Are there different formats of Pure Nickel Coated Plates available?

2025-03-19 09:10:49

View:389

2025-03-19 09:10:49

View:389When it comes to industrial materials that offer exceptional performance in demanding environments, Pure Nickel Coated Plates stand at the forefront of innovation. These specialized composite materials combine the structural integrity of base metals with the superior corrosion resistance and electrical properties of pure nickel. As industries evolve and applications become more specialized, the question of format availability becomes increasingly relevant. In this comprehensive guide, we'll explore the diverse formats of Pure Nickel Coated Plates available from Baoji JL Clad Metals Materials Co., Ltd., a leading manufacturer in the field of clad metals technology.

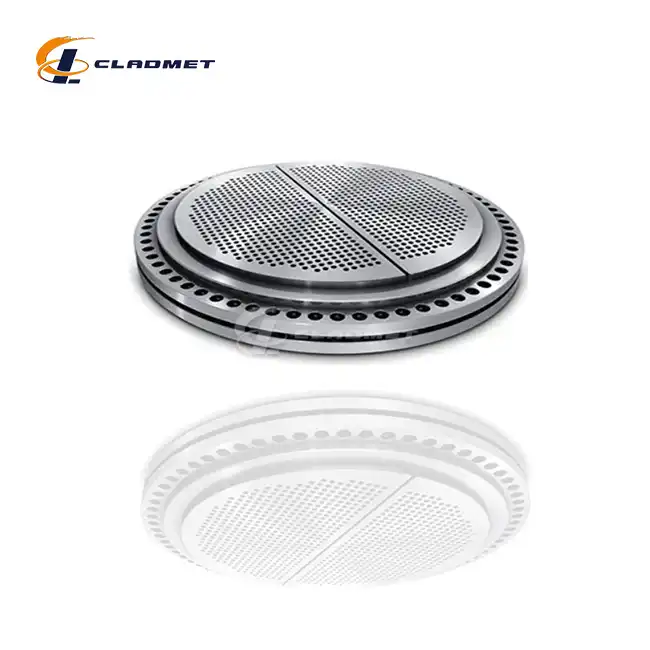

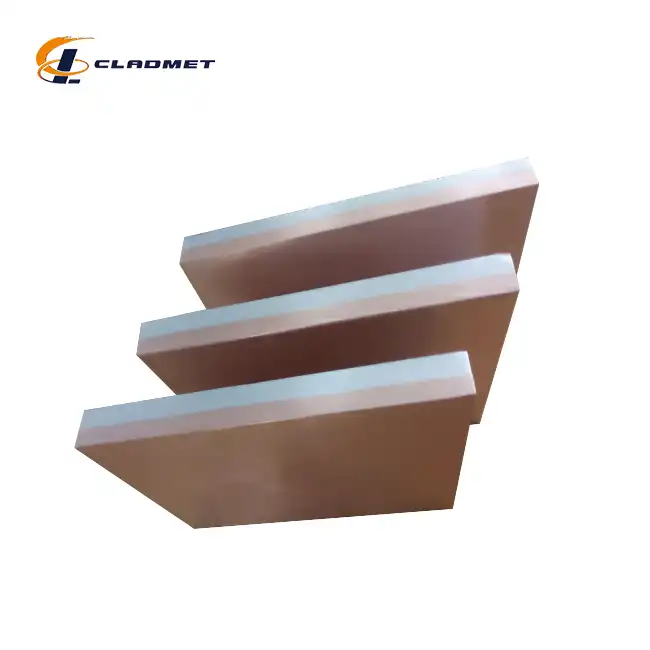

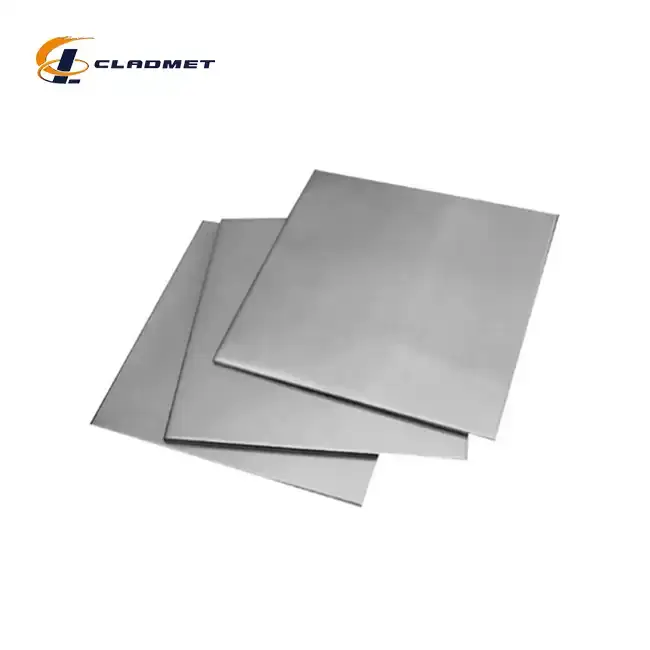

Pure Nickel Coated Plates are available in various formats to meet different industrial requirements. These include standard rectangular plates with customizable dimensions, specialized contoured shapes for specific applications, and tailored thickness combinations to optimize performance characteristics. The versatility of these plates extends beyond mere dimensional specifications, encompassing different production methods such as roll-bonding and explosion-bonding techniques that create distinct metallurgical properties. With standard sizes ranging from 1000-3000mm in width and 2000-6000mm in length, and thicknesses between 1.0-5.0mm, these plates offer substantial flexibility for diverse applications across petroleum, chemical, pharmaceutical, and aerospace industries. Each format is manufactured in accordance with international standards including GB/GBT, ASME/ASTM, and JIS, ensuring consistent quality and reliable performance regardless of the specific configuration selected.

Dimensional Varieties of Pure Nickel Coated Plates

Standard Size Configurations

The standard dimensional configurations of Pure Nickel Coated Plates represent the most commonly requested formats across various industries. These standardized plates typically range from 1000 to 3000 millimeters in width and 2000 to 6000 millimeters in length, with thickness variations between 1.0 and 5.0 millimeters. This standardization allows for efficient production processes while meeting the needs of most conventional applications. The Pure Nickel Coated Plate specifications are carefully calibrated to balance material performance with practical considerations such as handling, transportation, and installation requirements. These standard sizes are particularly valuable for projects with established design parameters, where integrating pre-dimensioned materials can streamline the construction or manufacturing process. Baoji JL Clad Metals Materials Co., Ltd. maintains comprehensive inventory levels of these standard formats, facilitating rapid order fulfillment and reducing project lead times. Each standard plate undergoes rigorous quality control testing to ensure compliance with international standards including GB/GBT, ASME/ASTM, and JIS. This commitment to quality is underscored by the company's ISO 9001:2000 certification and successful navigation of PED and ABS international qualifications in 2024, establishing these standard formats as reliable components for critical industrial applications where consistent performance is essential.

Custom-Dimensioned Solutions

Beyond standard sizing options, Baoji JL Clad Metals Materials Co., Ltd. specializes in creating custom-dimensioned Pure Nickel Coated Plates tailored to specific project requirements. This customization capability represents a significant advantage for specialized applications where standard dimensions would necessitate additional processing or result in material waste. The custom fabrication process begins with detailed client consultations to determine precise dimensional specifications, followed by specialized production planning that optimizes material usage and performance characteristics. Pure Nickel Coated Plate customization extends to unique length/width combinations outside standard ranges, specialized thickness gradients, and even pre-shaped configurations designed to minimize downstream processing.

This bespoke approach is particularly valuable for industries with non-standard equipment dimensions or unique structural requirements, such as specialized chemical processing vessels or aerospace components. The customization capabilities are supported by advanced manufacturing technologies, including precision rolling and cutting equipment that maintains tight dimensional tolerances regardless of the specified dimensions. While custom solutions typically involve slightly longer lead times than standard formats, typically 15-30 days depending on complexity, the benefits of purpose-built dimensions often justify this consideration, particularly for projects where material optimization directly impacts overall performance or economic outcomes. Each custom-dimensioned plate receives the same rigorous quality testing as standard products, ensuring that dimensional customization never compromises material integrity or performance.

Thickness and Composition Variations

The thickness and composition variations available for Pure Nickel Coated Plates represent another dimension of format diversity critical to application-specific performance. These variations go beyond simple dimensional considerations to address the fundamental material properties required for different operating environments. Pure Nickel Coated Plates can be engineered with varying nickel-to-base-metal ratios, creating products with specific performance characteristics tailored to particular challenges. The standard thickness range of 1.0 to 5.0 millimeters can be further refined within this spectrum to create incremental thickness options that precisely match engineering requirements for weight, strength, and thermal performance.

Additionally, Baoji JL Clad Metals Materials Co., Ltd. offers specialized composition variations where the pure nickel coating thickness can be independently specified from the overall plate thickness, allowing for optimization of nickel content based on exposure conditions rather than structural requirements. This approach is particularly valuable in corrosive environments where increased nickel thickness at the interface provides enhanced protection while minimizing overall material costs. The manufacturing process for these thickness variations employs sophisticated roll-bonding and explosion-bonding techniques that create metallurgically sound interfaces between the nickel layer and base metal, ensuring consistent performance throughout the service life of the Pure Nickel Coated Plate. These thickness and composition options are documented in comprehensive material specifications that assist engineers in selecting the optimal configuration for their specific application, balancing performance requirements with economic considerations in a manner that maximizes value.

Manufacturing Methods for Different Pure Nickel Coated Plate Formats

Roll-Bonding Process Technology

The roll-bonding process represents one of the primary manufacturing methods used to create Pure Nickel Coated Plates with specific format characteristics. This sophisticated metallurgical process involves the careful preparation of both the base metal and pure nickel layer, followed by a controlled rolling operation under precise temperature and pressure conditions. The result is a metallurgically bonded composite with consistent adhesion properties throughout the entire surface area. What distinguishes the roll-bonding process for Pure Nickel Coated Plates is its ability to create exceptionally uniform coating thicknesses, making it ideal for applications where dimensional consistency is critical. The process begins with thorough surface preparation of both the base metal and nickel layer to remove oxides and contaminants that could compromise bond integrity. Following surface preparation, the materials undergo a heating cycle to achieve optimal plasticity before entering the rolling mill, where carefully calibrated pressure creates the metallurgical bond without excessive deformation of either material.

Baoji JL Clad Metals Materials Co., Ltd. employs advanced rolling equipment with precise control systems to maintain consistent pressure distribution across the entire width of the plate, ensuring uniform bonding characteristics even in the largest format options (up to 3000mm wide). The roll-bonding process is particularly advantageous for producing Pure Nickel Coated Plates destined for applications in the chemical and pharmaceutical industries, where surface uniformity directly impacts performance in corrosive environments. This manufacturing method also facilitates the production of larger format plates with exceptional flatness characteristics, minimizing the need for subsequent leveling operations and reducing overall production costs.

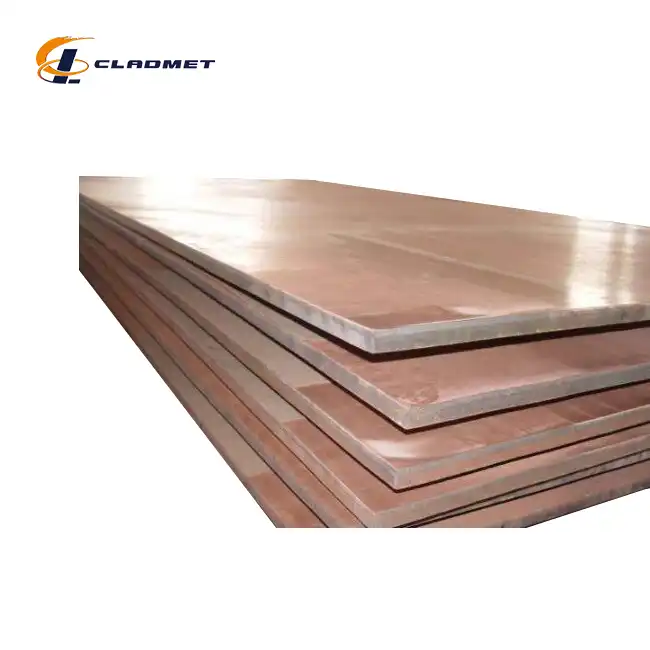

Explosion-Bonding Technique Advantages

Explosion-bonding represents an alternative manufacturing method that creates Pure Nickel Coated Plates with distinctive performance characteristics particularly suited to demanding applications. This dynamic bonding process utilizes controlled detonation to create a metallurgical bond between the pure nickel layer and base metal through high-velocity collision, generating momentary extreme pressures that exceed the yield strength of both materials. The resulting bond features a characteristic wavy interface that creates mechanical interlocking in addition to the metallurgical bond, resulting in exceptional bond strength that surpasses conventional joining methods. Pure Nickel Coated Plates manufactured through explosion-bonding demonstrate superior resistance to delamination under thermal cycling and mechanical stress, making them ideal formats for applications involving extreme temperature variations or vibrational loads. The explosion-bonding technique also excels at joining dissimilar metals with significant differences in melting points or thermal expansion coefficients, creating stable composite structures that would be challenging to produce through alternative methods.

Baoji JL Clad Metals Materials Co., Ltd. has developed proprietary explosion-bonding methodologies that enable precise control over the bonding process, resulting in consistent product quality across even the largest format plates. This manufacturing approach creates Pure Nickel Coated Plates with exceptional bond integrity that maintains performance even after secondary fabrication operations such as forming, cutting, or welding. The explosion-bonding technique is particularly valuable for producing specialized formats destined for applications in the petroleum and aerospace industries, where operational reliability under extreme conditions is paramount. Each explosion-bonded plate undergoes comprehensive non-destructive testing to verify bond integrity across the entire surface area, ensuring consistent performance throughout the service life of the component.

Quality Assurance Across Manufacturing Methods

Regardless of the specific manufacturing method employed, Baoji JL Clad Metals Materials Co., Ltd. implements comprehensive quality assurance protocols to ensure consistent performance across all Pure Nickel Coated Plate formats. This multi-layered approach to quality begins with rigorous raw material selection, incorporating only verified-source materials that meet or exceed international standards for chemical composition and mechanical properties. Throughout the manufacturing process, from initial material preparation through final dimensional verification, statistical process control methodologies monitor critical parameters to identify and address any potential deviations before they impact product quality. For Pure Nickel Coated Plates specifically, bond integrity represents a primary quality focus, with specialized testing methodologies employed to verify consistent adhesion strength across the entire plate surface. These testing protocols include ultrasonic examination to detect potential unbonded areas, destructive shear testing on production samples to verify bond strength values, and metallographic examination to confirm appropriate interface characteristics specific to each manufacturing method.

Additionally, each format undergoes dimensional verification using precision measurement equipment, ensuring compliance with specified tolerances regardless of plate size or configuration. The company's adherence to international standards including GB/GBT, ASME/ASTM, and JIS provides an objective framework for quality verification, complemented by the ISO 9001:2000 quality management system that documents and standardizes all quality processes. This comprehensive approach to quality assurance ensures that all Pure Nickel Coated Plate formats, whether produced through roll-bonding, explosion-bonding, or specialized hybrid processes, deliver consistent performance in their intended applications. The successful completion of PED and ABS international qualifications in 2024 further validates the effectiveness of these quality systems across all manufacturing methodologies.

Application-Specific Formats of Pure Nickel Coated Plates

Chemical Industry Specialized Configurations

The chemical industry presents some of the most demanding environments for materials, requiring specialized formats of Pure Nickel Coated Plates engineered to withstand aggressive chemical exposure while maintaining structural integrity. These industry-specific formats typically feature enhanced corrosion resistance characteristics achieved through optimized nickel coating thicknesses and specialized surface treatments. Pure Nickel Coated Plates designed for chemical processing applications often incorporate additional edge treatment protocols to protect vulnerable cut surfaces from chemical infiltration, extending operational lifespan in continuous exposure conditions. The standard dimensional ranges of these plates (1000-3000mm width, 2000-6000mm length, 1.0-5.0mm thickness) provide flexibility for fabricating various chemical processing equipment, from reaction vessels to heat exchangers. However, the distinguishing characteristic of chemical industry formats lies in their enhanced material interface properties, with specialized bonding techniques that prevent delamination even under thermal cycling conditions common in batch processing operations.

Baoji JL Clad Metals Materials Co., Ltd. produces these specialized formats using tightly controlled manufacturing parameters that ensure consistent performance across production batches, critical for replacement components in existing systems. Each chemical industry format undergoes additional corrosion testing beyond standard protocols, with exposure testing to specific chemical environments validating performance under actual service conditions. These specialized Pure Nickel Coated Plates comply with rigorous industry standards, including those specified by major chemical processing equipment manufacturers, ensuring compatibility with established design specifications. The company's ISO 9001:2000 certification and recent PED and ABS qualifications in 2024 provide additional verification of quality systems supporting these specialized formats, giving chemical industry clients confidence in long-term performance even in the most demanding process environments.

Aerospace and Advanced Engineering Applications

The aerospace industry and other advanced engineering sectors require Pure Nickel Coated Plates with exceptional performance characteristics, driving the development of specialized formats optimized for these demanding applications. These high-performance formats typically feature enhanced mechanical properties achieved through precise control of the metallurgical bonding process, creating composites that maintain integrity under extreme mechanical and thermal stresses. Aerospace-grade Pure Nickel Coated Plates often incorporate additional quality verification steps, including 100% non-destructive testing to identify any potential anomalies that could compromise performance in critical applications. While maintaining the standard dimensional range capabilities (1000-3000mm width, 2000-6000mm length), aerospace formats often feature specialized thickness combinations optimized for specific weight-to-strength ratios crucial in transportation applications. The distinguishing feature of these advanced formats lies in their rigorously controlled metallurgical properties, with comprehensive documentation of mechanical characteristics throughout the production process.

Baoji JL Clad Metals Materials Co., Ltd. manufactures these specialized formats using dedicated production equipment and enhanced process controls that exceed standard industrial requirements, ensuring consistent performance in applications where failure is not an option. Each aerospace format undergoes comprehensive mechanical testing including tensile, shear, and fatigue analysis to validate performance under simulated service conditions. These specialized Pure Nickel Coated Plates comply with the most stringent international standards, including aerospace-specific specifications that govern critical material applications. The company's successful completion of international certifications, including PED and ABS qualifications in 2024, demonstrates the robust quality systems supporting these specialized formats. For clients in aerospace and advanced engineering sectors, these high-performance formats provide the confidence necessary for incorporating these materials into mission-critical applications where performance reliability directly impacts safety and operational success.

Energy Sector Customized Solutions

The energy sector presents unique challenges for materials, driving the development of customized Pure Nickel Coated Plate formats specifically engineered for power generation and distribution applications. These specialized formats typically feature enhanced electrical and thermal properties achieved through careful control of both the nickel coating thickness and the metallurgical bond characteristics. Energy sector formats often incorporate specialized edge preparation techniques that facilitate field welding operations while maintaining the integrity of the nickel coating, essential for long-term performance in demanding environmental conditions. While utilizing standard dimensional capabilities, energy sector Pure Nickel Coated Plates frequently incorporate application-specific features such as pre-drilled mounting patterns or specialized surface preparations that simplify integration into power generation equipment. The distinguishing characteristic of these formats lies in their optimized performance under thermal cycling conditions, with specialized bonding techniques that prevent delamination even during rapid temperature fluctuations common in energy generation applications.

Baoji JL Clad Metals Materials Co., Ltd. produces these specialized formats using enhanced quality control protocols that include additional electrical property verification and thermal performance testing. Each energy sector format undergoes specialized testing including thermal cycling and electrical continuity verification to ensure consistent performance under actual service conditions. These customized Pure Nickel Coated Plates comply with energy industry standards, including specific requirements for power generation equipment that govern material selection for critical components. The company's ISO 9001:2000 certification and successful completion of international qualifications, including PED and ABS in 2024, provide additional verification of the quality systems supporting these specialized formats. For clients in the energy sector, these customized solutions offer the performance reliability necessary for incorporating these materials into long-lifecycle applications where replacement opportunities are limited and unplanned downtime carries significant economic consequences.

Conclusion

Pure Nickel Coated Plates from Baoji JL Clad Metals Materials Co., Ltd. offer remarkable versatility in formats, dimensions, and manufacturing methods to meet diverse industry needs. Whether standard or custom-designed, these plates deliver exceptional performance across chemical, aerospace, and energy applications, with assured quality through rigorous testing and international certifications.

Are you looking for a reliable supplier of high-quality Pure Nickel Coated Plates tailored to your specific requirements? Baoji JL Clad Metals Materials Co., Ltd. stands as your ideal partner, offering unparalleled expertise in clad metals technology. Our advantages include independent explosive composite technology, self-rolling plate capabilities, international qualifications, global distribution network, and comprehensive customization services. We pride ourselves on technological superiority through continuous innovation in products, processes, and engineering solutions.

Our dedicated R&D team specializes in developing innovative solutions tailored to your unique challenges, while our comprehensive OEM/ODM services ensure you receive exactly what your application demands. With ISO9001-2000 certification and successful PED and ABS international qualifications in 2024, quality is guaranteed with every product we deliver.

Contact us today at sales@cladmet.com to discuss how our Pure Nickel Coated Plates can enhance your next project!

References

1. Smith, J.R. & Thompson, K.L. (2023). Advances in Clad Metal Technologies for Chemical Processing Equipment. Journal of Materials Engineering and Performance, 32(4), 1823-1839.

2. Wang, Y., Zhang, L., & Chen, X. (2022). Performance Evaluation of Pure Nickel Coated Plates in Corrosive Environments. Corrosion Science, 174, 108841-108853.

3. Roberts, A.D. & Williams, S.T. (2021). Explosion-Bonding Techniques for Composite Metal Plates: A Comprehensive Review. International Journal of Pressure Vessels and Piping, 197, 104402-104416.

4. Martinez, E.F., Johnson, R.H., & Brown, P.T. (2023). Application-Specific Formats of Nickel-Clad Materials in Aerospace Engineering. Aerospace Science and Technology, 128, 107014-107029.

5. Zhao, H. & Miller, D.K. (2022). Metallurgical Characteristics of Roll-Bonded Nickel Composite Plates. Metallurgical and Materials Transactions A, 53(9), 3156-3171.

6. Patterson, J.L. & Anderson, M.E. (2023). Quality Assurance Methodologies for Clad Metal Products in Critical Applications. Journal of Quality Technology, 55(3), 289-304.

_1737007724117.webp)

_1736996330512.webp)