Base Metal Scope (carbon) Q235; Q345R, Q245R; 16Mn, 20 etc.

ASTM A283GRC, A284GRB, A306GR55; ASTM: A53-F, A283-D; A515 Gr.60, Gr.65, Gr.70; A 572 Gr. 50 etc.

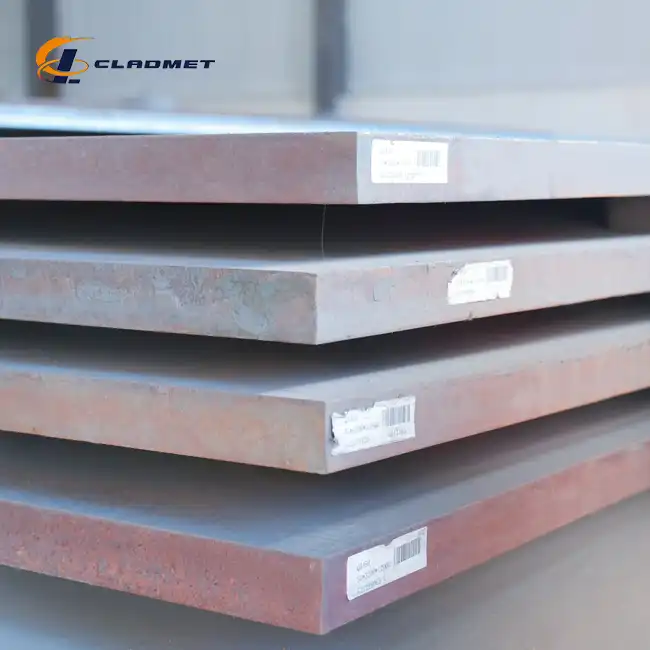

Clad Plate Total Thickness:8-30mmm, or Customizable

Copper clad steel sheets

PRODUCT INTRODUCTION

What is a Copper Clad Steel Sheet?

The copper clad steel sheet, also referred to as a copper steel clad plate, is a revolutionary bimetallic composite material created by explosion bonding or explosion-roll bonding techniques. This advanced cladding process ensures that the copper layer is permanently bonded to the steel base, forming an inseparable and uniform metallurgical connection.

The result is a composite material that combines the conductivity, corrosion resistance, and aesthetics of copper with the strength, formability, and affordability of steel. It is increasingly used in critical engineering applications where dual performance characteristics are essential.

Why Choose JL CLAD METALS Copper Clad Steel Sheet?

As a leading EXW clad metals materials manufacturer with over 35 years of experience, Baoji JL Clad Metals Materials Co., Ltd. integrates research, development, and mass production of high-performance clad metals. Our copper clad steel sheets have been widely adopted in petroleum, chemical, pharmaceutical, metallurgy, and electronic industries—domestically and abroad.

Product Specifications

| Product Name | Copper Steel Clad Plate |

|---|---|

| Standard | ASME B432, NB/T 47002.4 |

| Cladding Technique | Explosion bonding or Explosion + Hot Rolling |

| Cladding Material Scope | TU1, T2, B30; C10200, C11000, C71520, C71500 |

| Base Metal Scope (carbon) | Q235; Q345R, Q245R; 16Mn, 20 etc. ASTM A283GRC, A284GRB, A306GR55; A53-F, A283-D; A515 Gr.60, Gr.65, Gr.70; A 572 Gr. 50 |

| Clad Plate Total Thickness | 8–30mm or customizable |

| Clad Plate Width | Customizable |

| Clad Plate Length | Customizable |

| Surface Treatment | As per request or negotiable |

| Delivery Period | 3–6 months or negotiable |

| Package | Export-worthy package: waterproof paper + steel bands |

| Payment Terms | T/T, L/C or negotiable |

| Application Industries | Oil & Gas, Chemical, Pharma, Salt, Metallurgy, Machinery |

| Application Fields | Pressure vessels, vacuum equipment, electronic parts, decorative projects |

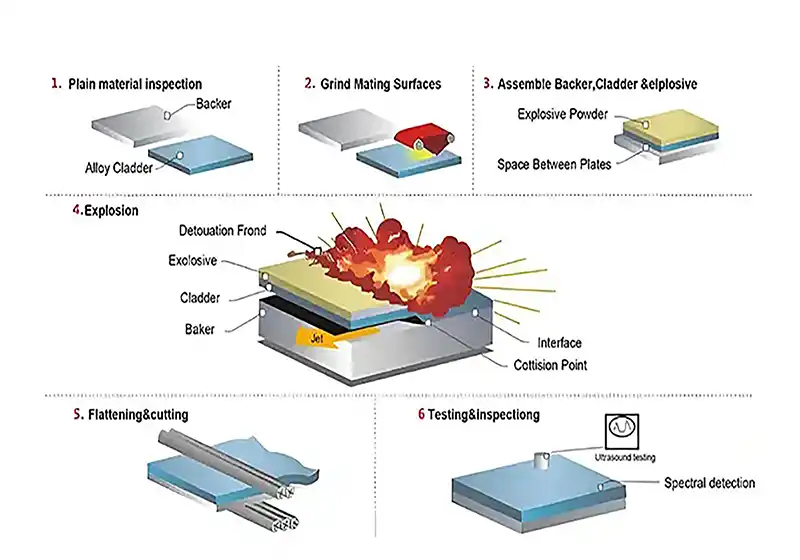

Manufacturing Process

-

Material Inspection & Selection – All raw copper and steel undergo spectral analysis.

-

Surface Cleaning & Treatment – To ensure bonding quality, all surfaces are precisely cleaned.

-

Explosive Bonding – Plates are bonded with precisely calculated detonation energies.

-

Hot Rolling (Optional) – Enhances surface flatness, uniform thickness, and bond strength.

-

Annealing & Finishing – Relieves internal stress and prepares the final surface.

-

Final Inspection & Testing – Ultrasonic testing, shear strength, corrosion resistance, and dimensional checks.

We strictly adhere to ASME, ASTM, JIS, and GB/GBT standards, and our processes are ISO9001:2000, PED, and ABS certified.

Cladding Technique: Explosive Bonding Method

JL CLAD METALS adopts explosive bonding—a high-energy cold welding technique that ensures metallurgical bonding between titanium and copper without melting the base metals. This results in:

- Excellent interfacial strength

- No intermetallic compounds

- Zero porosity and high reliability

- Ability to bond dissimilar metals that are otherwise unjoinable via welding

This method preserves the mechanical integrity of both metals and provides a long-lasting, durable composite.

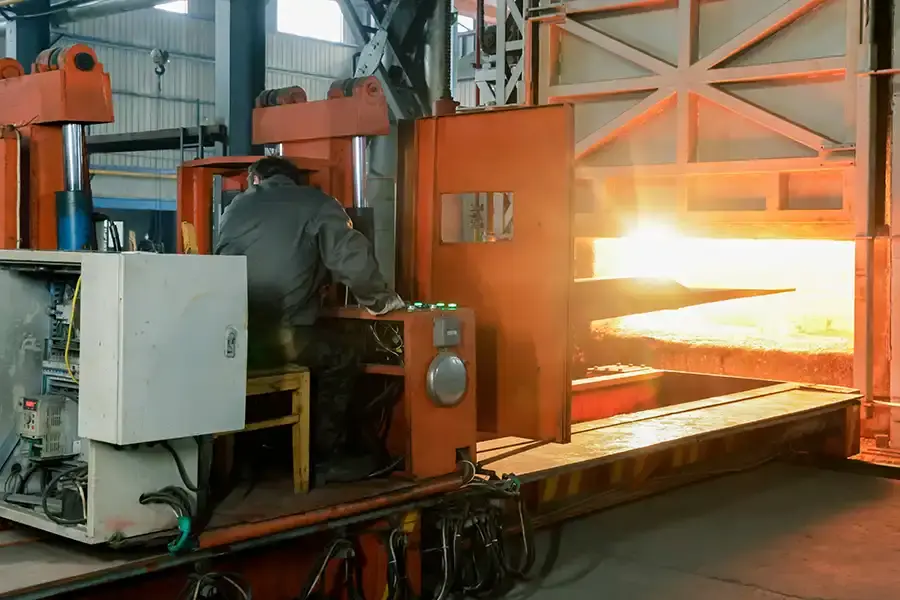

Explosive Composite Panel Production Site

Explosive Setup

Preparing materials for explosive bonding process.

Bonding Process

Our proprietary explosive bonding technology in action.

Product Features

High Strength

Integrates the toughness of steel with the versatility of copper

Excellent Corrosion Resistance

Copper layer prevents rust and chemical damage

Superb Conductivity

Ideal for applications requiring thermal or electrical flow

Light Weight

Reduces equipment bulk and cost

Product Advantages

Unmatched Material Combination

Harness copper’s conductivity with steel’s mechanical resilience.

Enhanced Durability

Suitable for long-term service under harsh conditions.

Lower Material Cost

Avoid full copper parts by using a copper-clad design.

Green & Recyclable

Eco-friendly metal choice—copper and steel are both recyclable.

Custom Processing Services

Plates, coils, cut parts, and pre-fabricated forms available.

Product Application Industries

Our Factory

Company gate

Factory

Quality Control Center

Dedicated QC team performing rigorous inspections at every stage.

Molding workshop

Melting workshop

Cold rolling workshop

Annealing workshop

Levelling workshop

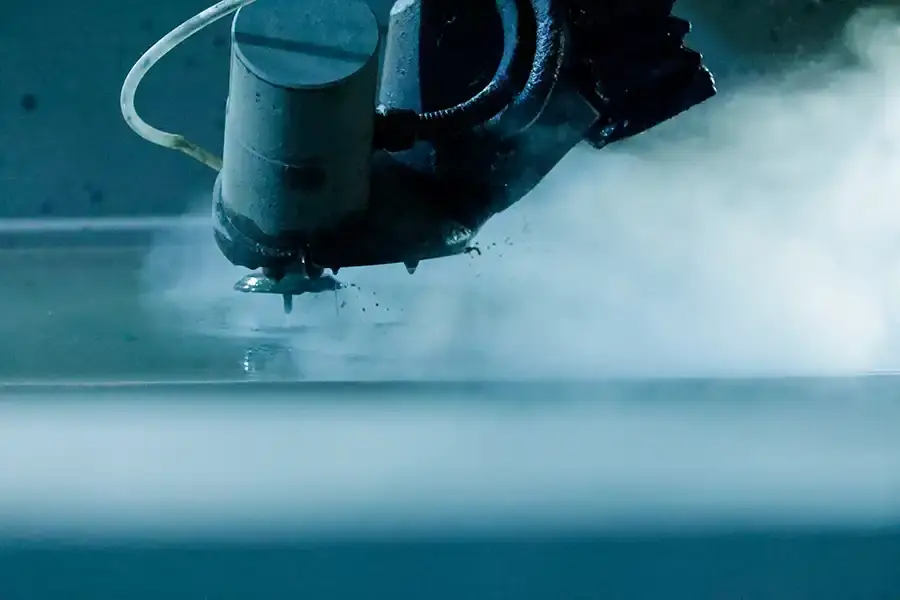

Water cutting workshop

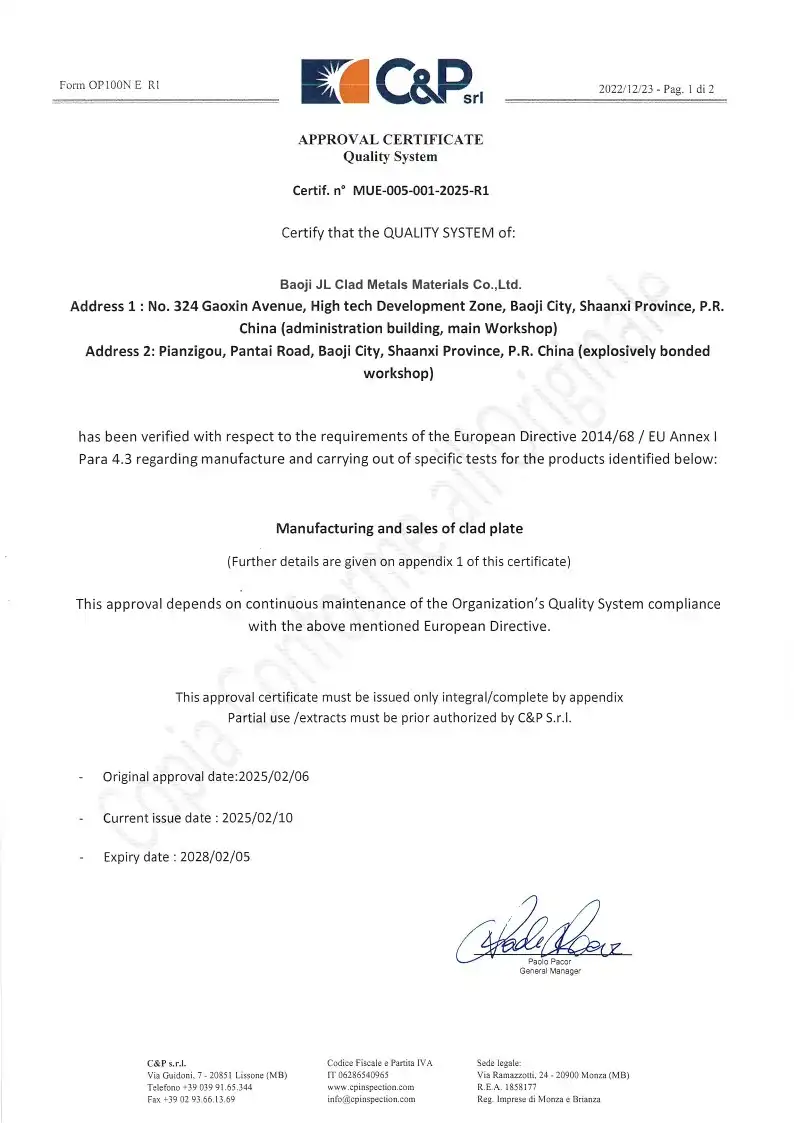

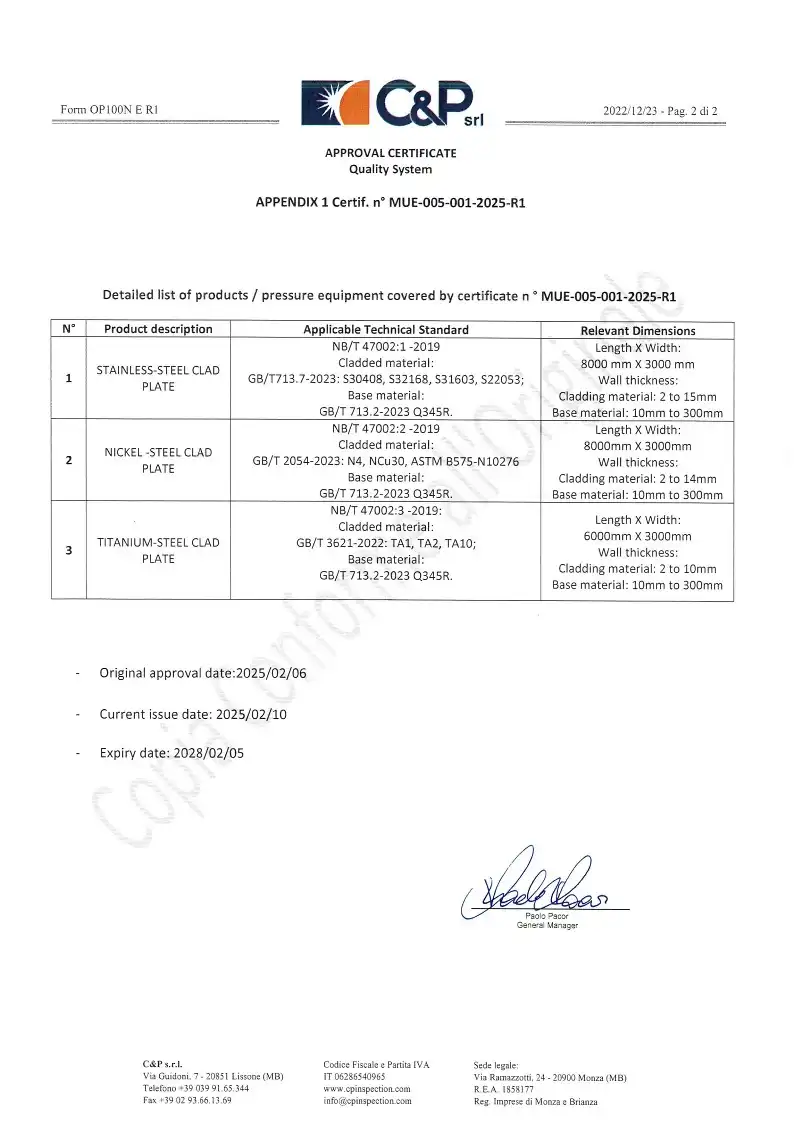

Certificates

Certif. MUE-005-001-2025-R1

Certif. MUE-005-001-2025-R1

OEM Services

Custom Fabrication

Custom material combinations and thicknesses tailored to your requirements

CNC Machining

Precision cutting, drilling, and bending to your specifications

Technical Support

Dedicated technical consultation and prototyping support

FAQ

Q1: Can I get samples of copper clad steel sheet before placing a bulk order?

Yes, we provide sample sheets for testing and evaluation.

Q2: How do you ensure the bond between copper and steel is secure?

Our explosion bonding method creates a high-strength, inseparable atomic bond across the interface, verified by ultrasonic and peel tests.

Q3: Do you offer surface treatments like polishing or passivation?

Absolutely. We can customize the surface finish based on your requirements.

Q4: What's your average delivery time?

Delivery usually takes 3–6 months, but this can be shortened for urgent orders or small batches.

Q5: Are your products export compliant?

Yes. All products are exported with seaworthy packaging and full documentation, including certifications, inspection reports, and COA upon request.

Contact Us

BAOJI JL CLAD METALS MATERIALS CO., LTD

Tel: +86-917-3372918

WhatsApp: +86 13530170059

Email: sales@cladmet.com

Address: FENGHUANG 4 ROAD, HIGH-TECH DISTRICT, BAOJI CITY, SHAANXI, CHINA 721013

_1737007724117.webp)