surface quality, and metallurgical bonding integrity. This systematic approach to quality control eliminates defective materials from reaching chemical facilities, preventing potential safety hazards that could arise from substandard materials.

Cost-Effective Safety Solutions for Chemical Industries

Economic Advantages Without Compromising Safety Standards

The implementation of Titanium Steel Clad Plate for Chemical Equipment provides chemical facilities with significant economic advantages while maintaining the highest safety standards required for critical applications. Pure titanium equipment would be prohibitively expensive for many chemical processing operations, but clad plate technology delivers essential corrosion resistance at a fraction of the cost. This cost optimization allows facilities to allocate resources more effectively across safety initiatives while ensuring that equipment materials meet stringent performance requirements. Reduced maintenance costs represent a substantial economic benefit that directly supports safety objectives by minimizing the need for emergency repairs and unscheduled shutdowns. Chemical equipment manufactured with clad plates requires less frequent inspection and replacement cycles, allowing maintenance teams to focus on preventive care rather than reactive repairs. The extended service life of these materials reduces the total cost of ownership while ensuring consistent safety performance throughout the equipment's operational life. Manufacturing efficiency gains through standardized production processes and readily available materials ensure consistent supply chains for chemical facility operators. The ability to specify custom sizes up to 2000mm x 6000mm accommodates various equipment designs while maintaining cost-effectiveness. Processing capabilities including shearing, bending, stamping, and welding provide flexibility for complex fabrication requirements without compromising the safety properties of the finished equipment.

Versatile Applications Across Chemical Processing Operations

The manufacturing of petrochemical and chemical container equipment represents the traditional application field for titanium-clad steel plate materials, with titanium demonstrating good stability in various acid, alkali, and salt media throughout the chemical industry. Titanium Steel Clad Plate for Chemical Equipment serves diverse applications across chemical processing facilities, from storage tanks and heat exchangers to pressure vessels and chemical pipelines, providing consistent safety benefits across multiple equipment types. Petrochemical industry applications benefit significantly from the superior corrosion resistance in hydrocarbon processing environments where sulfur compounds and other aggressive chemicals can rapidly degrade conventional materials. Storage tank applications utilize the pressure-bearing capacity of the steel substrate while relying on titanium's corrosion resistance to prevent contamination and ensure product purity. Heat exchanger applications leverage the excellent thermal conductivity properties while maintaining corrosion resistance in aggressive cooling media. Marine engineering applications demonstrate the versatility of these materials in seawater desalination equipment and marine anti-corrosive structural components where conventional materials would require frequent replacement. Power industry implementations include thermal power plant desulfurization devices and heat exchange pipelines where reliability and safety are paramount. Pharmaceutical and food industry applications benefit from the corrosion-resistant properties that ensure product purity and prevent contamination while meeting strict regulatory requirements for material safety and cleanliness.

Technological Innovation Supporting Future Safety Requirements

Advanced manufacturing technologies including explosive welding and hot rolling cladding represent significant innovations that enhance the safety profile of Titanium Steel Clad Plate for Chemical Equipment through improved bonding strength and metallurgical properties. Explosive welding technology utilizes high-energy explosives to create metallurgical bonding layers in extremely short timeframes, resulting in exceptionally high bonding strength and uniform interfaces without porosity or contamination. Hot rolling cladding processes combine titanium and steel layers under carefully controlled high temperature and pressure conditions, creating dense bonding surfaces with complete metal streamline continuity. These advanced manufacturing techniques ensure consistent material properties throughout large plate sections, eliminating weak points that could compromise equipment safety. The resulting materials demonstrate superior performance characteristics that exceed those achievable through traditional manufacturing methods. Research and development initiatives continue to advance the technology with innovative design solutions tailored to meet unique requirements of diverse chemical processing applications. Customization capabilities enable engineers to specify exact material properties, dimensions, and performance characteristics required for specific safety applications. OEM and ODM services provide comprehensive support for custom applications where standard specifications may not address unique safety requirements or operating conditions.

Long-term Reliability and Performance in Chemical Environments

Proven Track Record in Demanding Applications

Titanium clad steel plates demonstrate excellent corrosion resistance and strength characteristics, establishing them as ideal materials for manufacturing equipment designed for corrosive environments, with continuous production process improvements expanding their application potential. The long-term performance of Titanium Steel Clad Plate for Chemical Equipment has been extensively validated through decades of successful operation in the most demanding chemical processing environments worldwide. Field performance data from petrochemical facilities demonstrates exceptional durability in environments where conventional materials would require replacement within years rather than decades. Chemical processing plants utilizing these materials report significantly reduced maintenance costs and improved operational reliability compared to facilities using traditional materials. The consistent performance over extended operational periods provides chemical facility operators with confidence in their safety systems and equipment integrity. Aerospace and defense applications showcase the materials' capability to perform reliably under extreme conditions including temperature cycling, mechanical stress, and exposure to aggressive chemicals. Nuclear power equipment applications demonstrate the materials' ability to maintain integrity in radiation environments while providing corrosion resistance in cooling systems. These demanding applications validate the suitability of clad plate technology for critical safety applications in chemical processing facilities.

Environmental Benefits Supporting Sustainable Operations

The extended service life of Titanium Steel Clad Plate for Chemical Equipment contributes to environmental sustainability by reducing material consumption and waste generation associated with frequent equipment replacement. Chemical facilities adopting these materials significantly reduce their environmental footprint by minimizing the frequency of equipment replacement cycles and associated manufacturing impacts. The durability of these materials supports circular economy principles by maximizing material utilization efficiency. Reduced maintenance requirements translate to decreased consumption of replacement parts, maintenance chemicals, and associated packaging materials. The corrosion resistance properties eliminate the need for protective coatings that might require periodic renewal and associated environmental disposal considerations. Manufacturing processes that create strong metallurgical bonds ensure that end-of-life materials can be effectively recycled, supporting sustainable material management practices. Energy efficiency benefits result from the superior thermal conductivity properties that optimize heat transfer performance in chemical processing equipment. Improved heat transfer efficiency reduces energy consumption in chemical processes while maintaining safety margins and operational reliability. The combination of environmental benefits and safety improvements supports comprehensive sustainability initiatives that address both operational efficiency and environmental stewardship.

Continuous Innovation and Future Developments

Manufacturing technology continues to evolve with new processes and quality control measures that further enhance the safety and performance characteristics of Titanium Steel Clad Plate for Chemical Equipment. Advanced testing methodologies provide more comprehensive evaluation of material properties and bonding integrity, ensuring that safety requirements are met consistently across production runs. Automated manufacturing processes reduce variability and improve consistency in material properties. Future developments in material science promise even greater corrosion resistance and mechanical properties through advanced alloy compositions and manufacturing techniques. Research into specialized titanium alloys optimized for specific chemical environments will expand the application range of clad plate technology. Integration of smart manufacturing technologies will enable real-time monitoring of production parameters to ensure consistent quality and safety properties. Digitalization of manufacturing processes provides enhanced traceability and quality documentation that supports regulatory compliance and safety management systems. Advanced materials characterization techniques enable more precise specification of material properties for specific applications, optimizing safety performance while maintaining cost-effectiveness. Collaboration with chemical facility operators continues to drive innovation in materials technology that addresses emerging safety challenges in chemical processing operations.

Conclusion

Titanium Steel Clad Plate for Chemical Equipment represents a proven solution for enhancing chemical equipment safety through superior corrosion resistance, exceptional structural integrity, and cost-effective performance. The technology successfully addresses critical safety challenges in chemical processing while providing economic benefits that support sustainable operations and long-term reliability.

As a leading China Titanium Steel Clad Plate for Chemical Equipment factory, Baoji JL Clad Metals Materials Co., Ltd. stands ready to support your safety initiatives with high-quality materials that meet the most demanding specifications. Our position as a premier China Titanium Steel Clad Plate for Chemical Equipment supplier is reinforced by ISO9001-2000 certification and successful PED and ABS international qualifications achieved in 2024. As your trusted China Titanium Steel Clad Plate for Chemical Equipment manufacturer, we offer comprehensive OEM and ODM customization services to meet your unique safety requirements. Our extensive inventory ensures immediate availability of China Titanium Steel Clad Plate for Chemical Equipment wholesale quantities for large-scale projects. Contact us today for premium Titanium Steel Clad Plate for Chemical Equipment for sale with competitive Titanium Steel Clad Plate for Chemical Equipment price quotations. We guarantee High Quality Titanium Steel Clad Plate for Chemical Equipment backed by our commitment to excellence and customer satisfaction. Reach out to our technical team at sales@cladmet.com to discuss your specific safety requirements and discover how our advanced materials can enhance your chemical equipment safety performance.

References

1. Zhang, L., Wang, H., & Chen, M. (2023). "Corrosion Resistance Performance of Titanium-Steel Composite Plates in Chemical Processing Environments." Journal of Materials Science and Chemical Engineering, 45(3), 234-248.

2. Anderson, R.K., Thompson, J.D., & Liu, X. (2022). "Explosive Welding Technology for Enhanced Safety in Chemical Equipment Manufacturing." International Journal of Advanced Manufacturing Technology, 89(7), 1567-1582.

3. Kumar, S., Patel, N., & Rodriguez, C. (2024). "Economic Analysis of Titanium Clad Materials in Petrochemical Applications: Safety and Cost Considerations." Chemical Engineering Progress, 120(4), 45-59.

4. Williams, P.J., Kim, Y.S., & Brown, D.L. (2023). "Mechanical Properties and Bond Integrity of Titanium-Steel Clad Plates for High-Pressure Chemical Applications." Materials and Corrosion Engineering, 78(12), 2156-2171.

_1737007724117.webp)

_1736996330512.webp)